light HONDA INTEGRA 1998 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 661 of 1681

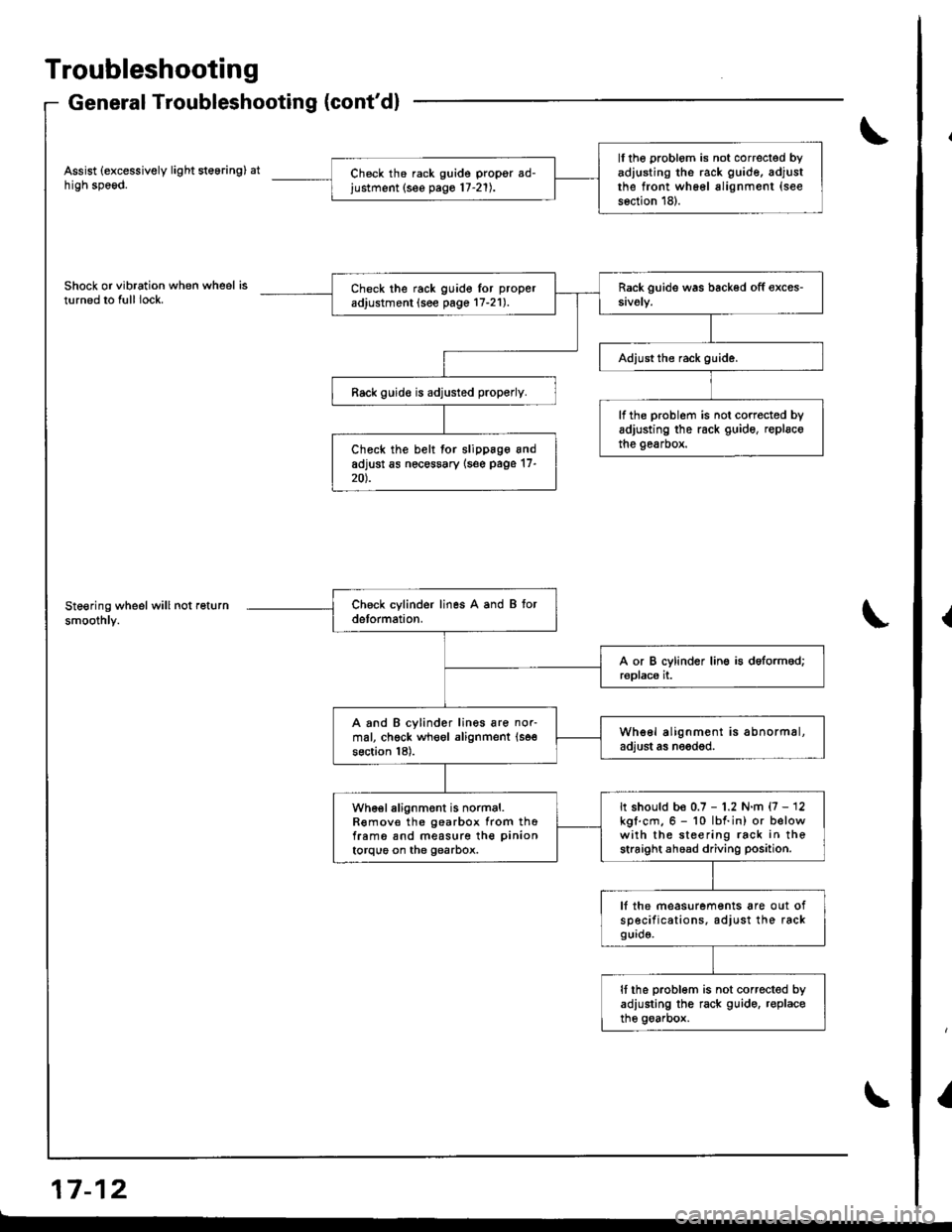

Troubleshooting

General Troubleshooting (cont'dl

Assist (excessively light steering) athigh speod.

Shock or vibration when wheel isturned to full lock.

Steering wheel will not return

smoothly.

a-, aa GrI r- tz

ll the problom is not correcled byadiusting the rack guide, adjustthe front wh66l alignment (see

s6ction 18).

Ch6ck th6 rack guide propgr ad-justment (see pago 17-21).

Check the rack guido lor proper

adjustment (see page 17-21).

Rack guid€ is adjusted properly.

lf the problem is not corrected byadjusting the rack guide, replscothe gearbox.Check the belt for slippage andadjust as nec€ssary {s6e page 17-20).

A and B cylinder lines are nor-mal, chgck wheol alignment (se€

section 18).

Whe6l alignment is abnormal,adjust as needod.

It should be 0.7 - 1.2 N.m {7 - 12kgl.cm.6 - 10 lbf.in) or belowwith the steering rack in thestraight ahoad driving position.

wh€el alignment is normal.R€mov€ the gearbox from thofram6 snd measure the pinion

torque on the gearbox.

lf the measurements are out ofsp€cifications. adjust the rackgurd9.

It the problom is not corrected byadiusting the rack guido. r€placethe goarbox.

{

I

Page 674 of 1681

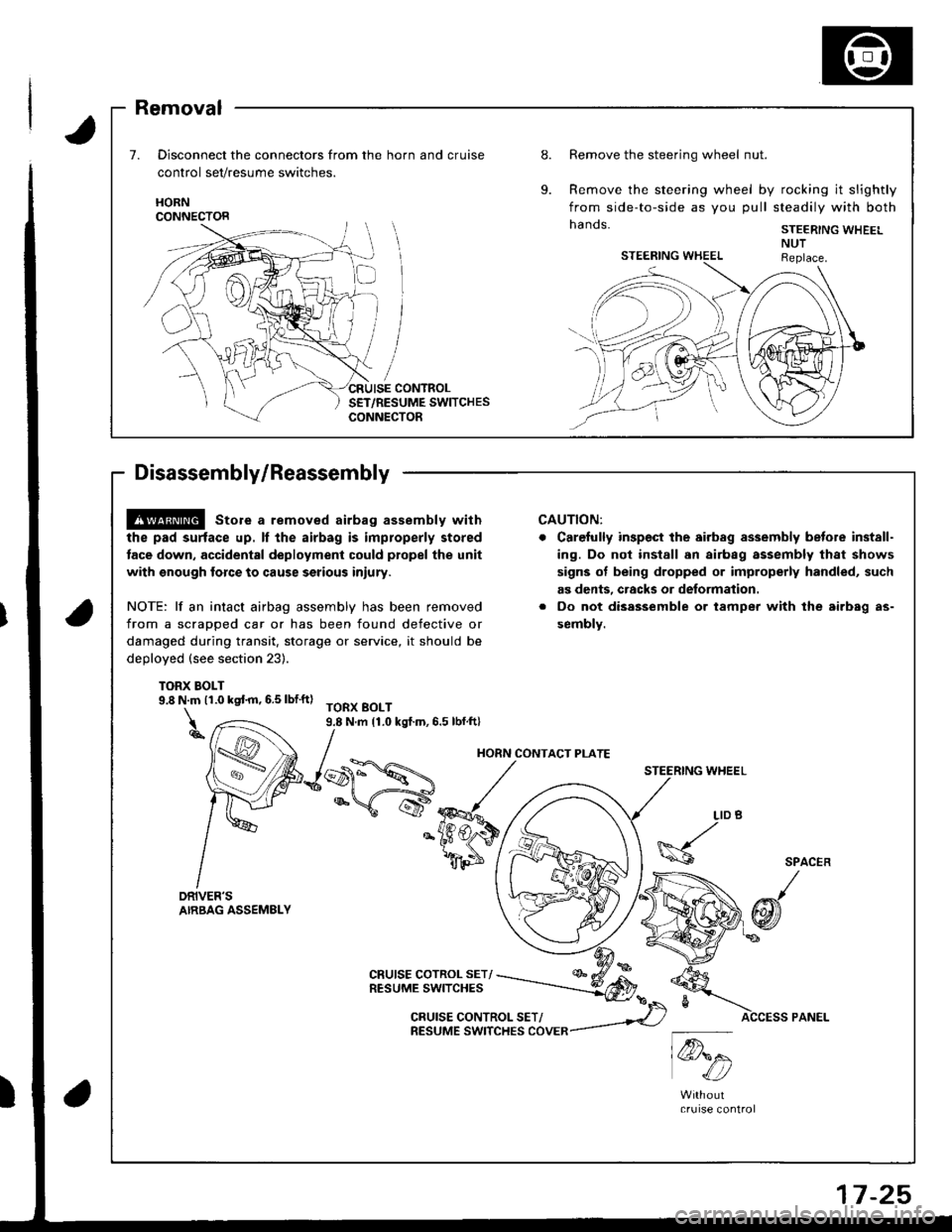

Removal

Disconnect the connectors from the horn and cruise

control set/resume switches.

Remove the steering wheel nut.

Remove the steering wheel by rocking it slightly

from side-to-side as you pull steadily with both

hands. STEER|NG WHEEL

HORNCONNECTOR

7 -25

@ store a removed airbag assembly with

the pad surtace up. ll the airbag is improperly stored

tace down. accidental deployment could propel the unit

with snough force to cause serious iniury.

NOTE: lf an intact airbag assembly has been removed

from a scrapped car or has been found defective or

damaged during transit, storage or service, it should be

deDloyed (see section 23).

TORX BOLT9.8 N.m (1.0 kqt m, 6.5 lbf'ft)TORX BOLT9.8 N.m 11.0 kgf.m,6.5 lbf.ft)

CRUISE COTROL SET/RESUME SWITCHES

CAUTION:

Carefully inspect the airbsg assembly betore inst8ll-

ing. Do nol install 8n airbag assembly that shows

signs ot being dropped or improperly handled, such

as dents, cracks or deformation.

Oo not disassemble or tampel with the airb8g as-

sembly.

STEERING WHEEL

\@.

LID

h6

w1c4:,/bA

4t

SPACER

@f

CRUISE CONTROL SET/RESUME SWITCHES COVER

HORN CONTACT PLATE

Page 676 of 1681

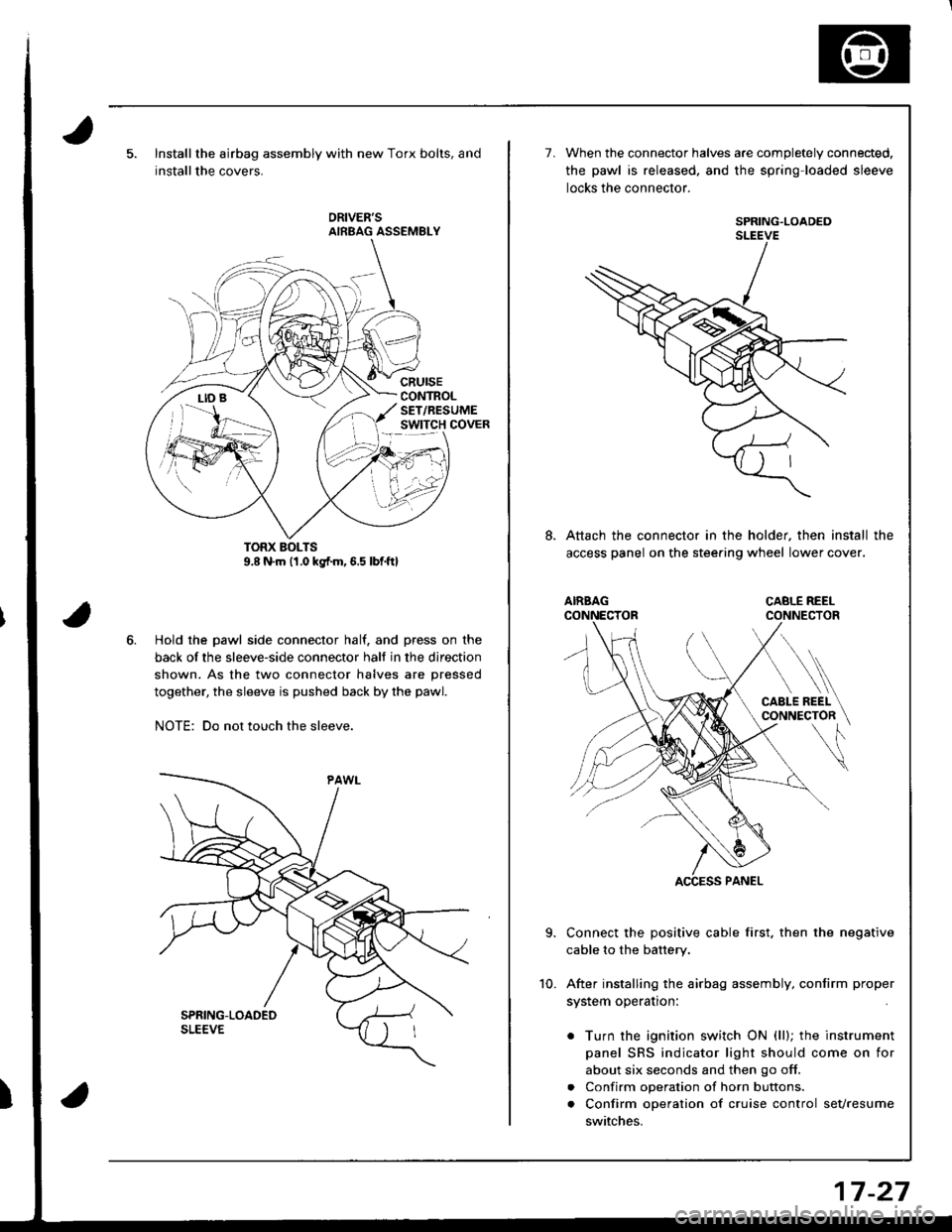

Installthe airbag assembly with new Torx bolts, and

installthe covers.

cRursECONTROLSET/RESUMEswtTcH covER

Hold the pawl side connector half. and press on the

back of the sleeve-side connector halt in the direction

shown. As the two connector halves are pressed

together, the sleeve is pushed back by the pawl.

NOTE: Do not touch the sleeve.

7.When the connector halves are completely connected.

the pawl is released. and the spring loaded sleeve

locks the connector.

SPRING.LOADEDSLEEVE

Attach the connector in the holder, then install the

access panel on the stee.ing wheel lower cover.

Connect the positive cable first. then the negative

cable to the battery.

After installing the airbag assembly, confirm proper

system operation:

. Turn the ignition switch ON (ll); the instrument

panel SRS indicator light should come on for

about six seconds and then go off.

. Confirm operation of horn buttons.

. Confirm operation of cruise control sevresume

switches.

10.

17-27

Page 707 of 1681

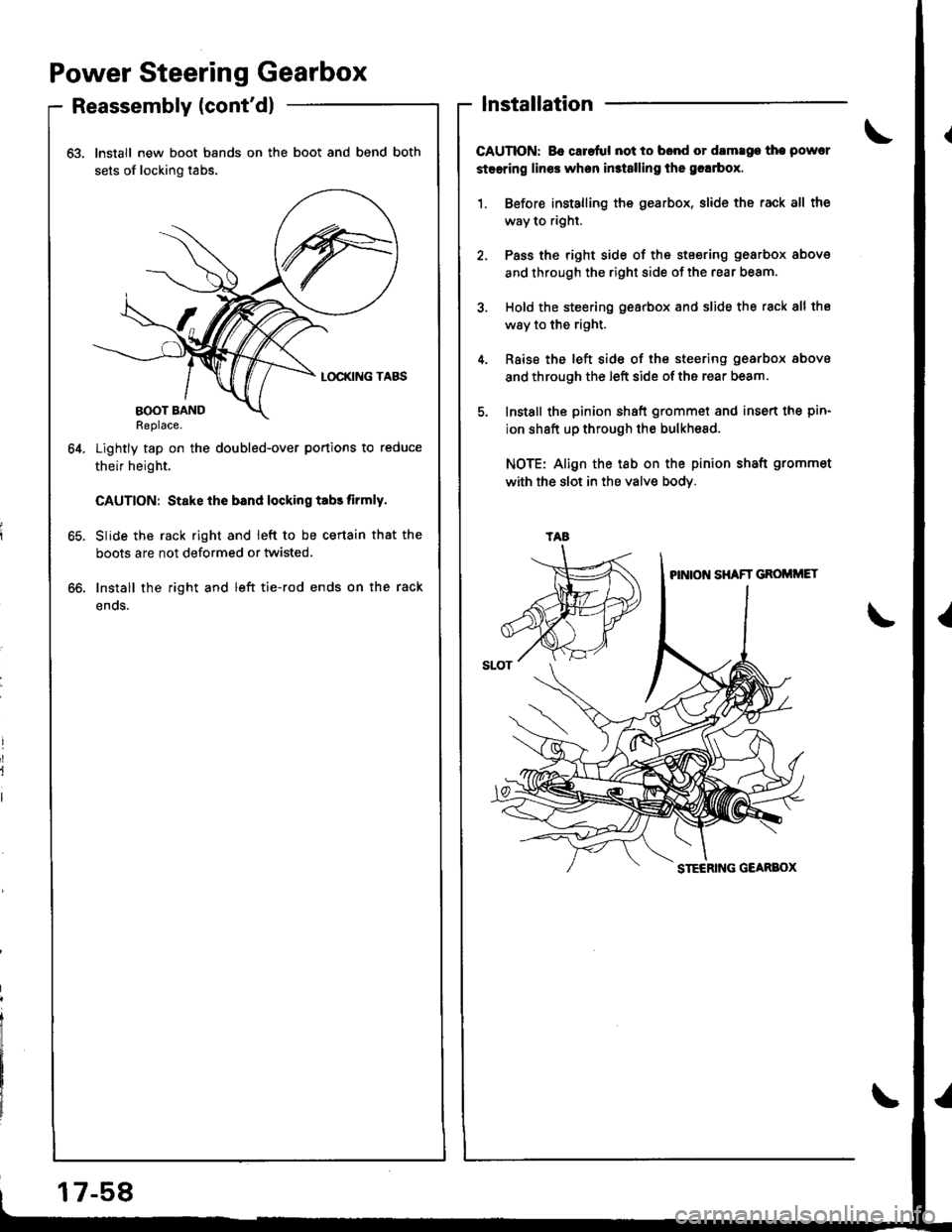

Power Steering Gearbox

Reassembly (cont'dl

63. Install new boot bands on the boot and bend both

sets of locking tabs.

Lightly tap on the doubled-over portions to reduce

their height.

CAUTION: Stake ihe bsnd locking tabs tirmly.

Slide the rack right and ieft to be certain that the

boots are not deformed or twisted.

Install the right and left tie-rod ends on the rack

enos.

64.

lnstallation

CAUTION: Bo caretul not to bond or damrge the powcr

steering lines when in3t8lling the grlrbox.

1. Before installing the gearbox, slide the rack all the

way to right.

2, Pass the right side of the stsering gearbox above

and through the right side of the rear beam.

3. Hold the steering gearbox and slide the rack 8ll the

way to the right.

4. Rsise the left side of the steering gearbox above

and through the left side of the rear beam.

5. Install the pinion shaft grommet and insert the pin-

ion shaft up through the bulkhesd.

NOTE: Align the tab on the pinion shaft grommet

with the slot in the valve bodY.

oo.

tAa

17-58

Page 721 of 1681

1.

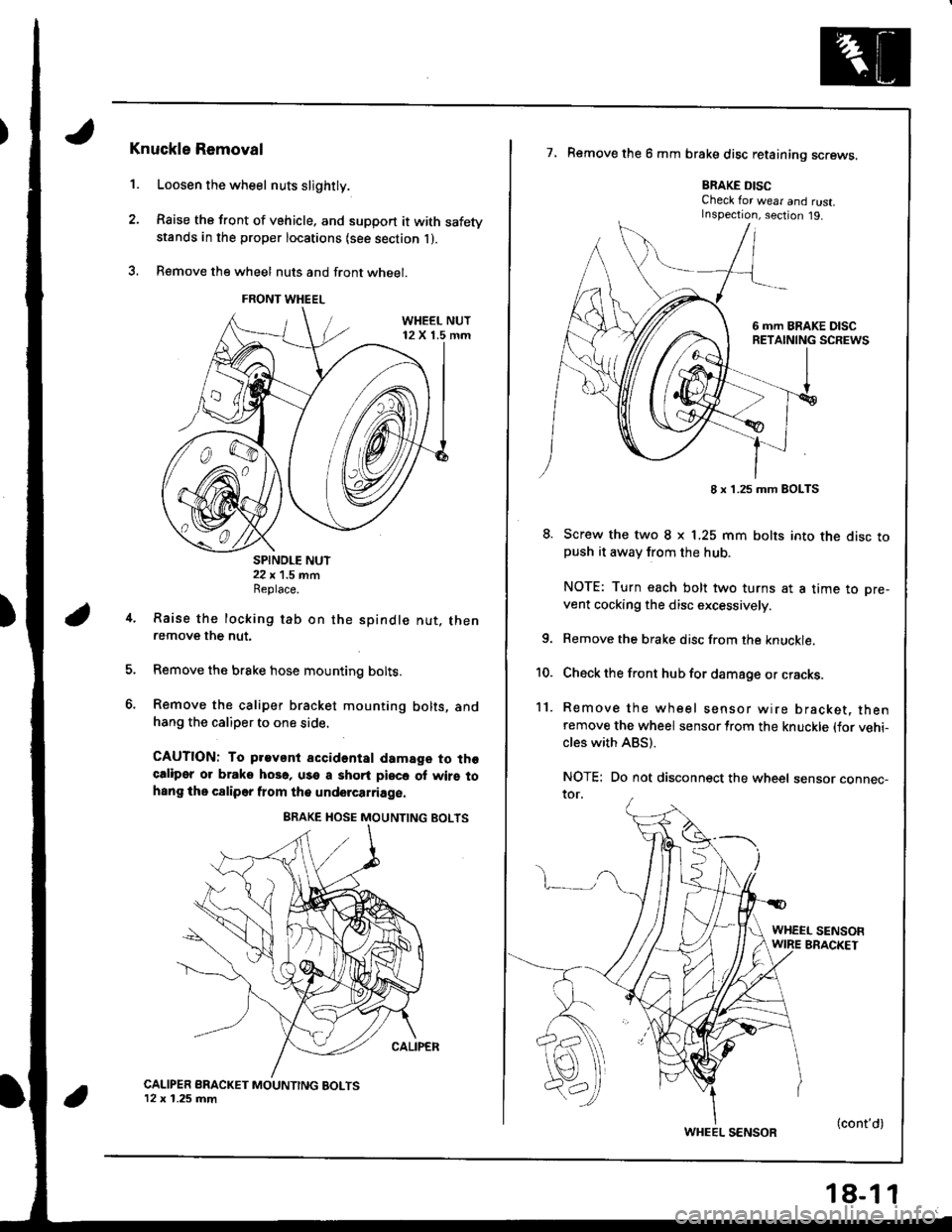

Knuckle Removal

Loosen the wheel nuts slightly.

Raise the front of vehicle. and support it with safetystands in the proper locations {see section l ).

B€move the wheel nuts and front wheel.

SPINDLE NUT22 x 1.5 mmReplace.

Raise the locking tab on the

remove the nut.

spindle nut. then

Remove the brake hose mounting bolts.

Remove the caliper bracket mounting bolts, andhang the caliper to one side.

CAUTION: To pravant accidental damage to thgcaliper or braks hoso, use a shqrt piece of wirs tohsng the c8liper flom the undercarriage.

CALIPER BRACKET MOUNTING BOLTS12 x 1.25 mm

7, Remove the 6 mm brake disc retaining screws.

BRAKE DISCCheck for wear and rust.Inspection, section j9.

8. Screw the two I x L25 mm bolts into the disc topush it awav from the hub.

NOTE: Turn each bolt two turns at a time to pre-

vent cocking the disc excessively.

Remove the brake disc from the knuckle.

Check the front hub for damage or cracks.

Remove the wheel sensor wire bracket, thenremove the wheel sensor lrom the knuckle (for vehi-cles with ABS).

NOTE: Do not disconnect the wheel sensor connec-ror.

4.

6.

10.

11.

WHEEL SENSOFWIRE BRACKET

FRONT WHEEL

8 x 1.25 mm BOLTS

WHEEL SENSOR(cont'd)

Page 739 of 1681

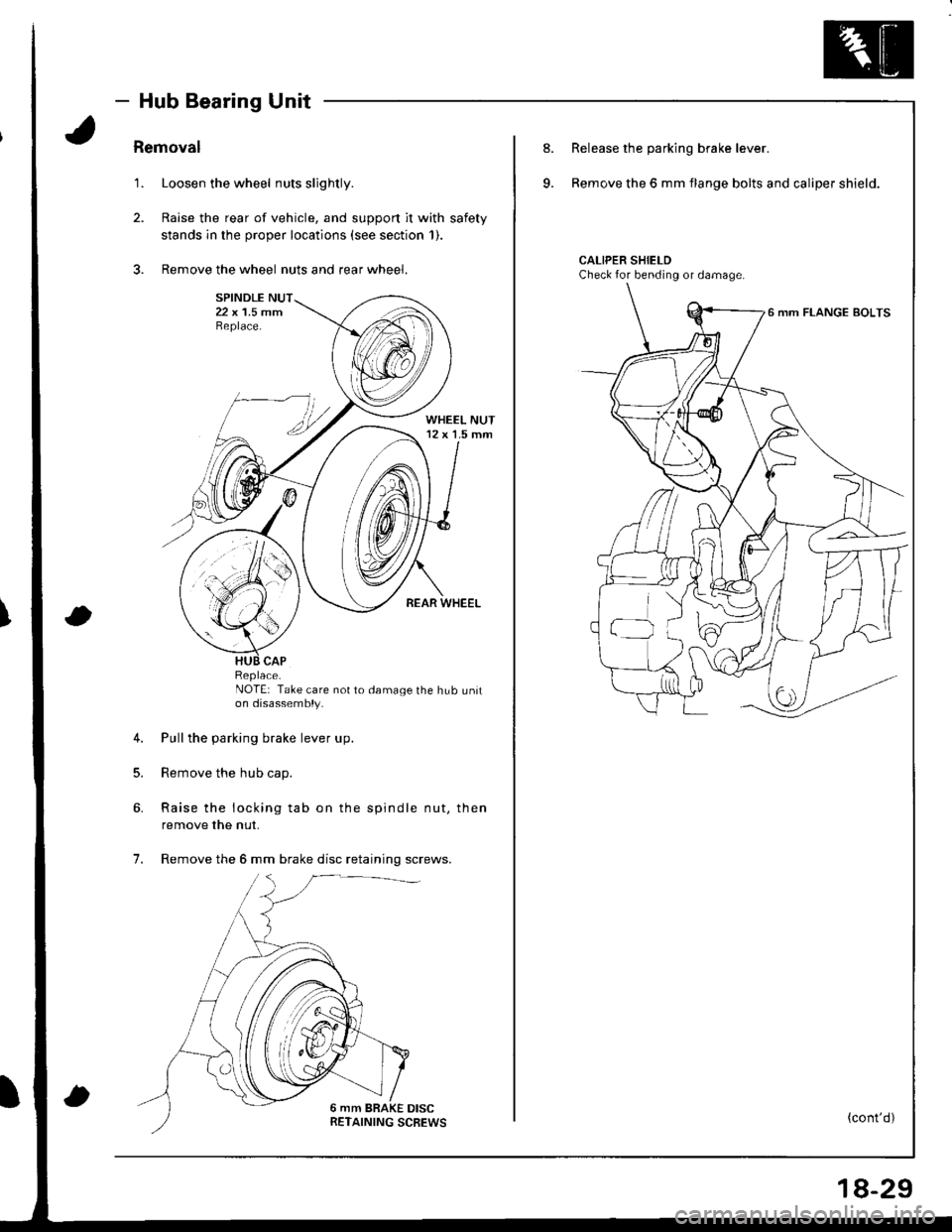

- Hub Bearing Unit

Removal

1. Loosen the wheel nuts slightly.

2. Raise the rear of vehicle, and support it with safety

stands in the proper locations (see section 1).

3. Remove the wheel nuts and rear wheel.

NOTE: Take care not to damage the hub uniton disassembly.

4. Pull the parking brake lever up.

5. Remove the hub cap.

6. Raise the locking tab on the spindle nut, then

remove the nut.

7. Remove the 6 mm brake disc retaining screws.

Replace.

8.

9.

Release the parking brake lever.

Remove the 6 mm flange bolts and caliper shield.

CALIPER SHIELDCheck for bending or damage.

6 mm FLANGE BOLTS

(cont'd)

18-29

Page 757 of 1681

a

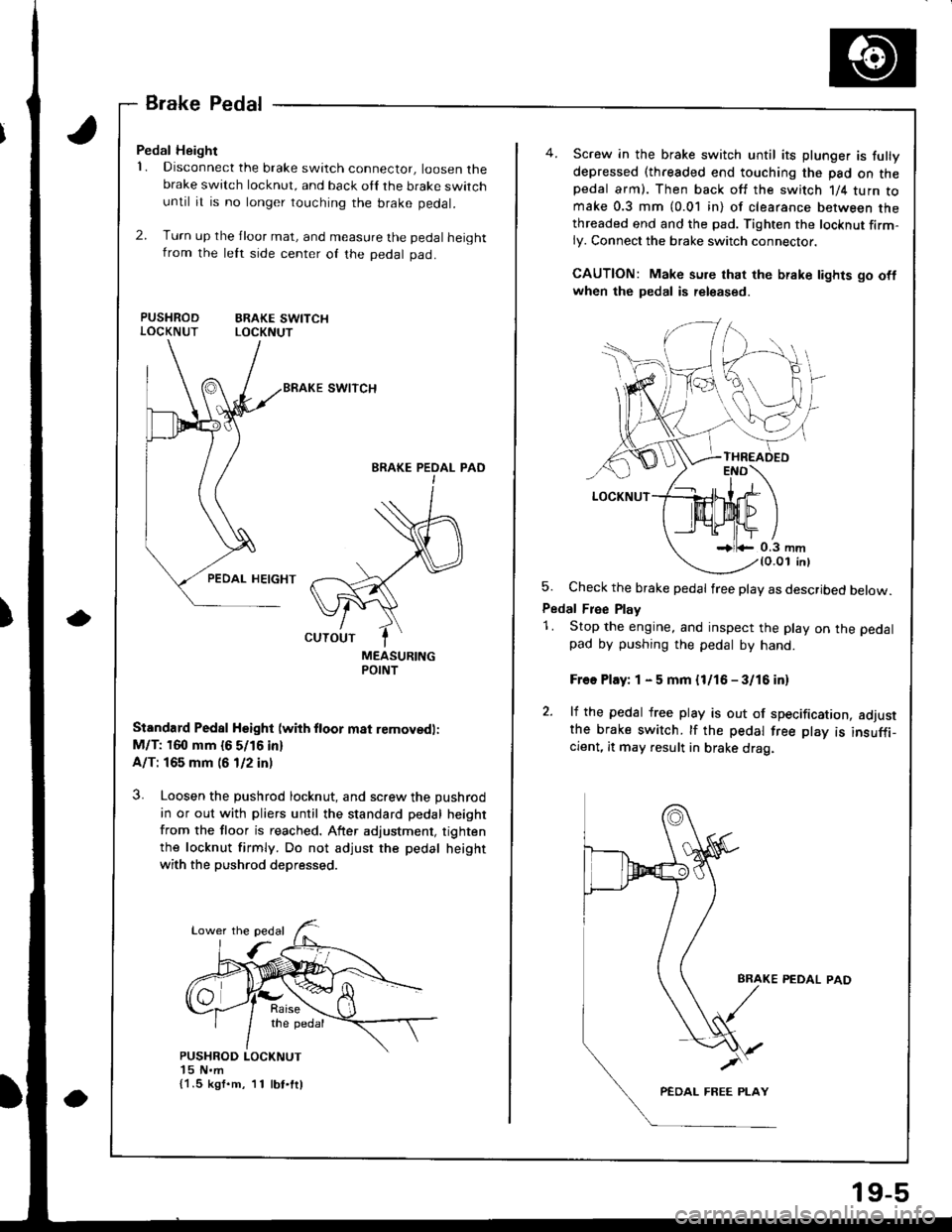

BrakePedal

Pedal Height

1. Disconnect the brake switch connector, loosen thebrake switch locknut, and back oll the brake switchuntil it is no longer touching the brake pedal.

2. Turn up the jloor mat, and measure the pedal heightfrom the lett srde center of the pedal pad.

PUSHROD ERAKE SWITCHLOCKNUT LOCKNUT

swtTcH

BRAKE PEOAL PAOI

MEASURINGPOINT

Standard Pedal Hsight (wiih ftoor m8t removedl:

M/T: 160 mm {6 5/16 in}

A/T: 165 mm (6 1/2 in)

3. Loosen the pushrod locknut, and screw the pushrod

in or out with pliers until the standard pedal height

from the floor is reached. After adjustment, tighten

the locknut firmly. Do not adjust the pedal height

with the pushrod depressed.

{1.5 kgf.m, 11 lbt.ftl

19-5

Screw in the brake switch until its plunger is fully

depressed (threaded end touching the pad on thepedal arm). Then back off the switch 1/4 turn tomake 0.3 mm (0.01 in) of clearance between thethreaded end and the pad. Tighten the locknut firm-ly. Connect the brake switch connector.

CAUTION: Make sure that the brake lights go oflwhen the pedal is released.

5. Check the brake pedal free play as described below.

Pedal Free Play

1. Stop the engine, and inspect the play on the pedal

pad by pushing the pedal by hand.

Free Play: 1 - 5 mm {l/16 - 3/16 in)

2. lf the pedal free play is out of specification, adjustthe brake switch. tf the pedal free play is insuffi_cient, it may result in brake drag.

PEDAL PAD

Page 758 of 1681

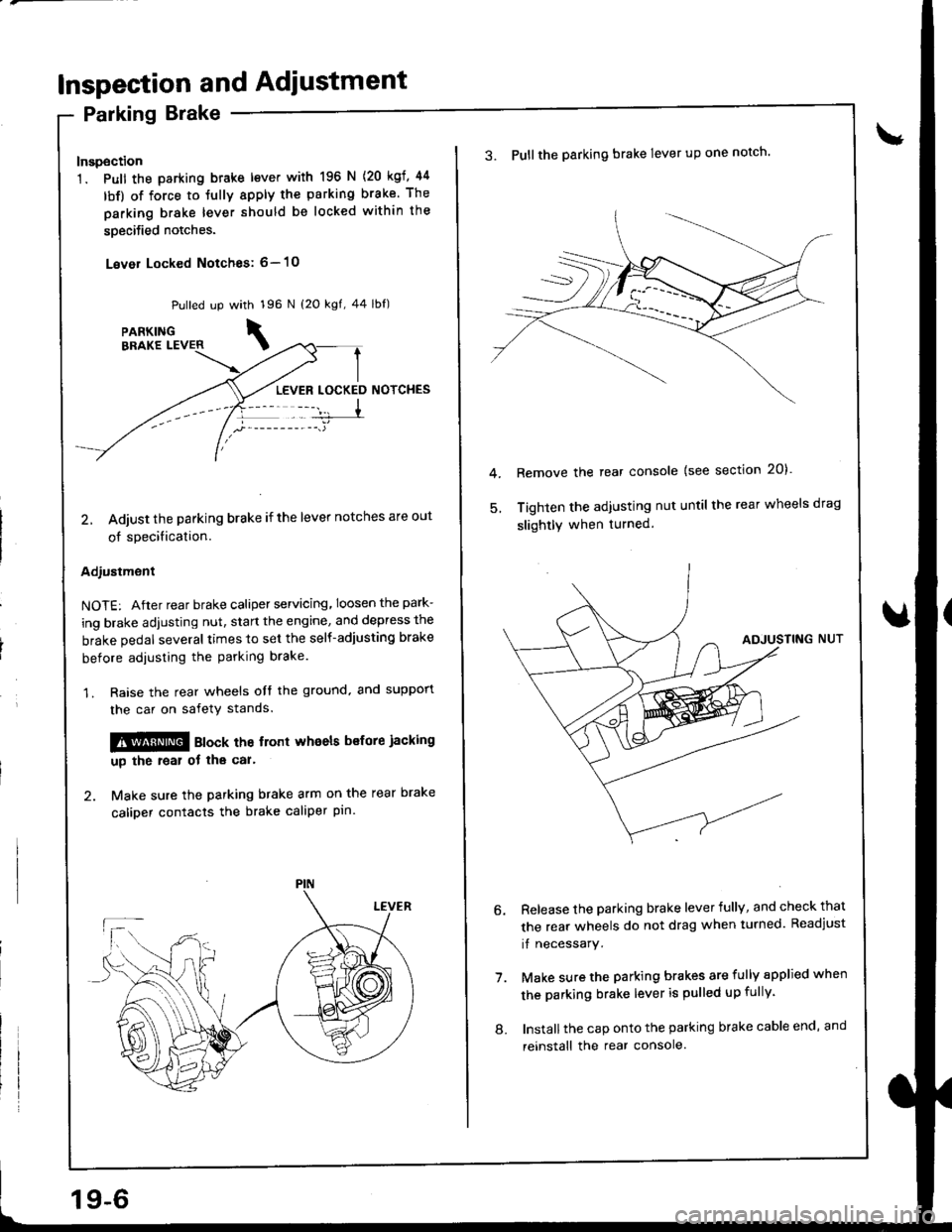

Inspection and Adiustment

Parking Brake

Inspection

1. Pull the parking btake lever with 196 N

lbf) of force to Jully apply the parking

parking brake lever should be locked

soecified notches.

Lever Locked Notches: 6- l0

{20 kgf, 44

brake. The

within the

Pulled up with 196 N {2O kgf, 44 lbf)

LEVER LOCKED NOTCHES

2, Adjust the parking brake if the lever notches are out

of specification.

Adjustment

NOTE: After rear brake caliper servicing.loosen the park-

ing brake adjusting nut, start the engine, and depress the

brake pedal several times to set the self-adjusting brake

before adiusting the parking brake

1. Raise the rear wheels oIt the ground. and suppon

the car on safety stands.

!!@ ato"t the trort whoels bsfore jacking

up the roal ot tha car'

2. Make sure the parking brake arm on the rear brake

caliDer contacts the brake caliper pin.

19-6

8.

3. Pullthe parking brake lever up one notch'

Remove the rear console {see section 20)'

Tighten the adjusting nut until the rear wheels drag

slightly when turned.

7.

Release the parking brake lever fully, and check that

the rear wheels do not drag when turned. Readjust

if necessary.

Make sure the parking brakes are fully spplied when

the parking brake lever is pulled up fully.

Install the cap onto the parking brake cable end, and

reinstall the rear console.

Page 760 of 1681

Front Brake Pads

Inspection and Replacement

fi

1i

INNER PAO SHIMSCheck lor weakness.(All .xc.pt Typc Rmodoll i

INNER PADCheck for woar.

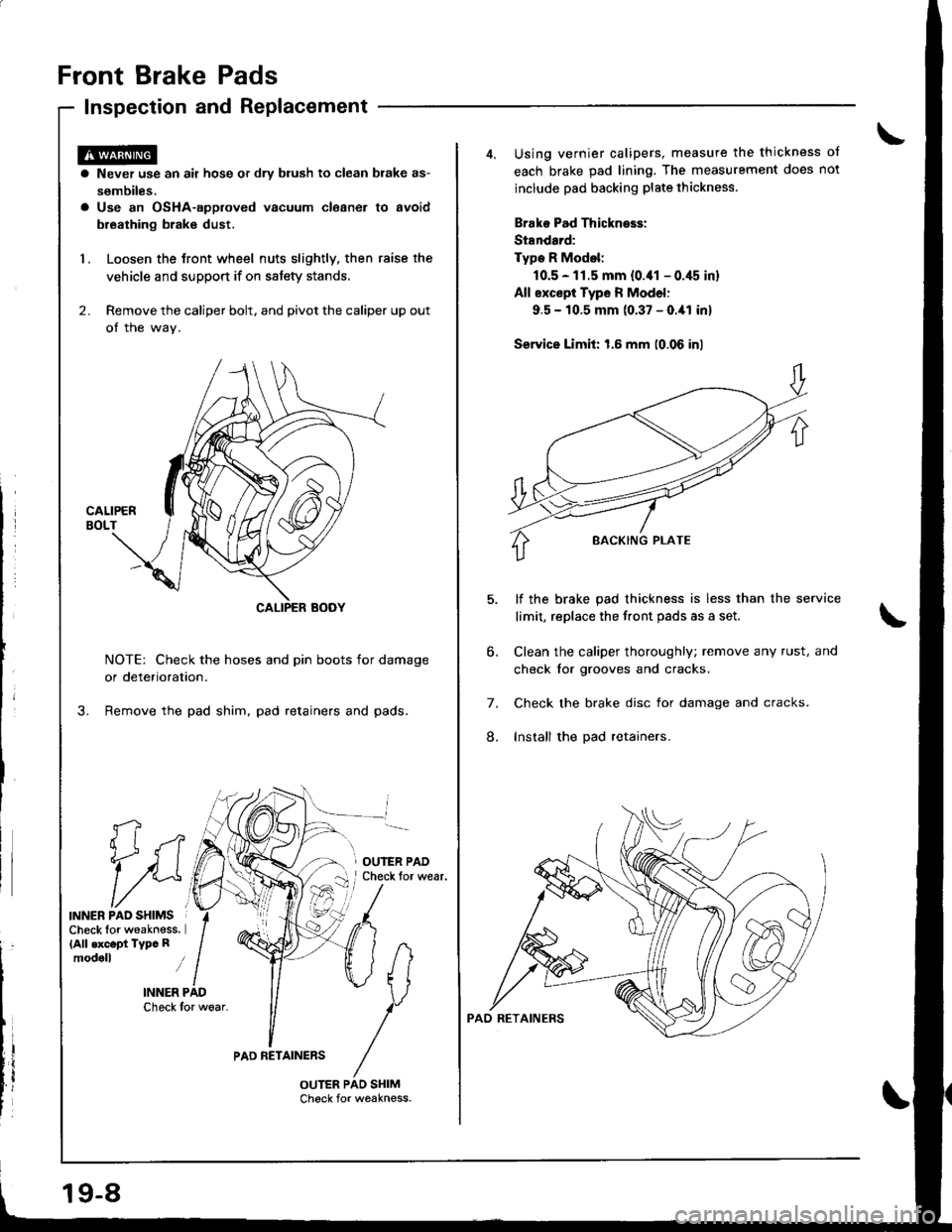

a Never use an air hose or dry blush to clean brake as-

sembiles.a Use an OsHA-approved vacuum cleaner to avoid

breathing brak€ dust.

1. Loosen the Jront wheel nuts slightly, then raise the

vehicle and support if on satety stands,

2. Remove the caliper bolt, and pivot the caliper up out

of the wav.

NOTE: Check the hoses and pin boots for damage

or deterioration.

Remove the pad shim, pad retainers and pads.

OUIER PADCheck tor wear.

PAD RETAINERS

19-8

Using vernier calipers, measure the thickness ot

each brake pad lining. The measurement does not

include pad backing plate thickness.

Brako Pad Thickness:

St8ndard:

Type R Modol:

10.5 - 11.5 mm {0.41 - 0.45 in}

All except Type R Model:

9.5 - 10.5 mm (0.37 - O.ial inl

Service Limit: 1.6 mm (0.06 inl

lf the brake pad thickness is less than the service

limit, replace the front pads as a set,

Clean the caliper thoroughly; remove any rust, and

check tor grooves and cracks.

Check the brake disc for damage and cracks.

Install the pad retainers.

6.

7.

8.

Page 762 of 1681

Front

Disc

Brake

Runout

Disc

InspectionDisc Thickness and Parallelism

\'L

2.

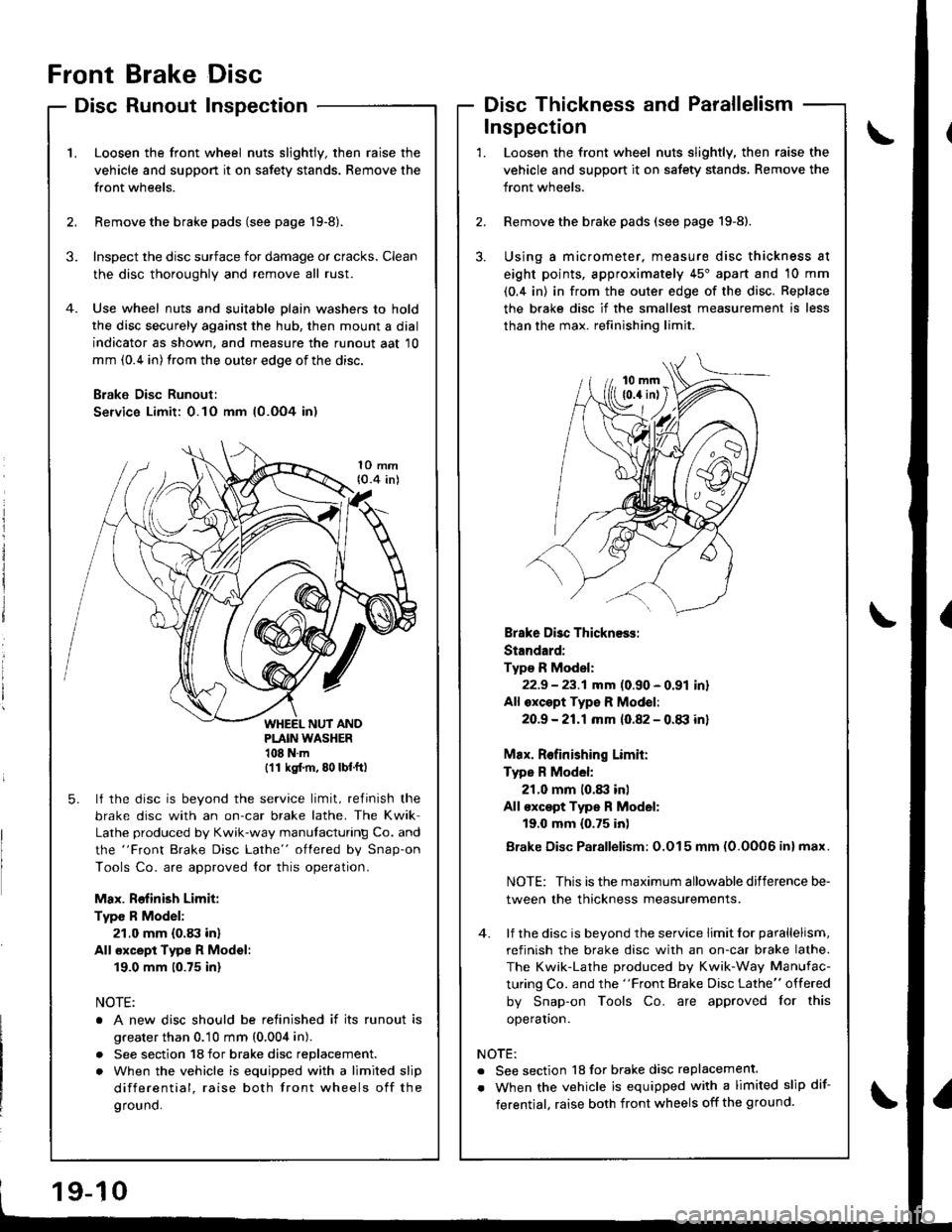

Loosen the front wheel nuts slightly, then raise the

vehicle and suppon it on safety stands. Remove the

front wheels.

Remove the brake pads (see page 19-8).

Inspect the disc surface for damage or cracks. Clean

the disc thoroughly and remove all rust.

Use wheel nuts and suitable plain washers to hold

the disc securely against the hub, then mount a dial

indicator as shown, and measure the runout aat 10

mm (0.4 in) from the outer edge of the disc.

B;ake Disc Runoul:

Service Limit: 0.10 mm (0.OO4 in)

3.

1O mm{0.4 inl

PLAIN WASHER108Nm(11 ksl.m, 80 lbf.ft)

5. lf the disc is beyond the service limit, refinish the

brake disc with an on-car brake lathe. The Kwik

Lathe produced by Kwik-way manutacturing Co. and

the "Front Brake Disc Lathe" oflered by Snap-on

Tools Co. are approved {or this operation.

Max. Rofinish Limit:

Type R Model:

21.0 mm (0.83 in)

All €xcept Type R Model:

19.0 mm (0.75 inl

NOTE:

o A new disc should be relinished if its runout is

greater than 0.10 mm (0,004 in).

. See section 18 for brake disc replacement.

. When the vehicle is equipped with a limited slip

differential, raise both front wheels off the

ground.

3.

Loosen the front wheel nuts slightly, then raise the

vehicle and support it on safety stands, Remove the

front wheels.

Remove the brake pads (see page 19-8).

Using a micrometer, measure disc thickness at

eight points, approximately 45'apart and 10 mm

(0.4 in) in from the outer edge of the disc. Replace

the brake disc if the smallest measurement is less

than the max. refinishing limit.

Inspection

2.

1.

Brake Disc Thickness:

Standard:

Type R Model:

22.9 - 23.1 mm (0.90 - 0.91 inr

All oxcept Typ€ R Mod€l:

2O.9 -21.1mm 10.82 - 0.tB inl

Max. Relinishing Limit:

Type R Model:

21.0 mm 10.83 inl

All €xc€pt Type R Model:

19.0 mm {0.75 inl

Brake Disc Parallelism: O.O15 mm (0.0006 inl max.

NOTE: This is the maximum allowable difference be-

tween the thickness measurements.

4. lf the disc is beyond the service limit lor parallelism,

refinish the brake disc with an on-car brake lathe.

The Kwik-Lathe produced by Kwik-Way Manufac-

turing Co. and the "Front Brake Disc Lathe" offered

by Snap-on Tools Co. are approved for this

operaton.

NOTE:

. See section 18 for brake disc replacement.

. When the vehicle is equipped with a limited slip dif-

ferentjal, raise both front wheels off the ground.