check oil HONDA INTEGRA 1998 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1057 of 1681

I

I

ChargingLeak Test

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrig6rant and

lubricant vapol or mist can irritate eyes. nose and

throat. Avoid broating the air conditione. relrigerant

and lubricant vapor o; mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

@ some mixtures of air and R-1348 have

been shown to be combustible at €levat€d pre3sures

and can rosult in fire or explosion causing iniury or

property damage. Never use compressed air to pressure

test R-134a s€rvics oquipment or vehicle air conditioner

Systems.

Additional health and safety information may be

obtained from the refrigerant and lubricant manufac-

rures.

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown in the pre-

vious column, following the equipment manufactur-

er's instructions.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the A/C system before

charging.

Open high pressure valve to charge the system to

the specified capacity, then close the supply valve,

and remove the charging system couplers.

R€frigerani capacity: 700 1o g 124.7 llroz)

Check the system for leaks using a R-134a refriger-

ant leak detector with an accuracy of 14 g (0.5 oz)

per year or better.

lf you find leaks that require the system to be

opened (to repair or replace houses. fittings, etc.),

recover the system according to the Recover

Procedure on page 22-22.

After checking and repairing leaks, the system must

be evacuated (see System Evacuation on page 22-

38).

JUse only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner r€frigsrant and

lubricant vapol or mist can irritate eyos, nose and

throat. Avoid broathing the air conditioner reftigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service. Additional health and

safety information may be obtained from the refrigerant

and lubricant manufactures.

Retrigerant capscity: 700 % g (2,[.7 i.sozl

CAUTION: Do nol overcharge tho sy3tem; the compres-

sor will b6 damaged.

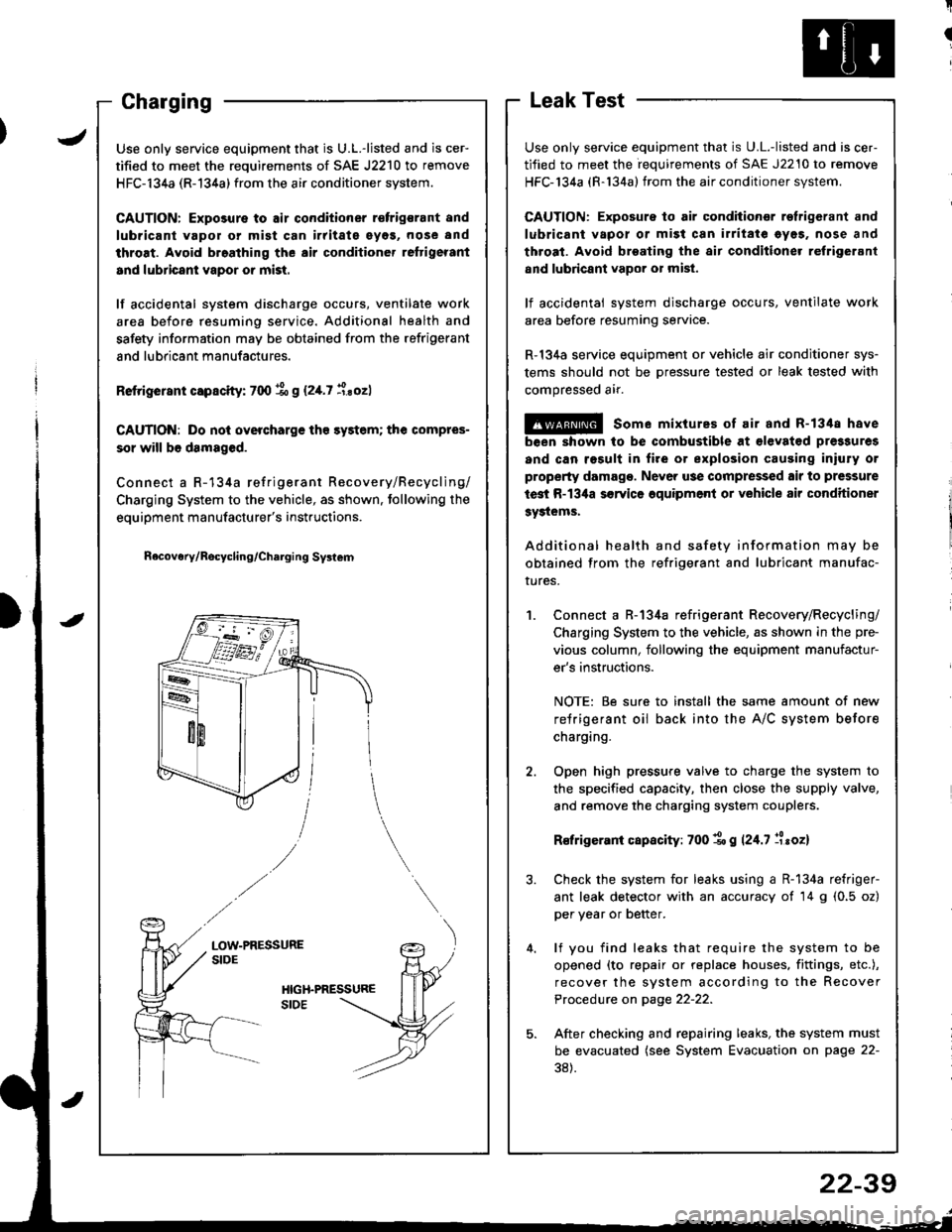

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown. tollowing the

equipment manufacturer's instructions.

n6covery/Rocycling/Charging Svslem

LOW-PRESSURESIDE

22-39

Page 1136 of 1681

![HONDA INTEGRA 1998 4.G Repair Manual 1.Remove the dashboard lower cover and knee bolster(see page 23-71],, then disconnect the 2P connector

from the switch.

Check for continuity between the terminals accord-

ing to the table.

2.

3.ll nec HONDA INTEGRA 1998 4.G Repair Manual 1.Remove the dashboard lower cover and knee bolster(see page 23-71],, then disconnect the 2P connector

from the switch.

Check for continuity between the terminals accord-

ing to the table.

2.

3.ll nec](/img/13/6069/w960_6069-1135.png)

1.Remove the dashboard lower cover and knee bolster(see page 23-71],, then disconnect the 2P connector

from the switch.

Check for continuity between the terminals accord-

ing to the table.

2.

3.ll necessary, replace the switch or adiustthe switch

position (see section 12).

Terminal

cr,t"hP;i

-_\B

RELEASED

PUSHEDoo

Clutch lnterlock Switch TestStarter Solenoid Test

1. Check for continuity between the terminals accord-

ing to the table.

HOLD_ IN COIL

23-79

I

/

-

I

-a

Coil

Teminalt\4sHousing

HOLD INO-o

PULL-INo-o

PULL_ IN COIL

Page 1141 of 1681

Starting System

Armature Inspection and Test (cont'd)

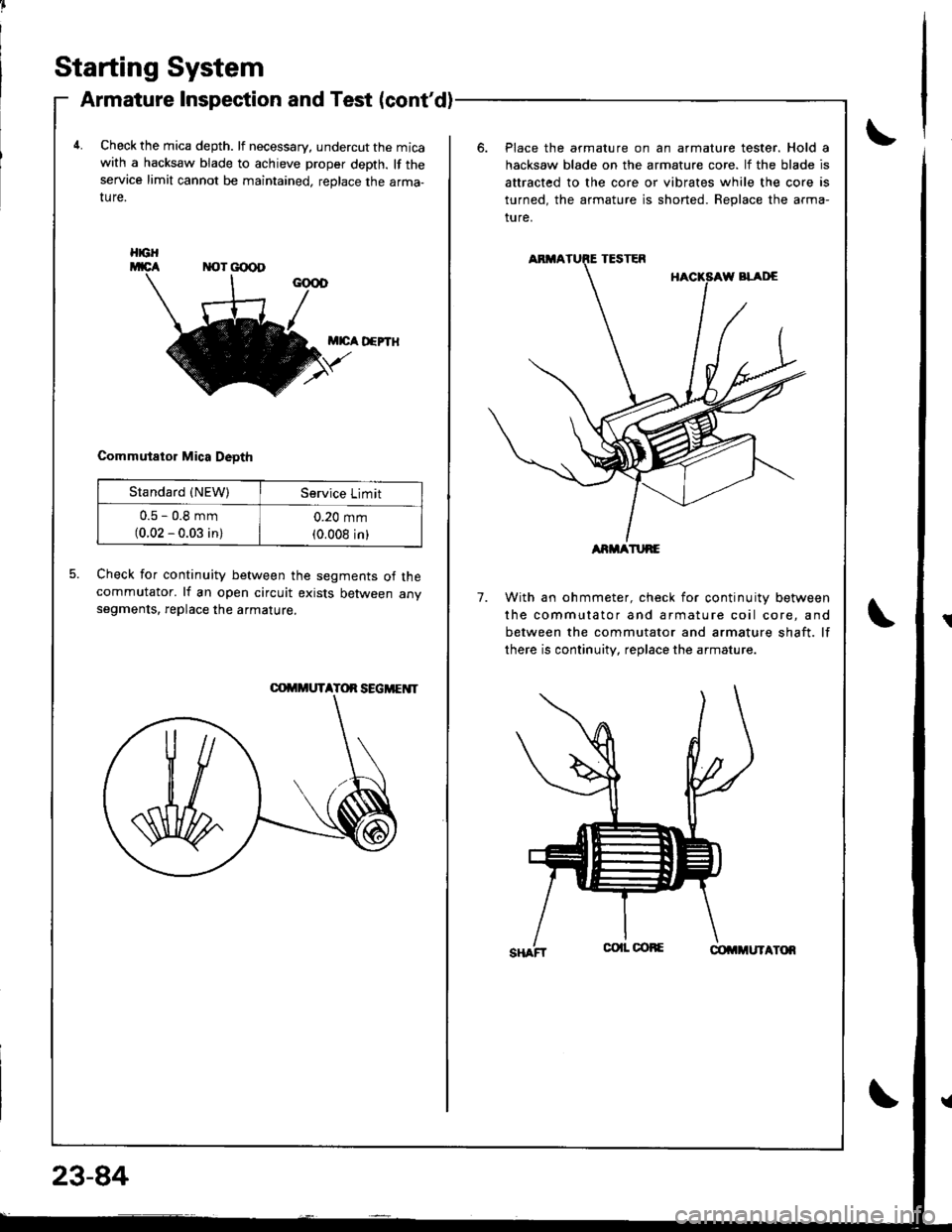

4.Check the mica depth. lf necessary, undercut the micawith a hacksaw blade to achieve proper depth. lf theservice limit cannot be maintained, replace the arma-ture.

Place the armature on an armature tester. Hold a

hacksaw blade on the armature core. lf the blade is

attracted to the core or vibrates while the core is

turned, the armature is shorted. Beplace the arma-

ture.

M|cA D€PTH

Commutator Mica Deoth

5.Check for continuity between the segments of thecommutator. lf an open circuit exists between anvsegments, replace the armature.7.With an ohmmeter, check for continuity between

the commutator and armature coil core, and

between the commutator and armature shaft. lf

there is continuity, replace the armature.

HGH

Standard {NEW)Service Limit

u.5 - u,6 mm(0.02 - 0.03 in)

0.20 mm(0.008 inlARMATURE

Page 1144 of 1681

J

Starting System

Performance Test

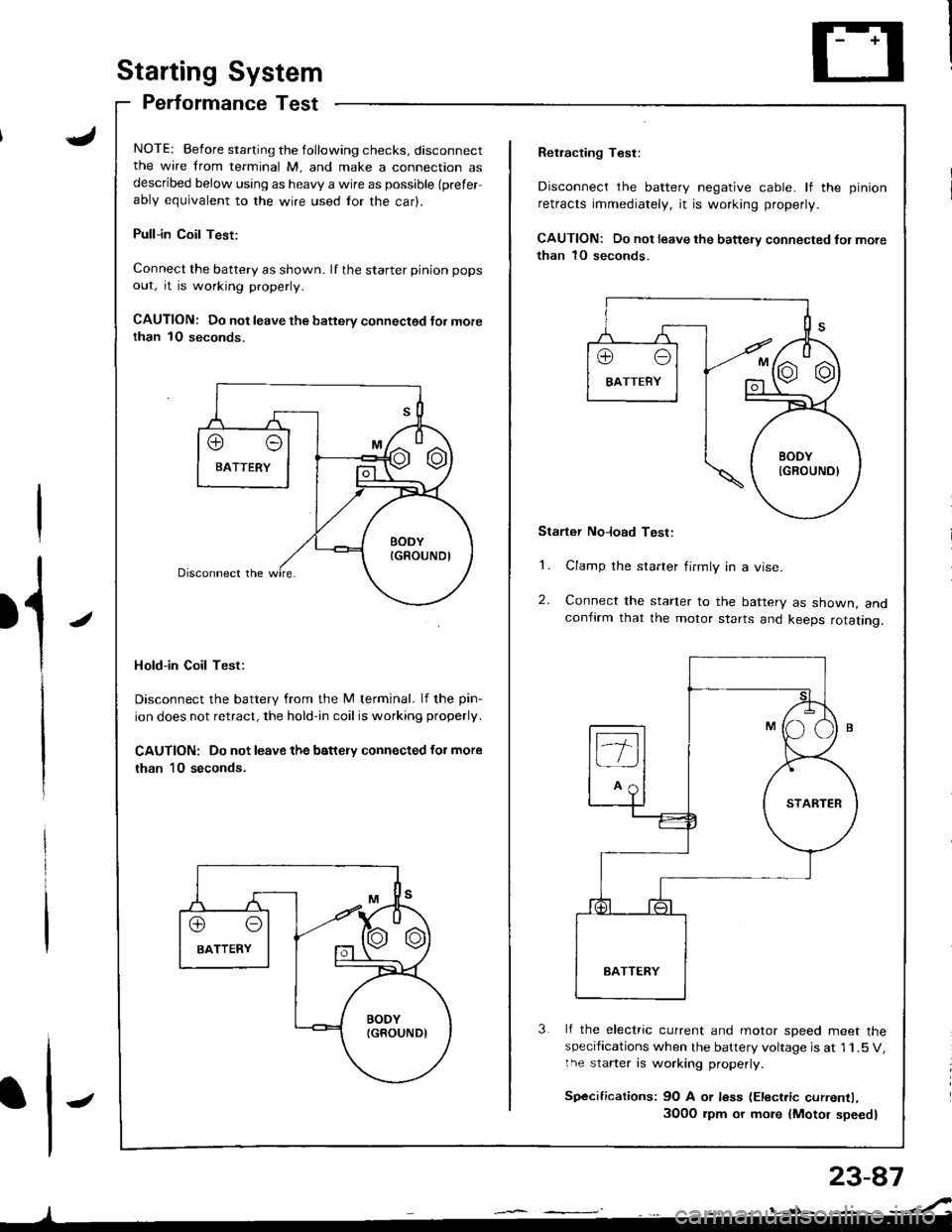

NOTE: Before starting the following checks, disconnectthe wire from terminal M, and make a connection asdescribed below using as heavy a wire as possible (prefer

ably equivalent to the wire used for the car).

Pull-in Coil Test:

Connect the battery as shown. If the starter pinion pops

out, it is working properly.

CAUTION: Do not leave the battery connectsd Jor morethan 1O seconds.

Hold-in Coil Test:

Disconnect the battery from the M terminal. lf the pin-

ion does not retract, the hold-in coil is working properly.

CAUTION: Do not leave the battery connected for more

than 10 seconds.

J

Retracting Test:

Disconnect the battery negative cable. lf the pinion

retracts immediately, it is working properly.

CAUTION: Do not leave the battery connected fol more

than 1O seconds.

Starter No]oad Test:

1. Clamp the starter firmly in a vise.

2. Connect the starter to the battery as shown, andconfirm that the motor starts and keeps rotating.

3 lf the electric current and motor soeed meet thespecifications when the battery voltage is at 1 1.5 V,the starter is working properly.

Sp€cifications: 9O A or less (Electric currentl,

3O0O rpm or more {Motor speed}

Page 1145 of 1681

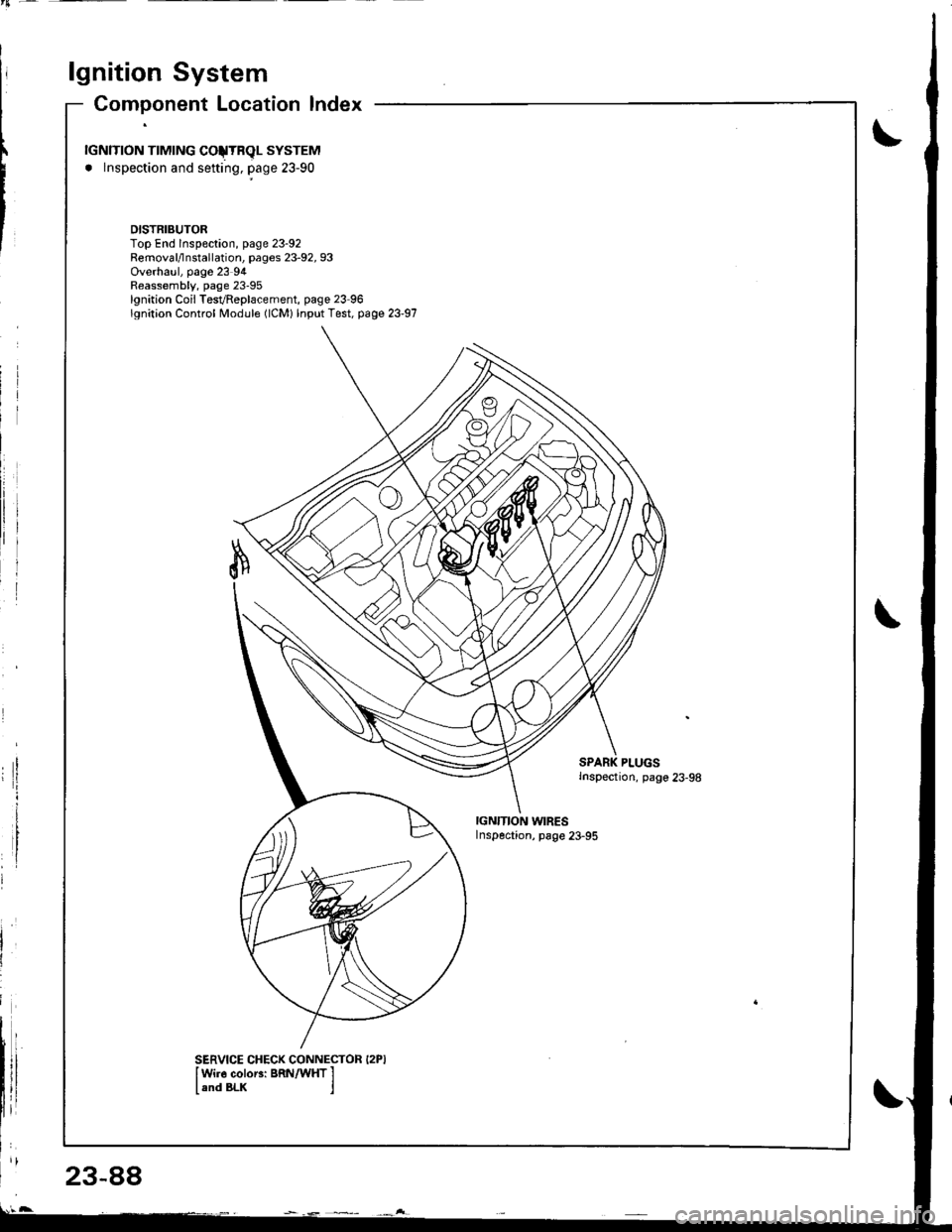

lgnition System

23-88

Component Location lndex

rGNlTroN TTMTNG COJTRqL SYSTEM

. lnspection and sefting, page 23-90

DISTRIBUTORTop End lnspeclion, page 23-92Removal/lnstallation, pages 23-92, 93Overhaul, page 23 94Reassembly, page 23-95lgnition Coil TesvReplacement, page 23 96lgnition Control Module (lCM) lnput Test, page 23-97

PLUGSInspection, pago 23-98

IGN'TION WIRESInspection, page 23-95

SERVICE CHECK CONNECTOR I2PIIWi]6 coloEi BRN/WHT I

land BLK j

Page 1154 of 1681

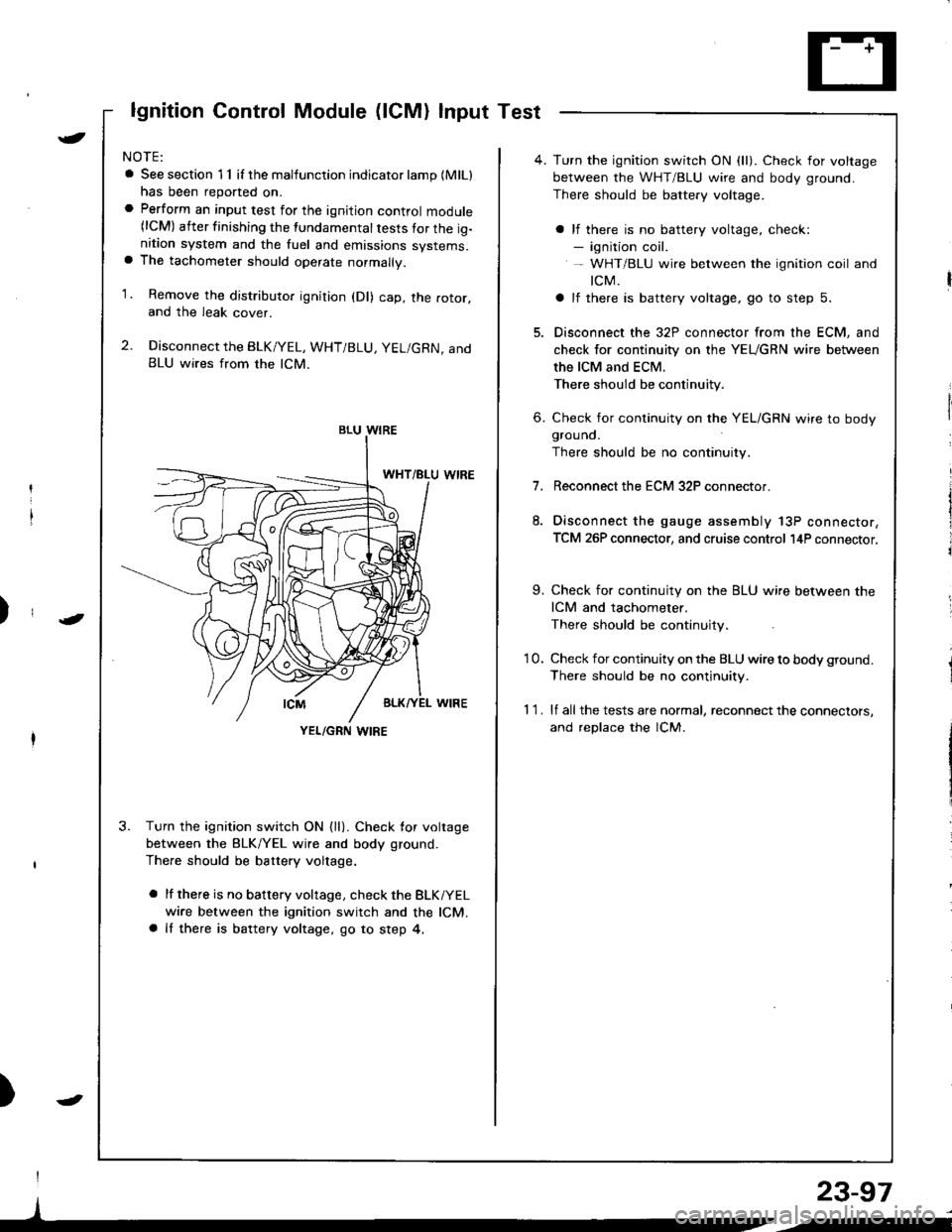

lgnition Control Module (lCM) Input Test

NOTE:

a See section 1 1 if the malfunction indicator lamp (MlLl

has been reported on.a Perform an input test for the ignition control module(lCM) after finishing the fundamental tests for the ig-nition system and the fuel and emissions systems.a The tachometer should operate normally.

1. Remove the distributo. ignition (Dl) cap, the rotor,and the leak cover.

2. Disconnect the BLK/YEL, WHT/BLU, YEL/GRN, andBLU wires from the lCM.

3. Turn the ignition switch ON {ll}. Check for voltage

between the BLK/YEL wire and body ground.

There should be battery voltage.

a lf there is no battery voltage, check the BLKiYEL

wire between the ignition switch and the lCM.a It there is battery voltage, go to step 4,

)

I

)

BLU WIRE

YEL/GRN I,\'IRE

4. Turn the ignition switch ON (ll). Check for voltage

between the WHT/BLU wire and body ground.

There should be battery voltage.

a lf there is no battery voltage, check:- ignition coil.- WHT/BLU wire between the ignition coil and

tcM.

a lf there is battery voltage, go to step 5.

5. Disconnect the 32P connector from the ECM, and

check for continuity on the YEUGRN wire between

the ICM and ECM.

There should be continuity.

6. Check for continuity on the YEL/GRN wire to bodygrouno.

There should be no continuity.

7.Reconnect the ECM 32P connector.

Disconnect the gauge assembly 13P connector,

TCM 26P connector, and cruise control l4P connector.

9. Check for continuity on the BLU wire between the

ICM and tachometer.

There should be continuity.

'10. Check for continuity on the BLU wire to body ground.

There should be no continuity.

1 1 . lf all the tests are normal, reconnect the connectors,

and replace the lCM.

23-97

/i

Page 1167 of 1681

Charging System

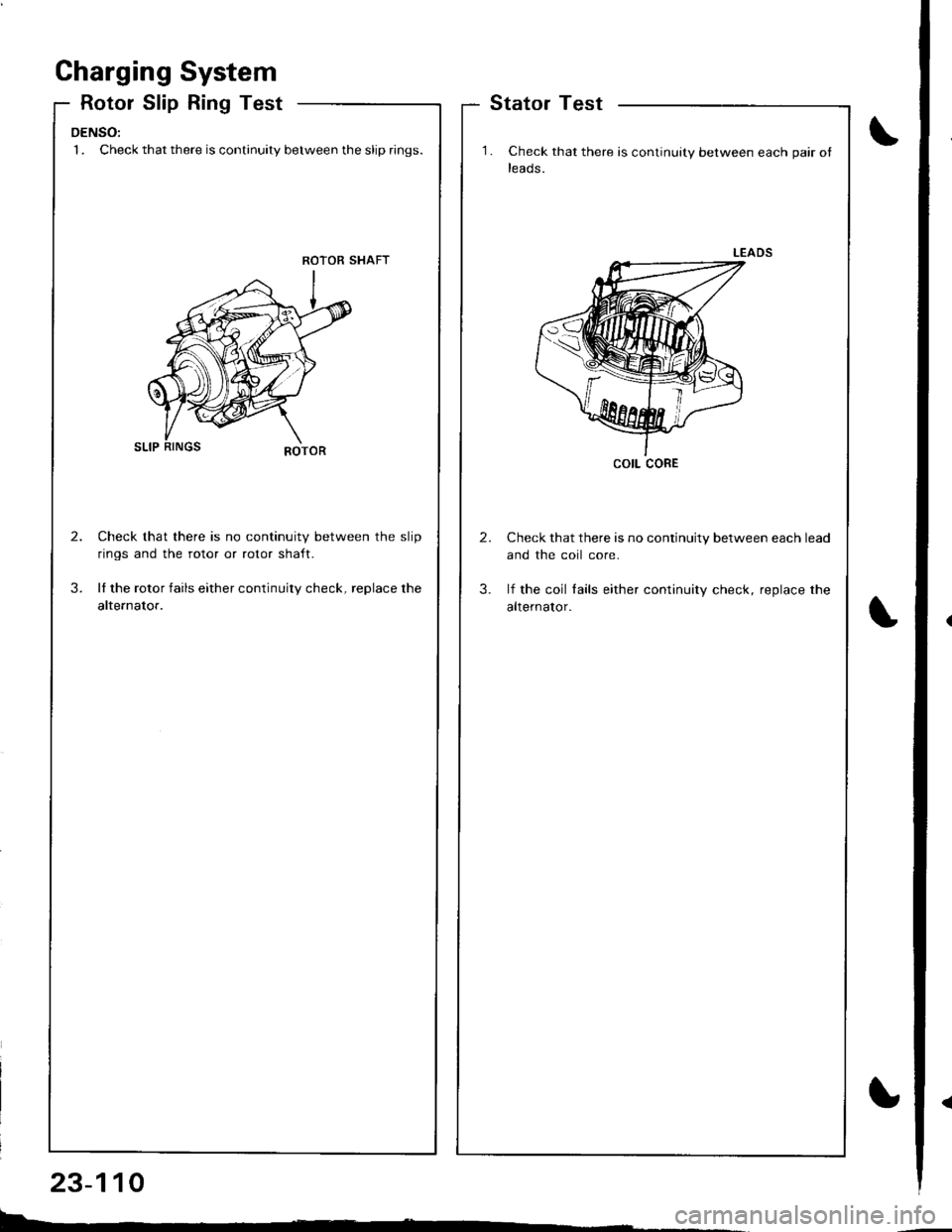

Rotor Slip Ring Test

DENSO:'l . Check that there is continuity between the slip rings.

ROTOR SHAFT

Check that there is no continuity between the slip

rings and the rotor or rotor shaft.

lf the rotor fails either continuity check, replace the

alternator.

Stator Test

1 . Check that there is continuity between each pair ot

leads.

Check that there is no continuity between each lead

and the coil core.

lf the coil lails either continuity check, replace the

alternator.

2.

3.

2.

3.

23-110

cotl coRE

b-.

Page 1170 of 1681

i'[

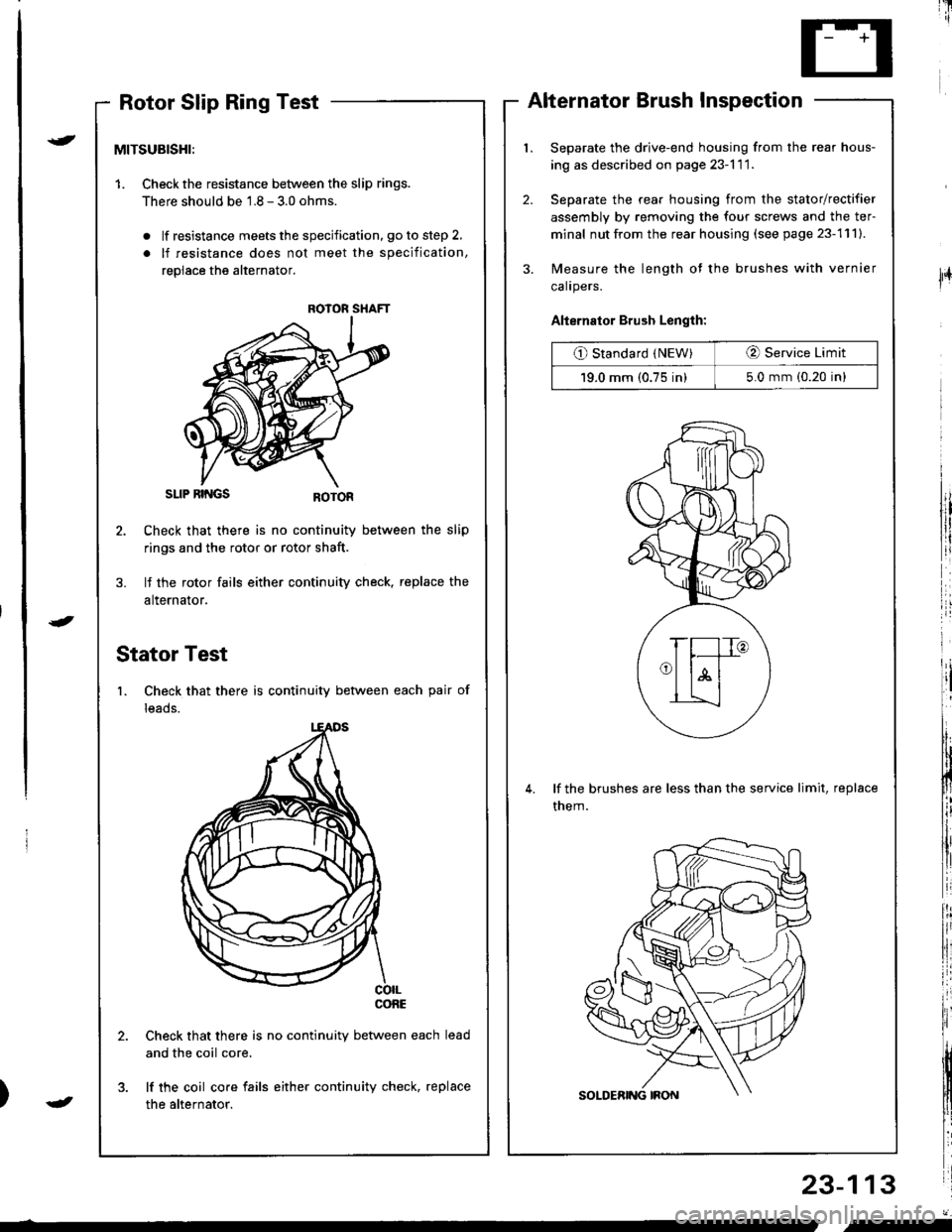

Rotor Slip Ring TestAlternator Brush Inspection

Separate the drive-end housing from the rear hous-

ing as described on page 23-l 1 1.

Separate the rear housing from the stator/rectifier

assembly by removing the four screws and the ter-

minal nut from the rear housing (see page 23-111).

Measure the length of the brushes with vernier

calrpers.

Alternator Brush Length:

O Standard (NEW)O Service Limit

19.0 mm (0.75 in)5.0 mm (0.20 in)

lf the brushes are less than the service limit, replace

them.

23-113

{

J

lFr

MITSUBISHI:

1. Checkthe resistance between the slip rings.

There should be 1.8 - 3.0 ohms.

. lf resistance meets the specification, go to step 2,

. lf resistance does not meet the specification,

replace the alternator.

SLIP RII{GS

Check that there is no continuity between the slip

rings and the rotor or rotor shaft.

lf the rotor fails either continuity check, replace the

alternator.

Stator Test

1. Check that there is continuity between each pair of

leads.

co|LconE

Check that there is no continuity between each

and the coil core.

lf the coil core fails either continuity check, replace

the alternator.

ROIOR SHAFT

J

"-

Page 1187 of 1681

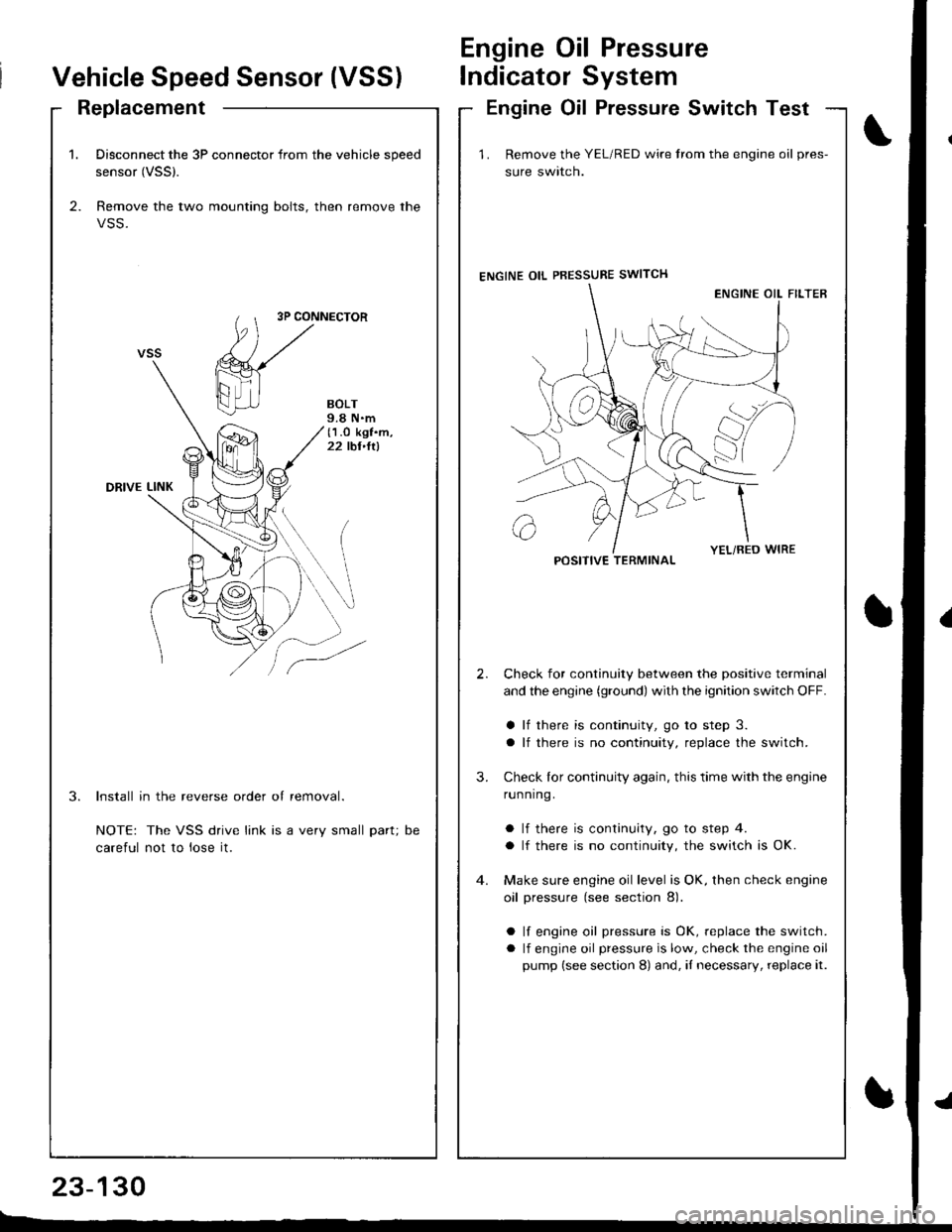

1. Disconnect the 3P connector from the vehicle speed

sensor (VSSl.

2. Remove the two mounting bolts, then remove the

VSS.

3P CONNECTOR

BOLT9.8 N.m(1.O kgf.m,22 tbt,ltl

DRIVE LINK

3.Install in the reverse order of removal.

NOTE: The VSS drive link is a very small part;

careful not to lose it.

DC

Vehicle Speed Sensor (VSS)

Engine Oil Pressure

lndicator System

ReplacementEngine Oil Pressure Switch Test

23-130

E-_

1 . Remove the YEL/RED wire trom the engine oil pres-

sure swlrcn.

ENGINE OIL PBESSURE SWITCH

Check for continuity between the positive terminal

and the engine (ground) with the ignition switch OFF.

a lf there is continuity, go to step 3.

a lf there is no continuity, replace the switch.

Check lor continuity again, this time with the engine

running.

a lf there is continuity, go to step 4.

a lf there is no continuity, the switch is OK.

Make sure engine oil level is OK, then check engine

oil pressure (see section 8).

a lf engine oil pressure is OK, replace the switch.

a lf engine oil pressure is low, check the engine oil

pump (see section 8) and, iI necessary, replace it.

2.

3.

POSITIVE TERMINAL

Page 1188 of 1681

)

{

t.t

t.!

23-131

Fuel Gauge

Gauge Test

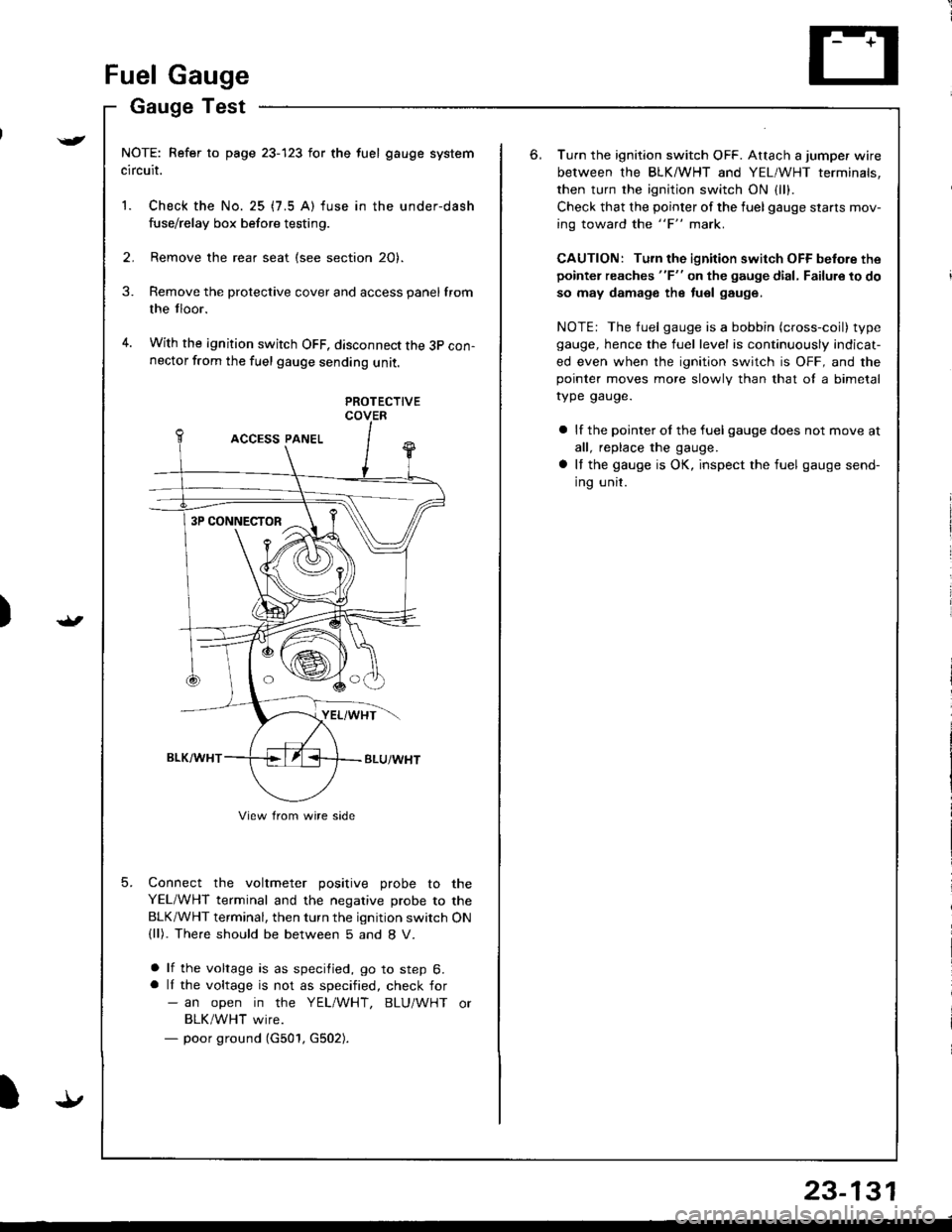

NOTE: Refer to page 23-123 for the fuel gauge system

circuit.

1. Check the No. 25 (7.5 A) fuse in the under-dash

fuse/relay box before testing.

2. Remove the rear seat (see section 20).

Remove the protective cover and access panel from

the tloor.

With the ignition switch OFF, disconnect the 3p con-nector from the fuel gauge sending unit.

3.

4.

5.

PROTECTIVECOVER

Connect the voltmeter positive probe to the

YEL/WHT terminal and the negative probe to the

BLK/WHT terminal, then turn the ignition switch ON(ll). The.e should be between 5 and 8 V.

a lf the voltage is as specified, go to step 6.a lI the voltage is not as specified, check for- an open in the YEL/WHT, BLU/WHT or

BLK/WHT wire.- poor ground (G501, G502).

3P CONNECTOR

View from wire side

6.Turn the ignition switch OFF. Attach a jumper wire

between the BLKMHT and YEL/WHT terminals,

then turn the ignition switch ON {1.,.

Check that the pointer of the fuel gauge starls mov-

ing toward the "F" mark.

CAUTION: Turn the ignition switch OFF before the

pointer reaches "F" on the gauge dial, Failure to do

so may damage the tuel gauge.

NOTE: The fuel gauge is a bobbin (cross-coil) type

gauge, hence the fuel level is continuously indicat-

ed even when the ignition switch is OFF, and thepointer moves more slowlv than that ol a bimetal

rype gauge.

a lf the pointer ol the fuel gauge does not move at

all, replace the gauge.

a It the gauge is OK, inspect the fuel gauge send-

ing unit.