wiring HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 45 of 1681

Engine Removal/lnstallation

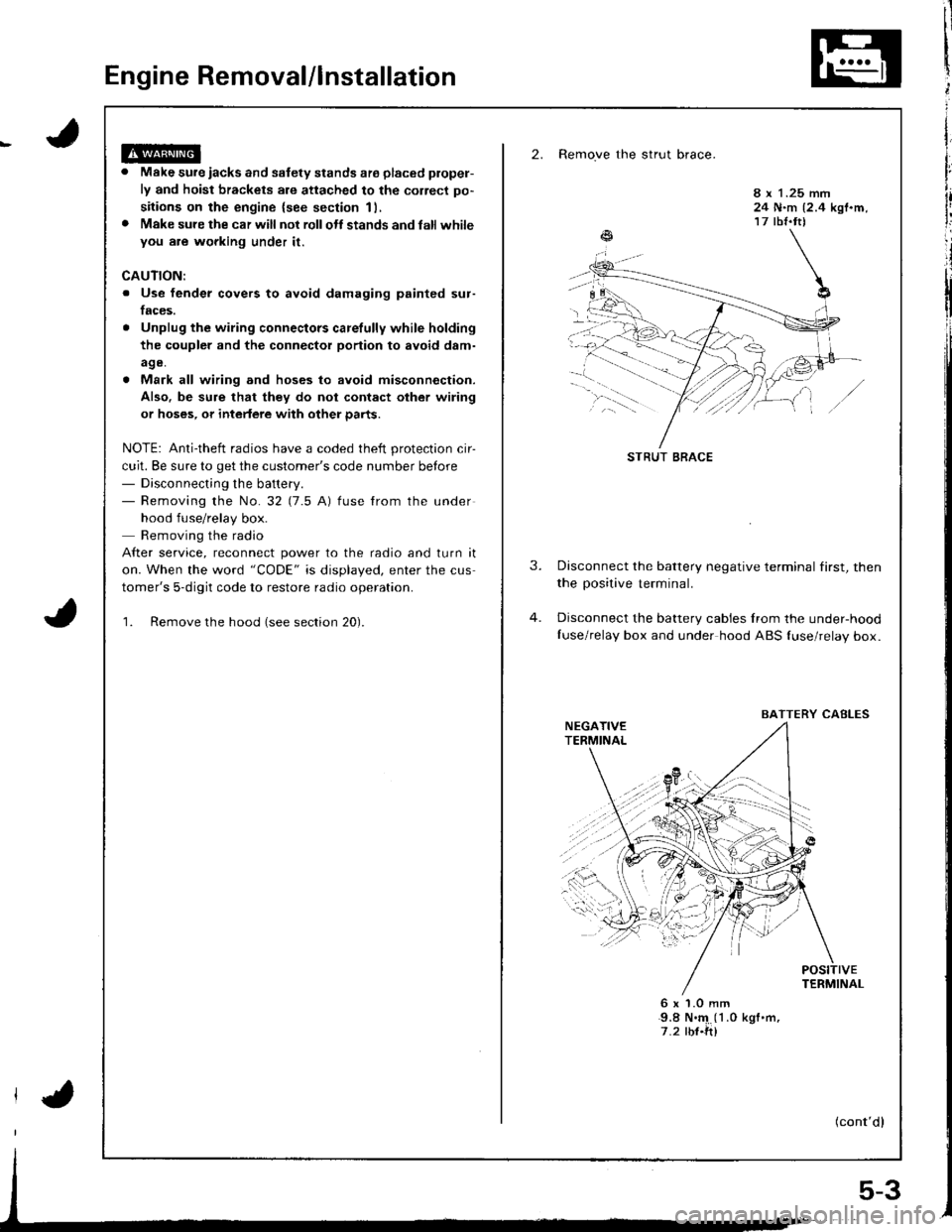

2. Remove the strut brace.

Make sure iacks and safety stands ate placed plopel-

ly and hoist brackets are attached to the correct po-

sitions on the engine {see section 11,

Make sure the car will not rollolt stands and latl whileyou are wgrking under it.

8 x 1.25 mm24 N.m {2.4 kgf.m,17 tbf.tt)

CAUTION:

. Use fender covers to avoid damaging painted sur-

faces.

Unplug the wiring connectors carelully while holding

the coupler and the connector portion to avoid d8m-

age.

Mark all wiring and hoses to avoid misconnection.

Also. be sure that they do not contact other wiring

or hoses, or intedere with other parts.

NOTE: Anti-theft radios have a coded theft protection cir-

cuit. Be sure to get the customer's code number betore- Disconnecting the battery.- Removing the No.32 (7.5 A) fuse from the under

hood fuse/relay box.

Removing the radio

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus

tomer's 5-digit code to restore radio operation.

1. Remove the hood (see section 20).

3.Disconnect the battery negative terminal first, then

the positive terminal.

Disconnect the battery cables Irom the under-hood

Iuse/relay box and under hood ABS {use/relay box.

6x1.0mm9.8 N.'4 (1 .0 kgf .m,

7.2 rbf.ft)

(cont'dl

STRUT BRACE

BAITERY CABLES

5-3

Page 650 of 1681

Steering

Componsnt Location

lndox

*Stooring Wheel

Removal ....

Disassombly/Ro8$.mbly

Disassombly ......

F08$€mbly

Powcr Stosring Gosrbox

R6moval

............................ 17-3

............. 17 -1

................ 17-16

............................. 17_25

17-30

17.31

.......17-21

Sy3tom DGcription

Fluid Flow Disgram

Steering Pump .............. 17-5

Stocring Goarbox ...17.8

Troublorhooting

Gonoral Troubleshooting .............................. 17.10

Noiso lnd Vibration ...... 17-1i[

Fluid Losk3

lnspoction

Installation

Powor Steering Hos6, Lino3

Roplacom€nt .................. 17.34

Powor Steoring Pump

RGplac6montlolpeqtion lnd Adiu3tm6nl

Stoo.ing Operation

Powor A$bi Chock

with v.hiclo Parked

Stcering Linkage 6nd Goarbox

Pump Bolt

17.18

17.18

17.19

17-20

17.35

t7-36

17 -37

r7-39

Inspoction

................... 17.41

Rack Guide Adiustmont ..........................-.-.-. 17 -21

Ffuid Rcplacemont ........17-21

Pump Prc&suro Chock ...,........................,..,..., 17 -22

Fluid Leakage Inrpection ............................... 17-23

Dissssembly

R€aEs€mbly

In3tallation........... 17_58

Ball Joint Boot Replacem.ni ........................ 17-61

17-U

17.49

J ,urrar*TNTAL REsrRArNr sysrEM (sRsr

The Integra SRS includes a driver's airbag located in the steering wheel hub and a passenger's airbag located inthe dashboard above the glove box,

Information necessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk(*) on the contents page include, or are located near, SRS components. Servicing, dissssembling or replacing

these items will require special pr6cautions and tools, and should therefore be done by an authorized Acura dealer.

. To avoid rondoring ths SRS inoparstivo. which could |rad to parsonal iniury or doath in the ov€nt of ! sev6.o

trontal collision, all SRS sarvice work must be perto.med by an authorizod Acura dsalor.. lmpropor 3orvic€ procadures, including inco[6ql rgmoval and inrtallation of the SRS, could l6ad to pgrsonal

iniury clus€d by unintentional doployment of the airbags,. Do nol bump tho SRS unh, (Xherwise, th6 3ystom may fail in cas€ ol a collision, or the airbags may d€ploy

when ths ignition switch is ON {ll).. All SRS electrical wiring harness€s aro covered with yallow insulation. Related component3 are located in ths

stcaring column. tront con3ol6, dashboard, d.shbolrd lower panel, and in the dashboard above ths glove box.

Do not u3o electrical test oquipm€nt on the3e circuii3.

NOTE: The original radio has a coded theft protection circuit. Be sure to get the customer's code number before- disconn€cting the battery.- removing the No. 47 (7.5 A) fuse from the under-hood fuse/relay box,- removing the radio.

After service, reconnect power to the radio and turn it on. When the word "CODE" is displayed. enter the cus-

tomer's 5-digit code to restore radio operation.

Page 1022 of 1681

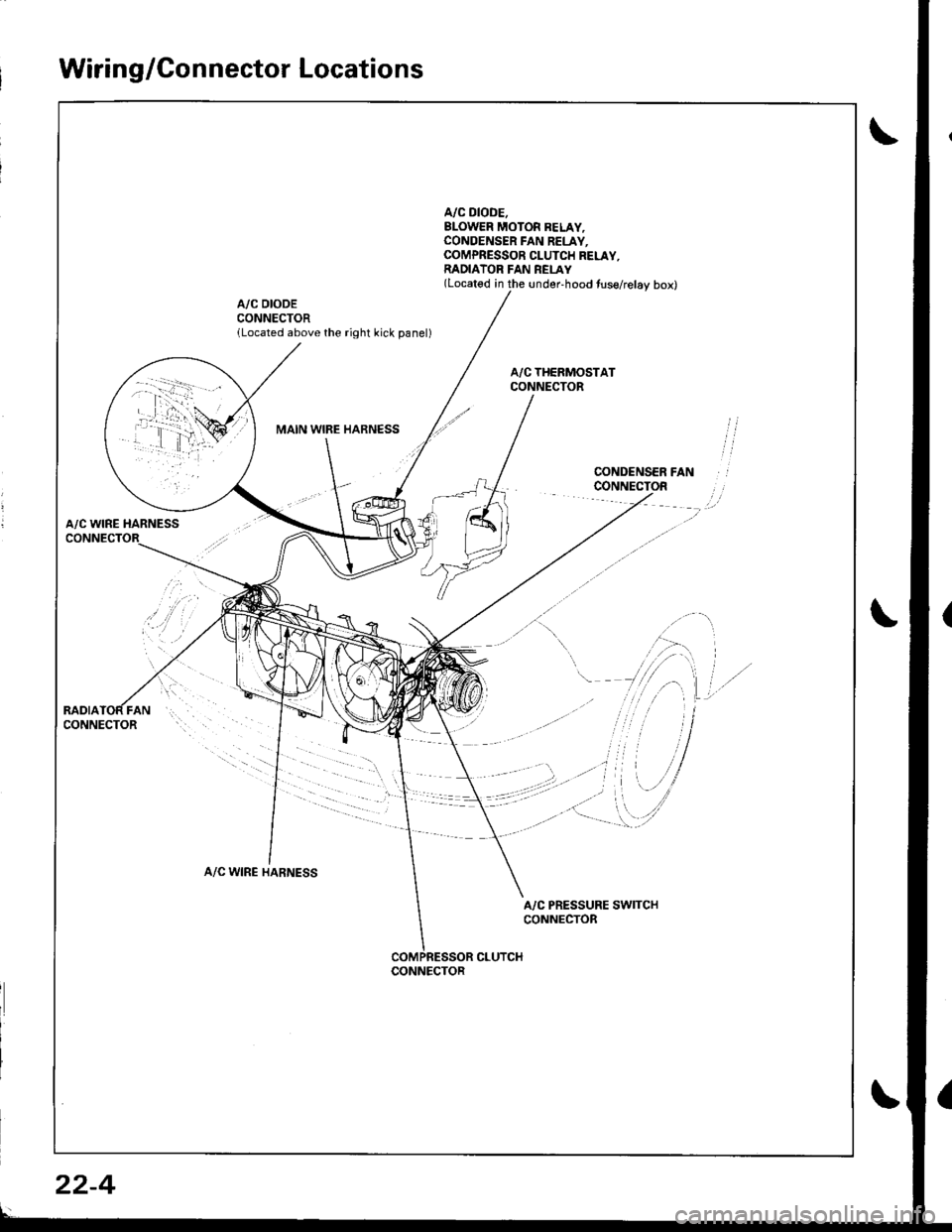

Wiring/Connector Locations

A/C DIODE.BLOWER MOTOR BELAY,CONOENSER FAN RELAY.COMPRESSOR CLUTCH RELAY,RADIATOR FAN REI-AY(Located in the under-hood tuse/relay box)

A/C DIODECONNECTORlLocated above the right kick panel)

MAIN WIBE HARNESS

A/C WINE HARNESS

A/C WIRE HARNESS

A/C PRESSURE SWITCHCONNECTOR

CLUTCHCONNECTOR

22-4

Page 1060 of 1681

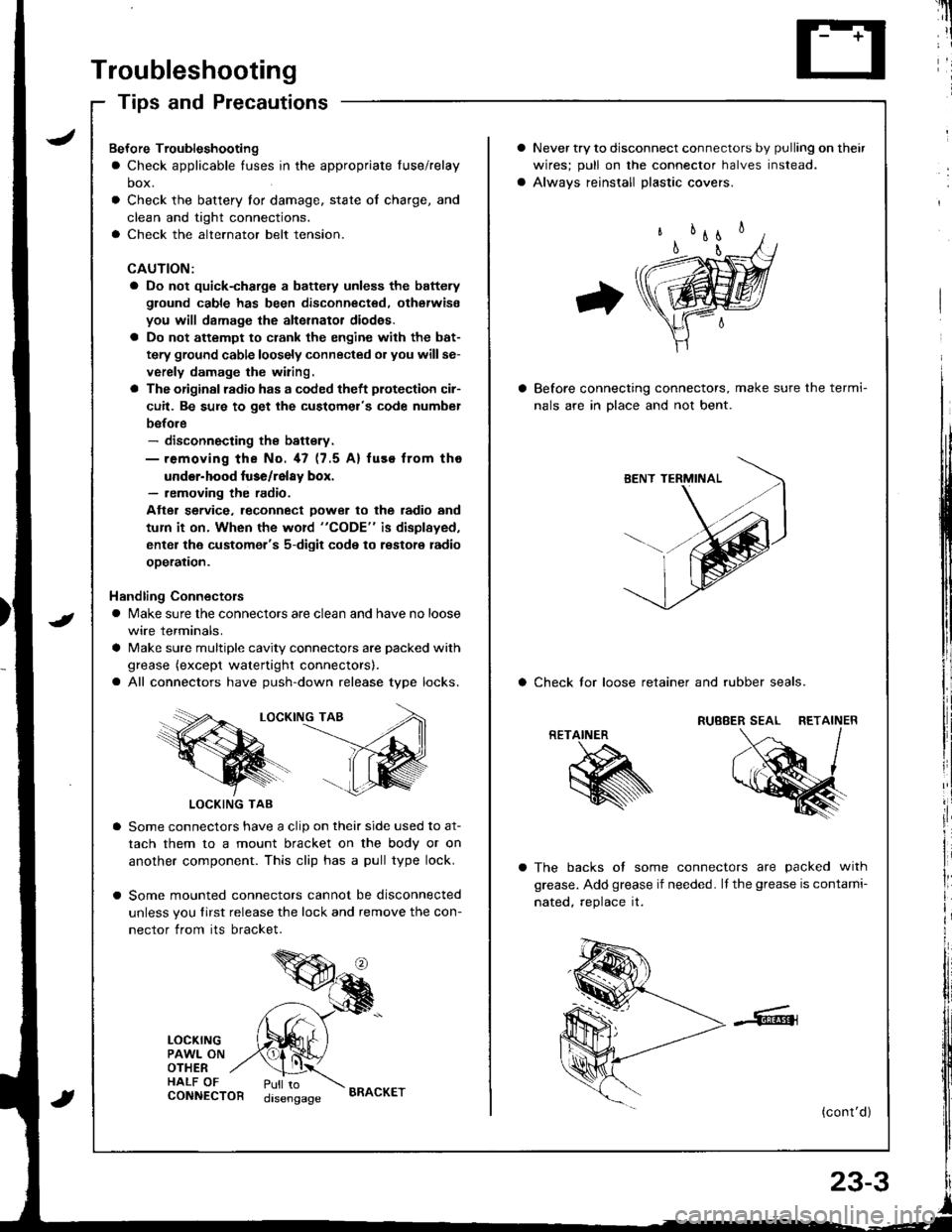

Troubleshooting

Tips and Precautions

Never try to disconnect connectors by pulling on their

wires; pull on lhe connector halves instead.

Alwavs reinstall Dlastic covers.

Before connecting connectors, make sure the termi-

nals are in Dlace and not bent.

a Check lor loose retainer and rubber seals.

The backs of some connectors are packed with

grease. Add grease if needed. lf the grease is contami-

nated, reolace it.

(cont'd )

RETAINER

K

Bef ore Troubleshooting

a Check applicable tuses in the appropriate fuse/relay

box.

Check the battery for damage, state of charge, and

clean and tight connections.

Check the alternator belt tension.

CAUTION:

a Do not quick-charge a battely unless the battery

ground cable has been disconnected. otherwise

you will damage the alternator diod€s.

a Do not attempt to crank the engine with the bat-

tery ground cable loosely connected or you willse-

verely damage the wiring.

a The originsl radio has a coded theft plotection cir-

cuit. Be sure to get the customel's code numbel

before- disconnecting the battsry.- removing the No. 47 (7.5 A) fuse from tho

under-hood luse/relay box.- removing the radio.

Atter service. leconnect Dower to the radio and

tum it on. When the word "CODE" is displayed,

enter the customer's 5-digit code to restore radio

ooeration.

Handling Connectors

a Make sure the connectors are clean and have no loose

wire terminals.

a Make sure multiple cavity connectors are packed with

grease (except watertight connectors).

a All connectors have push-down release type locks.

LOCKING TAB

LOCKING TAB

Some connectors have a clip on their side used to at-

tach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you tirst release the lock and remove the con-

nector from its bracket.

LOCKINGPAWL ONOTHERHALF OFCONNECTORPull todisengageBRACKET

Page 1190 of 1681

I

Seat Belt Reminder

SystemLow Fuel lndicator

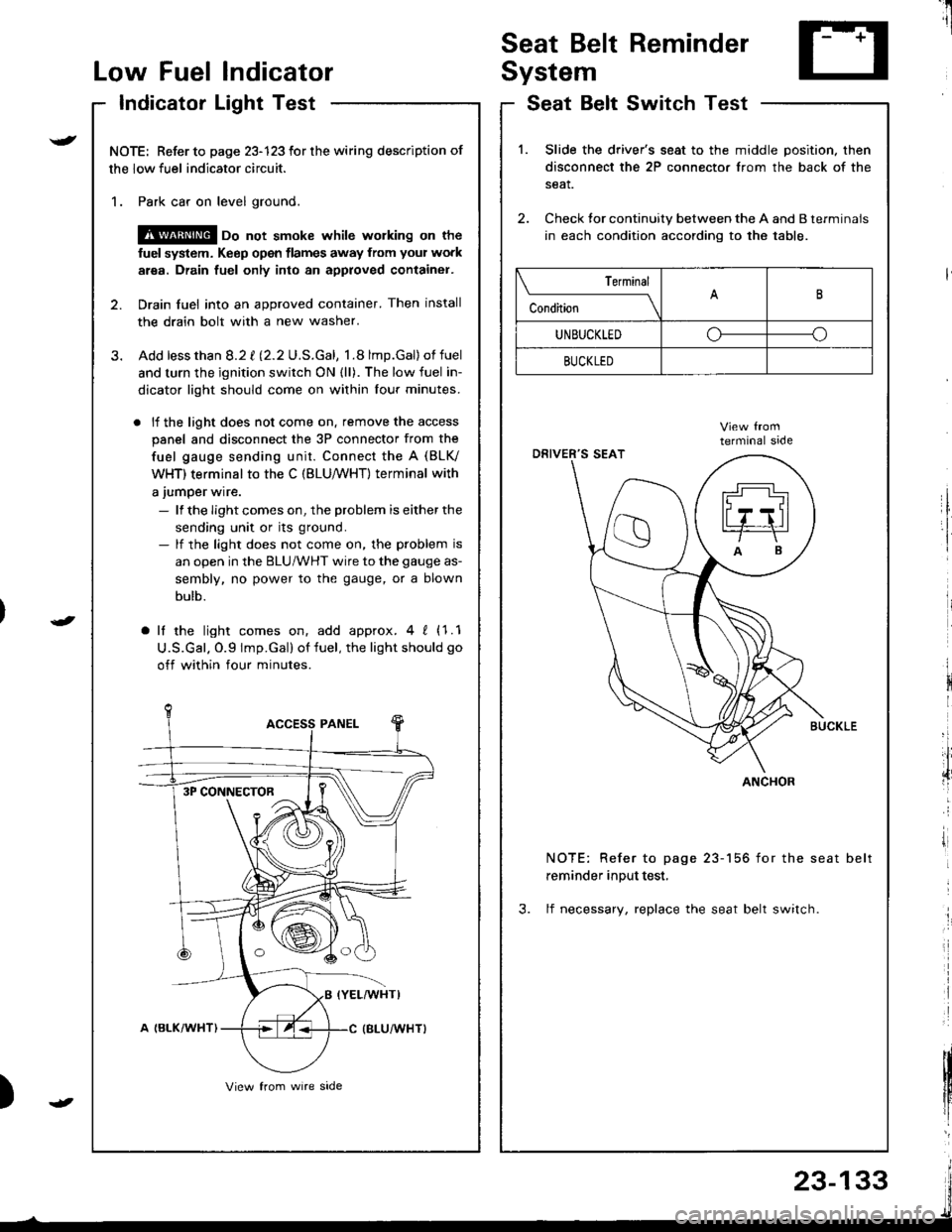

Indicator Light Test

NOTE: Refer to page 23-123 for the wiring description of

the low fuel indicator circuit.

1. Park car on level ground.

@ oo not smoke whilc wolking on the

fuel system. Keep open tlames away from your work

area. Drain fuel only into an approved container.

2. Drain fuel into an approved container. Then install

the drain bolt with a new washer.

3. Add lessthan 8.2 t l2.2U.S.Gal, 1.8 lmp.Gal)of fuel

and turn the ignition switch ON {ll). The low fuel in-

dicator light should come on within lour minutes.

. lf the light does not come on. remove the access

panel and disconnect the 3P connector from the

fuel gauge sending unit. Connect the A (BLV

WHT) terminal to the C (BLU,/WHT) terminal with

a jumper wire.

- lf the Iight comes on, the problem is either the

sending unit or its ground.- lf the light does not come on, the problem is

an open in the BLU/WHT wire to the gauge as-

sembly, no power to the gauge, or a blown

bulb.

a lf the light comes on, add approx.4 ! (1.1

U.S.Gal. O.9 lmp.Gal) of fuel, the light should go

off within four minutes.

I

i

)

SeatSwitchTestBelt

1.Slide the driver's seat to the middle position. then

disconnect the 2P connector from the back of the

seat.

Check tor continuity between the A and B terminals

in each condition according to the table.

NOTE: Refer to page 23-156 for the seat belt

reminder input test,

3. lf necessary, replace the seat belt switch.

Terminal

c""dil----lB

UNBUCKLEDoo

BUCKLED

ANCHOR3P CONNECTOR

23-133

Page 1191 of 1681

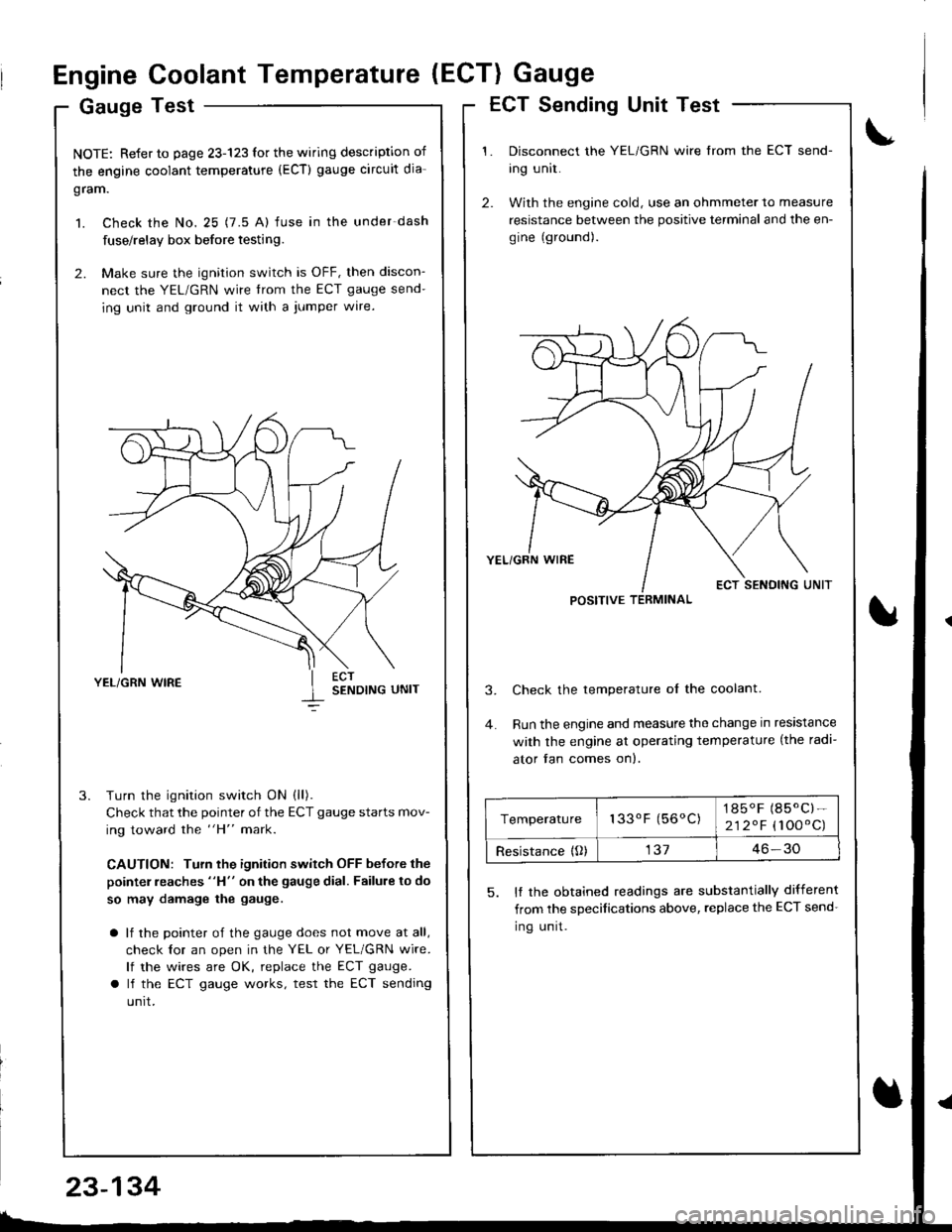

Engine Coolant Temperature (ECT) Gauge

Gauge Test

NOTE: Refer to page 23-123 for the wiring description of

the engine coolant temperature (ECT) gauge circuit dia-

gram.

1. Check the No. 25 (7.5 A) fuse in the under-dash

fuse/relay box before testing.

2. Make sure the ignition switch is OFF, then discon-

nect the YEL/GRN wire trom the ECT gauge send-

ing unit and ground it with a jumper wire.

YEL/GRN WIRESENDING UNIT

Turn the ignition switch ON (ll).

Check that the pointer of the ECT gauge starts mov-

ing toward the "H" mark.

CAUTION: Turn the ignition switch OFF before the

pointer reaches "H" on the gauge dial. Failure to do

so may damage the gauge.

a lf the pointer of the gauge does not move at all,

check lor an open in the YEL or YEL/GRN wire.

lf the wires are OK, replace the ECT gauge.

a lf the ECT gauge works, test the ECT sending

unrt.

ECT Sending Unit Test

Disconnect the YEL/GRN wire from the ECT send-

ing unit.

With the engine cold, use an ohmmeter to measure

resistance between the positive terminal and the en-

gine (ground).

Check the temperature ol the coolant.

Run the engine and measure the change in resistance

with the engine at operating temperature (the radi-

ator fan comes on).

5. It the obtained readings are substantially different

from the sDecifications above, replace the ECT send-

Ing unrt.

POSITIVE TERMINAL

Temperature133oF (56oC)1850F (85.C)-

212.F (100'C)

Resistance {O)13746-30

23-134

Page 1331 of 1681

Supplemental Restraint System (SRSI

Component/Wiring Locations

fndex ................ ......23-218

Description ................23-279

Circuit Diagram .........23-280

Precautions/Procedures

General Precautions ........................ 23-281

Airbag Handling and Storage .........23-281

SRS Unit Precautions ...................... 23-28P�

f nspection After Deployment ......... 23-282

Wiring Precautions .......................... 23-283

Backprobing Spring-loaded Lock

Troubleshooting

Seff-diagnostic Procedures ............. 23-287

Reading the DTC .................. ...........- 23-287

Erasing the DTC Memory ................ 23-289

Troubleshooting Intermittent

Failures .............. 23-289

Diagnostic Trouble Code (DTC)

Chart ................ ..23-290

SRS Indicator Light Wire

Connestions ...... 23-252

Ff owcharts .............23-293

Ailbag

Repf acement ......... 23-317

Disposaf .................23-320

Cable Reel

Replacement .........23-322

SRS Unit

Replacement .........23-326

1 Connectors ........23-28:t

.r/ Spring-foaded Lock Connector ....... 23-284

Spring-loaded Lock Connestor with

Buift-in Short Contact .............. ... 23-281

Disconnecting the Airbag

Connector(sl ......23-285

Steering-related Precautions .......... 23-286

)f-'Tl

Page 1332 of 1681

!

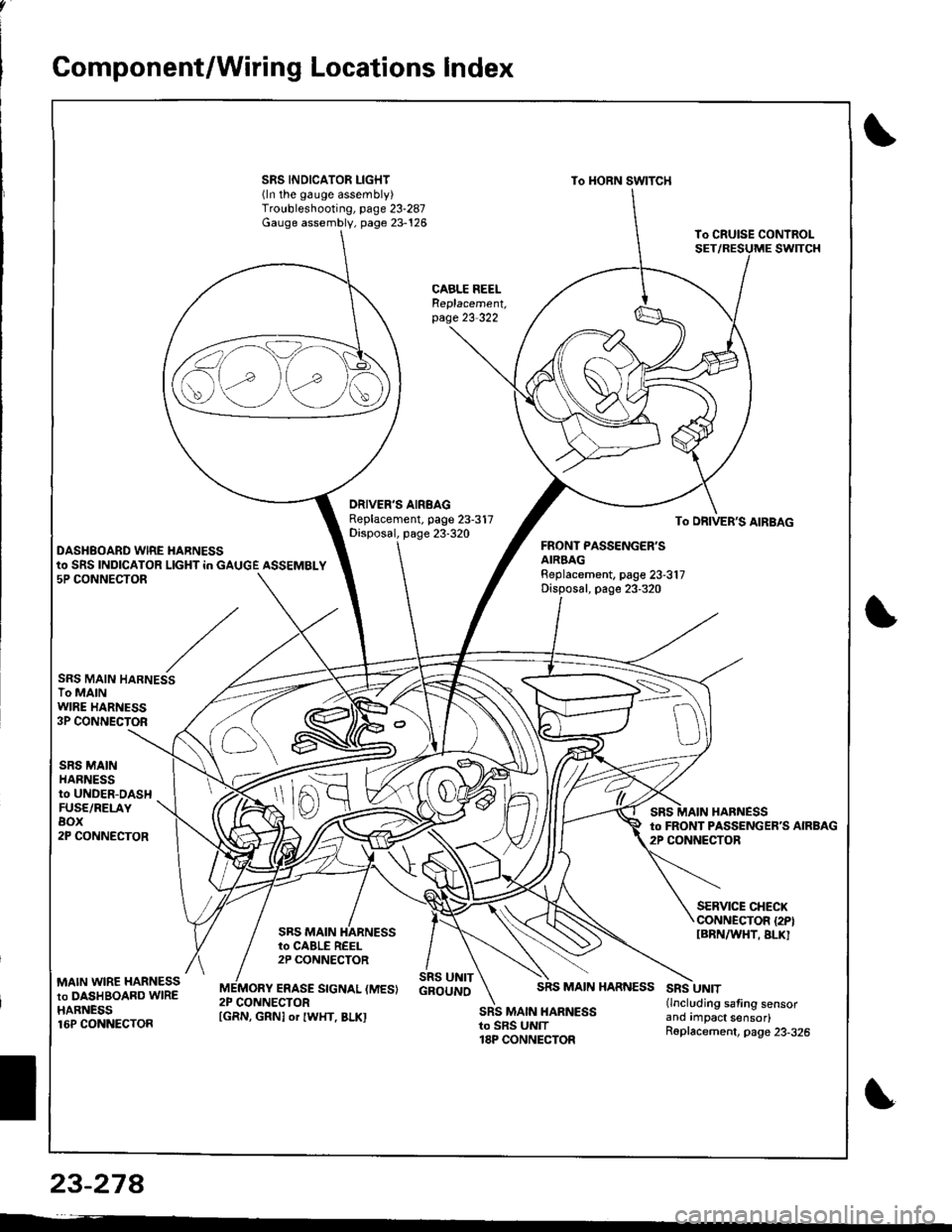

Gomponent/Wiring Locations Index

SRS INDICATOR LIGHT(ln the gauge assembly)Troubleshooting, page 23-287Gauge assembly, page 23-126

To HORN SWITCH

CABLE REELReplacement,page 23-322

DRIVER'S AIRBAGReplacement. page 23-317Disposal, page 23-320To DRIVER'S AIRBAG

DASHBOARD WIRE HARNESSFRONT PASSENGER'SAIRBAGBeplacement, page 23-317Disposal, page 23-320

to SRS INDICATOR LIGHT in GAUGE ASSEMBLY5P CONNECTOR

SRS MAIN HARNESSTo MAINWIRE HARNESS3P CONNECTOR

SRS MAINHARNESSto UNDER-DASHFUSE/RELAYBOX2P CONNECTOR

HARNESSto FRONT PASSENGERS AIRBAG2P CONNECTOR

SRS MAIN

SERVICE CHECXCONNECTOR {2PIIBRNAAIHT, BLK]to CABLE REEL2P CONNECTOR

MAIN WIRE HARNESSto DASHBOARD WIREHARNESS16P CONNECTOR

ERASE SIGNAL (MES}SRS UNITGBOUNOSRS MAIN HARNESSSRS UNIT(lncluding safing sensorano rmpact sensor)R6placement, page 23-326

2P CONNECTORSRS MAIN HARNESSto SRS UNIT18P CONNECTOR

S\--0

[GRN, GRNI or IWHT, BLKI

23-27A

Page 1336 of 1681

Precautions/Procedu res

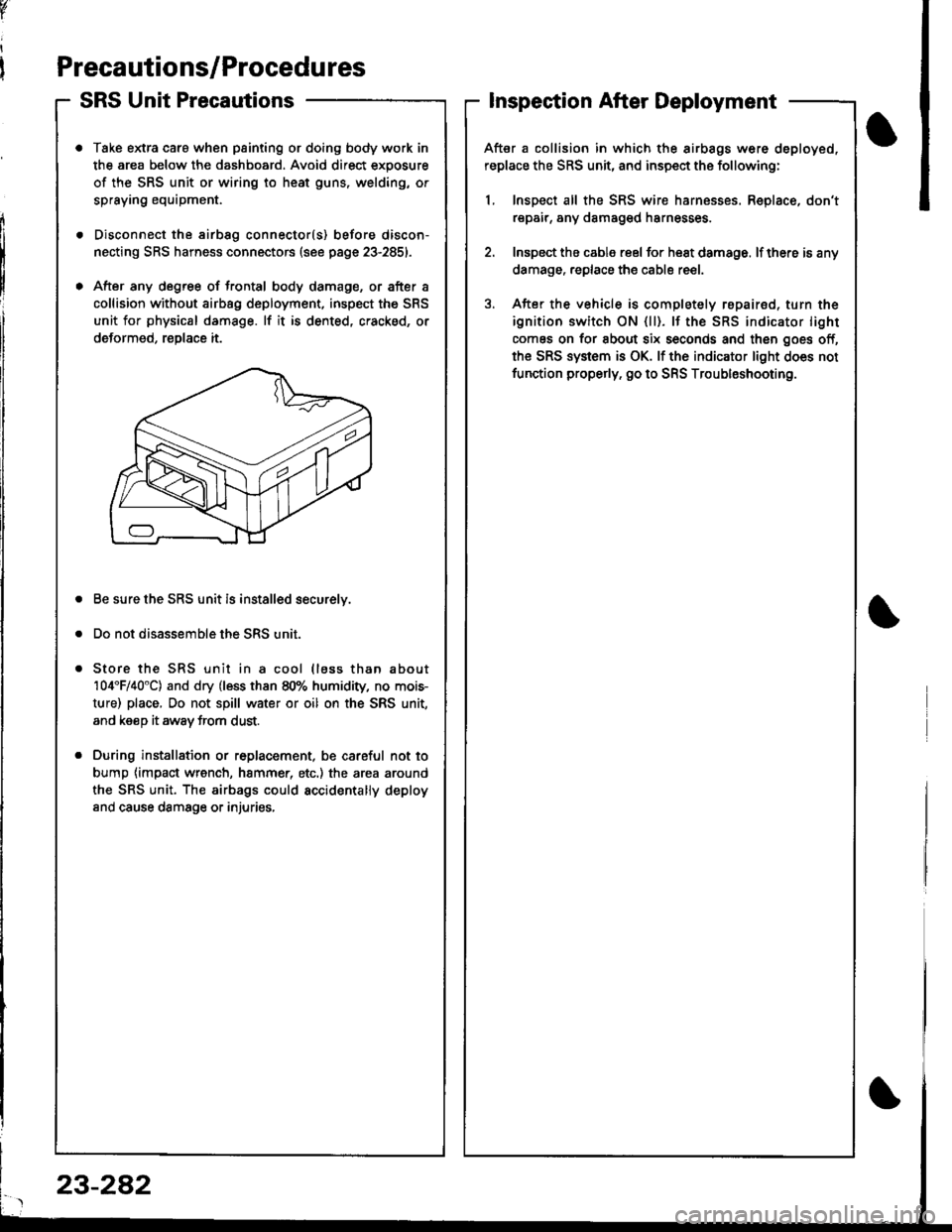

SRS Unit Precautions

Take extra caro when painting or doing body work in

the area below the dashboard. Avoid direct exposure

of the SRS unit or wiring to heat guns, welding, or

spraying equipment.

Disconnect the airbsg connector(s) before discon-

necting SRS harness connectors (see page 23-2851.

After any degree of frontal body damage, or after a

collision without airbag deployment, inspect the SRS

unit for physical damage. lf it is dented, cracked, or

deformed, reDlace it.

Be sure the SRS unit is installed securelv.

Do not disassemble the SRS unit.

Store the SRS unit in a cool (lass than about

104'F/40"C) and dry (less than 80% humidity, no mois-

ture) place, Do not spill water or oil on the SRS unit,

and keeD it awav trom dust.

During installation or r6placement, be careful not to

bump {impact wrench, hammer, etc.) the area around

the SRS unit. The airbags could accidentally deploy

and cause damsge or injuries,

v

Inspection After Deployment

After a collision in which the airbags w6re deployed,

replace the SRS unit, and inspect the following:

1, Inspect all the SRS wire harnesses. Replace, don't

repair, any damaged harnesses

2. Inspect the cable reel for heat damage. lf there is any

damage. replace the cable reel.

3. After the vehicle is completely repairod, turn the

ignition switch ON {ll). lf the SRS indicator light

comes on for about six seconds and then goes off,

the SRS system is OK. lf the indicator light does not

function properly. go to SRS Troubleshooting.

23-282

Page 1337 of 1681

)J

Wiring Precautions

. Never attempt to modify, splice or repair SRS wiring.

NOTE: SRS wiring can be identified by special yellow

outer protective covering.

. Be sure to install ihe harness wires so that they are not

pinched or interfering with other car parts.

. Make sure all SRS ground locations are clean and

grounds are securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent

problems that are difficult to diagnose.

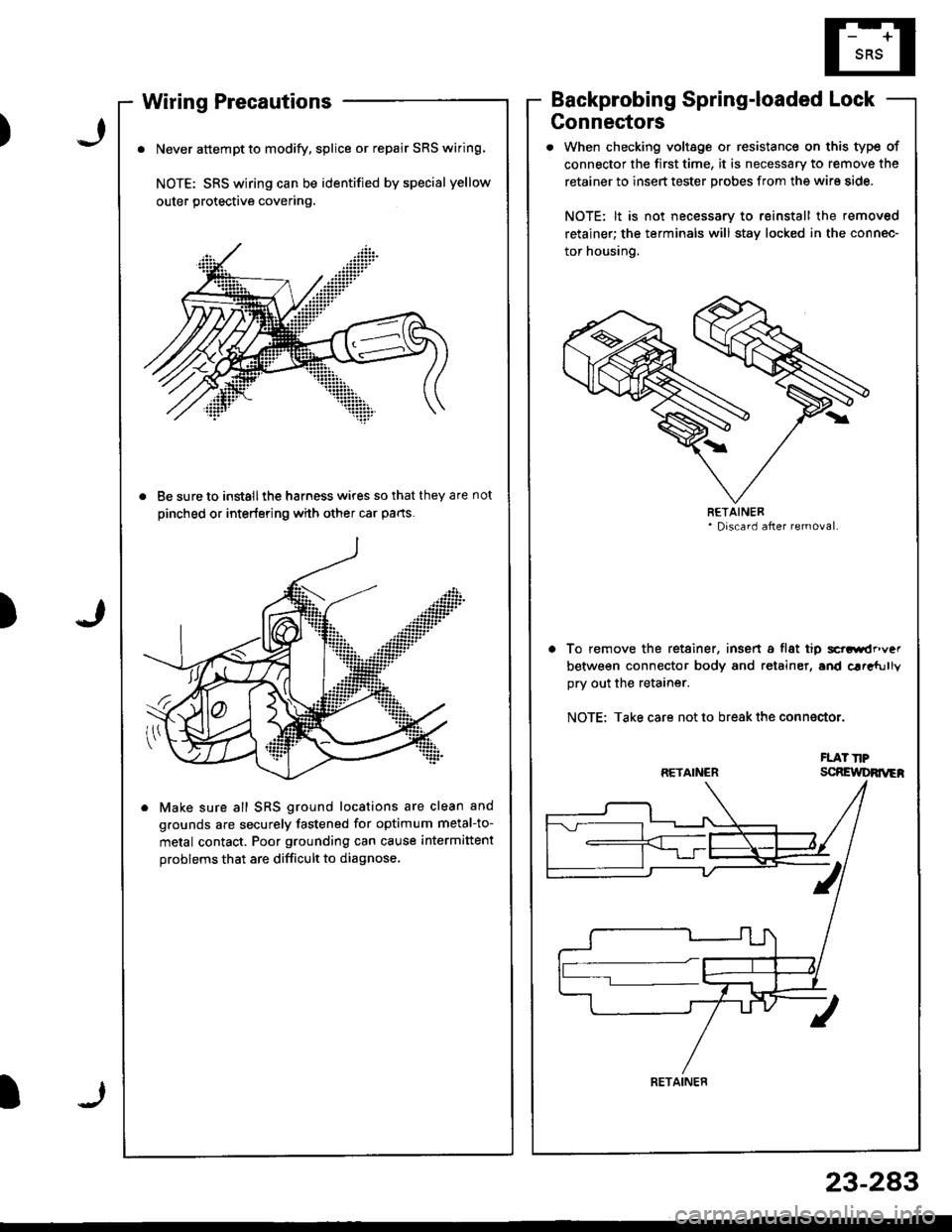

Backprobing Spring-loaded Lock

Connectors

. When checking voltage or resistance on this type of

connector the first time, it is necessary to remove the

retainer to insert tester probes from the wire side.

NOTE: lt is not necessary to reinstall the removed

retainer; the terminals will stav locked in the connec-

tor housing.

To remove the retainer, insen a flat tip scrGirdr'\/".

between connector body and retainer, and car"fully

ory out the retarner.

NOTE: Take care not to break the conn€ctor.

FLAT TIPscRElt DRrrrEh

)

RETAINER

RETAINER

RETAINER

23-283