light HONDA INTEGRA 1998 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 767 of 1681

1.

8.

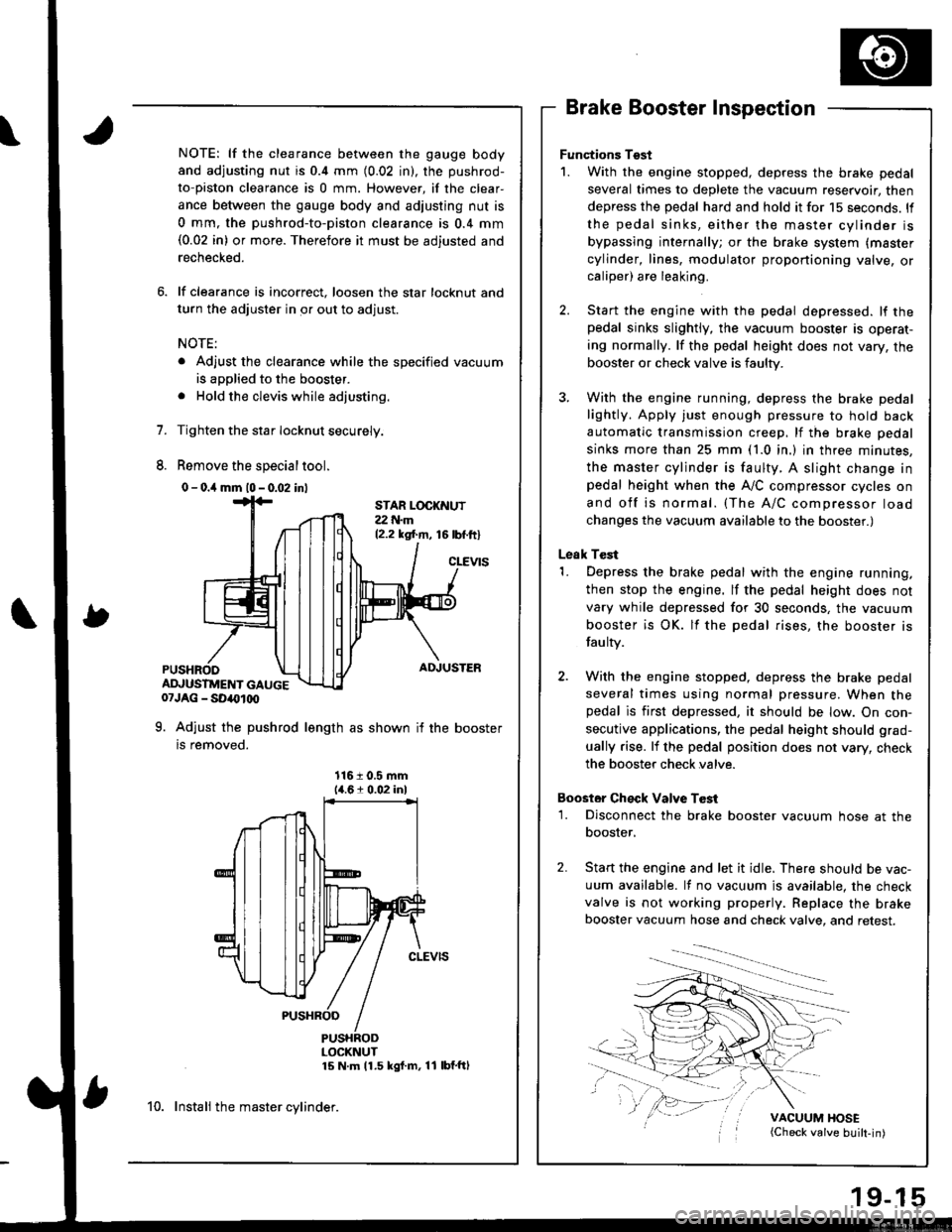

NOTE: lf the clearance between the gauge body

and adjusting nut is 0.4 mm (0.02 in), the pushrod-

to-piston clearance is 0 mm. However, if the clear-

ance between the gauge body and adjusting nut is

0 mm, the pushrod-to-piston clearance is 0.4 mm(0.02 in) or more. Therefore it must be adjusted and

rechecked.

lf clearance is incorrect, loosen the star locknut and

turn the adjuster in or out to adjust.

NOTE:

. Adjust the clearance while the specified vacuum

is applied to the booster.

. Hold the clevis while adjusting.

Tighten the star Iocknut securely.

Remove the special tool.

0 - o.il mm l0 - 0.02 inl

Brake Booster Inspection

Functions Tgst

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds. ll

the pedal sinks, either the master cylinder is

bypassing internally; or the brake system (master

cylinder, lines, modulator proportioning valve, orcaliper) are leaking.

Start the engine with the pedal depressed. lf thepedal sinks slightly, the vacuum booster is operat-

ing normally. lf the pedal height does not vary, the

booster or check valve is faulty.

With the engine running, depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep, lf the brake pedal

sinks more than 25 mm (1.0 in.) in three minutes,

the master cylinder is faulty. A slight change inpedal height when the A,,/C compressor cycles on

and off is normal. (The A/C compressor load

changes the vacuum available to the booster.)

Leak Test

1. Depress the brake pedal with the engine running,

then stop the engine. lf the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. lf the pedal rises, the booster is

fau lty.

2. With the engine stopped, depress the brake pedal

several times using normal pressure. When thepedal is first depressed, it should be low. On con-

secutive applications, the pedal height should grad-

ually rise. lf the pedal position does not vary, check

the booster check valve.

Boostor Ch€ck Valve T6st

1. Disconnect the brake booster vacuum hose at the

booster,

Start the engine and let it idle. There should be vac-

uum available. It no vacuum is available. the check

valve is not working properly. Replace the brake

booster vacuum hose and check valve, and retest.

VACUUM HOSE(Check valve built-in)

STAR LOCKNUT22 t{.m12.2 ksl.m, 16lbf.ftl

cLEVtS

ADJUSTER

ADJUSTMENT GAUGE07JAG - SD40t00

9. Adjust the pushrod length as shown if the booster

is removed.

1161 0.5 mm14.61 0.02 inl

PUSHRODLOCKNUT15 N m 11.5 kgf m, 11 lbf'ftl

10. Instali the master cylinder.

Page 768 of 1681

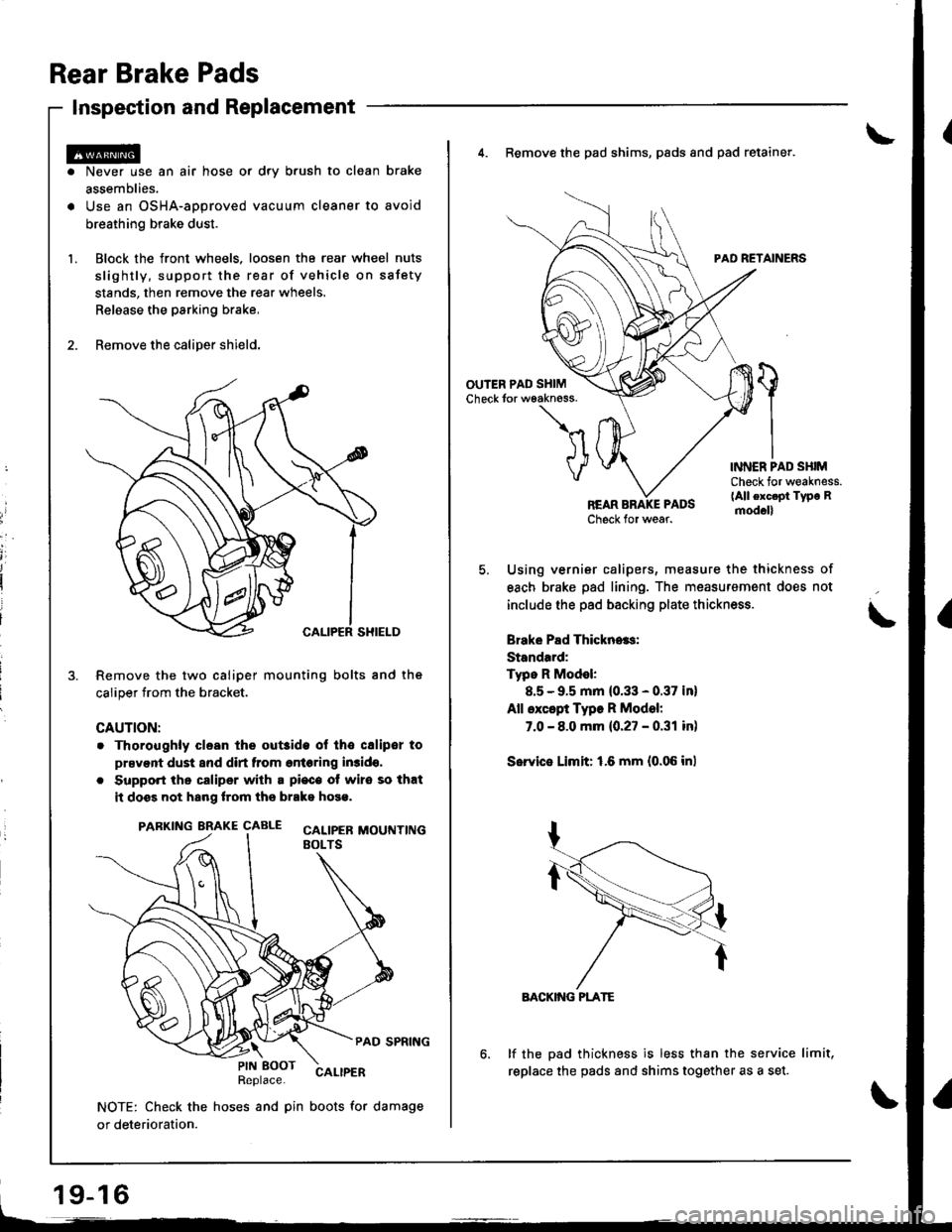

Rear Brake Pads

Inspection and Replacement

Never use an air hose or dry b.ush to clean brake

assemblies.

Use an OSHA-approved vacuum cleaner to avoid

breathing brake dust.

Block the front wheels. loosen tha rear wheel nuts

slightly, support the rear of vehicle on sstety

stands, then remove the rear wheels.

Relaase the parking brake,

Remove the caliper shield.

Remove the two caliper mounting bolts and the

caliper trom the bracket.

CAUTION:

. Thoroughly clesn the out3ide ol tho csliper to

prsvent dust and dirt from entering in3ido,

. Support the caliper with a pi€c€ ot wire so that

it doss not hang lrom ths brako hose.

PARKING BRAKE CAALE cALtpEB MOUTTT|NGEOLTS

PAD SPRING

Replace.CALIPER

NOTE: Check the hoses and pin boots for damage

or deterioration.

\PIN EOOT

19-16

4. Remove the pad shims, pads and pad retainer.

PAD RETAINERS

'l

VINNER PAD SHIMCheck for weakness.(All exc.pt Type Rmod.ll

Using vernier calipers, measure the thickness of

each brake pad lining. The measurement does not

include the pad backing plate thickness.

Brake Pad Thickn..s:

Standard:

Typo R Model:

8.5 - 9.5 mm (0.33 - 0.37 in)

All except Type R Model:

7.0 - 8.0 mm {0.27 - 0.31 in)

Sorvie Limit: 1.6 mm {0.06 inl

BACKIiIG PLATE

lf the pad thickness is less than the service limit,

replace the pads and shims together as a set.

Page 770 of 1681

Inspection

rrii tlmm {0.4 inl10

l.

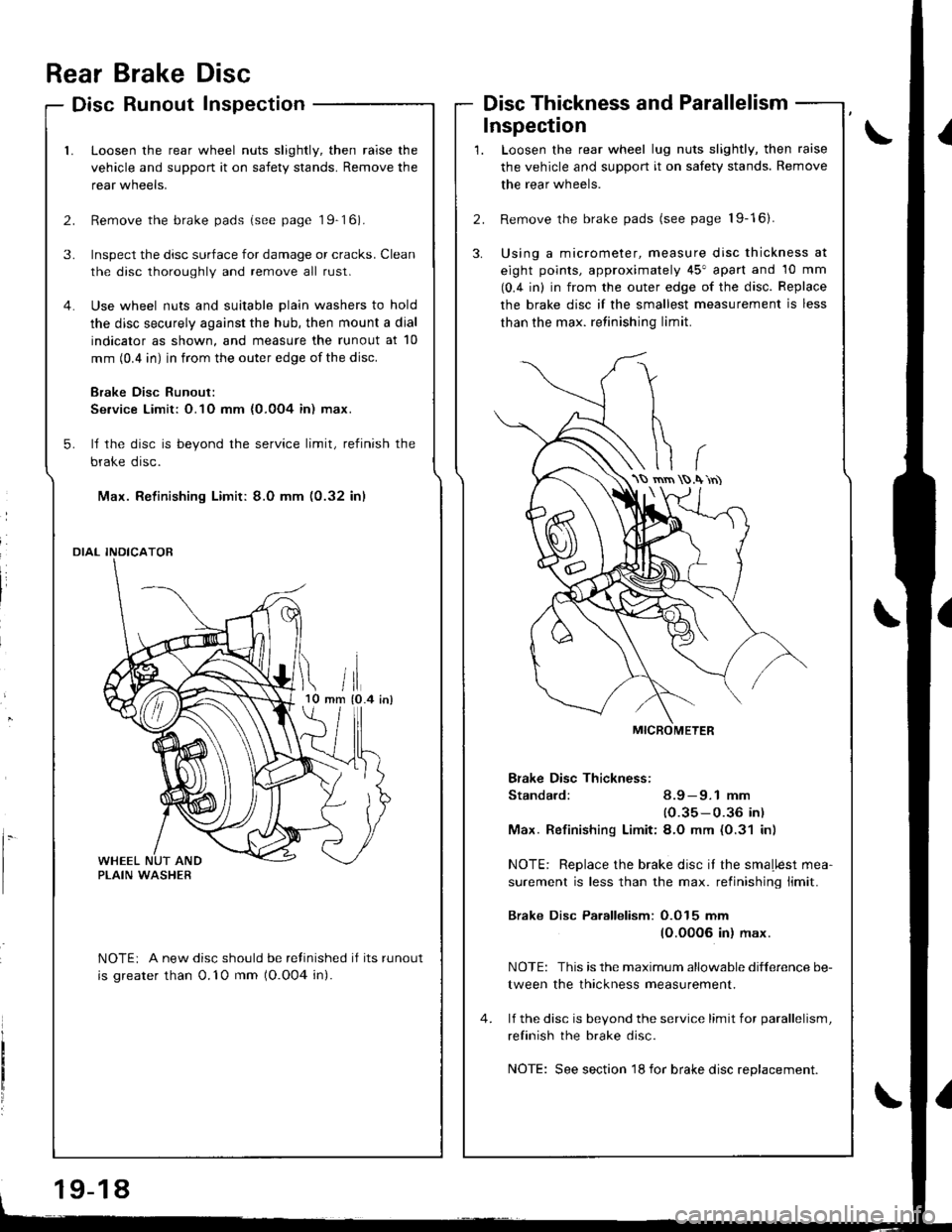

Rear Brake Disc

Disc Runout Inspection

Loosen the rear wheel nuts slightly, then raise the

vehicle and support it on safety stands. Remove the

rear wneers.

Remove the brake pads (see page 19-16).

Inspect the disc surface for damage or cracks. Clean

the disc thoroughly and remove all rust.

Use wheel nuts and suitable plain washers to hold

the disc securely against the hub, then mount a dial

indicator as shown, and measure the runout at 10

mm (0.4 in) in from the outer edge of the disc.

Brake Disc Runout:

Se.vice Limit: O.1O mm {0.0O4 in) max.

ll the disc is beyond the service limit, refinish the

brake disc.

Max. Refinishing Limit: 8.0 mm (0.32 in)

DIAL INDICATOR

NOTEi A new disc should be refinished if its runout

is greater than 0.'10 mm (O.O04 in).

Disc Thickness and Parallelism

Loosen the rear wheel lug nuts slightly, then raise

the vehicle and support it on safety stands. Remove

the rear wheels.

Remove the brake pads (see page 19-16).

Using a micrometer, measure disc thickness at

eight points, approximately 45" apart and 10 mm

(0.4 in) in from the outer edge of the disc. Replace

the brake disc if the smallest measurement is less

than the max. retinishing limit.

Bfake Disc Thickness:

Standard: 8.9 - 9.1 mm

(0.35-0.36 in)

Max. Refinishinq Limit:8.O mm (0.31 in)

NOTE: Replace the brake disc it the smaLlest mea-

surement is less than the max. retinishing limit.

Brake Disc Parallelism: O.O15 mm

(O.00O6 in) max.

NOTE: This is the maximum allowable difference be-

tween the thickness measurement.

lf the disc is bevond the service limit for parallelism,

refinish the brake disc.

NOTE: See section 18 for brake disc replacement.

\S rnrn .\'rn)

19-18

Page 792 of 1681

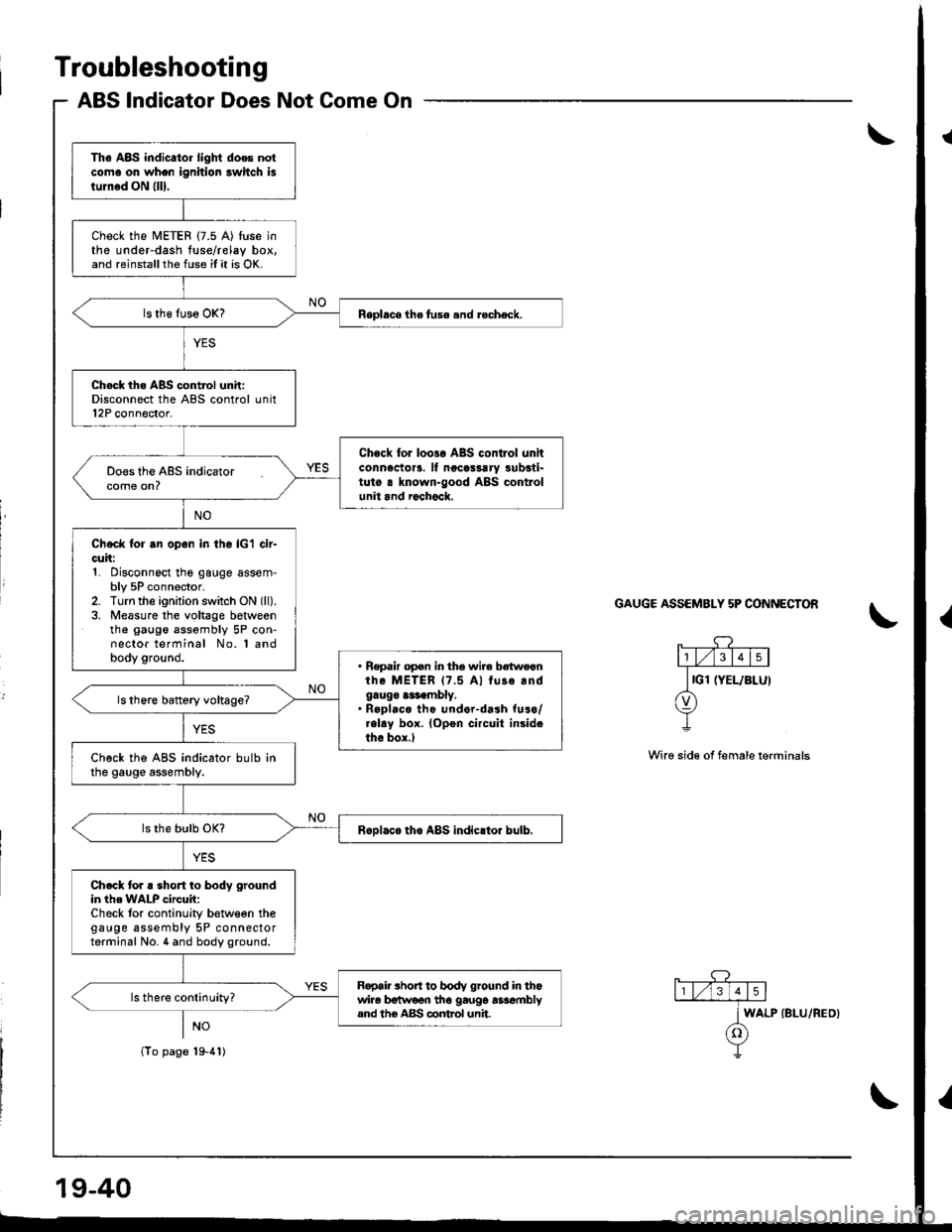

Troubleshooting

ABS lndicator Does Not Come On

\

GAUGE ASSEMBLY 5P CONNECTON

Wire sid€ of female terrninals

Th. A8S indicator light does notcoma on whon ignition swhch islum6d ON llll.

check the METER {7.5 A) tuse inthe under-dash tuse/relay box.and reinstallthe fuse it it is OK.

Replacsthefuse.nd recheck.

Ch.ck th. ABS control unit:Disconnect the ABS control unit12P connector.

Chock for loola ABS contlol unitconnector!. ll noco$rry !ubsti-tut6 a known-good ABS controlunit and r6chock.

Check tor .n opon in the lcl cir-cuit:1. Disconnect the gauge assem-bly 5P connector.2. Turn the ignition switch ON (ll).

3. Measure the voltage botweenthe gaugo assombly 5P con-nector terminal No. 'l andbody ground.. Repair open in tho wir. betwoanthe METER 17.5 A) tuso.ndgaugo a$embly.. R.pl.co tho under-dash furo/.elay box. lopen circuit insidethe box.l

check the A8s indicator bulb inthe gauge assembly.

R6olace tho ABS indicrtor bulb.

Ch.ck tor ! short to body groundin th6 WALP circuit:Check tor continuity b€tween thegauge assembly 5P connectorterminal No. 4 and body ground.

R€pair short to body ground in thowira b€tw6on tho gaug6 asscmblysnd the A&S control unit.

lTo page'19-41)

WALP {BLU/REO}

Page 793 of 1681

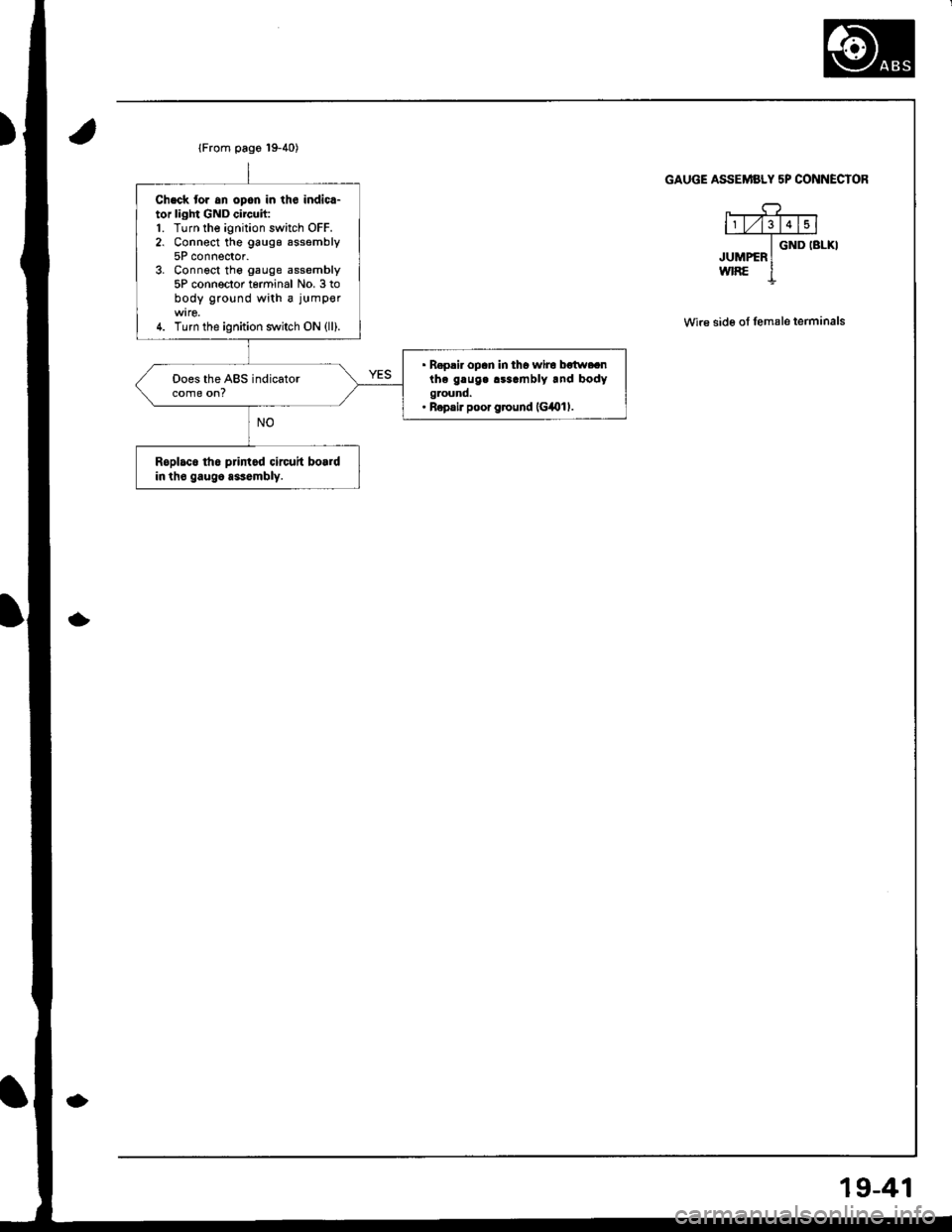

Chsck tor an opon in th6 indicr-tor light GND circuh:'1. Turn the ignition switch OFF.2. Connect the gaugs assembly5P connector.3. Connect the gauge assembly5P conneclor tgrminal No. 3 tobody ground with a jumper

4. Turn the ignition s:witch ON (ll).

. R€pair opan in tho wiro botw.anthe gaug. r$.mbly .nd bodyground.. Ropsir poor ground lcil()i l.

Does the ABS indicatorcome on?

Roplac6 th6 printod circuit bo.rdin tho gaug6 assembly.

GAUGE ASSEMBLY 5P CONNECIOR

F---.q-l1 l/l3l415l-J6ii-6r-xr

JUMPER IwrRE I

Wre sid6 of lemale terminals

19-41

Page 794 of 1681

Troubleshooting

ABS Indicator Does Not Go Off

JUMPERWIRE

ABS OO TNOL UMT 22P OO'{NECTOR

Wire side of temalo terminalg

A8S COI{TROL Ut{lT 12P OO I{ECTOR

JUMPEFWIRE

Wire side of femal€ terminala

|G2 IALK/YELI

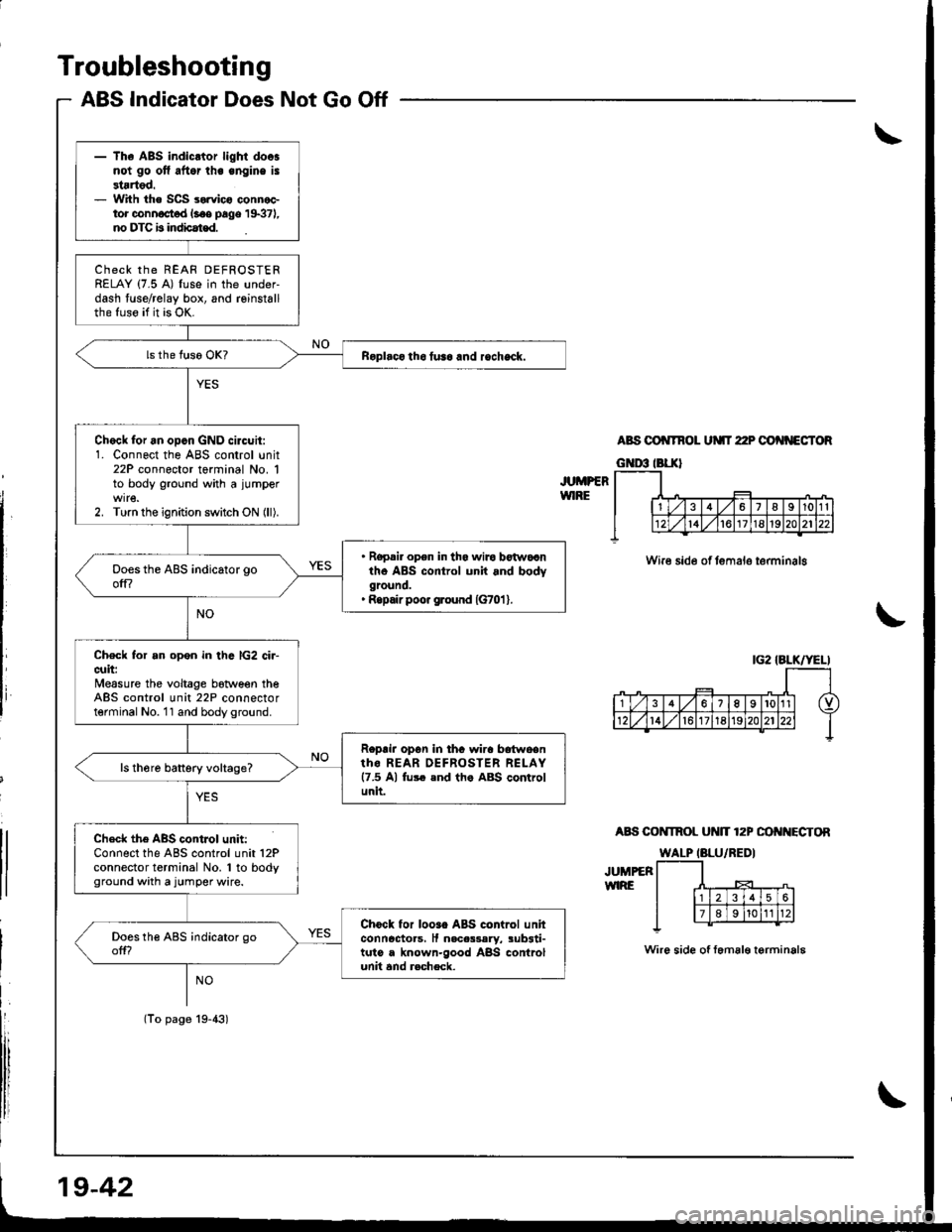

- The ABS indicltor light doosnot go ofl aftor lhe engine is3tartod.- With the SCS sorvico connoctor connoct d l.oe page 19371,no DTC b indbat€d.

ChECK thE REAF DEFROSTERRELAY (7.5 A) fuse in the under-dash fuse/relay box, and reinstallthe fuso if it is OK.

Roplaco tho tusa and rocheck.

Chock for an opcn GND circuit:1. Connect the ABS control unit22P connector terminal No. 1to body ground with a jumper

2. Turn the ignition switch ON (ll).

. Ropair opon in tha wiro botwocntho ABS control unit and bodyground.' Ropair poo. ground {G701 }.

Check for an open in thc lG2 ci.-cuit:Measure the voltage botween theABS control unit 22P connectorterminal No. 11 and body ground.

Roprir opon in thc wira bdtwoentho REAR OEFROSTER RELAY17.5 Al fu$ end th. ABS controlunit.

ls th6re battery voltage?

Check the ABS contJol unit:Connect the ABS control unit 12Pconnector terminal No. 1 to bodyground with a jumper wire.

Chock for looao ABS control unhconncctoas, It nacas3aly, sub3ti-tuto a known-good ABS controlunit and r.check.

(To page 19-43)

19-42

Page 859 of 1681

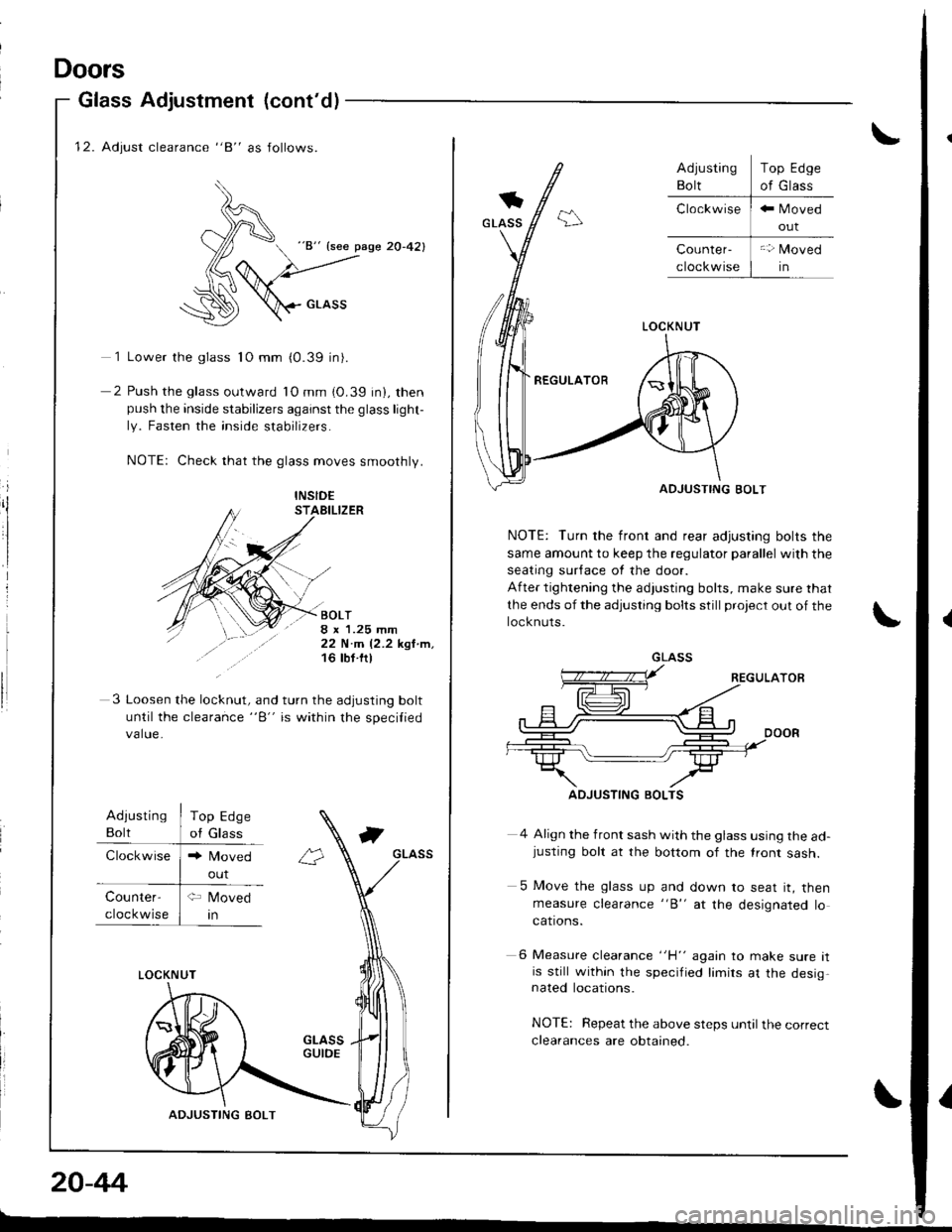

12. Adjust clearance "8" as follows.

)^

d "8" {see pase 20-42}

(6

:\D \crnss

1 Lower the glass 1O mm (0.39 in).

2 Push the glass outward lO mm (0.39 in), thenpush the inside stabilizers against the glass light-

ly. Fasten the inside stabilizers.

NOTE: Check that the glass moves smoothly.

i

ilINSID€STAEILIZER

BOLT8 x 1.25 mm22 N.m 12.2 kgl.m,16 tbt ftl

3 Loosen the lo"knrt, "nd turn the adjusting bolt

until the clearance "B" is within the specilied

value.

Adiusting

Bolt

Clockwise

Top Edge

of Glass

Counter-

cloc kwise

LOCKNUT

ADJUSTING BOLT

20-44

Doors

Glass Adjustment (cont'd)

out

\

LOCKNUT

REGULATOR

ADJUSTING BOLT

NOTE: Turn the front and rear adjusting bolts the

same amount to keep the regulator parallel with the

seating sur{ace ot the door.

After tightening the adjusting bolts, make sure that

the ends of the adjusting bolts still project out of the

locknuts.

4 Align the front sash with the glass using the ad-justing bolt at the bottom of the lront sash.

5 Move the glass up and down to seat it, thenmeasure clearance "B" at the designated locations.

6 Measure clearance "H" again to make sure itis still within the specified limirs at the desig,nated locations.

NOTE: Repeat the above steps until the correct

clearances are obtained.

Top Edge

of Glass

GLASS

ADJUSTING BOLTS

I

Page 861 of 1681

Doors

Glass Adjustment (cont'dl

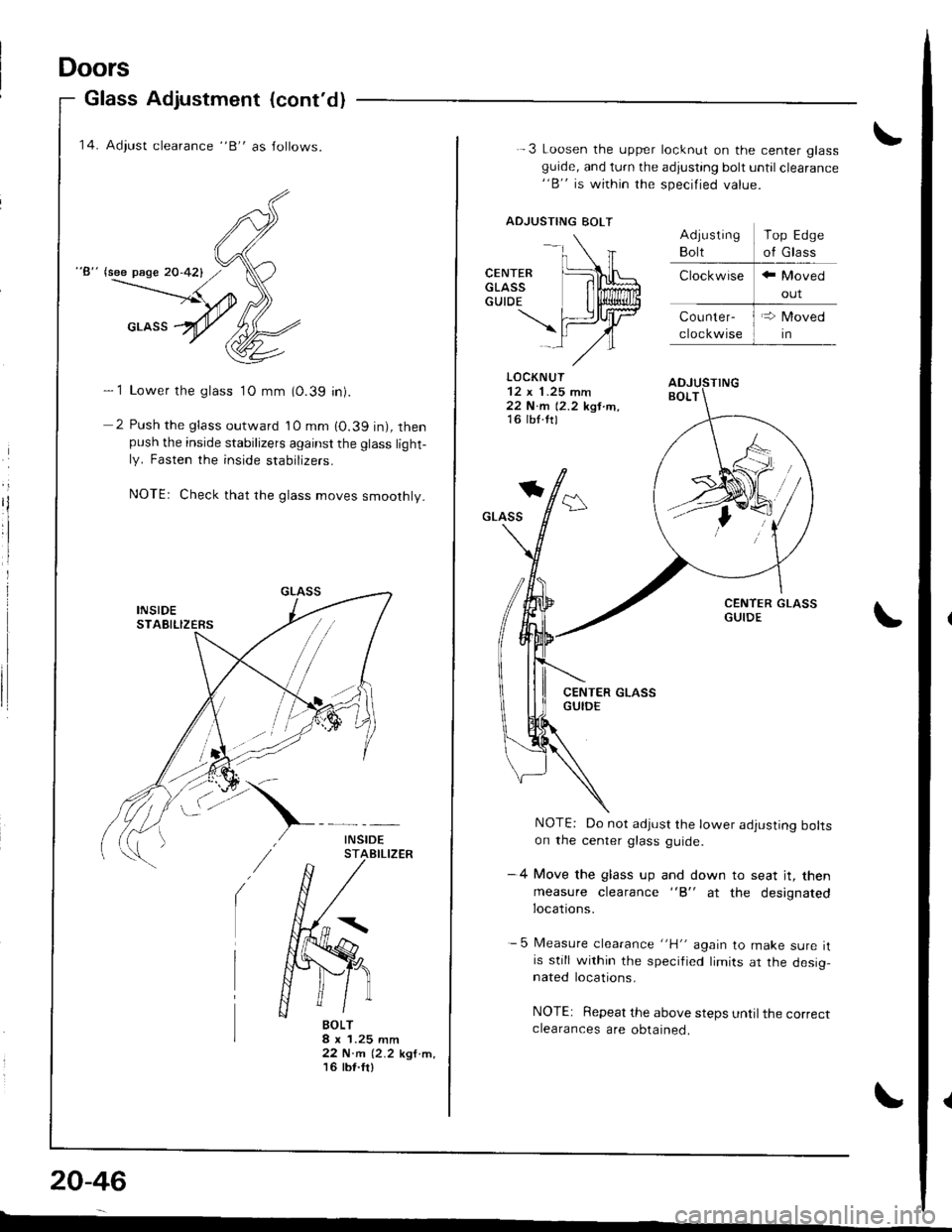

'14. Adiust clearance "B" as Jollows.

"8" lsee page 20-421

- 1 Lower the glass 1O mm (0.39 in).

2 Push the glass outward 10 mm 10.39 in), thenpush the inside stabilizers against the glass light-ly. Fasten the inside stabrIzers.

NOTEr Check that rhe glass moves smoothly.

BOLT8 x 1.25 mm22 N.m (2.2 kgf.m,'t6 tbt.fr)

20-46

-

-.\

CENTER [L\LGLAss lilffiGUTDE I li$lliun

\fiJrtrlAl-,/"

.-3 Loosen the upper locknut on the center glassguide, and turn the adjusting bolt until clearance"B" is within the specified value.

ADJUSTING BOLT

LOCKNUT

22 N.m 12.2 kgt tn,16 lb{.ttl

*

GLASS

NOTE: Do not adjust the lower adjusting boltson the center glass guide.

-4 Move the glass up and down to seat jt, then

measure clearance "B" at the designatedlocations.

- 5 Measure clearance "H" again to make sure itis still within the specified limits ar the desig,nated locations.

NOTE: Repeat the above steps until the correctclearances are obtained.

Top Edge

of Glass

Page 863 of 1681

Doors

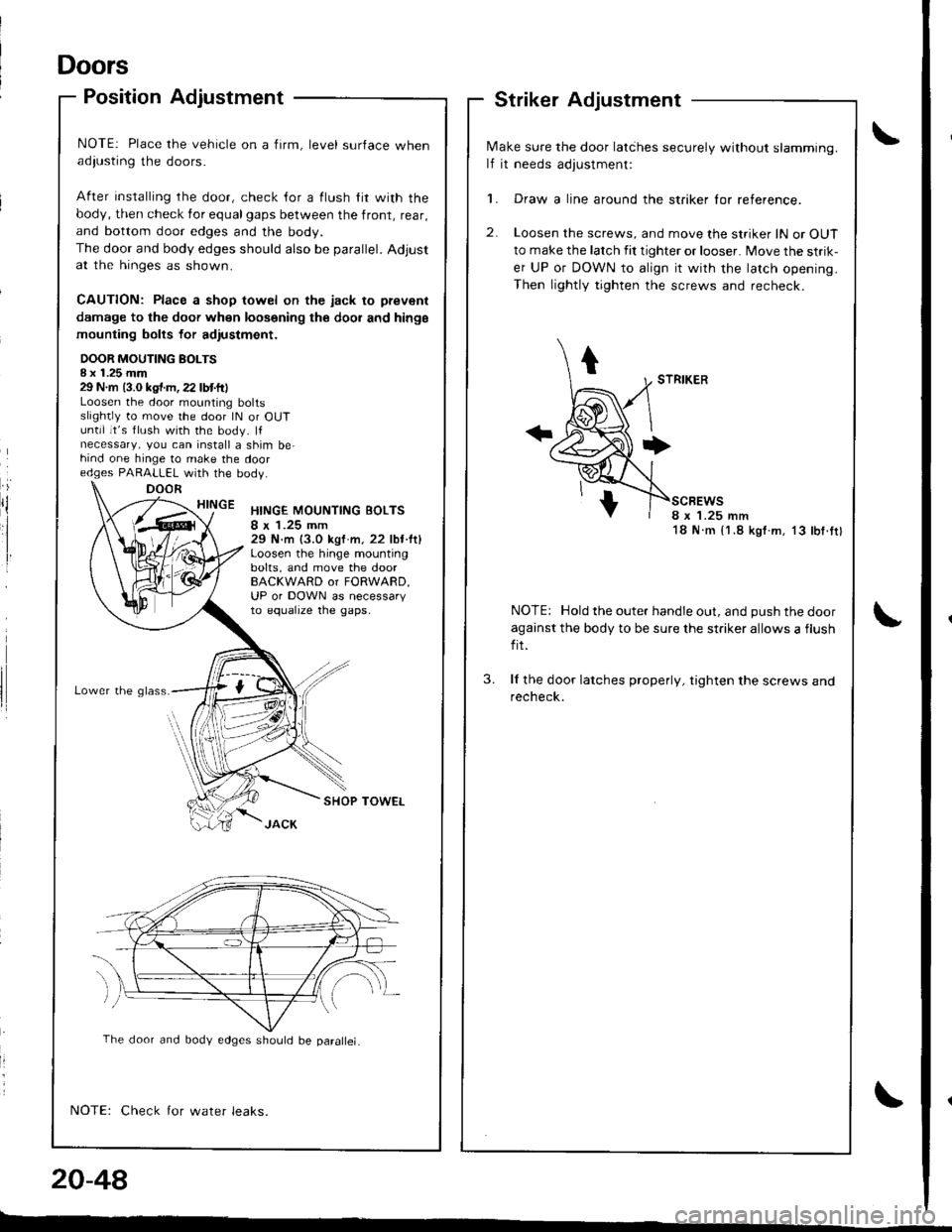

Position Adjustment

NOTE: Place the vehicle on a firm, level surface whenadiusting the doors.

After installing rhe door, check {or a flush lir with the

body, then check for equalgaps between the front, rear,

and bottom door edges and the body.

The door and body edges should also be parallel. Adjustat the hinges as shown.

CAUTION: Place a shop towel on the jack to prevenl

damage to the doof when loosening the dool and hinge

mounting bolts for adiustmont.

DOOR MOUTING BOLTSI x 1.25 mm29 N.m (3.0 kgt.m,22 lbtft)Loosen the door mounting boltsslightly to move the door lN or OUTuntil it's flush with the body. lfnecessary, you can install a shim be-hind one hinge to make the dooredges PARALLEL with the bodV.

HINGEHINGE MOUNTING BOLTS8 x 1.25 mm29 N.m (3.0 kgf m, 22 lbt.lt)Loosen the hinge mountingbolts, and move the doorBACKWARD or FORWARD,UP or DOWN as necessaryto equalrze tne gaps,

Lower the g lass.

SHOP TOWEL

Check for water leaks.

.iDOOR

N,4ake sure the door latihes securely without slamming.

lf it needs adjustment:

1. Draw a line around the striker lor reference.

2. Loosen the screws, and move the striker lN or OUT

to make the latch fit tighter or looser. Move the strik-

er UP or DOWN to align it with the latch opening.

Then lightly tighten the screws and recheck.

scBEws8 x '1.25 mm18 N.m {1.8 kgf.m. 13 lbf.tt}

NOTE: Hold the outer handle out, and push the door

against the body to be sure the striker allows a flush

fit.

ll the door latches properly, tighten the screws andrecheck.

3.

20-48

The door and body edges should be parallel.

-"

Page 873 of 1681

Windshield

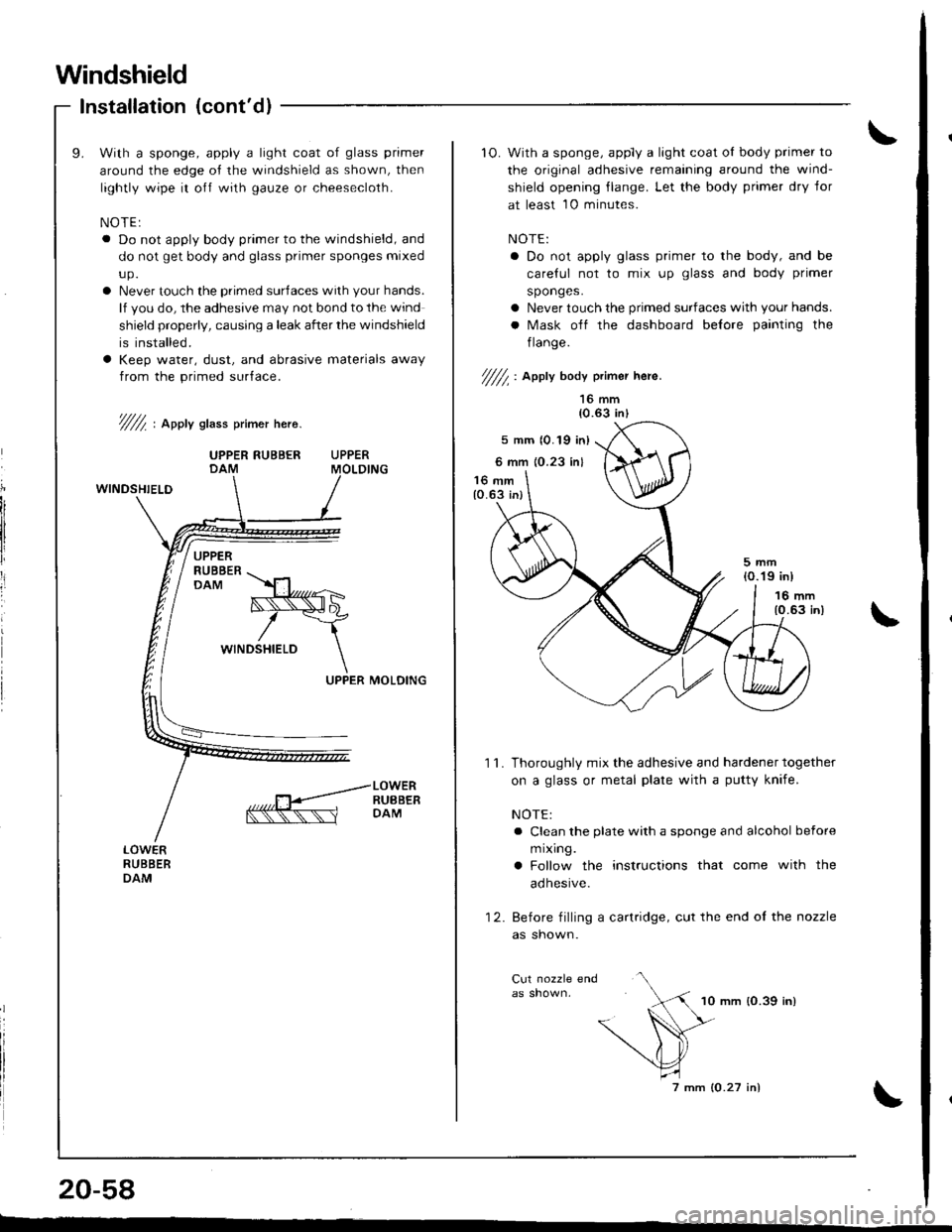

Installation (cont'dl

With a sponge, apply a light coat of glass primer

around the edge of the windshield as shown, then

lightly wipe it o{f with gauze or cheesecloth.

NOTE:a Do not apply body primer to the windshield, and

do not get body and glass primer sponges mixed

up.

a Never touch the primed surtaces with your hands.

lf you do, the adhesive may not bond to the wind

shield properly, causing a leak after the windshield

is installed.

a Keep water, dust, and abrasive materials away

from the primed sur{ace.

V///t t applv slass primer her6.

UPPER RUBBER UPPERDAM MOLDING

WINDSIIIELD

UPPER MOLOING

n------kBB''i+,

KKKxxl DAM

20-58

1O. With a sponge, apply a light coat oI body primer to

the original adhesive remaining around the wind-

shield opening llange. Let the body primer dry tor

at least 10 minutes.

NOTE:

a Do not apply glass primer to the body, and be

carelul not to mix up glass and body primer

sponges.

o Never touch the primed surfaces with your hands.

a Mask olf the dashboard be{ore painting the

flange.

/////,, epptv body p.imer here.

16 mm{0.63 inl

5 mm {0.19 in)

6 mm {0.23 inl'16 mm{0.63 in}

5mm(O.'19 inl

16 mm10.63 in)

1'1. Thoroughly mixthe adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

a Clean the plate with a sponge and alcohol before

mlxlng.

a Follow the instructions that come with the

adhesive.

12. Before filling a cartridge, cut the end of the nozzle

as shown.

10 mm {O.39 in}