HONDA RIDGELINE 2010 1.G Owner's Guide

Manufacturer: HONDA, Model Year: 2010, Model line: RIDGELINE, Model: HONDA RIDGELINE 2010 1.GPages: 421, PDF Size: 7.23 MB

Page 31 of 421

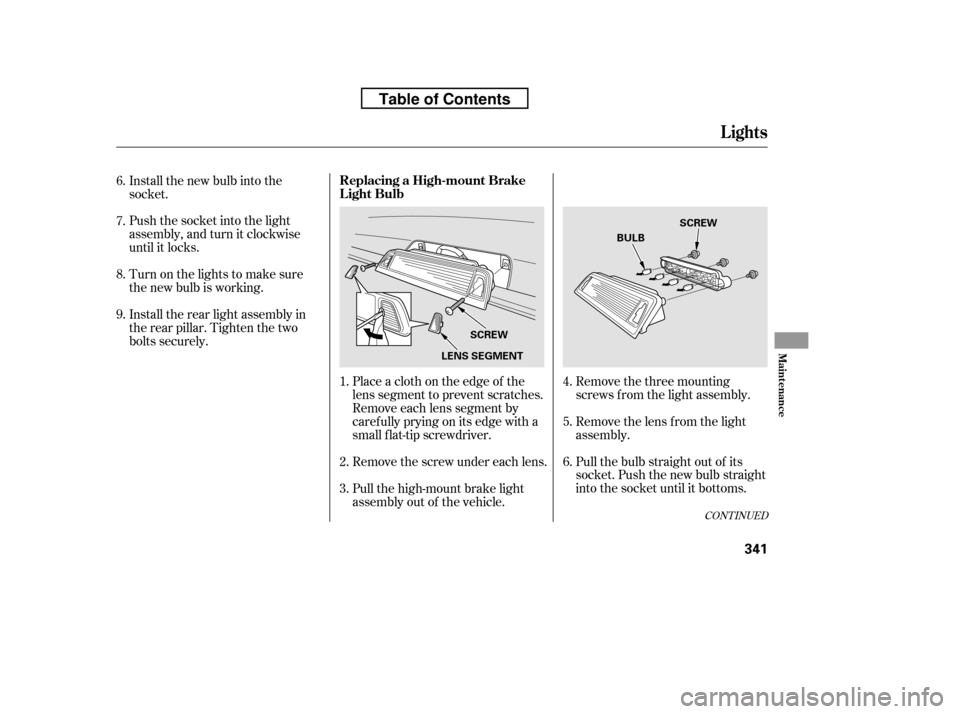

Remove the three mounting

screws f rom the light assembly.

Remove the lens f rom the light

assembly.

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

Place a cloth on the edge of the

lens segment to prevent scratches.

Remove each lens segment by

caref ully prying on its edge with a

small f lat-tip screwdriver.

Remove the screw under each lens.

Pull the high-mount brake light

assembly out of the vehicle.

Install the new bulb into the

socket.

Push the socket into the light

assembly, and turn it clockwise

until it locks.

Turn on the lights to make sure

the new bulb is working.

Install the rear light assembly in

the rear pillar. Tighten the two

bolts securely.

1. 2. 3. 4. 5.6.

6.7. 8. 9.

CONT INUED

Replacing a High-mount Brake

Light Bulb

Lights

Maint enance

341

LENS SEGMENT

SCREW SCREW

BULB

Table of Contents

Page 32 of 421

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

Push the socket into the light

assembly, and turn it clockwise

until it locks.

Remove the license plate light

assembly by pulling it towards you,

and then pulling the f ront edge

upward.

Remove the socket f rom the light

assembly by turning it one-quarter

turn counterclockwise.

Put the lens back on the light

assembly, and tighten the

mounting bolts securely.

Turn on the lights to make sure

the new bulb is working.

Put the light assembly back into

the vehicle. Install the screws and

tighten them securely.

Reinstall the lens segments.

1. 2. 3. 4.

8.

7. 9.

Lights

Replacing a Rear License Plate Bulb

342

BULB

SOCKET

Table of Contents

Page 33 of 421

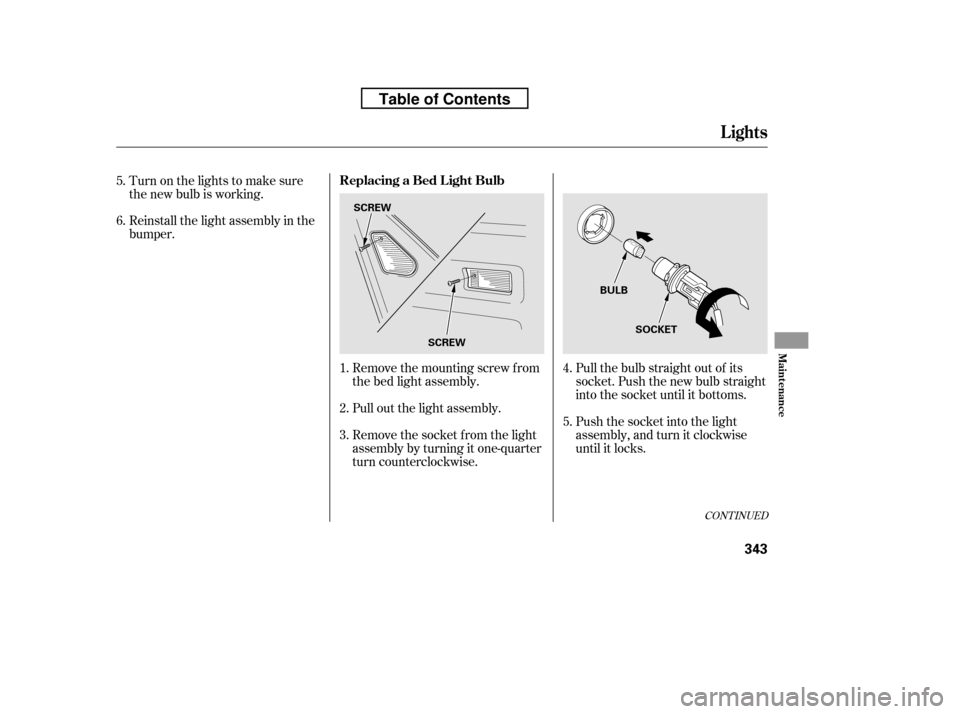

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

Push the socket into the light

assembly, and turn it clockwise

until it locks.

Remove the mounting screw f rom

the bed light assembly.

Pull out the light assembly.

Remove the socket f rom the light

assembly by turning it one-quarter

turn counterclockwise.

Turn on the lights to make sure

the new bulb is working.

Reinstall the light assembly in the

bumper.

1. 2. 3. 4. 5.

5. 6.

CONT INUED

Replacing a Bed L ight Bulb

Lights

Maint enance

343

SCREW

SCREW BULB

SOCKET

Table of Contents

Page 34 of 421

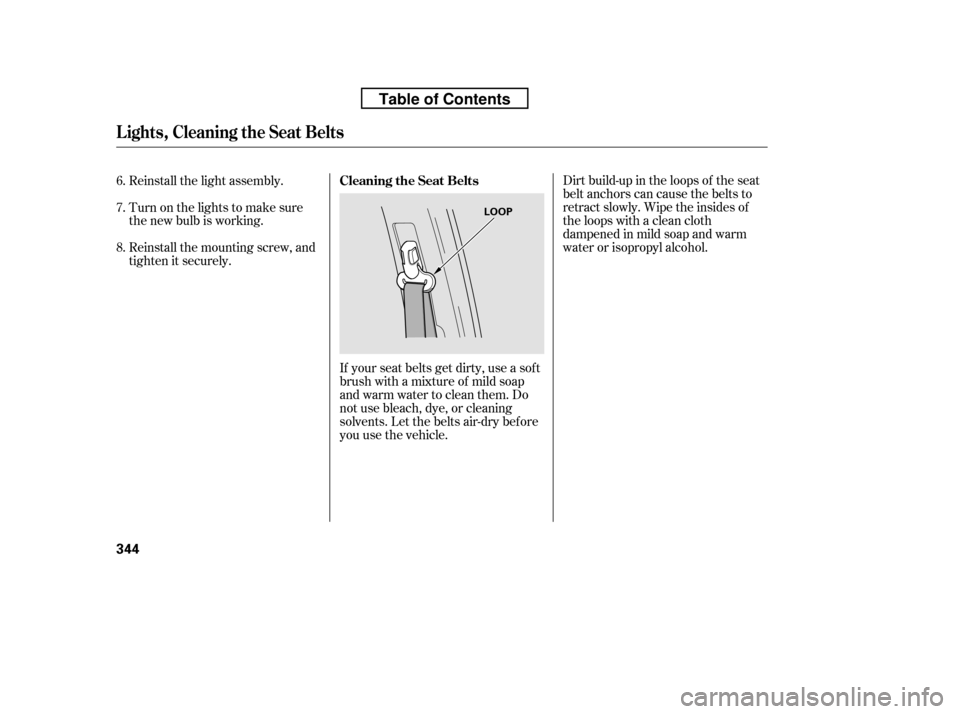

If your seat belts get dirty, use a sof t

brush with a mixture of mild soap

and warm water to clean them. Do

not use bleach, dye, or cleaning

solvents. Let the belts air-dry bef ore

you use the vehicle.Dirt build-up in the loops of the seat

belt anchors can cause the belts to

retract slowly. Wipe the insides of

the loops with a clean cloth

dampened in mild soap and warm

water or isopropyl alcohol.

Reinstall the light assembly.

Turn on the lights to make sure

the new bulb is working.

Reinstall the mounting screw, and

tighten it securely.

6. 7. 8.

Cleaning the Seat Belts

Lights, Cleaning the Seat Belts

344

LOOP

Table of Contents

Page 35 of 421

The floor mats that came with your

vehicle hook over the f loor mat

anchors. This keeps the f loor mats

f rom sliding f orward, possibly

interf ering with the pedals, or

backwards, making the f ront

passenger’s weight sensors

inef f ective.

If you remove a f loor mat, make sure

tore-anchoritwhenyouputitback

in your vehicle.A non-Honda f loor mat may not f it

your vehicle properly. This could

prevent the proper operation of the

f olding rear seats and the passenger’s

seat weight sensors. We recommend

using genuine Honda f loor mats. Do

not put additional f loor mats on top

of the anchored mats.

This f ilter removes the dust and

pollenthatisbroughtinfromthe

outside through the heating and

cooling system/climate control

system.

Have your dealer replace the filter

when this service is indicated by a

maintenance message on the

inf ormation display or multi-

inf ormation display (depending on

the models). It should be replaced

every 15,000 miles (24,000 km) if you

drive primarily in urban areas that

have high concentrations of soot in

the air, or if the flow from the

heating and cooling system/climate

control system becomes less than

usual.

Floor Mats, Dust and Pollen Filter

Floor Mats

Dust and Pollen Filter

Maint enance

345

Table of Contents

Page 36 of 421

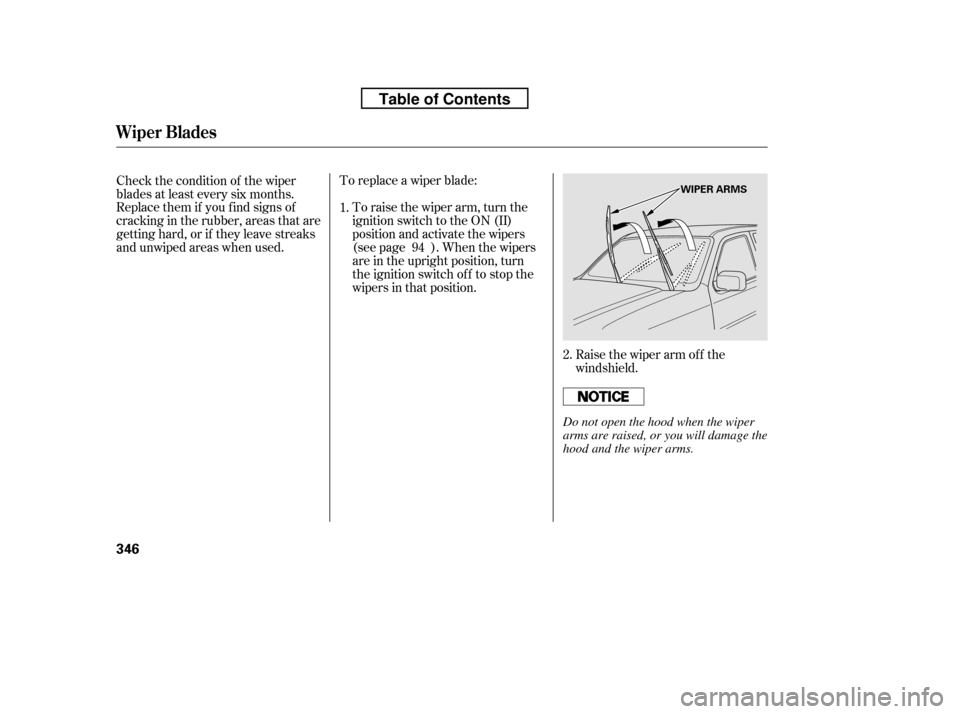

Raise the wiper arm of f the

windshield.

To replace a wiper blade:

To raise the wiper arm, turn the

ignition switch to the ON (II)

position and activate the wipers

(see page ). When the wipers

are in the upright position, turn

the ignition switch off to stop the

wipers in that position.

Check the condition of the wiper

blades at least every six months.

Replace them if you f ind signs of

cracking in the rubber, areas that are

getting hard, or if they leave streaks

and unwiped areas when used.

1.

2.

94

Wiper Blades

346

WIPER ARMS

Do not open the hood when the wiper

arms are raised, or you will damage the

hood and the wiper arms.

Table of Contents

Page 37 of 421

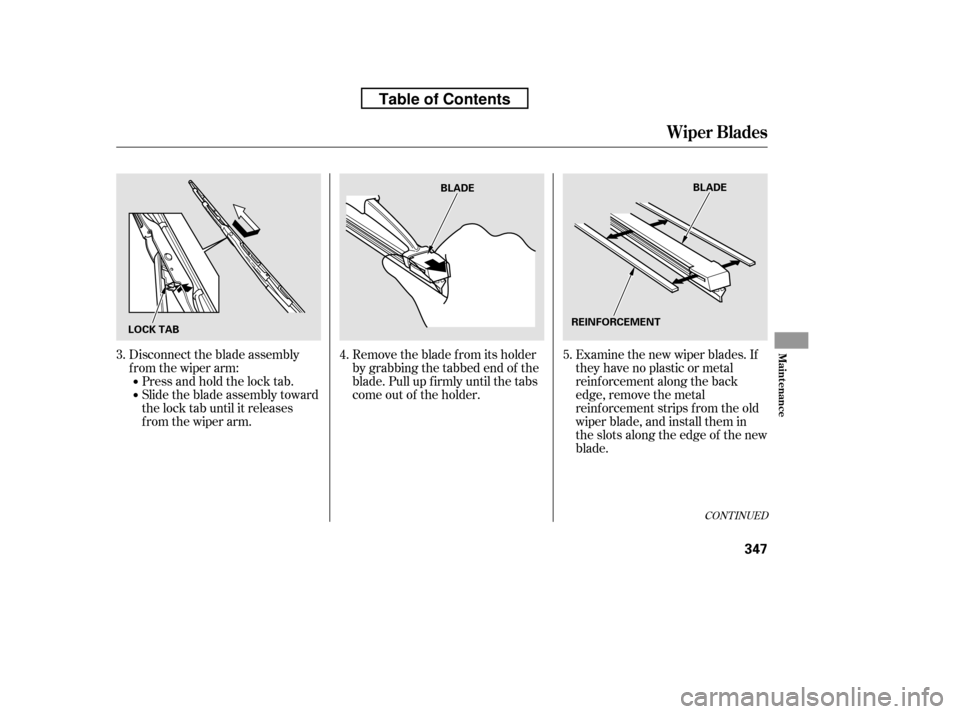

CONT INUED

Remove the blade f rom its holder

by grabbing the tabbed end of the

blade. Pull up f irmly until the tabs

come out of the holder.Examine the new wiper blades. If

they have no plastic or metal

reinf orcement along the back

edge, remove the metal

reinf orcement strips f rom the old

wiper blade, and install them in

the slots along the edge of the new

blade.

Disconnect the blade assembly

from the wiper arm:

Press and hold the lock tab.

Slide the blade assembly toward

the lock tab until it releases

from the wiper arm.

3.

4.5.

Wiper Blades

Maint enance

347

LOCK TAB BLADE

BLADE

REINFORCEMENT

Table of Contents

Page 38 of 421

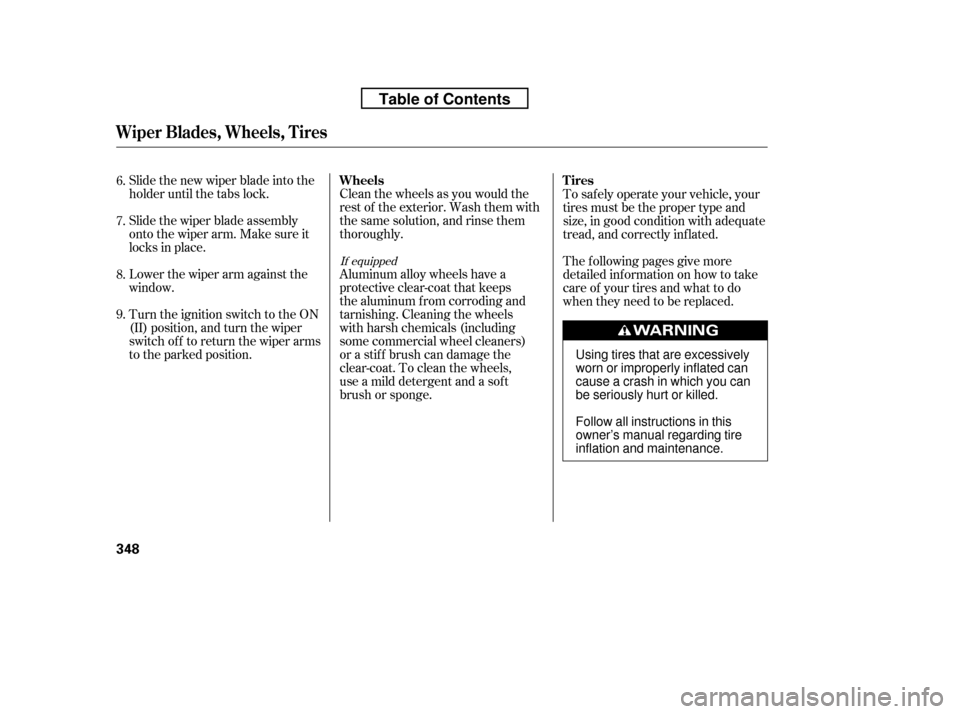

Slide the new wiper blade into the

holder until the tabs lock.

Slide the wiper blade assembly

onto the wiper arm. Make sure it

locks in place.

Lower the wiper arm against the

window.

Turn the ignition switch to the ON

(II) position, and turn the wiper

switch of f to return the wiper arms

to the parked position.Clean the wheels as you would the

rest of the exterior. Wash them with

thesamesolution,andrinsethem

thoroughly.

Aluminum alloy wheels have a

protective clear-coat that keeps

the aluminum f rom corroding and

tarnishing. Cleaning the wheels

with harsh chemicals (including

some commercial wheel cleaners)

or a stif f brush can damage the

clear-coat. To clean the wheels,

use a mild detergent and a sof t

brush or sponge. To saf ely operate your vehicle, your

tires must be the proper type and

size, in good condition with adequate

tread, and correctly inf lated.

The f ollowing pages give more

detailed inf ormation on how to take

care of your tires and what to do

when they need to be replaced.

6. 7. 8. 9.

If equipped

Wiper Blades, Wheels, Tires

Wheels T ires

348

Using tires that are excessively

worn or improperly inflated can

cause a crash in which you can

be seriously hurt or killed.

Follow all instructions in this

owner’s manual regarding tire

inflation and maintenance.

Table of Contents

Page 39 of 421

CONT INUED

Keeping the tires properly inf lated

provides the best combination of

handling, tread lif e, and riding

comf ort.Underinf lated tires wear unevenly,

adversely affect handling and fuel

economy, and are more likely to

fail from being overheated.

Overinf lated tires can make your

vehicleridemoreharshly,are

more prone to damage f rom road

hazards, and wear unevenly. Even though your vehicle is

equipped with TPMS, we

recommend that you visually check

your tires every day. If you think a

tire might be low, check it

immediately with a tire gauge.

Use a gauge to measure the air

pressure in each tire at least once a

month. Even tires that are in good

condition may lose 1 to 2 psi (10 to

20 kPa, 0.1 to 0.2 kgf /cm ) per

month. Remember to check the

sparetireatthesametime.

Check the air pressures when the

tires are cold. This means the

vehicle has been parked f or at least 3

hours, or driven less than 1 mile (1.6

km). Add or release air, if needed, to

match the recommended cold tire

pressures on page . If you check air pressures when the

tires are hot (driven f or several

miles/kilometers), you will see

readings 4 to 6 psi (30 to 40 kPa, 0.3

to 0.4 kgf/cm ) higher than the cold

readings. This is normal. Do not let

air out to match the recommended

cold air pressure. The tire will be

underinf lated.

Youshouldgetyourowntire

pressure gauge and use it whenever

you check your tire pressures. This

will make it easier f or you to tell if a

pressure loss is due to a tire problem

and not due to a variation between

gauges.

While tubeless tires have some

ability to self -seal if they are

punctured, you should look closely

for punctures if a tire starts losing

pressure.

The tire pressure monitoring system

(TPMS) warns you when a tire

pressure is low. See page or

f or more inf ormation.

350

278

281

Tires

Inf lation Guidelines

Maint enance

349

Table of Contents

Page 40 of 421

Never use a puncture-repairing agent

in a f lat tire. If used, you will have to

replace the tire pressure sensor.

Havetheflattirerepairedbyyour

dealer as soon as possible.

The following chart shows the

recommended cold tire pressures f or

most normal and high-speed driving

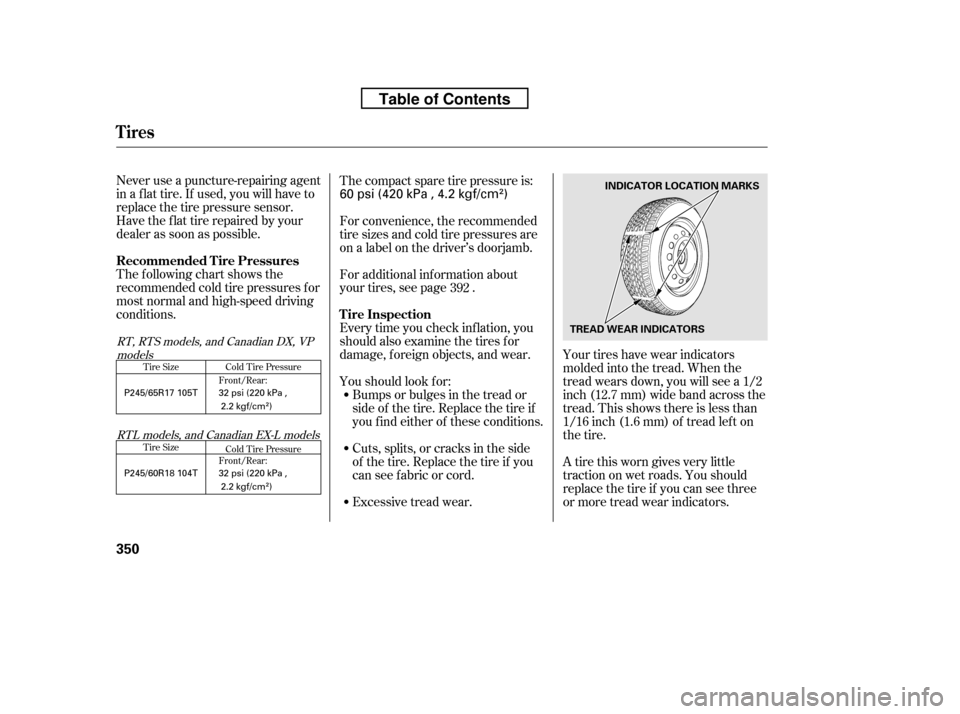

conditions.Your tires have wear indicators

molded into the tread. When the

tread wears down, you will see a 1/2

inch (12.7 mm) wide band across the

tread. This shows there is less than

1/16 inch (1.6 mm) of tread lef t on

the tire.

A tire this worn gives very little

traction on wet roads. You should

replace the tire if you can see three

or more tread wear indicators.

Thecompactsparetirepressureis:

Excessive tread wear.

Cuts, splits, or cracks in the side

of the tire. Replace the tire if you

can see f abric or cord.

Bumps or bulges in the tread or

side of the tire. Replace the tire if

youfindeitherof theseconditions.

Every time you check inf lation, you

should also examine the tires f or

damage, f oreign objects, and wear.

Youshouldlookfor:

For additional inf ormation about

your tires, see page .

For convenience, the recommended

tire sizes and cold tire pressures are

on a label on the driver’s doorjamb.

392

Tire Size Cold Tire Pressure

Cold Tire Pressure

Tire Size Front/Rear:

Front/Rear:

RT, RTS models, and Canadian DX, VP

models

RTL models, and Canadian EX-L models

Tires

Recommended Tire Pressures Tire Inspection

350

INDICATOR LOCATION MARKS

TREAD WEAR INDICATORS

32 psi (220 kPa , 2.2 kgf/cm

)

P245/65R17 105T

P245/60R18 104T 32 psi (220 kPa ,

2.2 kgf/cm

)

60 psi (420 kPa , 4.2 kgf/cm)

Table of Contents