check oil HONDA INTEGRA 1998 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1209 of 1681

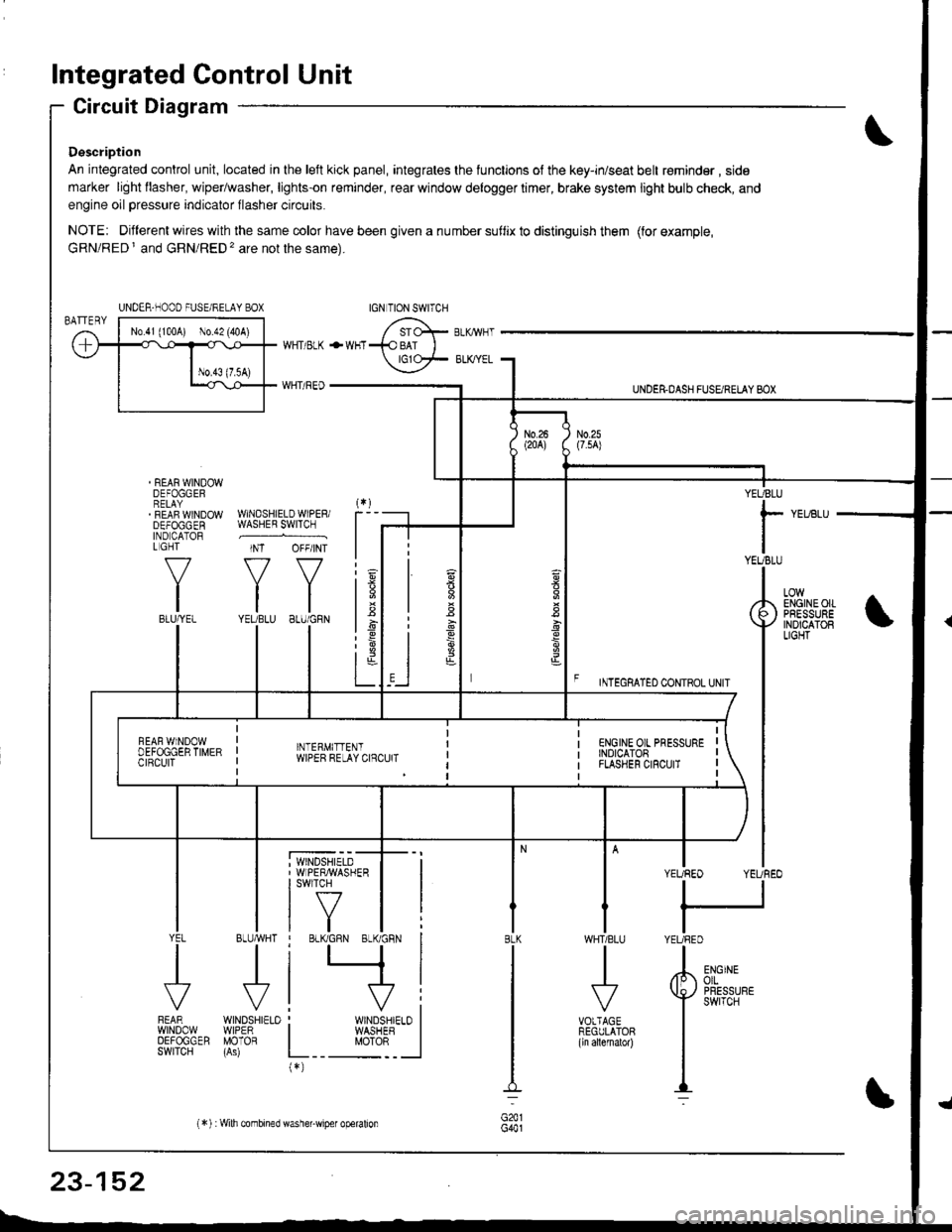

Integrated Control Unit

Circuit Diagram

Description

An integrated control unit, located in lhe left kick panel, integrates the lunctions of the key-in/seat belt r€minder , side

marker light llasher, wiper/washer, lights-on reminder, rear window delogger timer, brake system light bulb check, and

engine oil pressure indicator flasher circuits.

NOTE: Different wires with the same color have been given a nu mber suflix to distinguish them (for example,

GRN/RED I and GRN/RED'� are not the same).

REAR WINDOWDEFOGGERRELAYREAF WINDOWDEFOGGENIND CATORL GHT

f-7

IIBLU/YEL

WHT/ BLK

WHT/ REO

+WHT

WNDSHIELDWIPERiWASHER SWITCH

INT OFF/INT

f7 f7

tltlYEUBLU 8LU/GRN

BLUMHT

J

wtN0sHr€10WIPERMOTOR

UNDER.DASH FUSARETAY BOX

F rmecnlleo counoL ultr

YEUBLU

rYEUBLU

YEUREO YEUREO

tl

IYEURED

LOWENGINEOIIPRESSUREINOICATOBLIGHT

; WINDSHIELD' WIPERMASHERI swlTcH

tf7IVtlYEL

J

FEARwtN00wOEFOGGERSWITCH

WHTIBLU

J

VOTTAGEREGULATOR(ln allernatol)

BLK

G441

ENGINEolLPRESSUREswrTcH

UNDER-NOOO FUSE/RELAY BOX

1.6

:6

t;t-L

i

"'i'- 'i*-

|

I Il

I vi: WINDSHIELO II WASHEB I

L__ "oto: _ __l(*)

n

s

s

,]

23-152

(*) :Wilh combined washer-wiper operalion

Page 1213 of 1681

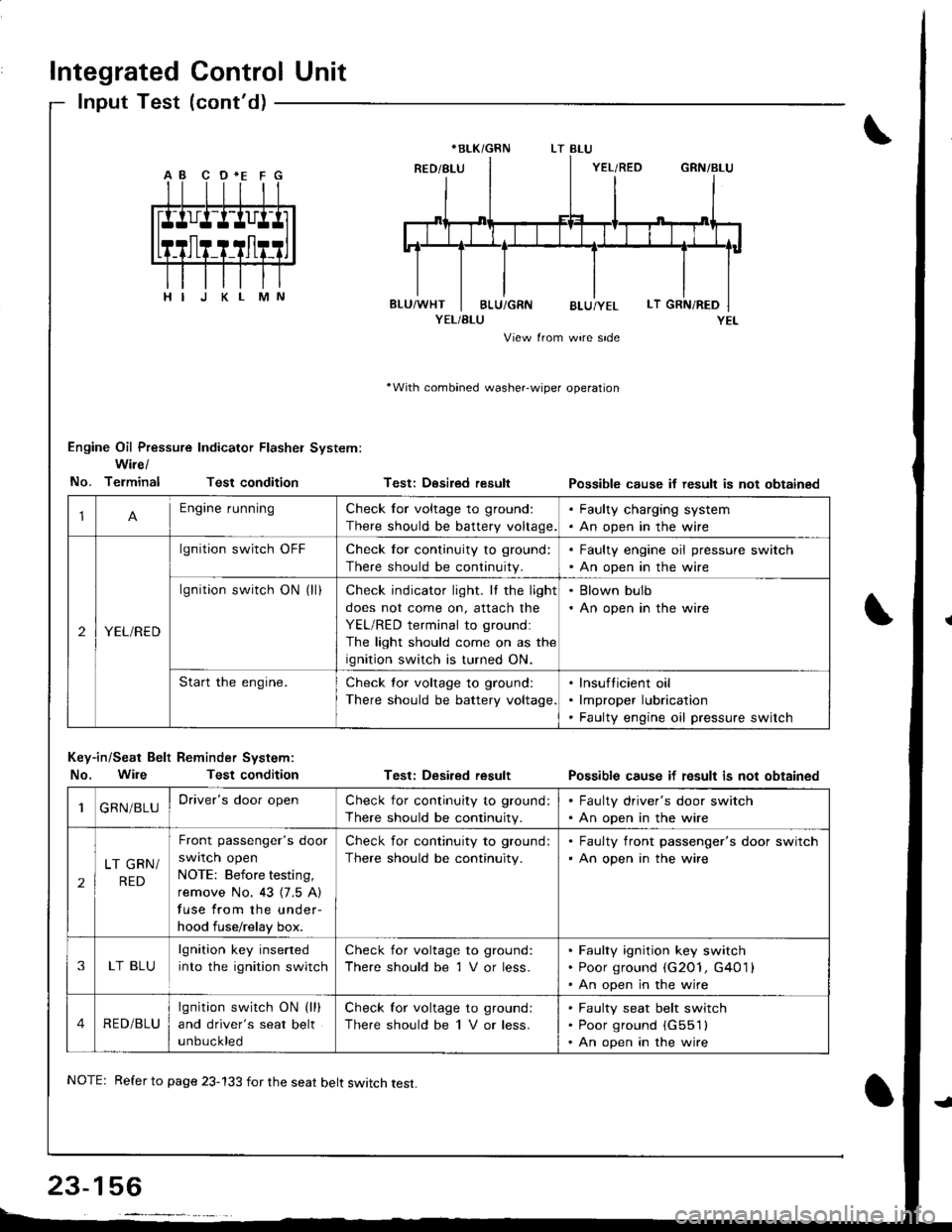

Integrated Control Unit

lnput Test (cont'd)

YEL/BLU

View from wire side

'With combined washer-wiper operation

Engine Oil Pressure Indicator Flasher System:

Wire/

No. TerminalTest condition

Key-in/Seat Belt Reminder System:

No. WileTest condition

Testi Desired result

Test: Desired result

Possible cause if result is not obtainsd

Possible cause if fesult is not obtained

*BLK/GRN

1Engine runningCheck for voltage to ground:

There should be battery voltage.

. Faulty charging system. An open in the wire

2YEL/RED

lgnition switch OFFCheck for continuity to ground:

There should be continuity.

. Faulty engine oil pressure switch. An open in the wire

lgnition switch ON (ll)Check indicator light. It the light

does not come on, attach the

YEL/RED terminal to groundl

The light should come on as the

ignition switch is turned ON.

. Blown bulb. An open in the wire

Start the engine.Check tor voltage to ground:

There should be battery voltage

lnsufticient oil

lmproper lubrication

Faulty engine oil pressure switch

1GRN/BLUDriver's door openCheck for continuity to ground:

There should be continuity.

. Faulty driver's door switch. An open in the wire

2

LT GRN/

RED

Front passenger's door

swrlcn open

NOTE: Before testing,

remove No. 43 {7.5 A)

fuse from the under-

hood fuse/relay box.

Check for continuity to ground:

There should be continuity.

. Faulty front passenger's door switch'An open in the wire

3LT BLU

lgnition key inserted

into the ignition switch

Check for voltage to ground:

There should be 1 V or less.

Faulty ignition key switch

Poor ground (G2O1, G401 l

An open in the wire

4RED/BLU

lgnition switch ON (lll

and driver's seat belt

unbuckled

Check for voltage to ground:

There should be 1 V or less.

Faulty seat belt switch

Poor ground (G551l

An open in the wire

NOTE: Refer to page 23-133 for the seat belt switch test.

Page 1245 of 1681

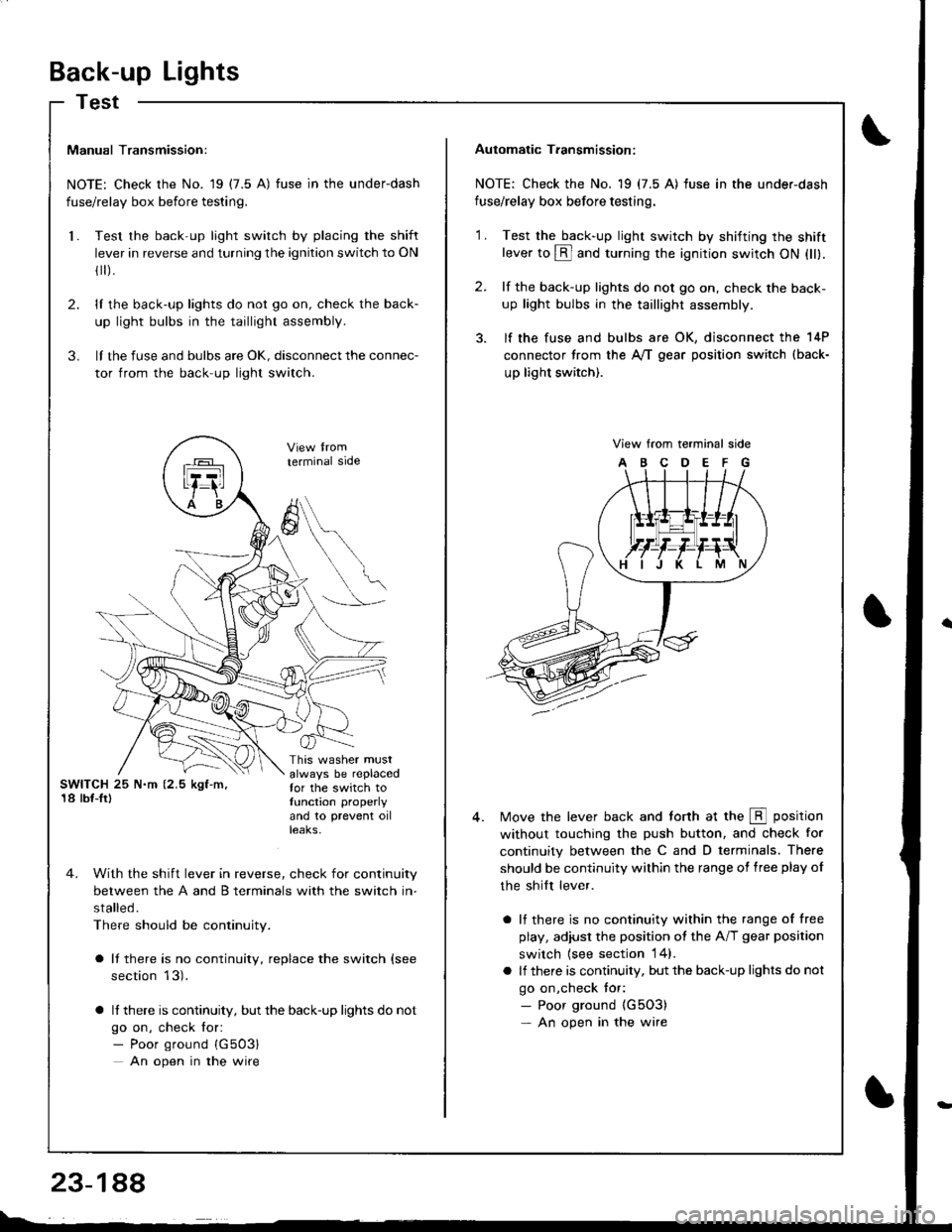

Back-up Lights

Test

Manual Transmission:

NOTE: Check the No. 19 (7.5 A) fuse in the underdash

fuse/relay box before testing.

Test the back-up light switch by placing the shift

lever in reverse and turning the ignition switch to ON

fl r).

lI the back-up lights do not go on, check the back-

up light bulbs in the taillight assembly.

lI the fuse and bulbs are oK, disconnect the connec-

tor from the back-up light switch.

2.

3.

l.

SWITCH 25 N.m (2.5 kgf-m,'18 lbf-Ir)

This washer mustalways be replacedfor the switch totunction properly

and 10 prevent oilteaKs,

terminal side

4. With the shift lever in reverse, check for continuity

between the A and B terminals with the switch in-

stalled.

There should be continuity.

a It there is no continuity, replace the switch (see

section 13).

a lf there is continuity, but the back-up lights do not

go on, check for:- Poor ground {G503}

An open in the wire

A

6

Automatic T.ansmission:

NOTE: Check the No. 19 (7.5 A) fuse in the under-dash

fuse/relay box before testing.

2.

'1 .Test the back-up light swirch by shifting the shiftlever to @ and turning the ignition switch ON (ll).

lf the back-up lights do not go on, check the back-

up light bulbs in the taillight assembly.

lf the fuse and bulbs are OK, disconnect the 14P

connector from the A,/T gear position switch (back-

up light switch).

View from terminal side

ABCDEFG

Move the lever back and torth at the E position

without touching the push button, and check for

continuity between the C and D terminals. There

should be continuity within the range of free play of

the shilt lever.

a lf there is no continuity within the range of free

play, adiusl the position ot the A/T gear position

switch {see section 14}.

a lf there is continuity, but the back-up lights do not

go on,check tor:- Poor ground {G5O3)- An open in the wire

Page 1247 of 1681

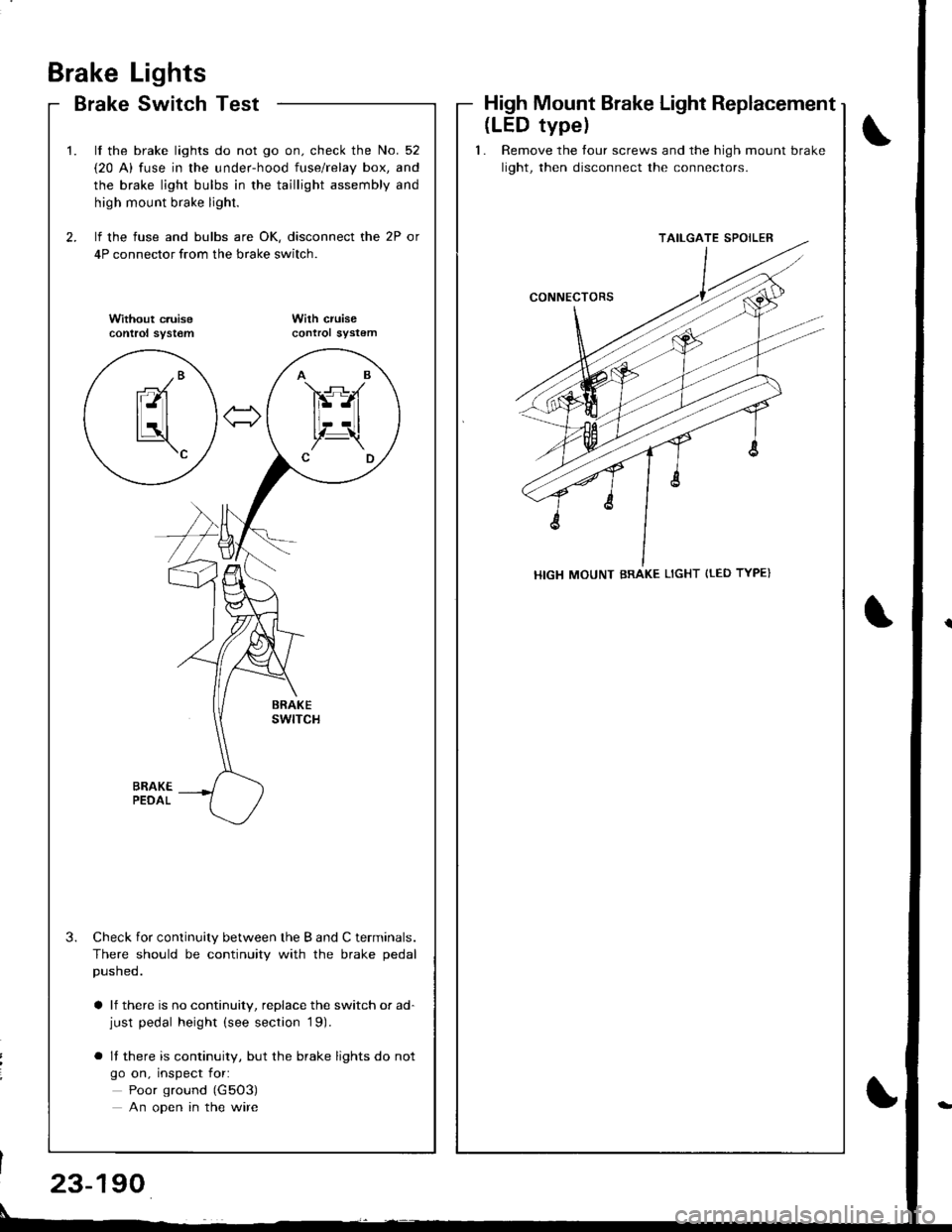

Brake

Brake

Lights

Switch TestHigh Mount Brake Light Replacement

\

t

2.

t.

3.

lf the brake lights do not go on. check the No. 52

{20 A) fuse in the under-hood fuse/relay box, and

the brake light bulbs in the taillight assembly and

high mount brake light.

lf the fuse and bulbs are OK, disconnect the 2P or

4P connector from the brake switch.

Without c.uisecontrol syst€mWilh cruisecontrol sYstem

Check for continuity between the B and C terminals.

There should be continuity with the brake pedal

pusneo.

a lf there is no continuity, replace the switch or ad-just pedal height (see section '19).

o It there is continuity, but the brake lights do not

go on, inspect for:

Poor ground (G5O3)

An open in the wire

AB

FS-A

lt--Ltl, t!,Z-\CD

-/Branl-ltl

tLatl\c

(LED typel

1. Remove the tour screws and the high mount brake

light, then disconnect the connectors.

TAILGATE SPOILER

HIGH MOUNT BRAKE LIGHT {tED TYPE}

23-190

Page 1335 of 1681

)

Precautions/Procedures

General Precautions

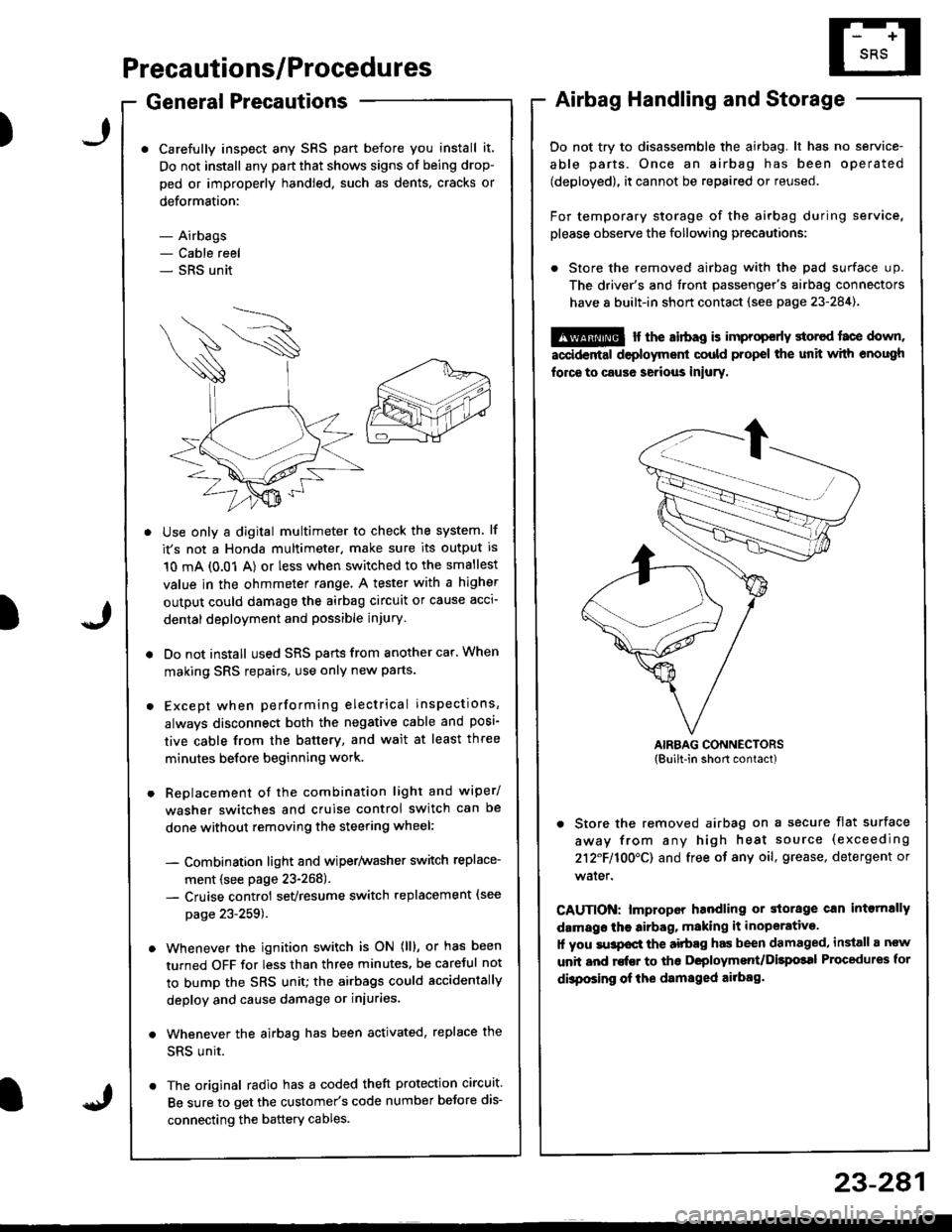

Carefully inspect any SRS part before you install it,

Do not install any part that shows signs of being drop-

ped or improperly handled. such as dents, cracks or

deformstion:

- Airbags- Cable reel- SRS unit

' Use only a digital multimeter to check the system lf

it's not a Honda multimeter. make sure its output is

10 mA (0.01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury.

r Do not install used SRS parts from anothercar.When

making SRS repairs, use only new parts.

r Except when performing electrical inspections,

always disconnect both the negative cable and posl-

tive cable from the batterY, and wait at least three

minutes before beginning work.

r Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combination light and wiperlwasher switch replace-

ment (see page 23-268).- Cruise controi sevresume switch replacement (see

page 23-259t�.

. Whenever the ignition switch is ON (ll), or has been

turned OFF for less than three minutes, be caretul not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or iniuries.

. Whenever the airbag has been activated, replace the

SRS unit.

. The original radio has a coded theft protection circuit.

Be sure to get the customer's code number beJore dis-

connecting the battery cables.

23-281

Airbag Handling and Storage

Do not try to disassemble the airbag. lt has no service-

able parts. Once an airbag has been operated

(deployed), it cannot be repaired or reused.

For temporary storage of the airbag during service,

please observe the following precautions:

. Store the removed airbag with the pad surface up.

The driver's and tront passenger's airbag connectors

have 8 built-in short contact (see page 23-284).

@ r the airbag is improp€rly storcd face down,

accidental deployment could propel the unit with enough

force to caus6 serious iniury.

AIRBAG CONNECTORS(Built-in short contact)

. Store the removed airbag on a secure flat surface

away from any high heat source (exceeding

212F110O'CI and free of any oil, grease, detergent or

water.

CAUTION: lmproper handling or storage can intornally

damags the airbag, making it inoperative.

1l you su3pocl the aitbag has been damaged, install a ncw

unit and rofEr to ths Deployment/Dilpolal Procedures for

dbposing of ihe damsged ailbag.

)

Page 1464 of 1681

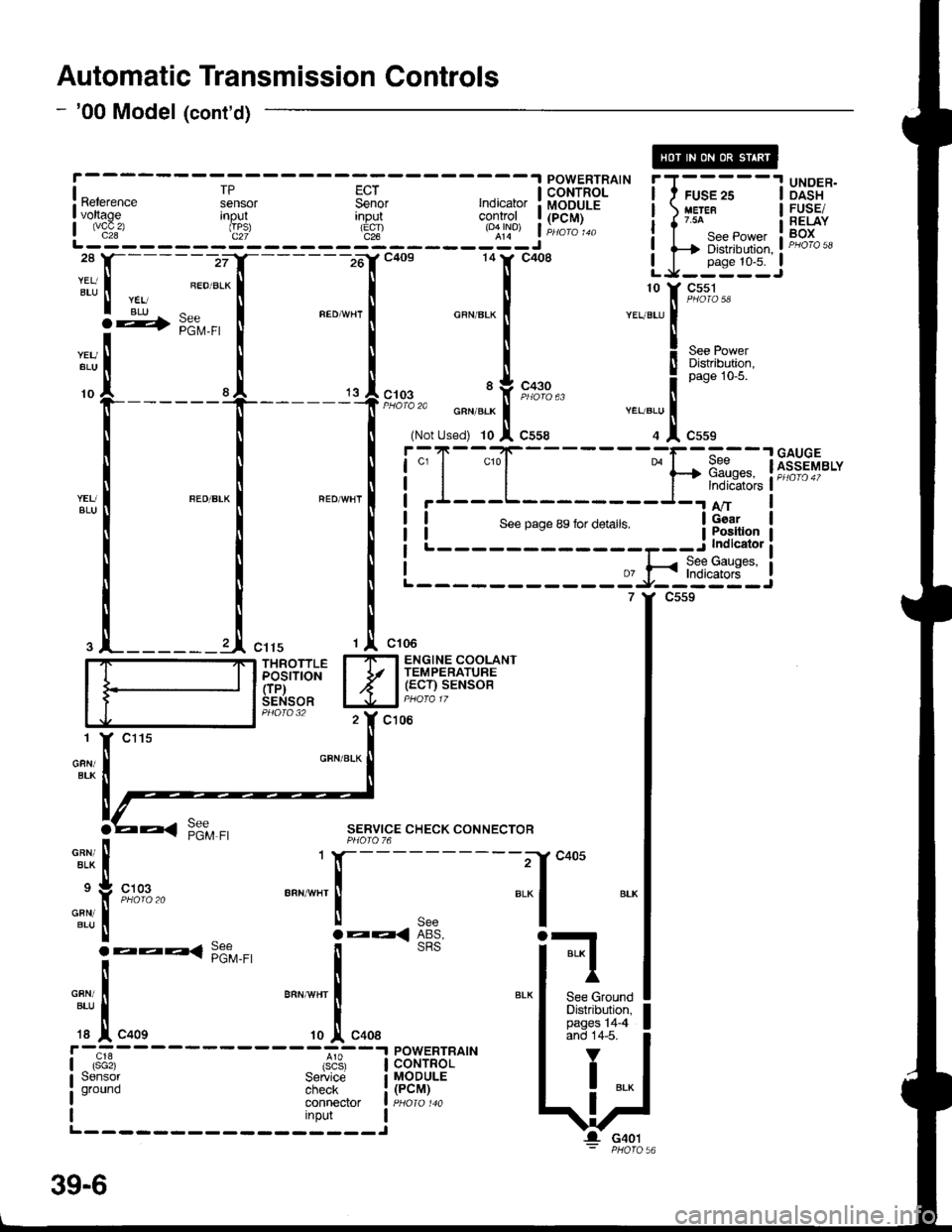

Automatic Transmission Controls

- '00 Model (cont'd)

[---;""'.f

-lc+os 141' c4o8 LJ-:*:IJ

|

:t

, ;:".1

*"",",1 "**-

I

-.11,[t*r'""

I .l ,.,1,","" .J,o*". i

r*ru;l

i.";-

- - -

Is"*

- - - - -

Fsil

- - -

;; I i.l{T'Fil^'- i I ;;

- -

I Ui3"*I voltage Inout

L js!'- - - - - - d": - - - - - 3t - - - - - roql j Hili:

i i-Ti*.*,*,, i F"H*i,'ll-------zrI_------16'rc4os 14tr' c408 LJ_j*::J

:tt, I ".ou.*l I I

r rii ^ r "."-,. r ^""",. r ". ::[ 9#3-

**[

[ [ X"., !r*g+;l"f-----

t

't

l;:,.il*[;,;

""T1",,,""

! ! !i;T-"{_

___-}.[1dnw'"t*il *"*-l "'o*n'l i'I---L-

I I NLi::--::::-:=a-*$$ti

.l_______l ",,, ,l ",,.

'r "*'

I_ITI ENGINE COOLANT

iddirioil I Jr l,.g:tilu;SENSOR lJJal PHora 17

c106

GFN/BLK

SERVICE CHECK CONNECTORPHOIO 76

-"^,:,[

.:

"{

'T[_:'*' "..1

;*liil, lFffi*'" I

c405

BLI

BLK I

I'

See GroundDistribution,pages 14-4and 14-5.

V

I ..

G401

39-6

Page 1641 of 1681

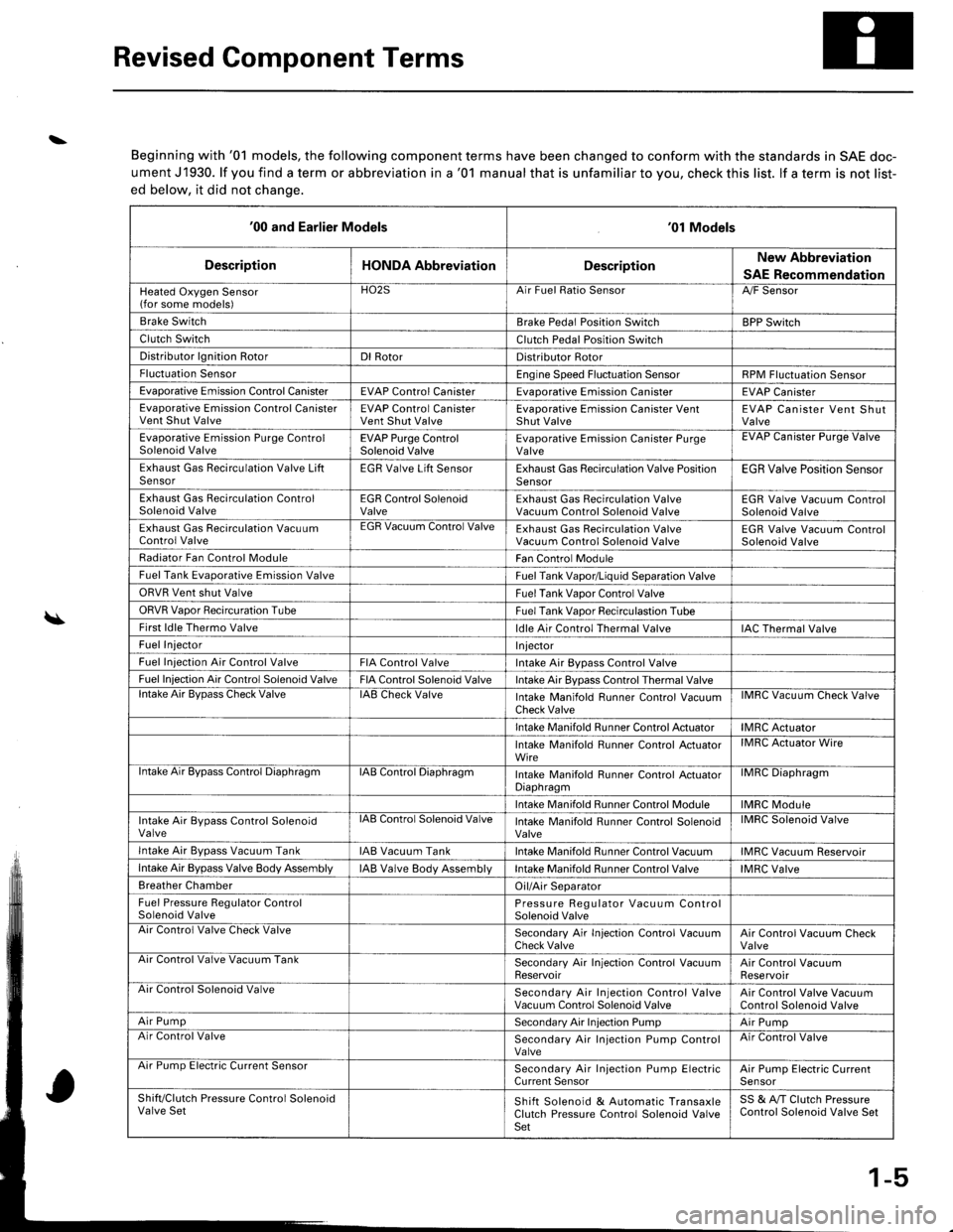

Revised Component Terms

\

\

Beginning with '01 models, the following component terms have been changed to conform with the standards in SAE doc-

ument J1930. lf you find a term or abbreviation in a '01 manual that is unfamiliar to you, check this list. lf a term is not list-

ed below, it did not chanqe.

'00 and Earlier Models'01 Models

DescriptionHONDA AbbreviationDescriptionNew Abbreviation

SAE Recommendation

Heated Oxygen Sensor(for some models)HO2SArr ruet llalto )ensorA,/F Sensor

Brake SwitchBrake Pedal Position SwitchBPP Switch

Clutch SwitchClutch Pedal Position Switch

Distributor lgnition RotorDl RotorDistributor Rotor

Fluctuation SensorEngine Speed Fluctuation SensorRPM Fluctuation Sensor

Evaporative Emission Control CanisterEVAP Control CanisterEvaDorative Emission CanisterEVAP Canister

Evaporative Emission Control CanisterVent Shut ValveEVAP Control CanisterVent Shut ValveEvaporative Emission Canister VentShut ValveEVAP Canister Vent ShutValve

Evaporative Emission Purge ControlSolenoid ValveEVAP Purge ControlSolenoid ValveEvaporative Emission Canister PurgeValveEVAP Uanister Purge Valve

Exhaust Gas Recirculation Valve LiftSensorEGR Valve Lift SensorExhaust Gas Recirculation Valve PositionSensorEGR Valve Position Sensor

Exhaust Gas Recirculation ControlSolenoid ValveEGR Control SolenoidValveExhaust Gas Recirculation ValveVacuum Control Solenoid ValveEGR Valve Vacuum ControlSolenoid Valve

Exhaust Gas Recirculation VacuumControl ValveEGR Vacuum Control ValveExhaust Gas Recirculation ValveVacuum Control Solenoid ValveEGR Valve Vacuum ControlSolenoid Valve

Radiator Fan Control ModuleFan Control Module

Fuel Tank Evaporative Emission ValveFuel Tank Vapor/Liquid Separation Valve

ORVR Vent shut ValveFuel Tank Vaoor Control Valve

ORVR Vaoor Recircuration TubeFuel Tank Vaoor Recirculastion Tube

First ldle Thermo Valveldle Air Control Thermal ValveIAC Thermal Valve

Fuel InjectorI njector

Fuel Iniection Air Control ValveFIA Control ValveIntake Air Bypass Control Valve

Fuel Injection Air Control Solenoid ValveFIA Control Solenoid ValveIntake Air Bypass Control Thermal Valvelntake Air BvDass Check ValveIAB Check ValveIntake Manifold Runner Control VacuumCheck ValveIMRC Vacuum Check Valve

Intake Manifold Runner Control ActuatorIMRC Actuator

Intake Manifold Runner Control ActuatorWireIMRC Actuator Wire

ntake Air Bypass Control DiaphragmIAB Control DiaphragmIntake Manifold Runner control ActuatorDiaphragmilvrr1u urapnragm

Intake Manifold Runner Control ModuleIMRC Module

Intake Air Bypass Control SolenoidValvelAts Control Solenoid ValveIntake Manifold Runner Control SolenoidValveIMRC Solenoid Valve

Intake Air Bvpass Vacuum TankIAB Vacuum TankIntake Manifold Runner Control VacuumIMRC Vacuum Reservoir

Intake Air Bypass Valve Body AssemblyIAB Valve Body AssemblVIntake Manifold Runner Control ValveIMRC Valve

Breather ChamberOil/Air Separator

Fuel Pressure Regulator ControlSolenoid ValvePressure Regulator Vacuum ControlSolenoid ValveAir Control Valve Check ValveSecondary Air In.jection Control VacuumCheck ValveAir Control Vacuum CheckValveArr Control Valve Vacuum TankSecondary Air Injection Control VacuumReservoirAir Control VacuumReservoirAir Control Solenoid ValveSecondary Air Injection Control ValveVacuum Control Solenoid ValveAir Control Valve VacuumControl Solenoid Valve

Air PumpSecondary Air Injection PumpAir PumpAir Control ValveSecondary Air Injection Pump ControlValveAir Control Valve

Arr rump tsreclnc uurrent bensorSecondary Air Injection Pump ElectricCurrent SensorAir Pump Electric CurrenlSensor

Shift/Clutch Pressure Control SolenoidValve SetShift Solenoid & Automatic TransaxleClutch Pressure Control Solenoid ValveSet

SS & A,/T Clutch PressureControl Solenoid Valve Set

1-5

Page 1654 of 1681

MFASIIREMENTSTANDARD (NEW}

Wire Dia.o.D.Free LengthNo. of Goils

SpringsRegulator valve spring ARegulator valve spring BStator reaction sPringModulator valve springTorque converter check valve springCooler relief valve springRelief valve spring2nd orifice control valve spring1-2 shift valve spring2-3 shift valve spring3-4 shift valve spring1st accumulator spring4th accumulator spring B4th accumulator spring A2nd accumulator spring A3rd accumulator spring A2nd accumulator spring B3rd accumulator spring B3rd sub accumulator spring2nd accumulator spring CLock-up shift valve springLock-up timing valve springLock-up control valve spring3-4 orifice control valve springServo control valve springCPB valve spring4th exhaust valve spring

1.8 (0.071)

1.8 (0.071)

4.5 rc.177].1.4 (0.05s)

1.2 10.047l.1.0 (0.039)

1.1 (0.043)

0.7 (0.0281

0.9 (0.035)

0.9 (0.035)

0.9 (0.035)

2.1 (0.083)

2.3 (0.091)

2.6 (0.102)

2.4 (0.094)

2.8 (0.110)

1.6 (0.063)

2.1 (0.083)

2.7 (0.106)

2.2 l0.o87l0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

0.6 (0.024)

1.0 (0.039)

0.9 (0.0351

0.9 (0.035)

14.7 (0.5791

9.6 (0.378)

35.4 (1 .394)9.4 (0.370)

8.4 (0.331)

8.4 (0.331)

8.6 (0.339)

6.6 (0.260)

7.6 (0.299)

7.6 (0.299)

7.6 (0.299)

16.0 (0.630)

10.2 rc.402117.0 (0.669)

29.0 11.142117.5 (0.689)

9.0 (0.354)

31.0 (1 .220)17.0 (0.669)

14.5 (0.571)

7.6 (0.299)

8.1 (0.319)

6.6 (0.260)

6.6 (0.260)

8.1 (0.319)

8.1 (0.319)

6.1 (0.240)

87.8 (3.457)

44.0 (1.732\

30.3 (1.193)

35.0 (1.378)

32.4 (1.2761.

33.8 (1.331)

37.1 (1.461)

34.8 (1.370)

41.3 (1.626)

57.0 12.244157.0 12.244].89.1 (3.508)

s1.6 (2.0311

88.4 (3.480)

39.0 (1 .53s)94.3 (3.713)

20.7 (0.815)

38.2 (1.504)

39.0 (1.535)

68.0 (2.677)

73.7 (2.9021

81.4 (3.205)

38.0 (1.496)

37.9 (1.492)

52.1 (2.0511

47.2 (1 .858)36.4 (1.433)

16.51 1.01.910.912.78.213.422.01A ?

26.826.8't6.2

13.814.2z.J15.9o. l2.66.313.932.O47.814.1?1 A

20.8ttJ.JI v.5

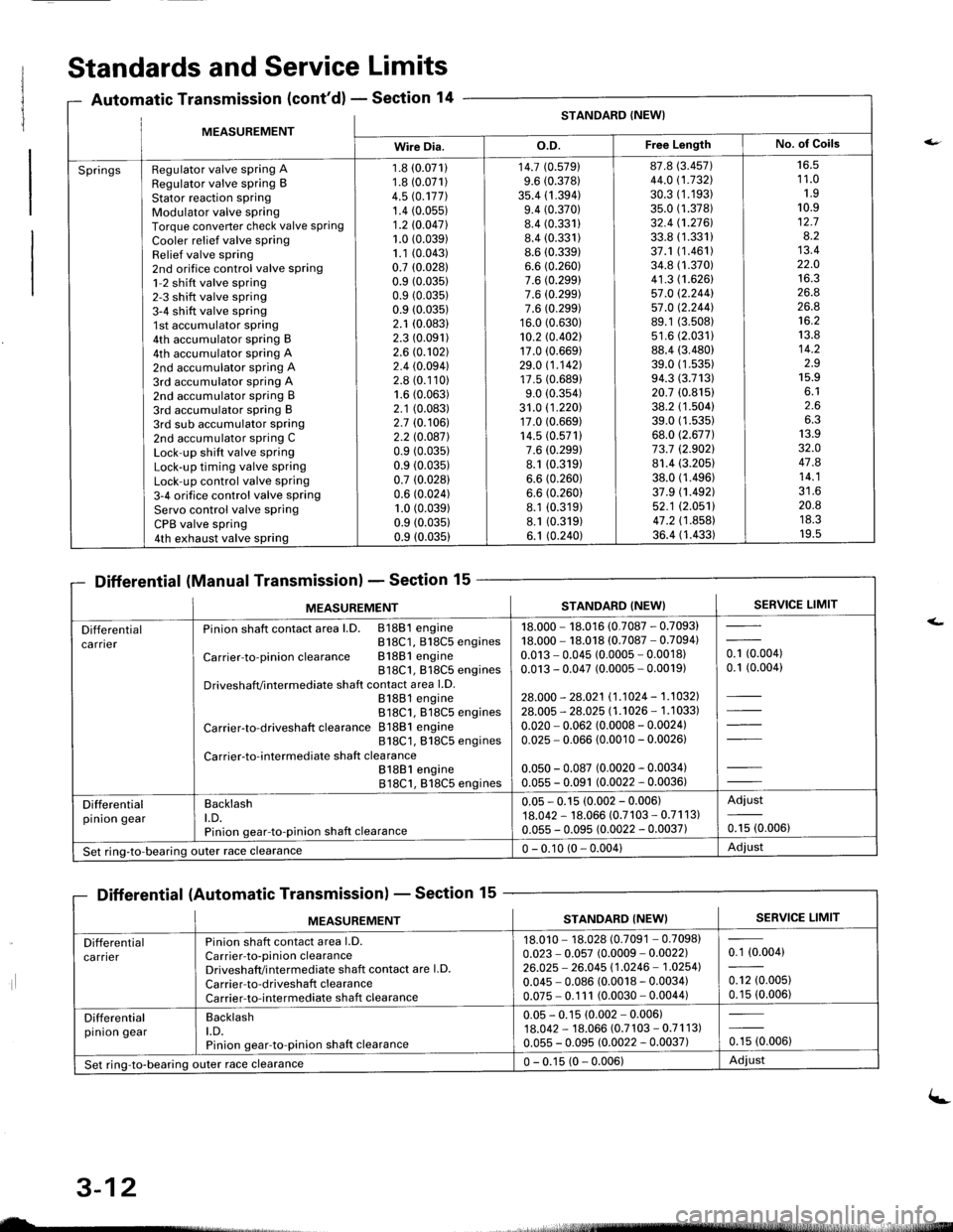

Standards and Service Limits

Automatic Transmission (cont'd) - Section 14

Differential (Manual Transmission) - Section 15

Differential (Automatic Transmission) - Section 15

ilt5stlrrr, - 4,

MEASUREMENTSTANDARD (NEW}SERVICE LIMIT

Differentialca rnerPinion shaft contact area l.D. 81881 engineB18C1, 818C5 engines

Carrier-to-pinionclearance Bl88lengine818C1, 818C5 enginesDriveshafVintermediate shaft contact area l.D.81881 engine818C1. 818C5 engines

Carrier-to-driveshaft clearance 81881 engine818C1, 818C5 engines

Carrier-to-intermediate shaft clea rance81881 engine818C1, 818C5 engines

18.000 - 18.016 (0.7087 - 0.7093)18.000 - 18.018 (0.7087 - 0.7094)0.013 - 0.045 (0.0005 - 0.0018)0.013 - 0.047 (0.0005 - 0.0019)

28.000 - 28.021 11.1024 - 1.1032].28.005 - 28.025 l1 .'�t026 - 1 .1 033)

0.020 - 0.062 (0.0008 - 0.0024)0.025 - 0.066 (0.0010 - 0.00261

0.050 - 0.087 (0.0020 - 0.0034)0.055 - 0.091 (0.0022 - 0.0036)

- toooot0.1 (0.004)

Differentialpinion gearBacklasht.D.Pinion gear-to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.042 - 18.066 (0.7103 - 0.71 1 3)0.055 - 0.095 (0.0022 - 0.0037)

Adjust

0.15 (0.006)

Set ring-to-bearing)uter race clearance0 - 0.10 (0 - 0.004)Adjust

nsmlssaonl - Sectton

MEASUREMENTSERVICE LIMITSTANDARD (NEW}

Differentialca rrierPinion shaft contact area l.D.Carrier-to-pinion clearanceDriveshaft/i ntermediate shaft contact are l.D.

Carrier-to-driveshaft clearanceCarrier-to-intermediate shaft clearance

18.010 - 18.028 (0.7091 - 0.7098)0.023 - 0.057 (0.0009 - 0.0022)26.025 - 26.045 11.0246 - 1.02541

0.045 - 0.086 (0.0018 - 0.0034)0.075 - 0.1 11 (0.0030 - 0.0044)

0.1 (0.004)

0.12 (0.005)

0.15 (0.006)

Differentialpinion gearBacklasht.D.Pinion gear-to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.042 - 18.066 (0.7 103 - 0.71 1 3)0.055 - 0.095 (0.0022 - 0.0037)0.15 (0.006)

Set ring-to-bearing outer race clearance0 - 0.15 (0 - 0.006)Adiust

uL-

3-12

(-