engine HONDA INTEGRA 1998 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 200 of 1681

Radiator

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to shut

th6 relay box lid and not to l€t coolant spill on th6 el€c-

trical parts or the paint. lf any coolant spills, rinse it off

immediately.

1. Slide the heater temDerature control lever to maxi-

mum heat.

Make sure the engine and radiator are cool to the

touch.

2. Remove the radiator cap.

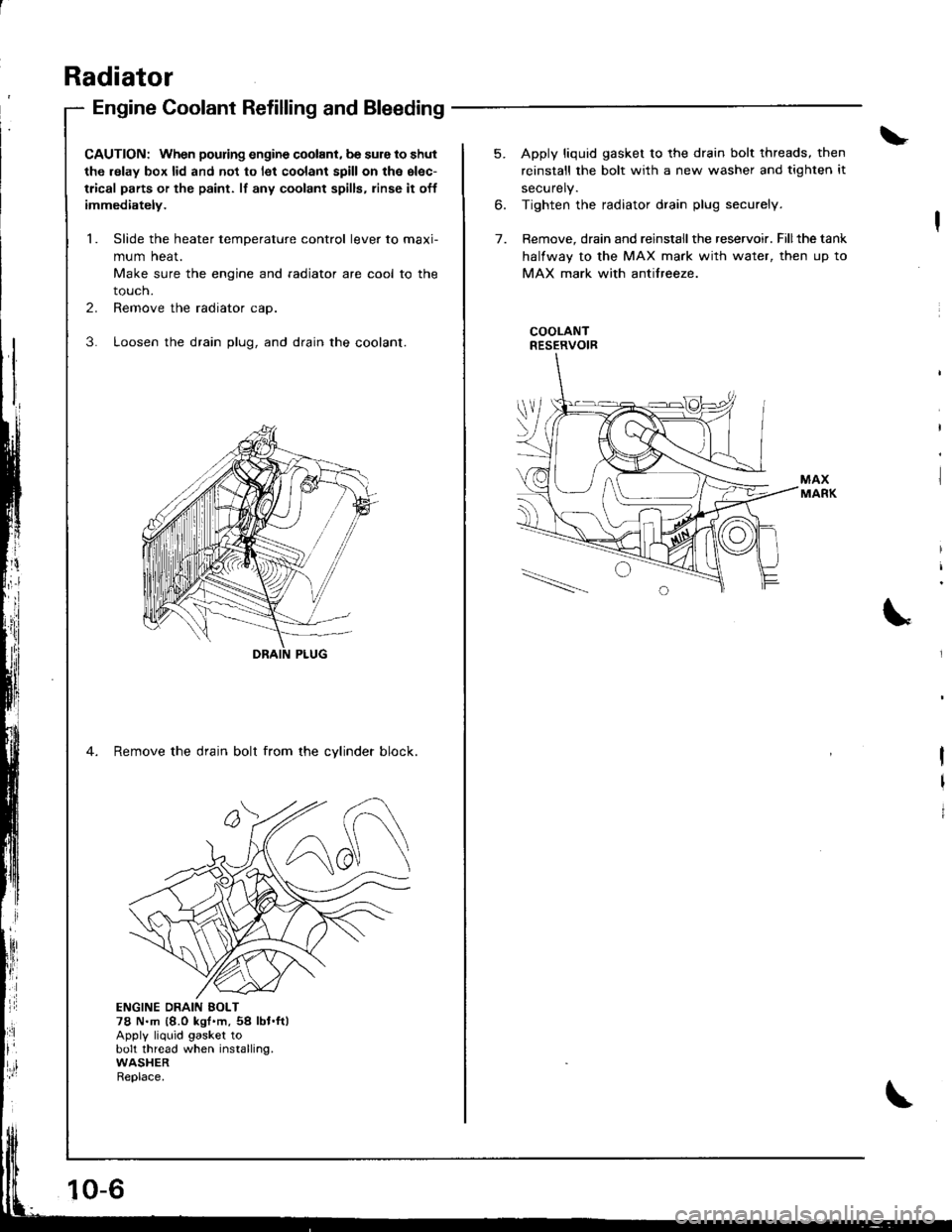

3. Loosen the drain plug, and drain the coolant.

4. Remove the drain bolt from the cvlinder block.

ji

Ii'

l:ll

ENGINE DRAIN EOLT78 N.m {8.0 kgt'm,54 lbt.ft)Apply liquid gasket tobolt thread when installing.WASHERReplace.

10-6

5. Apply liquid gasket to the drain bolt threads, then

reinstall the bolt with a new washer and tighten it

securely.

6. Tighten the radiator drain plug securely.

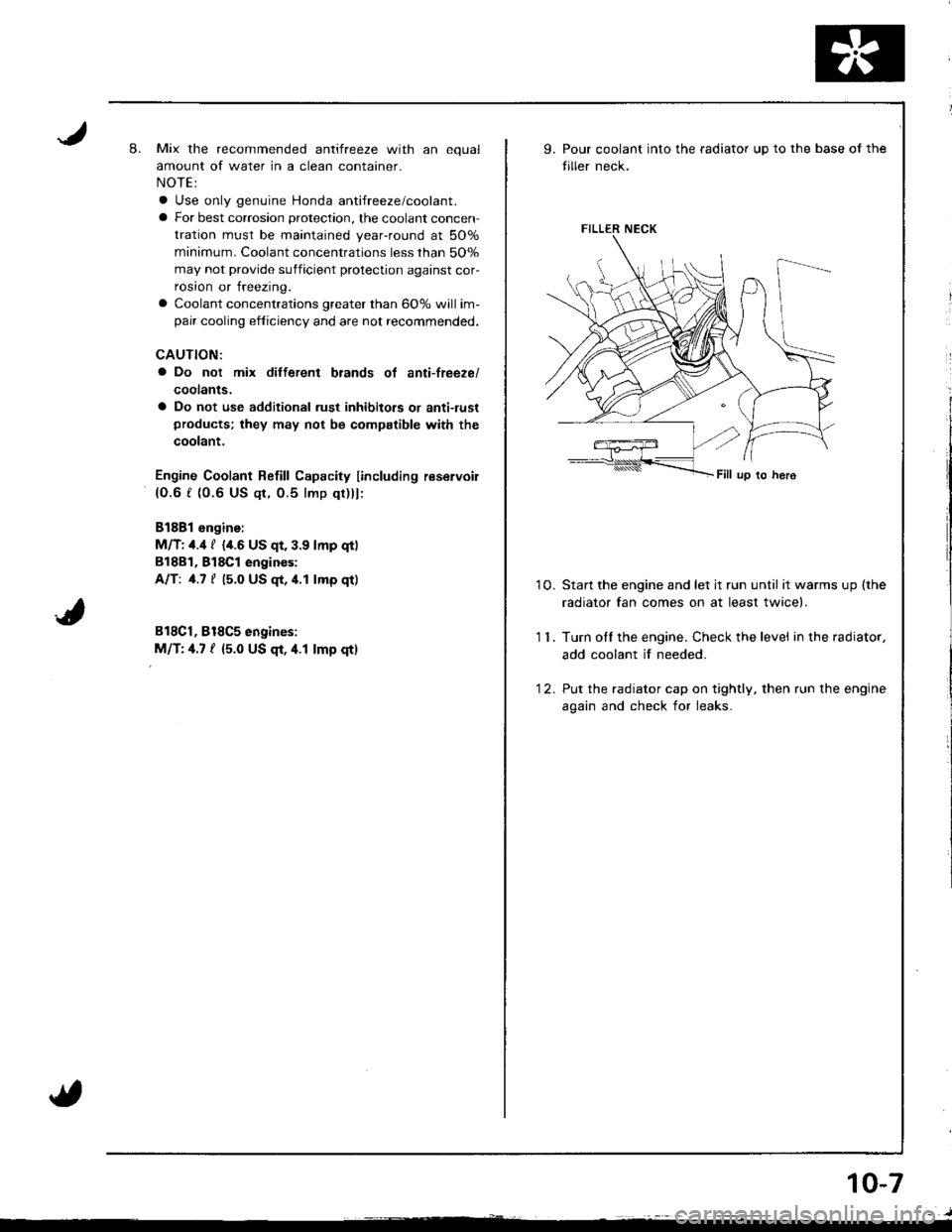

7. Remove, drain and reinstall the reservoir. Fillthe tank

halfway to the MAX mark with water, then up to

MAX mark with antifreeze.

COOLANTRESERVOIR

I

I

I

Page 201 of 1681

8.Mix the recommended antifreeze with an equal

amount of water in a clean container.

NOTE:

a Use only genuine Honda antifreeze/coolant.

a For best corrosion protection, the coolant concen-

tration must be maintained year-round at 500,6

minimum. Coolant concentrations less than 507o

may not provide sufficient protection against cor,

rosion or freezing.

a Coolant concentrations greater than 60% will im-

pair cooling efliciency and are not recommended.

CAUTION:

a Do not mix different brands of anti-lrcezel

coolants.

a Do not use additional rust inhibitots or anti-tustproducts; they may not be compatible with the

coolant.

Engine Coolant Refill Capacity [including reservoir

{0.6 { (0.6 US qt, 0.5 lmp qr)ll:

81881 engine:

Ml7:1-1t {/t.6 US qt. 3.9 lmp qtl

818B1, 818C1 engin€s:

AlTt 1.7 | 15.0 US qt, 4.1 lmp qt)

818C1, B18C5 engines:

MlTt 1.7 t 15.0 US $, 4.1 lmp qtl

FILLER NECK

9.Pour coolant into the radiator up to the base of the

tiller neck.

10. Startthe engine and let jt run until itwarmsup(the

radiator fan comes on at least twice).

1 1 . Turn olf the engine. Check the level in the radiator,

add coolant if needed.

'12. Put the radiator cap on tightly, then run the engine

again and check for leaks.

10-7

Page 202 of 1681

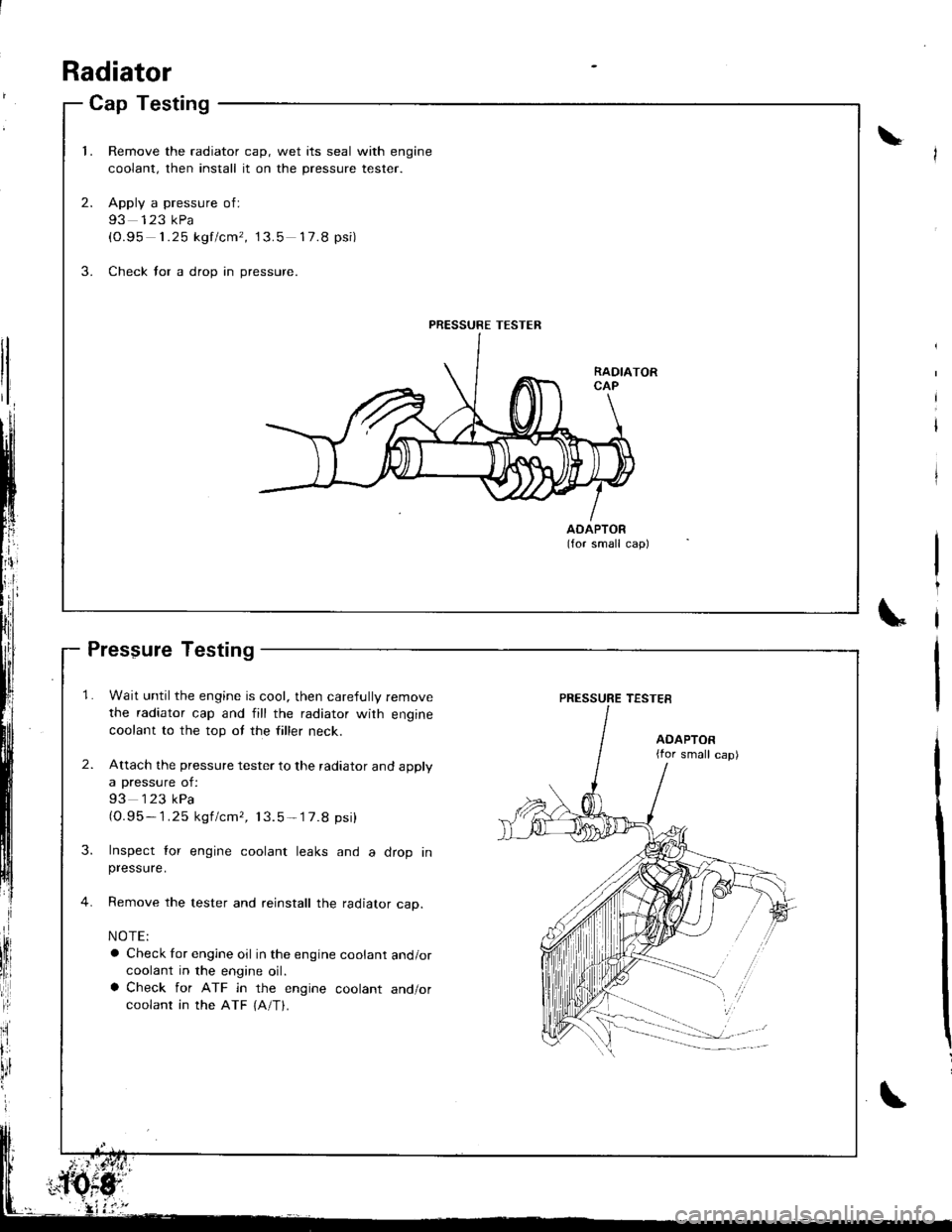

Cap Testing

1.Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester.

Apply a pressure of:

93 123 kPa(0.95 1.25 kgf/cm', 13.5 17.8 psi)

Check for a drop in pressure.

2.

3.

AOAPTOR(for small cap)

PRESSURE TESTER

Radiator

Pressure Testing

1. Wait until the engine is cool, then carefully remove

the radiator cap and fill the radiator with engine

coolant to the top ot the filler neck.

2. Attach the pressure tester to the radiator and apply

a pressure of:

93 123 kPa(O.95- 1.25 kgf/cmr, 13.5-'17.8 psi)

3. Inspect lor engine coolant leaks and a drop inpressure.

4. Remove the tester and reinstall the radiator cap.

NOTE:

a Check for engine oil in the engine coolant and/orcoolant in the engine oil.a Check for ATF in the engine coolant and/orcoolant in the ATF {A/T}.

\

PRESSURE TESTES

AOAPTOR{for small cap)

Page 204 of 1681

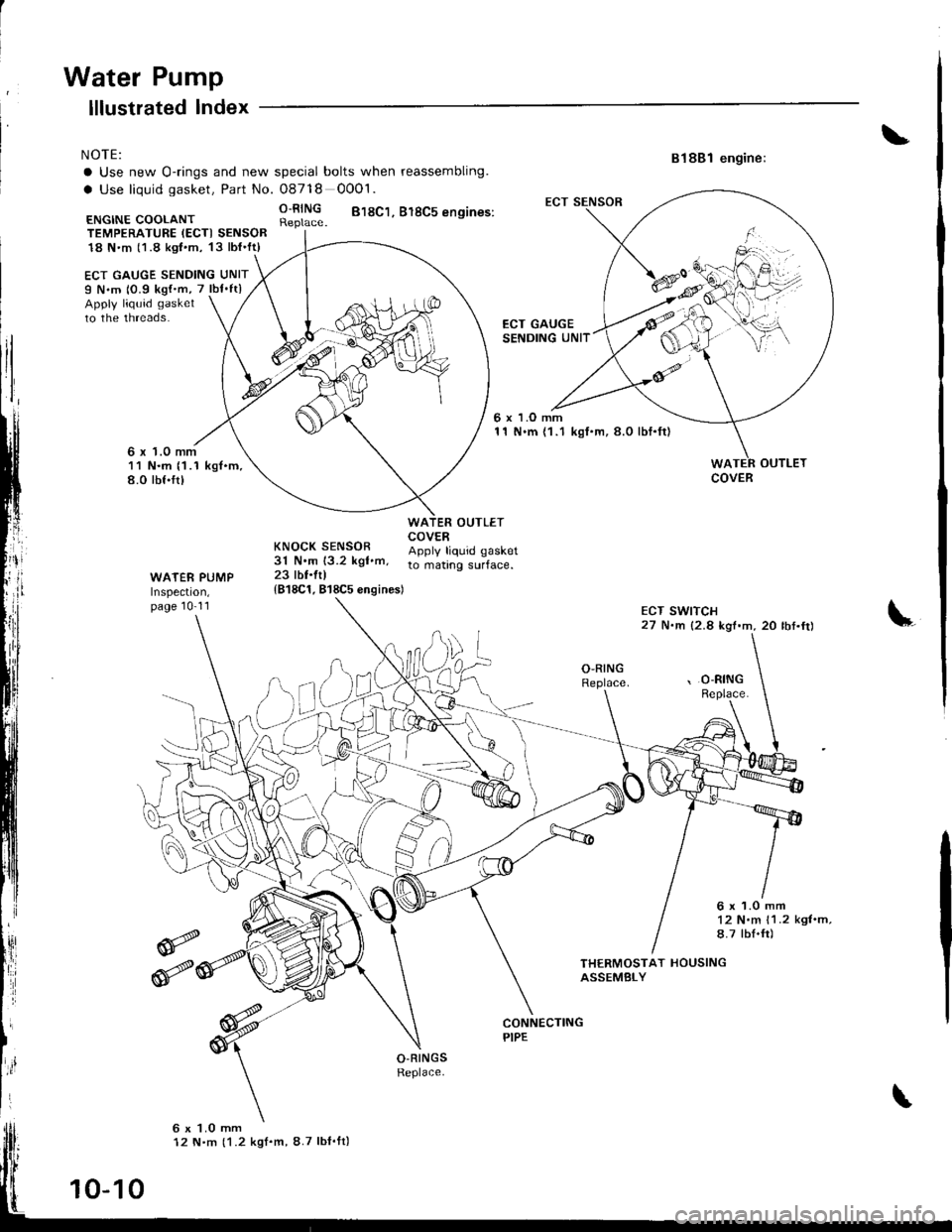

Water Pump

NOTE:

a Use new O-rings and new spgcial bolts when reassembling.

a Use liquid gasket, Part No. O8718 0001.

R;lll$ 818c1. 818c5 ensines:

ECT GAUGE SENDING UNITI N.m 10.9 kg{'m, 7 lbf'ftlApply liquid gasket

to the threads.

lllustrated lndex

6 x 1.0 mm11 N.m (1 .1 kgt.m.8.0 rbf.frt

ECT GAUGESENDING UNIT

818B1 engine:

OUTLET

ECT SWITCH27 N.m {2.8 kgf.m,20 lbf.fr)

ECT SENSOR

ENGINE COOLANTTEMPERATT,IRE IECTI SENSOR18 N'm (1.8 kgt.m, 13lbl'ft)

6 x 1.O mm11 N.m {1.1 kgI.m, 8.0 lbf.ft}

OUTLETCOVER

WATER PUMPInspecl|on,page 10-11

KNOCK SENSOR ADotv trouid oasket31 N.m 13.2 kgt.m, to ."t,nq .uif""".23 lbl.ftl

{818C1. 818C5 engines)

\,

O,RINGReplace.',O-RINGReplace.

6x1.0mm'12 N.m 11.2 kgt.m,8.7 lbI.fr)

THERMOSTAT HOUSINGASSEMBLY

O-RINGSReplace.

6 x 1.0 mm12 N.m (1.2 kgf.m, 8.7 lbI'ft)

COVER

10-10

Page 205 of 1681

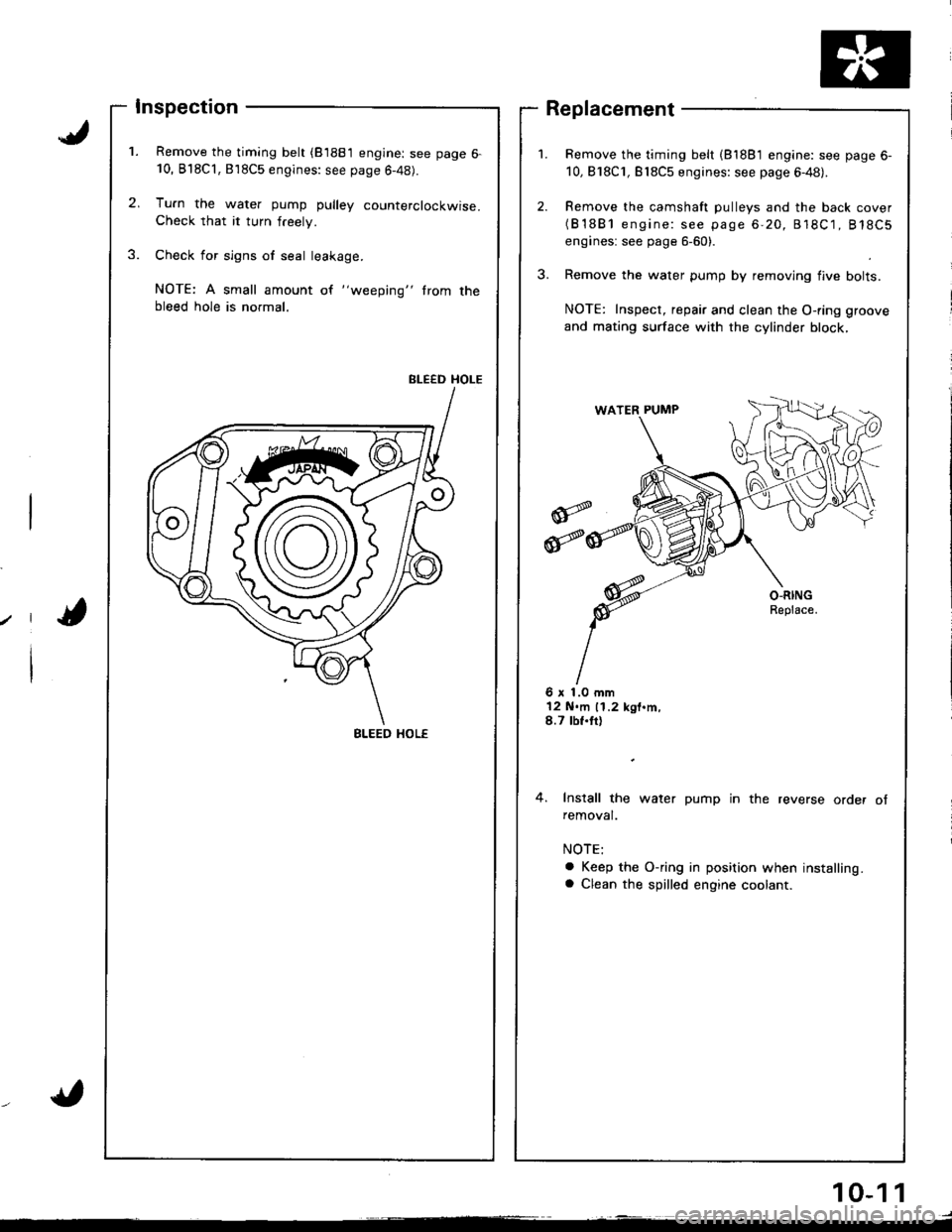

Inspection

Remove the timing belt (81881 engine: see page 6-10, B'l8Cl,818C5 engines: see page 6-48).

Tu.n the water pump pulley counterclockwise.Check that it turn freely.

Check for sign6 of seal leakage.

NOTE: A small amount of "weeping" trom thebleed hole is normal.

BLEED HOLE

Remove the timing belt (81881 engine: see page 6-

10,818C1, Bl8C5 engines: see page 6-48).

Remove the camshaft pulleys and the back cover(B'1881 engine: see page 6-20, 818C1, 818C5

engines: see page 6-60).

Remove the water pump by removing flve bolts.

NOTE: Inspect, repair and clean the O-ring groove

and mating surface with the cylinder block,

Replacement

6 x 1.0 mm12 N.m 11.2 kgt.m,8.7 tbf.tt)

4. Install the water pump in the reverse order ofremoval.

a Keep the O-ring in position when installing.a Clean the spilled engine coolant.

BLEED HOL€

10-1 1

Page 206 of 1681

i

iFuel and Emissions

SDeciaf Toofs ..,...,...............11-2

Component Locations

Index.,..,.,..................................,.,.,.,.,.,..,.,....... 11-3

System Description

Vacuum Connections ..................................,. 11-8

Electrical Connections ................................... 1 1-14

System Connectors ....,.,.,.,............................ 1 1-22

Troubleshooting

Troubfeshooting Procedures ........................ 11.32

Engine Control Module T€rminalArrangement .,.,.,..,.,. 11-39

Diagnostic Trouble Cods Chart .......-.-.......... 11-42

Howto Read Flowcharts ......,..,.,................... 1147

PGM-Fl System

System Description ............ 11-4

Troubleshooting Flowcharts

Engine Control Module ............,...,..,.,........... 11-50

Manifold Absolute PressureSensor...............................,..,.,...,................ 11-54

Intake Air TemDerature Sensor ..........,...,..... 11-58

Engine Coolant TemperatureSensor ....................,.,...,.,........................... 11-60

Throttle Position Sensor .,...........................,. 11-63

Primary Heated Oxygen Sensor(Sensor'l) .......,......,.,. 11-67

Secondary Heated Oxygen Sensorlsensor 2) .................. 11-71

Heated Oxygen Sensor Heater .....................'t1.74

Fuel Supply System ....................................... 1 1-76

Random Mistire ............. 11-78

Misfire Detected in One Cylinder .....,..:,,.,.... 11-79

Knock Sensor .........,.,..,. f -A2

Crankshaft Position/Top Dead Center/Cylinder Position Sensor .,........................ 11-83

Vehicle Speed Sensor .............,.,.,.,....,........... 11-85

Barometric Prsssute Sensor ..,...................... 11-86

Electrical Load Detector ...................,.,.......... 11-88

Crankshaft SDeed FluctuationSensor ...........................................,...,........ 11-90

ECM lnternal Circuit,..............................-......, 11-92

A/T Fl Date Line ............ 11-93

A/T Fl Signal A/B .......... 11-95

I,-1

Page 208 of 1681

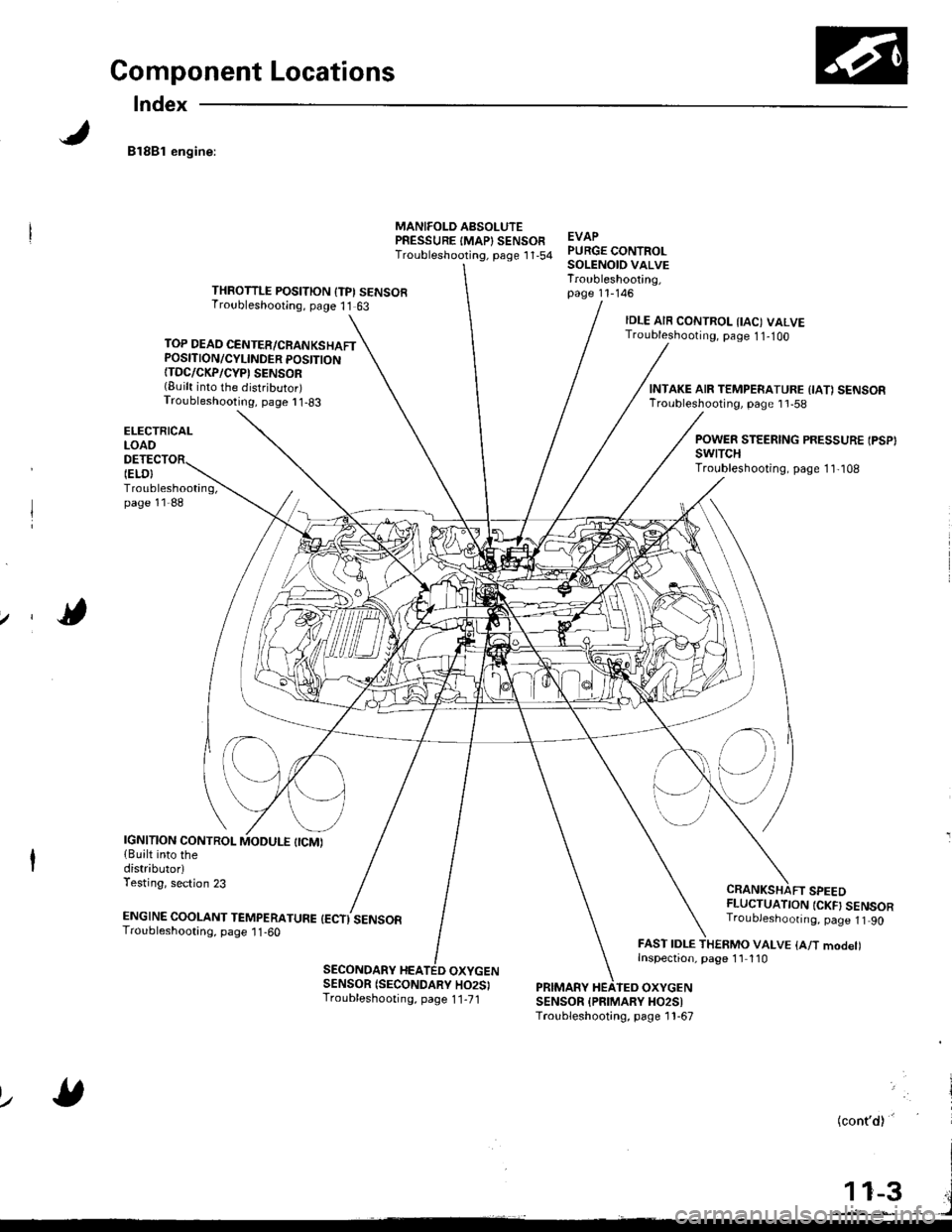

Component Locations

Index

81881 engine:

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITION{TDC/CKP/CYP' SENSOR(Built into the distributor)Troubleshooting, page I 1-83

ELECTRICALLOAO

Troubleshooting,page 11-88

MANIFOLD AsSOLUTEPRESSURE IMAP} SENSOFTroubleshooting, psge 1 '1,54EVAPPURGE CONTROLSOLENOID VALVETroubleshooting,page 11-146THROTTLE POSITION {TPI SENSORTroubleshooting, page 11 63

IELO}

IDLE AIR CONTROL IIAC) VALVETroubleshooting, page 1 1-1OO

CRANKSHAFT SPEEDFLUCTUATION {CKF} SENSORTroubJeshoonng. page 1t 90

FAST IDLE THERMO VALVE {A/T modet)Inspection, page 1'l 110

INTAKE AIR TEMPERATURE {IA1 SENSORTroubleshooting, page 1 'l -58

POWER STEERING PRESSURE IPSP}swtTcHTroubleshooting, page 1 1,108

IGNITION CONTROL{Built into thedistributorlTesting, section 23

ENGTNE cooLANT TEnapenerune {ectisensoaTroubleshooting, page 1 1 -60

SECONDARY HEATED OXYGENSENSOR (SECONDARY HO2SITroubleshooting, page 1 1-71PRIMARY HEATEO OXYGENSENSOR {PFIMARY HO2SITroubleshooting, page 1 1-67

lz

(cont'd)'

Page 209 of 1681

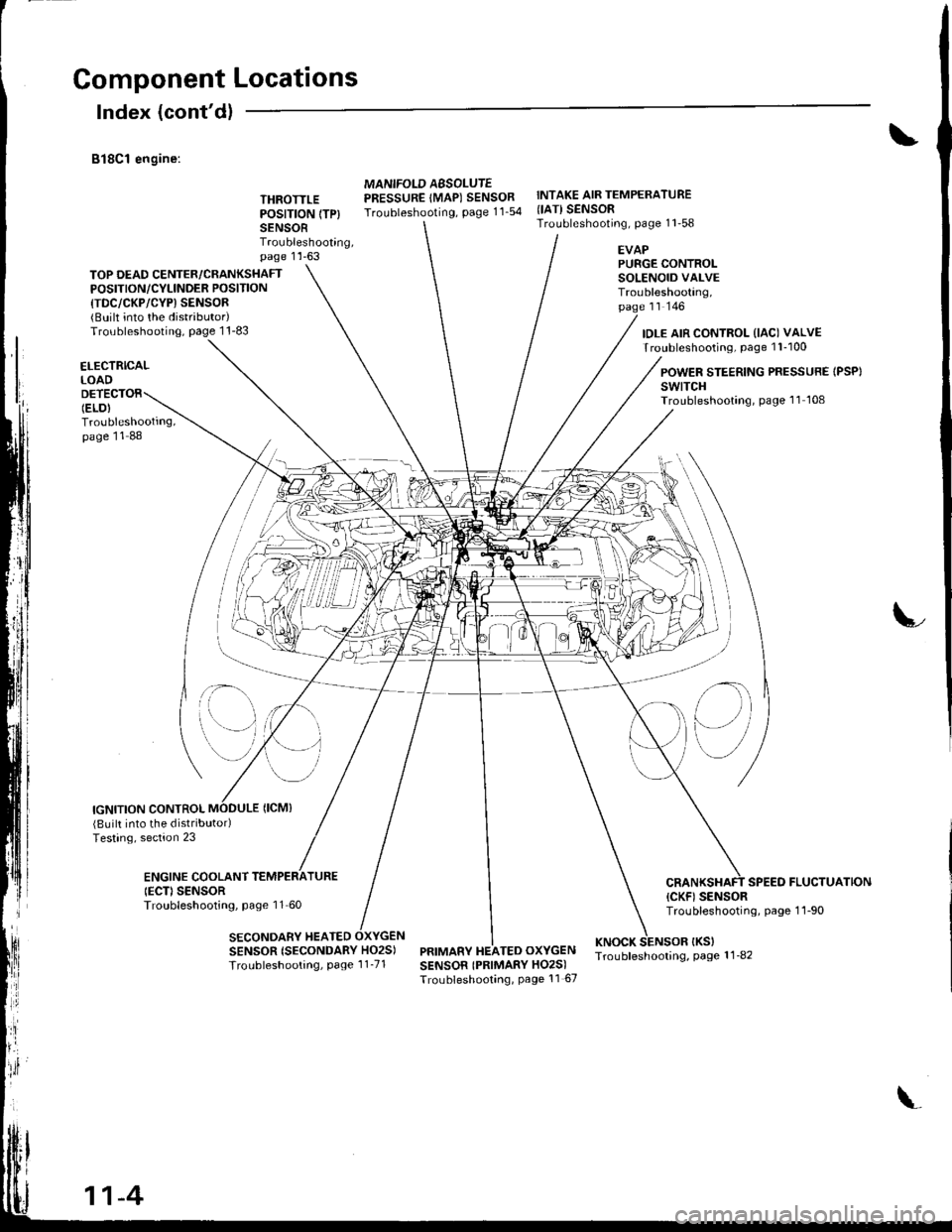

Component Locations

Index (cont'dl

B18C1 engine:

THROTTLEPOSITION (TP}

SENSORTroubleshooting,page 1 'l -63

MANIFOLD AESOLUTEPRESSURE IMAP) SENSORTroubleshooting, page 11_54

INTAKE AIR TEMPERATURE{IATI SENSORTroubleshooting, page 11'58

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINOER POSITION

{TDC/CKP/CYP) SENSOR{BUilt into the distributor)Troubleshooting, page 1 1-83

EVAPPURGE CONTROLSOLENOID VALVETroubleshooting,page rr rqo

IDLE AIR CONTROL (IAC) VALVETroubleshooting, page 1 l-100

ELECTRICALLOAD

Troubleshooting,page 11 88

POWER STEERING PRESSURE IPSP}swtTcHTroubleshooting, page 'l1 108

IGNITION CONTROL

;- \

SENSOR {SECONDARY HO2S)

Troubleshooting, Page 1 1_71

(Built into the distributodTesting, section 23

ENGINE COOLANTIECD SENSORTroubleshooting, page 11 60

SECONDARY HEATED

SPEED FLUCTUATION(CKF) SENSORTroubleshooting, page 1 1-90

PRIMARY HEATED OXYGENKNOCK SENSOR IKSITroubleshooling, page 1 1_82SENSOR IPRIMARY HO2S)Troubleshooting, Page 11 67

il\

e)

11-4

Page 210 of 1681

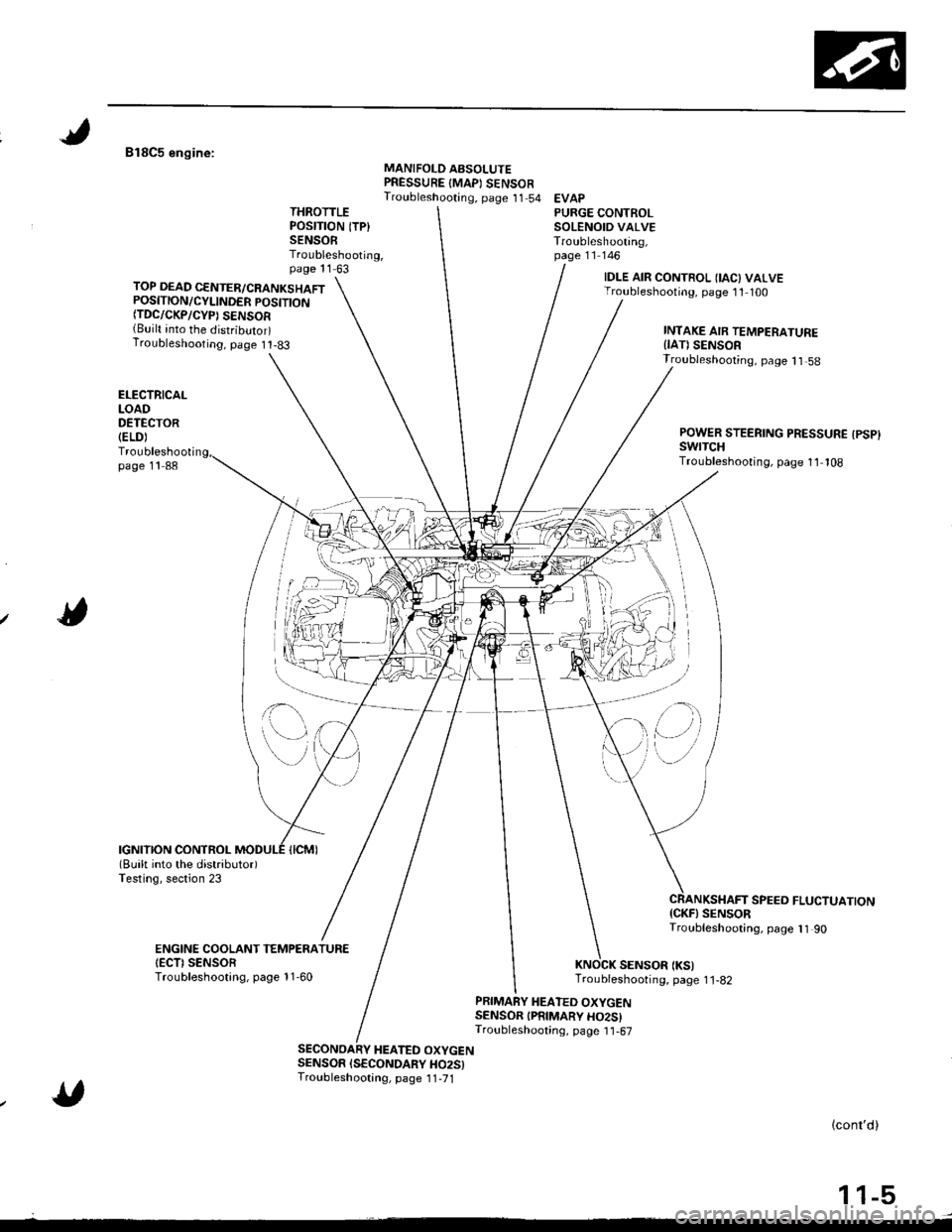

818C5 engine:MANIFOLD ABSOLUTEPRESSURE {MAPI SENSOFTroubleshooting, page 11 54 EVAPTHROTTLEPOSITION ITP}SENSORTroubleshooting,page 11 63

PURGE CONTROLSOLENOID VALVETroubleshooting,page 11 146

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITTONfiDC/CKP/CYP) SENSOR{Built into the distributor)Troubleshooting, page I t-83

IDLE AIR CONTROL IIAC) VALVETroubleshooting, page 11 100

INTAKE AIR TEMPERATUREIIAT) SENSOR

ELECTRICALLOADDETECTOR(ELD)

Troubleshootipage 11 88

Troubleshooting, page 1 1,58

POWER STEERING PRESSURE {PSP}swrTcHTroubleshooting, page 11 108

SPEEO FLUCTUATION{CKF} SENSORTroubleshooting, page 11 90

SENSOR (KS)Troubleshooting, page 1 1-82

ENGINE COOLANT TEMPENATUR€IECTI SENSORTroubleshootang, page 11-60

PRIMARY HEATED OXYGENSENSOR IPRIMARY HO2SITroubleshooting, page I1-67

HEATED OXYGENSENSOR ISECONDARY HO25)Troubleshootang, page 1 1,71

lcont'd)

1 1-5

,'(l)

Page 211 of 1681

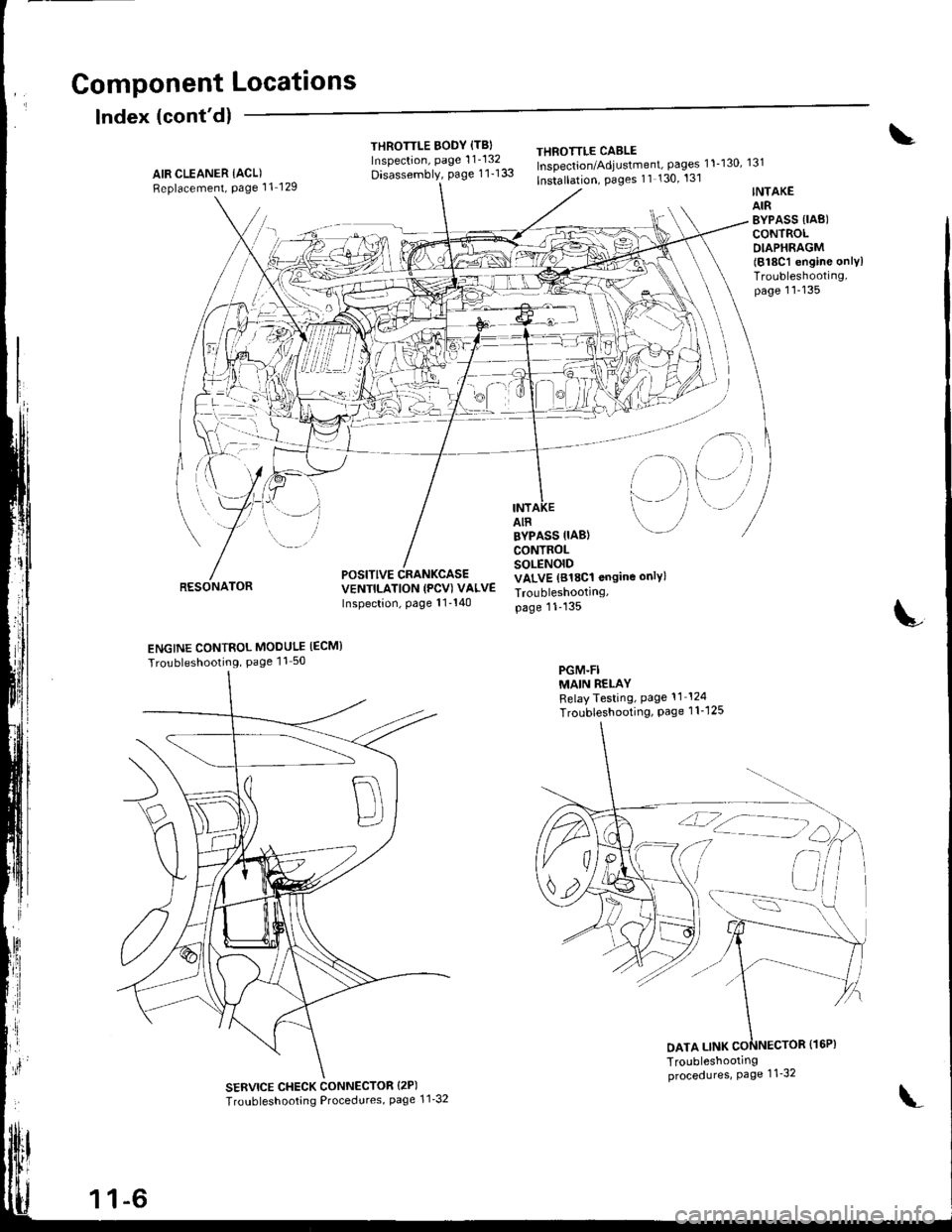

Gomponent Locations

Index (cont'dl

THROTTLE BODY {TBIInspection, page 1 1'132

Disassembly, page 1 1-133

THEOTTLE CABLEInspection/Adjustment, pages 11-130, 131

lnstallation, Pages 11 130' 131AIR CLEANER IACL)Replacement, Page 11 129

RESONATOR

INTAKEAIRBYPASS {IAB)CONTROLDIAPHRAGM(818C1 engine onlylTroubleshooting,page 11-135

i-)

i--- / /

i rl

l'-' i

INTAIR

POSITIVE CRANKCASEVENTILATION (PCV) VALVEInspection, page 11'140

BYPASS IIAB}CONTROLSOLENOIDVALVE (818C1 ongine only)

Troubleshootrng,page 11-135

PGM-FIMAIN RELAYRelayTesting, Page 11 124

Troubleshooting, Page 1 1-1 25

L

ENGINE CONTROL MODULE IECM}

Tro!bleshooting, Page 11 50

SERVICE CHECK CONNECTOR {2P)

Troubleshooting Procedures, page 1 1'32

DATA LINK

1 1-6

\'