Check engine Hyundai Coupe 2004 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Coupe, Model: Hyundai Coupe 2004Pages: 389, PDF Size: 10.22 MB

Page 301 of 389

3

IN CASE OF EMERGENCY

3

!

!

D010C01A-AAT If Engine Turns Over Normally but Does Not Start

1. Check fuel level.

2. With the key in the off position,

Check all connectors at ignition coils and spark plugs. Reconnect any that may be disconnected or loose.

3. Check the fuel line in the engine room.

4. If engine still refuses to start, call a Hyundai dealer or seek other quali- fied assistance.

D010D01A-AAT If Engine Stalls While Driving

1. Reduce your speed gradually, keep- ing a straight line. Move cautiously off the road to a safe place.

2. Turn on your emergency flashers.

3. Try to start the engine again. If your vehicle will not start, contact aHyundai dealer or seek other quali-fied assistance. SD030A2-E

CAUTION:

Personal injury and damage to thevehicle may occur if jump startingis not performed correctly. If any doubt exists as to how this opera- tion should be performed, seek as-sistance from qualified personnel.

JUMP STARTING

WARNING:

Motor vehicle batteries contain sulphuric acid and emit hydrogen gas. Protective clothing should beworn and care exercised to prevent the acid from coming into contact with skin or clothing and the ve-hicle. Naked lights should not be permitted in the vicinity of the bat- tery. Care should be exercised toprevent sparks occurring during connection. If acid accidentally comes into contact with skin oreyes, the affected area should im- mediately be flushed with copious amounts of water and medical as-sistance sought.

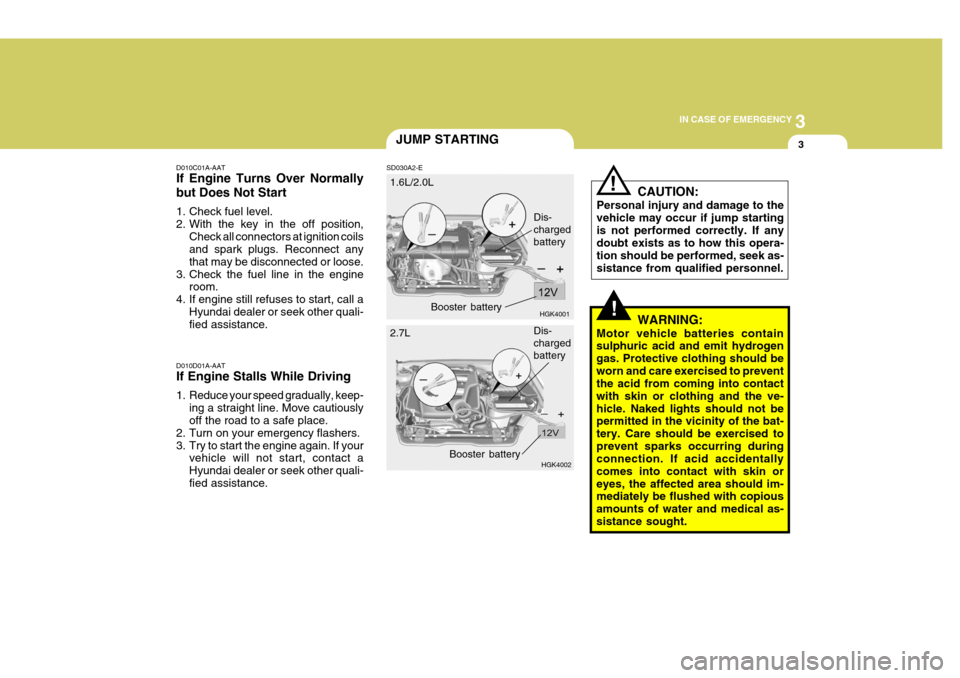

1.6L/2.0L

HGK4001

HGK4002

Dis- chargedbattery

2.7L Booster battery

Dis- chargedbattery

Booster battery

Page 302 of 389

3 IN CASE OF EMERGENCY

4

7. Swithc "ON" the main beam

headlamps before carefully remov- ing the jumper cables have been removed, switch "OFF" the main beam geadlamps. SD040A2-E If the temperature gauge indicates overheating:

1. Pull off the road and stop as soon as

it is safe to do so.

2. Place the gear selector lever in "P"

(automatic), or neutral (manual transaxle) and set the parking brake. If the air conditioning is on, turn it off.

3. If coolant is running out under the car or steam is coming out fromunder the bonnet stop the engine. Do not open the bonnet until thecoolant has stopped running or the steaming has stopped. If there is no visible loss of coolant and no steam,leave the engine running and check to be sure the engine cooling fan is operating.If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is missing. If it is not missing,check to see that it is tight. If the drive belt seems to be satisfac-tory,check for coolant leaking from the radiator, hoses or under the car. (If the air conditioning had been in use,it is normal for cold water to be draining from it).

IF THE ENGINE OVERHEATS

1. Ensure that the booster battery is 12 volt type. If the booster battery is installed in another vehicle, ensure that the two vehicles are not touch- ing.

2. Turn off all unnecessary electrical equipment in both vehicles.

3. Ensure that the engine of the ve- hicle providing the jump start is run- ning prior to connection of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the boosterbattery and the other end to thepositive (+) terminal of the dis- charged battery.

5. Attach the black jump cable to the negative (-) terminal of thebooster battery, and the other end to a ground point within the enginecompartment of the vehicle with the flat battery. Do not connect to the negative battery terminal of the flatbattery since sparks may be gener- ated with the subsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start theengine of the vehicle with the flatbattery. CAUTION:

If the jump cable is incorrectly in-stalled, damage to the vehicle elec-trical system may occur, in particu- lar the electronic components such as the Fuel Injection system com- puter and the Automatic Transaxle computer. The battery must neverbe disconnected whilst the engine is running.

!

Page 303 of 389

3

IN CASE OF EMERGENCY

5

!

!WARNING:

Whilst the engine is running, keep hands and clothing away from mov- ing parts such as the fan and drive belts to prevent injury.

5. If the water pump drive belt is bro- ken or coolant is leaking out, stop the engine immediately and call the nearest Hyundai dealer for assis-tance.

WARNING:

Do not remove the radiator cap when the engine is hot since steam and boiling water may be ejected fromthe radiator resulting in burns or scalding.

!

6. If the cause of the overheating can- not be found, wait until the engine temperature has returned to nor- mal. Then, if coolant has been lost, carefully add coolant to the reser-voir (page 6-11) to bring the fluid level in the reservoir up to the base of the radiator fill opening. Fill thecoolant expansion tank to the half- way mark.

7. Proceed with caution until it is es- tablished that the engine is operat-ing normally. If the engine over- heats repeatedly, the advice of aHyundai dealer should be sought.

CAUTION:

Serious loss of coolant indicatesthere is a leak in the cooling systemand this should be checked as soon as possible by a Hyundai dealer.D040A01GK-EAT TEMPORARY SPARE TYRE The following instructions for the tem- porary spare tyre should be observed:

1. Check inflation pressure as soon as practical after installing the spare tyre, and adjust to the specified pressure. The tyre pressure should be periodically checked and main-tained at the specified pressure while the tyre is stored.

2. The spare tyre should only be used temporarily and should be returnedto the luggage compartment as soon as the original tyre can be repairedor replaced.

SPARE TYRE

Tyre Size

Inflation Pressure T125/70 R16

420 kPa (60 psi)

Spare Tyre Pressure

3. Continuous use at speeds of over 50 mph (80 km/h) is not recom- mended.

4. As the temporary spare tyre is spe-

cifically designed for your car, itshould not be used on any other vehicle.

Page 309 of 389

3

IN CASE OF EMERGENCY

11

SD070K1-E AFTER CHANGING WHEELS The pressure of the spare tyre should be checked at the first available oppor-tunity. If any doubt exists as to the tyre pressure, the vehicle should be driven slowly to the nearest service stationand the tyre pressure checked and adjusted as required. If the valve cap is lost from any of thevalves, a replacement should be ob- tained and fitted at the first available opportunity. The valve cap preventsthe ingress of dirt which may cause the valve to stick and therefore leak and is part of the valve sealing function. Ensure that the spare wheel, jack and wheel nut wrench as well tools are correctly located in the boot of the vehicle to prevent damage and noise. HGK4032

IF YOUR VEHICLE MUST BE TOWED

D080A01O-GAT If your vehicle has to be towed, it should be done by your Hyundai dealeror a commercial tow truck service. This will help assure that your vehicle is not damaged in towing. Also, profes-sionals are generally aware of local laws governing towing. In any case, rather than risk damage to your car, itis suggested that you show this infor- mation to the tow truck operator. Be sure that a safety chain system is usedand that all local laws are observed. It is recommended that your vehicle be towed with a wheel lift and dollies orflatbed equipment with all the wheels off the ground.

! CAUTION:

o Your vehicle can be damaged if towed incorrectly!

o Be sure the transaxle is in neu-

tral.

o When the engine will not start, be

sure the steering is unlocked by placing the key in the "ACC" po- sition.

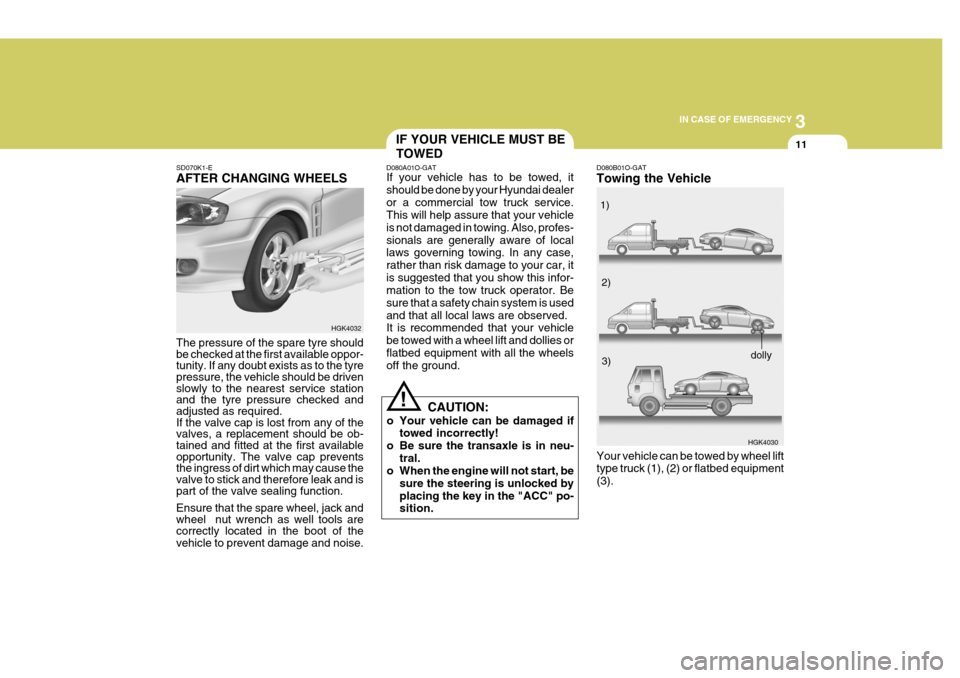

D080B01O-GAT Towing the Vehicle

HGK4030

Your vehicle can be towed by wheel lift type truck (1), (2) or flatbed equipment (3). 1)

2)

3)

dolly

Page 318 of 389

5VEHICLE MAINTENANCE REQUIREMENTS

2MAINTENANCE AND SER- VICING REQUIREMENTS

SF020A1-E To ensure the continued reliability and safety of the vehicle, certain routinemaintenance operations are required at specific mileage or time intervals. It is the responsibility of the vehicle owner to ensure that the maintenance schedules shown in both this OwnersManual and the Warranty and Service Passport are adhered to. The new vehicle warranty may be invalidated if the routine maintenance operations are not performed in line with the recommendations outlined andthe safety and durability of the vehicle adversely affected. It is recommended that all mainte- nance operations with the exception of the daily operating checks are en-trusted to a Hyundai dealer to ensure that the latest repair and maintenance procedures and specialized servicingtools are employed. In addition, the use of genuine Hyundai replacement parts will ensure that the vehicle safetyand performance will not be compro- mised. NOTE:

The inspection and testing of cer-

tain electronic fuel injection/enginemanagement and automatic trans- mission control systems requirespecialised electronic equipment specifically designed for Hyundai vehicles. The use of general pur-pose electrical test equipment may result in damage to the control unit microprocessors. SF020C2-E

Specified Scheduled Procedures

The Specified scheduled procedures

are listed in the maintenance charts beginning at page 5-3. The operations specified must be performed at thetime or mileage intervals shown irre- spective of whether the mileage inter- val has been reached before the speci-fied time interval.

Certain lubricants and components

degrade with both time and mileage (e.g. engine oil and brake fluid) and therefore it is not permissable to basethe maintenance schedule upon mile- age alone. It is strongly recommended that the maintenance operations areperformed by the factory-trained or distributor-trained technicians at your Hyundai dealer because of the needfor specialized knowledge and tooling and to ensure that no possibility of invalidating the manufacturers warrantyexists. The maintenance schedules relate to

vehicles operated under normal condi-tions, vehicles which are operated under adverse conditions will require more frequent maintenance which isdescribed at page 5-6.

Page 323 of 389

5

VEHICLE MAINTENANCE REQUIREMENTS

7EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

6ZF060M1-A

o Engine oil and filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B2-A

o Drive belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oilsaturation and replace if necessary. Drive belts should be checked periodi- cally for proper tension and adjustedas necessary. 6ZF060C1-A

o Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently. After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections.

6ZF060D1-A

o Fuel lines, fuel hoses and

connections

Check the fuel lines, fuel hoses and

connections for leakage and damage. Replace any damaged or leaking parts immediately. 6ZF060E1-A o Timing belt Inspect all parts related to the timing belt for damage and deformation. Replace any damaged parts immedi- ately. 6ZF060G1-A

o Vapour hose and fuel filler cap The vapor hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched- ule. Make sure that a new vapour hoseor fuel filler cap is correctly replaced.

Page 324 of 389

5VEHICLE MAINTENANCE REQUIREMENTS

8

6ZF060F1-A

o Vacuum, crankcaseventilation hoses

Inspect the surface of hoses for evi- dence of heat and/or mechanical dam- age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Particu- lar attention should be paid to examin- ing those hose surfaces nearest tohigh heat sources, such as the ex- haust manifold. Inspect the hose routing to assure that the hoses do not come in contact with any heat source, sharp edges or mov- ing component which might cause heatdamage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they aresecure, and that no leaks are present. Hoses should be replaced immedi- ately if there is any evidence of dete-rioration or damage. 6ZF060H1-A

o Air cleaner filter

A Genuine Hyundai air cleaner filter is

recommended when the filter is re- placed.

6ZF060J1-A

o Spark plugs

Make sure to install new spark plugs

of the correct heat range.

F060N02E-EAT

o Valve Clearance

Inspect excessive valve noise and/or

engine vibration and adjust if neces- sary. A qualified technician should perform the operation. 6ZF070B1-A

o Cooling system

Check the cooling system part, such

as radiator, coolant reservoir, hosesand connections for leakage and dam- age. Replace any damaged parts.

6ZF070C1-A

o Coolant

The coolant should be changed at

the intervals specified in the mainte-nance schedule.

6ZF070D1-A

o Manual transaxle oil

Inspect the manual transaxle oil ac-

cording to the maintenance schedule. NOTE:

If the oil level is low, check for

possible leaks before adding oil. Do not overfill.

Page 325 of 389

5

VEHICLE MAINTENANCE REQUIREMENTS

9

6ZF070F1-A

o Brake hoses and lines

Visually check for proper installation, chafing, cracks, deterioration and anyleakage. Replace any deteriorated or damaged parts immediately. A6ZF070G2-A

o Brake fluid

Check brake fluid level in the brake

fluid reservoir. The level should bebetween "MIN" and "MAX" marks on the side of the reservoir. Use onlyhydraulic brake fluid conforming to DOT 3 or DOT 4.

6ZF070H1-A

o Rear brake drums and linings/

parking brake

Check the rear brake drums and lin-

ings for scoring, burning, leaking fluid,broken parts, and excessive wear. In- spect the parking brake system in-cluding the parking brake lever and cables. For detailed service proce- dures, refer to the Shop Manual. 6ZF070J1-A

o Brake pads, calipers and ro- tors Check the pads for excessive wear, discs for run out and wear, and cali- pers for fluid leakage. 6ZF070K1-A

o Exhaust pipe and muffler Visually inspect the exhaust pipes, muffler and hangers for cracks, dete- rioration, or damage. Start the engine and listen carefully for any exhaustgas leakage. Tighten connections or replace parts as necessary. 6ZF070L1-A

o Suspension mounting bolts Check the suspension connections for looseness or damage. Retighten to the specified torque.

F070E05A-AAT

o Automatic Transaxle Fluid

The fluid level should be in the "HOT"

range of the dipstick, after the engineand transaxle are at normal operating temperature. Check the automatic transaxle fluid level with the enginerunning and the transaxle in neutral, with the parking brake properly ap- plied. Use Hyundai Genuine ATF SP-III, DIAMOND ATF SP-III, SK ATF SP-III or other brands appraoved by Hyundai Motor Co., when adding orchanging fluid.

Page 326 of 389

5VEHICLE MAINTENANCE REQUIREMENTS

10

6ZF070M1-A

o Steering gear box, linkage &boots/lower arm ball joint

With the vehicle stopped and engine off, check for excessive freeplay in the steering wheel. Check the linkage for bends or dam- age. Check the dust boots and ball joints for deterioration, cracks, or dam- age. Replace any damaged parts. 6ZF070N1-A

o Power steering pump, belt and hoses

Check the power steering pump and hoses for leakage and damage. Re- place any damaged or leaking partsimmediately. Inspect the power steer- ing belt for evidence of cuts, cracks, excessive wear, oiliness and propertension. Replace or adjust it if neces- sary. 6ZF070P1-A

o Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, ordamage. Replace any damaged parts and, if necessary, repack the grease.

6ZF070Q1-A

o Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and damage. Check air conditioning performance according to the relevant shop manualif necessary.

Page 327 of 389

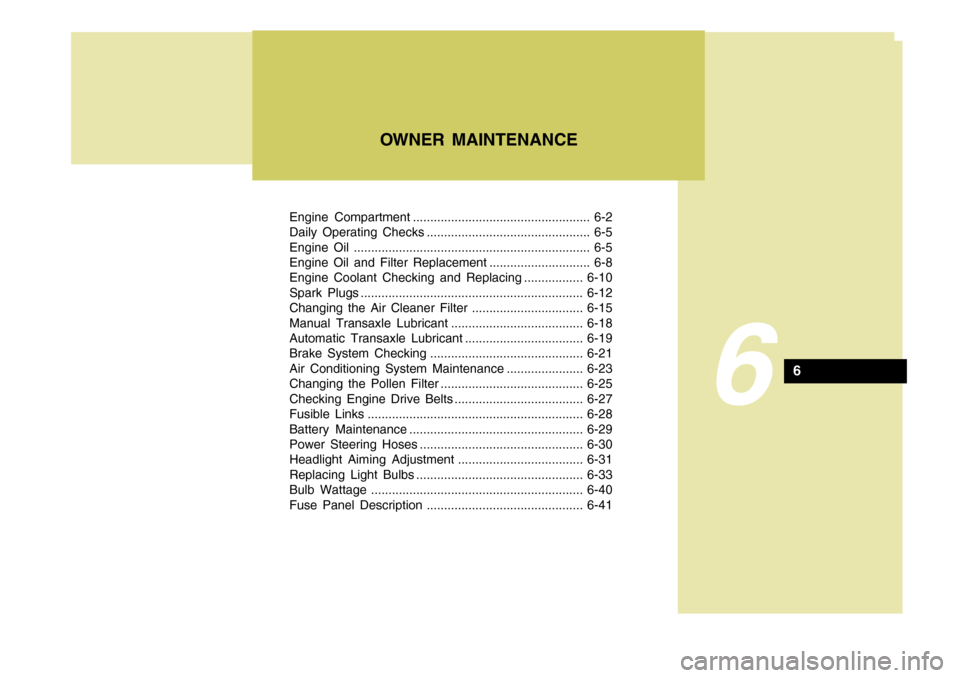

6

Engine Compartment ................................................... 6-2

Daily Operating Checks ............................................... 6-5

Engine Oil .................................................................... 6-5

Engine Oil and Filter Replacement ............................. 6-8

Engine Coolant Checking and Replacing .................6-10

Spark Plugs ................................................................ 6-12

Changing the Air Cleaner Filter ................................ 6-15

Manual Transaxle Lubricant ...................................... 6-18

Automatic Transaxle Lubricant .................................. 6-19

Brake System Checking ............................................ 6-21

Air Conditioning System Maintenance ...................... 6-23

Changing the Pollen Filter ......................................... 6-25

Checking Engine Drive Belts ..................................... 6-27

Fusible Links .............................................................. 6-28

Battery Maintenance .................................................. 6-29

Power Steering Hoses ............................................... 6-30

Headlight Aiming Adjustment .................................... 6-31

Replacing Light Bulbs ................................................ 6-33

Bulb Wattage ............................................................. 6-40

Fuse Panel Description ............................................. 6-41

OWNER MAINTENANCE

6