engine oil HONDA INTEGRA 1998 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 607 of 1681

Differential (818C1 engine)

Special Tools ........ ........ 15-10

Differential

lllustrated Index......... . 15-11

Backfash Inspection .,.. 15-12

Finaf Driven Gear Replacement ...... 15-12

Tapered Roller Bearing Replacement. 15-13

Oil Seal Removal ........ 15-13

Bearing Outer Race Replacement ... 15-14

Tapered Roller Bearing Preload

Adjustment ............. 15-15

Oif Seaf Installation ..... 15-17

Page 609 of 1681

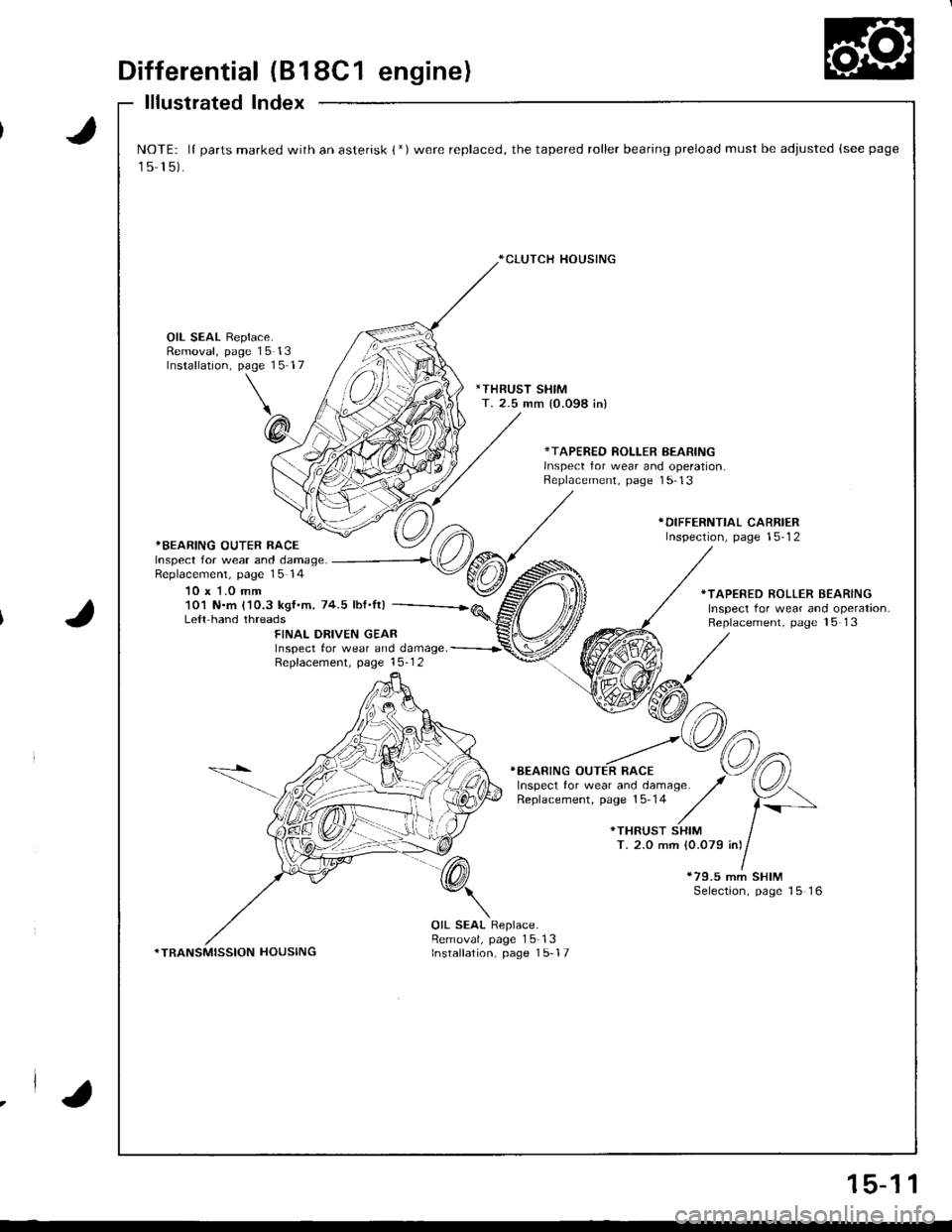

Differential (B18C1 engine)

lllustrated Index

J

J

NOTE: lI parts marked with an asterisk {*)were replaced, the tapered roller bearing preload must be adjusted (see page

15 15).

*CLUTCH HOUSING

OIL SEAL Replace.Removal, page 15 13Installation, page 15 17

*THRUST SHIMT. 2.5 mm {0.098 in)

*TAPERED ROLLER BEARINGlnsDect for wear and ooeration.Replacement, page 1 5-13

*BEARING OUTER RACEInspect for wear and damage.Replacemenl, page 15 14

10 x 1.0 mm

*DIFFERNTIAL CARRIERInspection, page 15-12

101 N.m {'10.3 kgf.m, 74.5 lbf.It)Le{t hand threads

*TAPERED ROLLER BEARINGInspect tor wear and operation.Replacement, page 15 13FINAL DRIVEN GEARInspect tor wear and damage. -----------r'

Repfacement. page 15-1 2

}BEARING OUTER RACE

*79.5 mm SHIMSelection, page 15 16

*TRANSMISSION HOUSING

OIL SEAL Replace.Removal, page 15-13Installation, page 1 5-17

.la

15-1 1

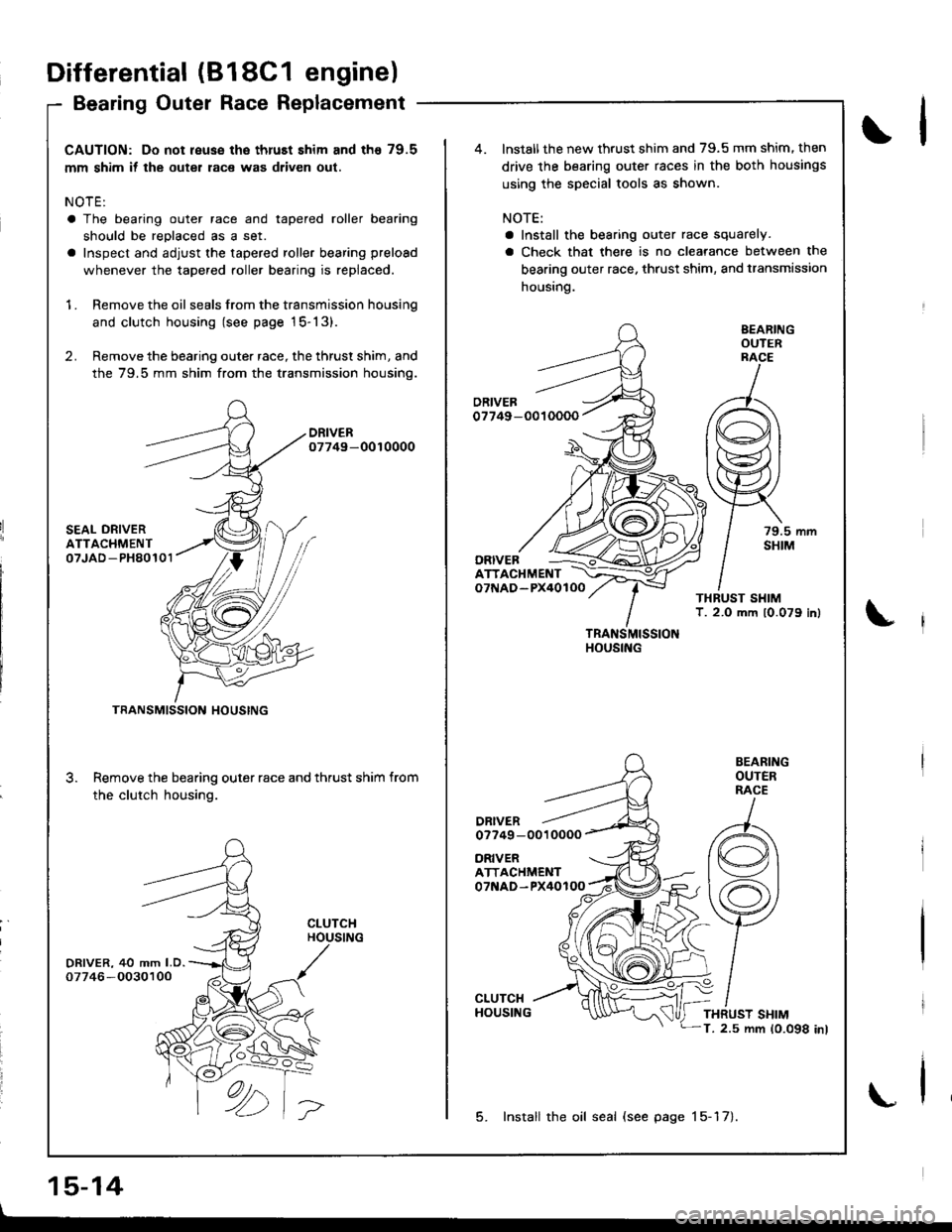

Page 612 of 1681

CAUTION: Do not reuse the thruEt shim and th€ 79.5

mm shim if the outer race was driven out.

NOTE:

a The bearing outer race and tapered roller bearing

should be reDlaced as a set.

a Inspect and adjust the tapered roller bearing preload

whenever the tapered roller bearing is replaced.

1 . Remove the oil seals from the transmission housing

and clutch housing (see page 15-13).

2. Remove the bearing outer race, the thrust shim, and

the 79.5 mm shim from the transmission housino.

DRIVER07749-0010000

SEAL ORIVERATTACHMENT07JAD -PH80101

DRIVER, 40 mm LD.07746 -O030100

3.

TRANSMISSION HOUSING

Remove the bearing outer race and thrust shim from

the clutch housing.

CLUTCHHOUSING

ORIVERATTACHMENT07NAD-PX40100

ATTACHMENTo7f{AD-PX40lOO

DRIVERo7749 -0010000

TRANSMISSIONHOUSING

BEARINGOUTERRACE

79.5 mmSHIM

BEARINGOUTERRACE

THRUST SHIMT. 2.5 mm 10.098 inl

lnstall the new thrust shim and 79.5 mm shim. then

drive the bearing outer races in the both housings

using the special tools as shown.

NOTE:

a Install the bearing outer race squarely.

a Check that there is no clearance between the

bearing outer race. thrust shim, and transmission

housing.

ORIVEB

5. Install the oil seal (see page 15-17).

Differential (818C1 engine)

Bearing Outer Race Replacement

15-14

\l

\

\

Page 621 of 1681

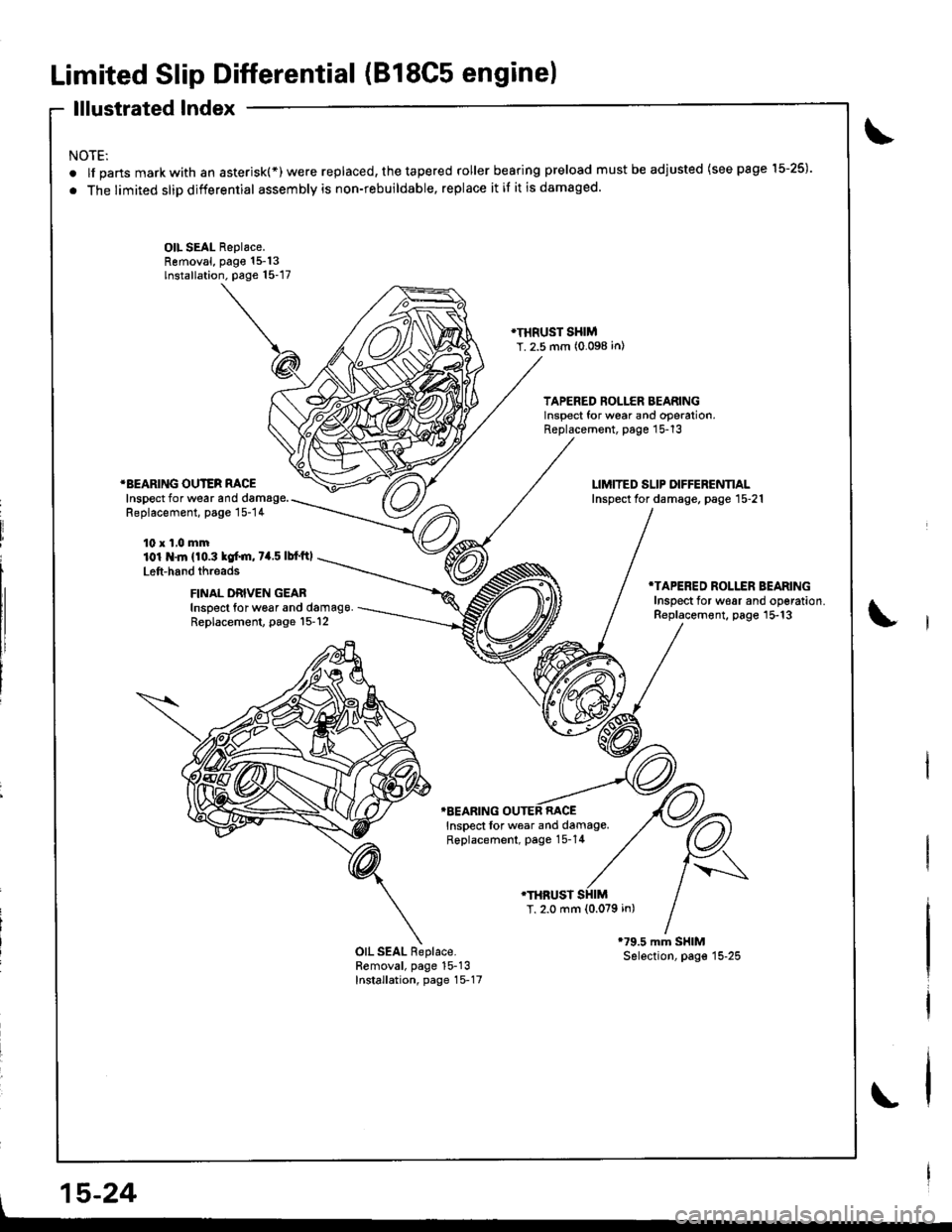

Limited Slip Differential (B18C5 engine)

lllustrated Index

NOTE:

.lfpartsmarkwithanasterisk(*)werereplaced,thetaperedrollerbearingpreloadmustbeadjusted(seepagel5-25).

. The limited slip differential assembly is non-rebuildable, replace it if it is damaged.

OIL SEAL Replace.Removal, page 15-13lnstallation. page 15-17

}I}IRUST SHIMT. 2.5 mm (0.098 in)

TAPERED ROLLER BEARINGlnsoect for wear and ooeration,Replacement, page 15-13

*BEARING OUTER RACEInspect for wear and damage.Replacement, page 15-14

10 x 1,0 mm101 .ln {10.3 kof.m, 7a.5 lbf'ftl

Left-hand threads

FINAL DRIVEN GEABInspect for w6ar and damag9.Replacement, page l5-12

*TAPERED ROLLER BEARINGInsDect for w€ar and oo€ration.Replacement, page 15-13

TBEARING OUTEB RACEInspect lor wear and damage.Replacement, page 15-14

.THRUST

T, 2.0 mm {0.079 in)

OIL SEAL Replace.Removal, page 15-13Installation, page 15-17

l,

, 15-24

Page 662 of 1681

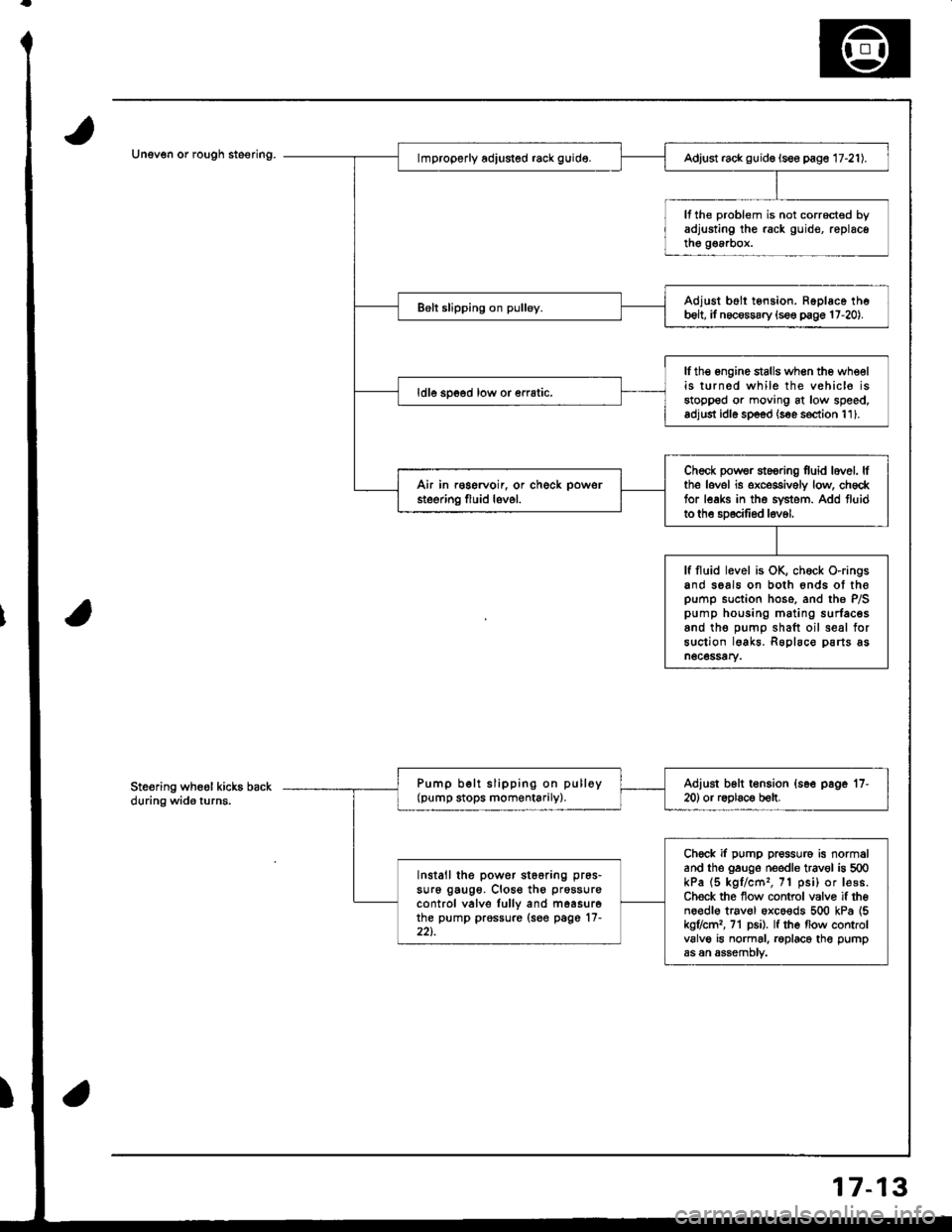

Unev€n or rough steering.Adjust rack guid€ (see page 17-21).

It the problem is not corrocted byadjusting the rack guid€, replacethe g€a.box.

Adjust b6ll tension. Ropl6ce theb6lt, it necossary {s€e p€ge 17-20).

lfth€ engine stalls when the wheelis turned while the vehic16 isstopped or moving at low speed.adjust idl6 sp6od (s€e s€ction 111.

ldle spoed low or €rratic.

Check powsr st6oring fuid lovel. lfthe lovel is exceggively low, ch6cktor leaks in the svstem. Add fluidto the sD6cilied l6v6l,

Air in r€gervoir, or check powsr

steering fluid lovel.

lf fluid level is OK, chock O-ringsand seals on both 6nds ot thepump suction hose. and the P/Spump housing mating surfacesand tho oumo shaft oil seal forsuction lgakr. Roplaco parts asn6c6ssary.

Pump b€lt slipping on pulloy(pump stops momentarily).Adiust b6lt t€nsion {s6e page '17-

20) or r6olac€ b€lt.

Chock if pump pressure is normaland the gauge needle trav€l is 500kPa (5 kgl/cm'�, 71 psi) or lesB.Ch€ck the flow control valvo if theno€dl€ trav€l oxco€ds 500 kPa {5kg7cml, 71 p6i). lf the flow controlvalve is normal. roplace the pumpas an assemDtv.

Install the power st66ring pr6s-

su16 gaug6. Close th6 prossure

control valve lully and m6asurethe pump prossure (see page'17-22t.

Ste€ring wheol kicks backduring wide turns.

7-13

Page 670 of 1681

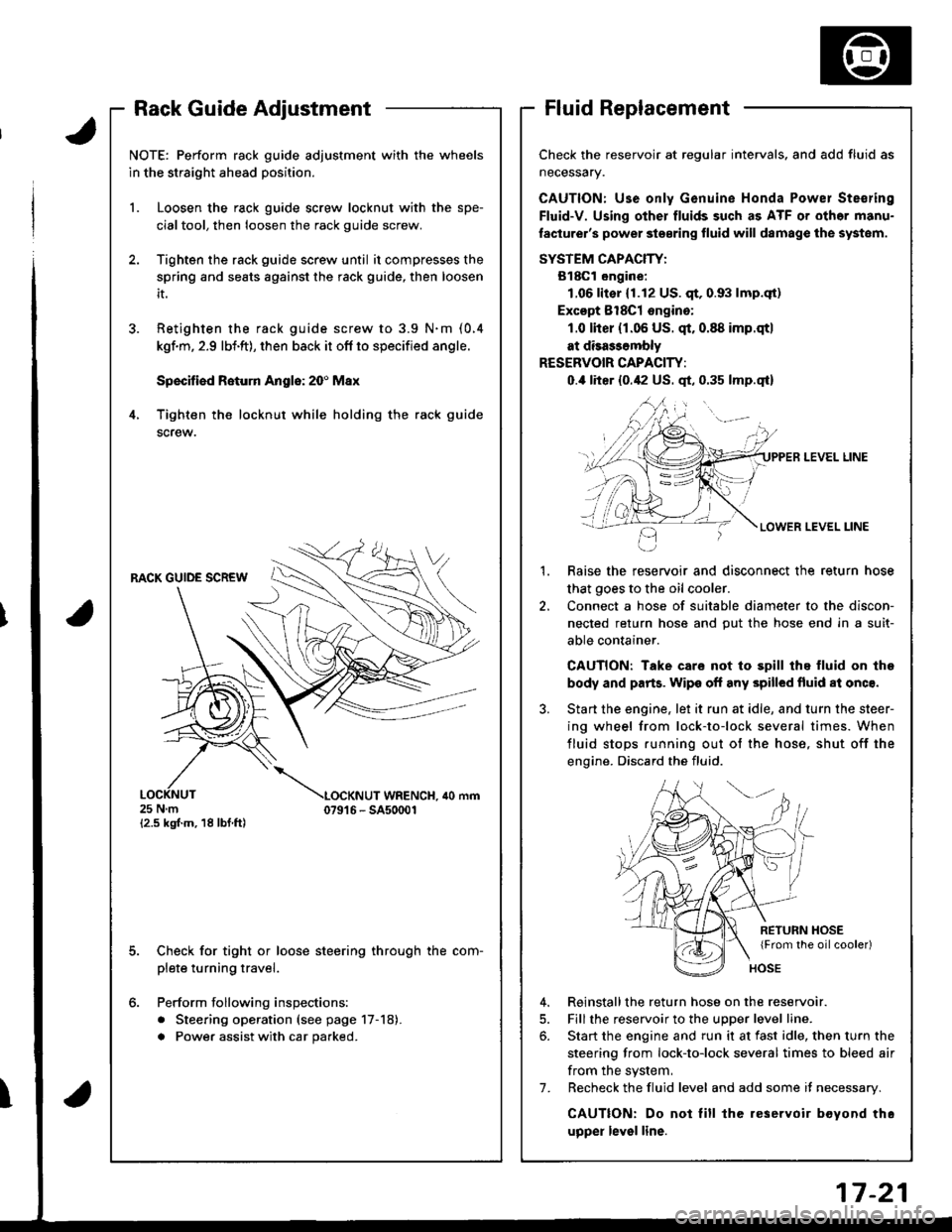

Rack Guide AdjustmentFluid Replacement

Check the reservoir at regular intervals, and add fluid as

neceSsary.

CAUTION: Use only Genuine Honda Powel Ste€ring

Fluid-V. Using other fluids such as ATF or othor manu-

laclurer's power ste€ring fluid will damag€ the systom.

SYSTEM CAPACIW:

B18Gl ongine:

1.06lit€r (1.12 US. qt,0.93 lmp.qt)

Excopt 8l8Cl ongino:

1.0 lher (r.06 US. qt.0.88 imp.qtl

at disa$ombly

RESERVOIR CAPACITY:

0.,0 liter {0.42 US. qt, 0.35 lmp.qt}

LEVEL LINE

LEVEL LINE

Raise the reservoir and disconnect the return hose

that goes to the oil cooler.

Connect a hose of suitable diameter to the discon-

nected return hose and put the hose end in a suit-

able container.

CAUTION: Take care not to spill thq fluid on lhe

body and parts. Wipe off any spilled fluid al onc€.

Start the engine. let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid.

2.

RETURN HOSE{From the oilcooler)

4. Reinstallthe return hose on the reservoir.

5. Fill the reservoir to the uDDer level line.

6. Start the engine and run it at fast idle, then turn the

steering from lock-to-lock several times to bleed air

from the system,

7. Recheck the fluid level and add some it necessary.

CAUTION: Do not lill the reservoir boyond thc

upper level line.

J.

4.

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead position.

1. Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

Tighten the rack guide screw until it compresses the

spring and seats against the rack guide, then loosen

it.

Retighten ihe rack guide screw to 3.9 N.m (0.4

kgf.m, 2.9 lbi.ft), then back it ofl to specified angle.

Speciliad Roturn Anglo: 20' Max

Tighten th€ locknut while holding the rack guide

screw.

RACK GUIDE SCREW

25Nm{2.5 kgf.m, 18 lbf ft)

LOCKNUT WRENCH. ilo mm079't 6 - SA50001

E

6.

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-18).

a Power assist with car parked.

I

Page 1049 of 1681

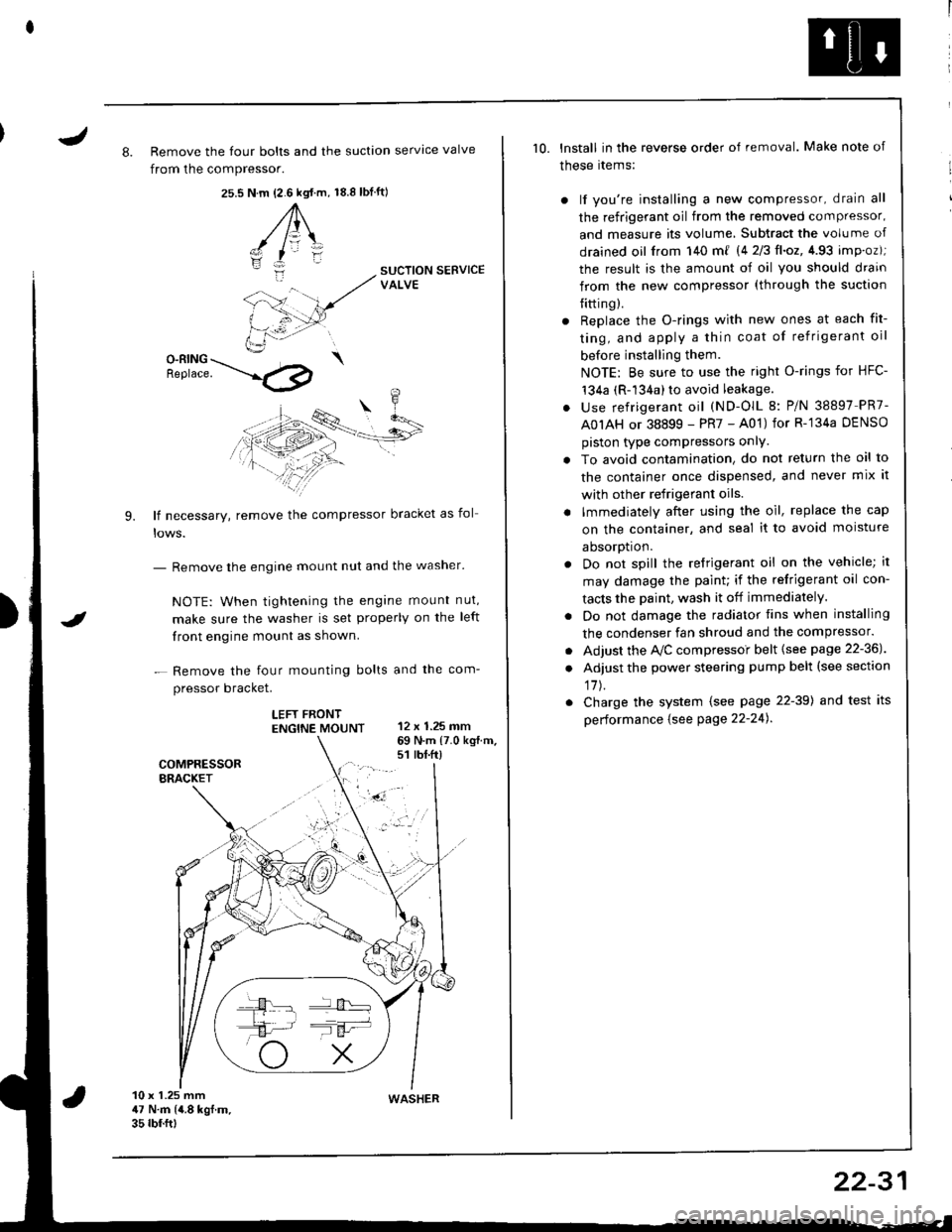

J8. Remove the four bolts and the suction servtce valve

from the compressor.

25.s18.8 tbf.ft)N.m {2.6 kgt.m,

A\

-/ l=\'zI

i:-

9.

SUCTION SERVICEVALVE

O-RING \Benrace. --'.l4p

lf necessary, remove the compressor bracket as fol

- Remove the engine mount nut and the washer'

NOTE: When tightening the engane mount nut,

make sure the washer is set properly on the left

front engine mount as shown.

- Remove the four mounting bolts and the com-

pressor bracket.

LEFT FRONTENGTNE MOUNT 12 x 1.25 mm

I

69 N.m {7.0 kg{.m.s1 rbt.ft)

10 x 1.25 mm47 N.m (4.8 kgf.m.35 rbf.ftt

10. lnstall in the reverse order of removal. Make note of

these rtems:

) lf you're installing a new compressor, drain all

the refrigerant oil from the removed compressor,

and measure its volume, Subtract the volume of

drained oil from 140 m{ 14 2/3ll.oz,4.93 imp.oz);

the result is the amount of oil you should drain

from the new compressor (through the suction

{itting).

r Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them.

NOTE: Be sure to use the right O-rings for HFC-'t34a (R-134a) to avoid leakage.

. use refrigerant oil (ND-OlL 8: P/N 38897 PR7-

A0IAH or 38899 - PR7 - A01) for R-'134a DENSO

piston type compressors onlY.

. To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediately after using the oil, replace the cap

on the container, and seal it to avoid moisture

aDsorDt|on.

. Do not spill the refrigerant oil on the vehicle; it

may damage the paint; if the refrigerant oil con-

tacts the Daint, wash it off immediately.

. Do not damage the radiator fins when installing

the condenser fan shroud and the compressor.

. Adjust the Ay'C compressoi belt {see page 22-36J

. Adjust the power steering pump belt (see section

17J.

. Charge the system (see page 22-39) and test its

performance {see Page 22-24).

WASHER

22-31

Page 1070 of 1681

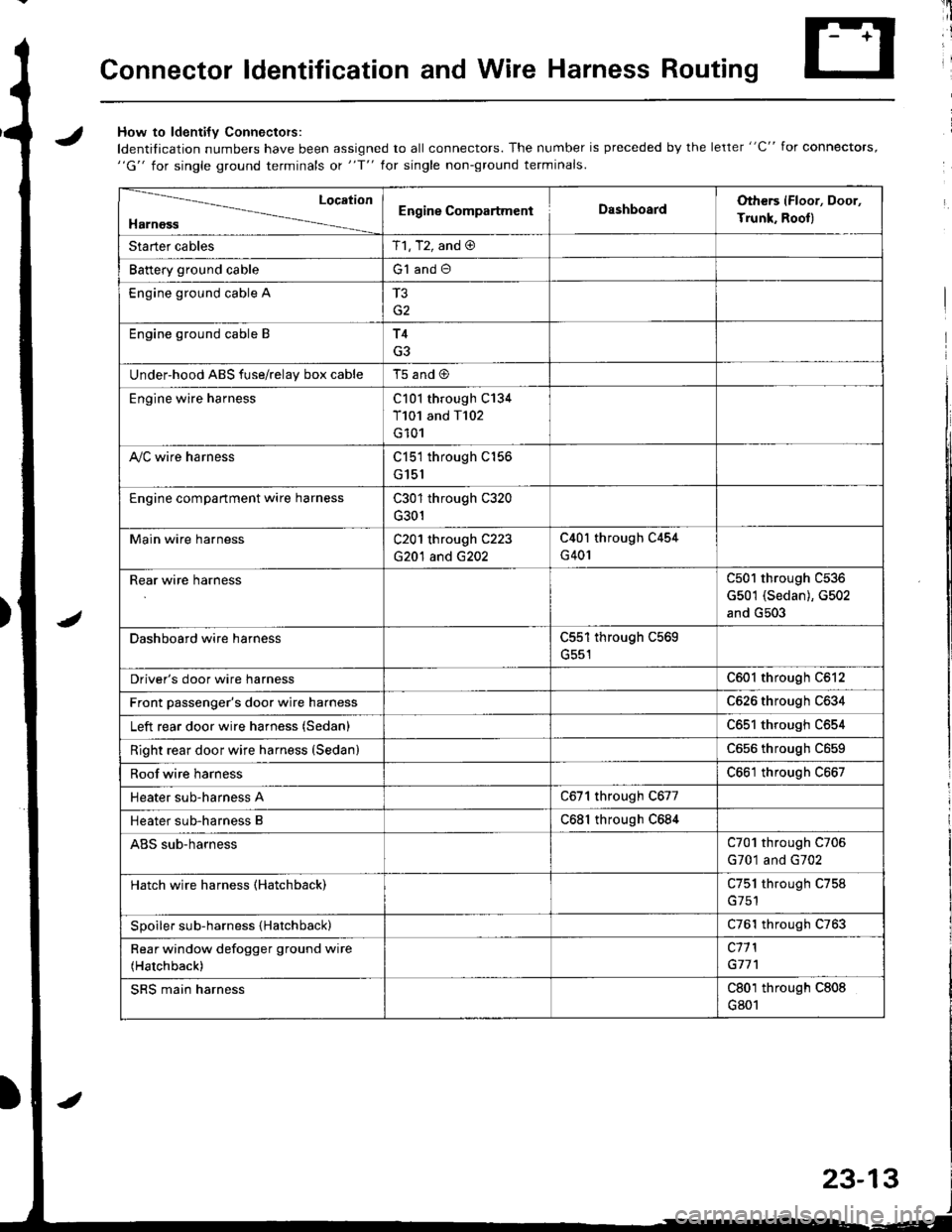

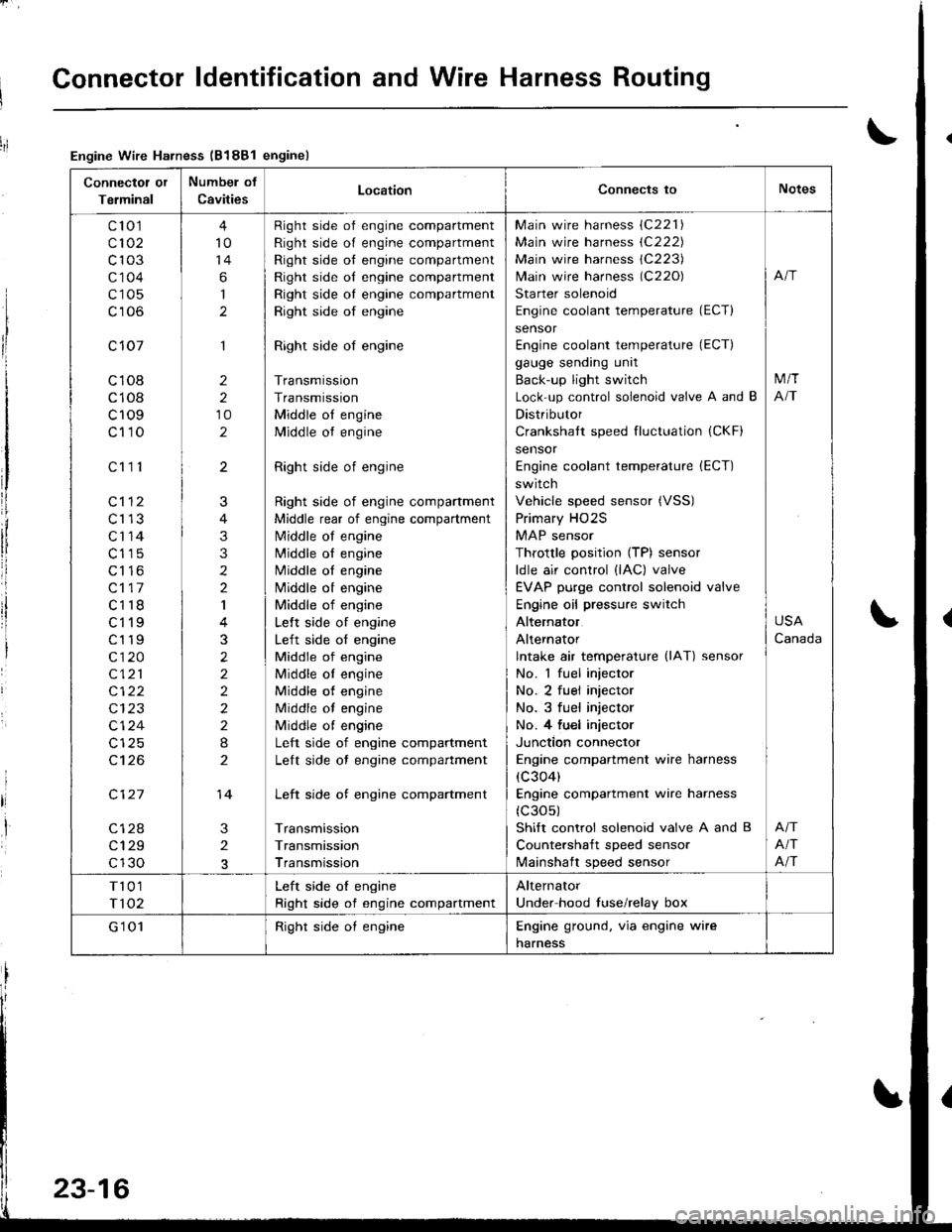

Connector ldentification and Wire Harness Routing

JHow to ldenti{v Connectors:

ldentification numbers have been assigned to all connectors. The number is preceded by the letter "C" for connectors,"G" for single ground terminals ot "f" lor single non-ground terminals.

/

Location

HarnossEngine CompartmentDashboardOthers (Floor, Door,

Trunk. Rooll

Starter cablesT1, T2, and @

Battery ground cableG1 and O

Engine ground cable A

G2

Engine ground cable BT4

G3

Under-hood ABS fuse/relav box cableT5 and @

Engine wire harnessC101 through C134

T101 and T102

G101

A,/C wire harnessC151 through C156

G151

Engine compartment wire harnessC301 through C320

G301

Main wire harnessC201 through C223

G20'l and G202

C40l through C454

G401

Rear wire harnessC501 through C536

G501 (Sedan), G502

and G503

Dashboard wire harnessC551 through C569

G551

Driver's door wire harnessC601 through C612

Front passenger's door wire harnessC626 through C634

Left rear door wire harness (Sedan)C65l through C654

Right rear door wire harness (SedanlC656 throughc659

Roof wire harnessC661 through C667

Heater sub-harness AC671 through C677

Heater sub-harness BC68l through C684

ABS sub-harnessC701 through C706

G701 and G702

Hatch wire harness (Hatchback)C751 through C758

Spoiler sub-harness {Hatchback)C761 through C763

Rear window defogger ground wire

(Hatchback)

c11 l

G77'l

SRS main harnessC801 through C808

G801

23-13

Page 1073 of 1681

Connector ldentification and Wire Harness Routing

Connectot or

Terminal

Numbel of

CavitiesLocationConnects toNotes

c'to 1

c102

c103

c'1 04

c105

c106

c 107

c108

c108

c109

c110

c112

c113

c'r 14

c115

c116

c117

c118

ct'l9

c119

c120

c121

c122

c124

c't 26

c127

c128

c129

c130

c111

4

10

14

6

I

1

2

2

10

2

3

2

J

4

3

3

2

2

I

3

2

2

2

2

2

I

2

14

Right side of engine compartment

Right side of engine compartment

Right side ot engine compartment

Right side of engine compartment

Right side oI engine compartment

Right side of engine

Right side of engine

Transmission

Transmission

Middle ot engine

Middle ot engine

Right side of engine

Right side of engine compartment

Middle rear of engine compartment

N4iddle of engine

N4iddle ol engine

Middle oI engine

Nliddle ot engine

Middle of engine

Lelt side of engine

Left side of engine

Middle of engine

Middle oI engine

Middle of engine

Middle of engine

Middle ot engine

Left side of engine compartment

Lelt side ot engine compartment

Left side of engine compartment

Transmission

Transmission

Transmission

Main wire harness (C221)

Main wire harness (C222)

Main wire harness 1C223)

lvlain wire harness (C220)

Starter solenoid

Engine coolant temperature (ECT)

sensor

Engine coolant temperature (ECT)

gauge sending unit

Back-up light switch

Lock-up control solenoid valve A and B

Distributor

Crankshatt speed fluctuation (CKF)

sensor

Engine coolant temperature (ECT)

switch

Vehicle speed sensor (VSS)

Primary HO2S

MAP sensor

Throttle position (TP) sensor

ldle air control (lAC) valve

EVAP purge control solenoid valve

Engine oil pressure switch

Alternator

Alternator

lntake air temperature (lAT) sensor

No. 1 fuel injector

No. 2 fuel injector

No. 3 fuel injector

No. 4 fu€l injector

Junction connector

Engine compartment wire harness

(c304)

Engine compartment wire harness

(c30s)

Shift control solenoid valve A and B

Countershaft speed sensor

lvlainshaft speed sensor

M/T

NT

USA

Canada

Afi

Afi

T101

T102

Left side oI engine

Right side of engine compartment

Alternator

Under hood fuse/relay box

G'1 01Right side oI engineEngine ground. via engine wire

harness

Engine Wire Harness (B188l enginel

23-16

Page 1075 of 1681

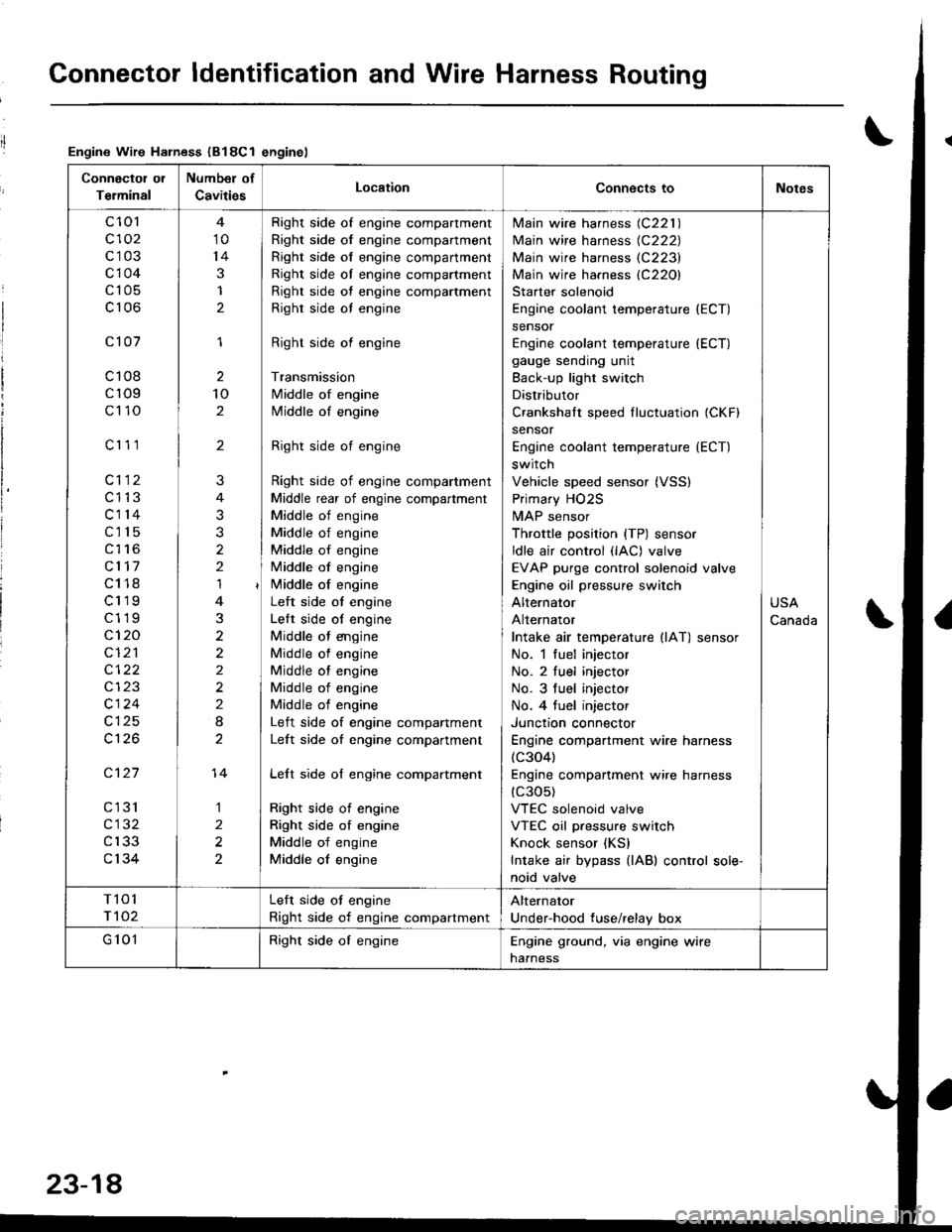

Connector ldentification and Wire Harness Routing

Engine Wire Harness (B18Cl enginel

Connectol ol

Terminal

Number of

CavitiesLocationConnects toNotes

c 101

c102

c103

c104

c105

c106

c101

c108

cr09

c110

c'r 11

cl12

c1't3

c114

c115

c116

cl17

c118

c119

c119

c120

cI2'l

cl24

c126

c127

cl31

c132

c133

c134

10

14

3

1

2

1

2

10

2

'I

3

2

2

2

I

1

2

2

?

3

2

14

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side ol engine compartment

Right side of engine compartment

Righr side oI engine

Right side of engine

Transmission

Middle of engine

Middle of engine

Right side of engine

Right side of engine compartment

Middle rear of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

i/iddle of engine

Left side ot engine

Lelt side ot engine

Middle ot engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left side of engine companment

Left side of engine compartment

Lelt side of engine compartment

Right side of engine

Right side of engine

Middle of engine

Middle of engine

lvlain wire harness (C221 )

Main wire harness {C222)

Main wire harness (C223)

Main wire harness (C220)

Starter solenoid

Engine coolant temperature (ECT)

sensor

Engine coolant temperature (ECT)

gauge sending unit

Back-up light switch

Distributor

Crankshalt speed fluctuation (CKFI

sensor

Engine coolant temperature {ECT)

switch

Vehicle speed sensor (VSS)

Primary HO2S

MAP sensor

Throttle position {TP) sensor

ldle air control (lAC) valve

EVAP purge control solenoid valve

Engine oil pressure switch

Alternator

Alternator

Intake air temperature llAT) sensor

No. 1 fuel injector

No. 2 fuel injector

No. 3 tuel injector

No. 4 tuel injector

Junctron connector

Engine compartment wire harness(c304)

Engine companment wire harness(c30s)

VTEC solenoid valve

VTEC oil pressure switch

Knock sensor (KS)

Intake air bypass {lAB) control sole-

noid valve

USA

Canada

T101

r 102

Left side ot engine

Right side of engine compartment

Alternator

Under-hood fuse/relay box

G 101Right side of engineEngine ground, via engine wire

naaness

23-18