ECU Hyundai Elantra 2006 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Elantra, Model: Hyundai Elantra 2006Pages: 277, PDF Size: 10.18 MB

Page 207 of 277

5

VEHICLE MAINTENANCE REQUIREMENTS

9

F060H01A-AAT

o Air Cleaner Filter A Genuine Hyundai air cleaner filter is

recommended when the filter is re- placed. F060J01A-AAT

o Spark Plugs Make sure to install new spark plugs of the correct heat range. F070B01A-GAT

o Cooling System Check the cooling system part, such as radiator, coolant reservoir, hosesand connections for leakage and dam- age. Replace any damaged parts.

F060E01A-AAT

o Timing Belt

Inspect all parts related to the timing belt for damage and deformation. Replace any damaged parts immedi- ately. F060G01A-AAT

o Vapor Hose and Fuel Filler Cap

The vapor hose and fuel filler cap should be inspected at those inter- vals specified in the maintenanceschedule. Make sure that a new va- por hose or fuel filler cap is correctly replaced. F060F01A-AAT

o Vacuum, Crankcase Ventila-

tion Hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam- age. Hard and brittle rubber, crack- ing, tears, cuts, abrasions, and ex-cessive swelling indicate deteriora- tion. Particular attention should be paid to examine those hose surfacesnearest to high heat sources, such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact withany heat source, sharp edges or mov- ing component which might cause heatdamage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they aresecure, and that no leaks are present. Hoses should be replaced immedi- ately if there is any evidence of dete-rioration or damage. F060N02E-GAT

o Valve Clearance

Inspect excessive valve noise and/or engine vibration and adjust if neces- sary. A qualified technician shouldperform the operation.

Page 225 of 277

6 DO-IT-YOURSELF MAINTENANCE

16

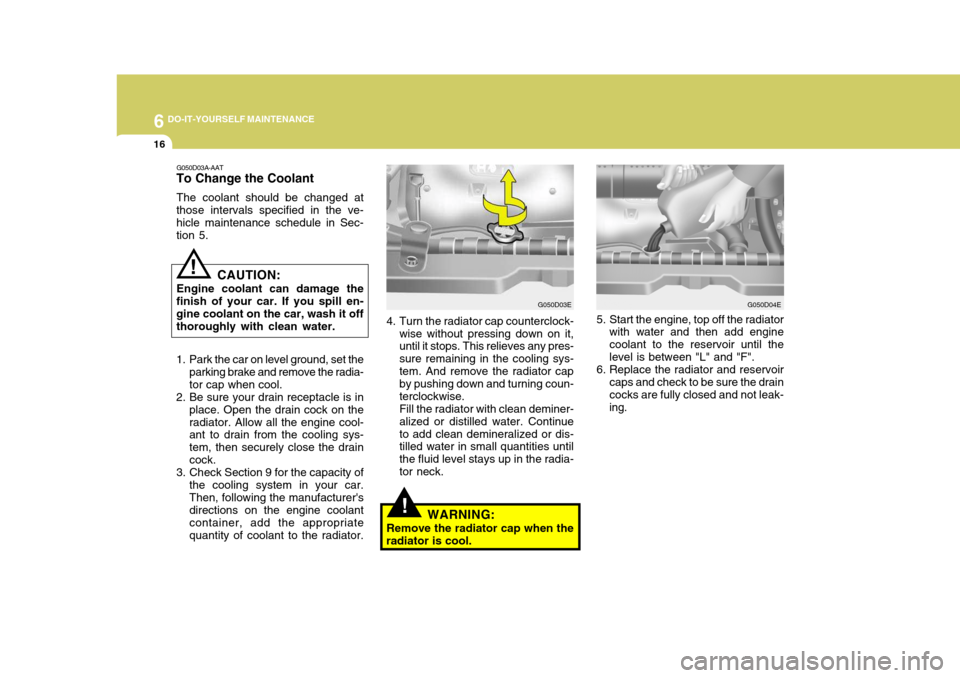

4. Turn the radiator cap counterclock-

wise without pressing down on it, until it stops. This relieves any pres- sure remaining in the cooling sys- tem. And remove the radiator cap by pushing down and turning coun-terclockwise.Fill the radiator with clean deminer-alized or distilled water. Continueto add clean demineralized or dis- tilled water in small quantities until the fluid level stays up in the radia-tor neck. G050D03E

G050D04E

G050D03A-AAT

To Change the Coolant

The coolant should be changed at

those intervals specified in the ve- hicle maintenance schedule in Sec- tion 5.

! CAUTION:

Engine coolant can damage the

finish of your car. If you spill en- gine coolant on the car, wash it off thoroughly with clean water.

1. Park the car on level ground, set the parking brake and remove the radia- tor cap when cool.

2. Be sure your drain receptacle is in

place. Open the drain cock on theradiator. Allow all the engine cool- ant to drain from the cooling sys- tem, then securely close the draincock.

3. Check Section 9 for the capacity of the cooling system in your car.Then, following the manufacturer's directions on the engine coolant container, add the appropriatequantity of coolant to the radiator.

!WARNING:

Remove the radiator cap when the

radiator is cool. 5. Start the engine, top off the radiator

with water and then add engine coolant to the reservoir until thelevel is between "L" and "F".

6. Replace the radiator and reservoir

caps and check to be sure the draincocks are fully closed and not leak- ing.

Page 231 of 277

6 DO-IT-YOURSELF MAINTENANCE

22

1. Using a wrench of the correct size,

loosen the oil filler plug by turning it counterclockwise and remove it with your fingers.

2. Use your finger or suitable tool to feel inside the hole. The oil levelshould be at its bottom edge. If it is not, check for leaks before addingoil. To refill the transaxle or bring the oil level up,add oil slowly until it reaches the proper level. Do notoverfill.

3. Replace the plug and washer, screw it in with your fingers and then tighten securely with the wrench.

G110A02E-AAT

AUTOMATIC TRANSAXLE

Transaxle fluid in the automatictransaxle should be checked at those intervals specified in the vehicle main- tenance schedule in Section 5.

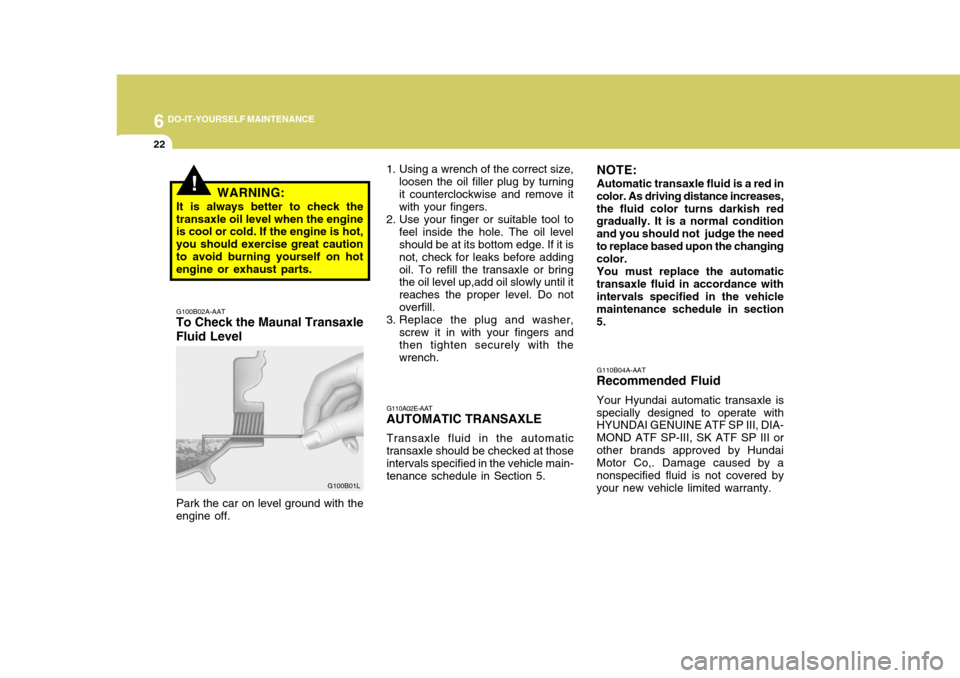

G100B02A-AAT

To Check the Maunal Transaxle Fluid Level

G100B01L

Park the car on level ground with the

engine off. G110B04A-AAT

Recommended Fluid

Your Hyundai automatic transaxle is

specially designed to operate with HYUNDAI GENUINE ATF SP III, DIA- MOND ATF SP-III, SK ATF SP III orother brands approved by Hundai Motor Co,. Damage caused by a nonspecified fluid is not covered byyour new vehicle limited warranty. NOTE: Automatic transaxle fluid is a red in

color. As driving distance increases, the fluid color turns darkish red gradually. It is a normal condition and you should not judge the needto replace based upon the changing color.

You must replace the automatic

transaxle fluid in accordance withintervals specified in the vehicle maintenance schedule in section5.

!WARNING:

It is always better to check the

transaxle oil level when the engine is cool or cold. If the engine is hot, you should exercise great cautionto avoid burning yourself on hot engine or exhaust parts.

Page 233 of 277

6 DO-IT-YOURSELF MAINTENANCE

24

!

!

CHECKING THE BRAKES

G120A01A-AAT

! CAUTION:

Because brakes are essential to

the safe operation of the car, it is suggested that they be checked and inspected by your Hyundai dealer. The brakes should bechecked and inspected for wear at those intervals specified in the vehicle maintenance schedule inSection 5.

WARNING (Diesel only):

Never work on injection system

with engine running or within 30 seconds after shutting off engine. High pressure pump, rail, injec-tors and high pressure pipes are subject to high pressure even af- ter the engine stopped. The fuel jetproduced by fuel leaks may cause serious injury, if it touch the body. People using pacemakers shouldnot move than 30cm closer to the ECU or wiring harness within the engine room while engine is run-ning, since the high currents in the Common Rail system produce considerable magnetic fields.

WARNING:

The cooling fan is controlled byengine coolant temperature and may sometimes operate even when the engine is not running. Useextreme caution when working near the blades of the cooling fan so that you are not injured by arotating fan blade. As the engine coolant temperature decreases, the fan will automatically shut off. Thisis a normal condition.

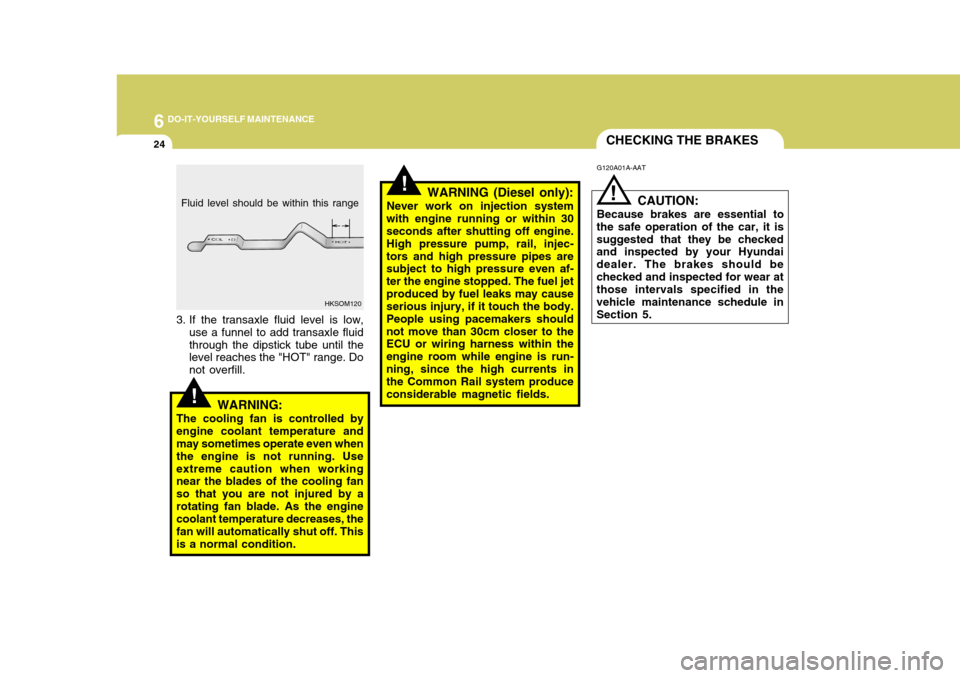

HKSOM120

Fluid level should be within this range

3. If the transaxle fluid level is low, use a funnel to add transaxle fluid through the dipstick tube until the level reaches the "HOT" range. Do not overfill.

Page 255 of 277

6 DO-IT-YOURSELF MAINTENANCE

46FUSE PANEL DESCRIPTION

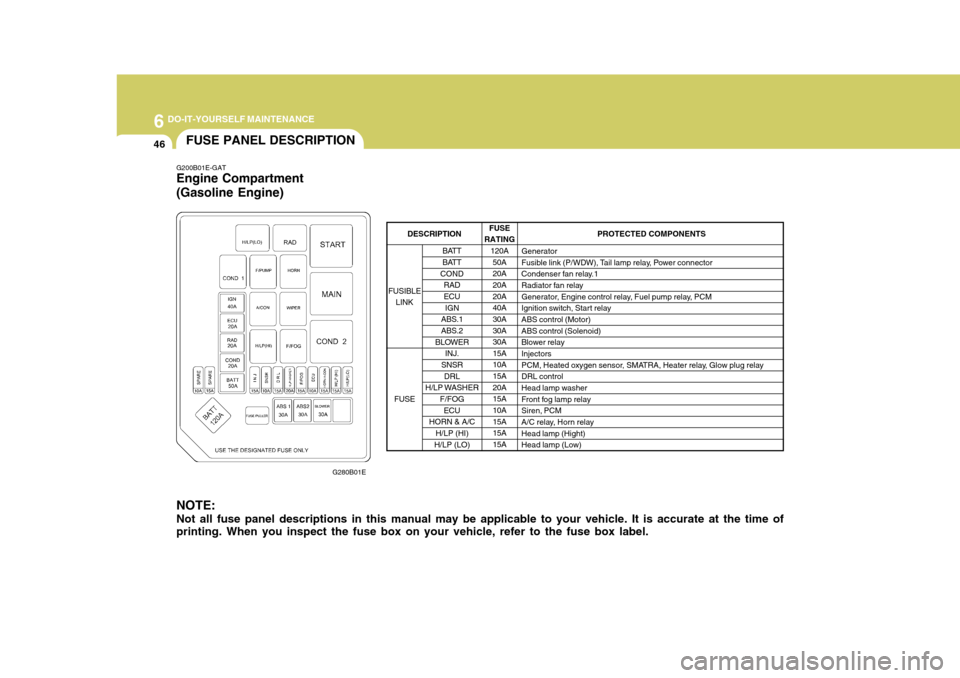

G200B01E-GAT Engine Compartment (Gasoline Engine)

G280B01E

NOTE: Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing. When you inspect the fuse box on your vehicle, refer to the fuse box label.

FUSE

RATING 120A

50A 20A20A 20A 40A30A 30A 30A15A10A 15A 20A15A 10A 15A15A 15A PROTECTED COMPONENTS

Generator

Fusible link (P/WDW), Tail lamp relay, Power connector

Condenser fan relay.1

Radiator fan relay

Generator, Engine control relay, Fuel pump relay, PCM

Ignition switch, Start relay ABS control (Motor) ABS control (Solenoid)

Blower relay Injectors

PCM, Heated oxygen sensor, SMATRA, Heater relay, Glow plug relayDRL control Head lamp washer

Front fog lamp relaySiren, PCM

A/C relay, Horn relay Head lamp (Hight)

Head lamp (Low)

BATT

BATT

COND RADECU

IGN

ABS.1

ABS.2

BLOWER INJ.

SNSR

DRL

H/LP WASHER F/FOG

ECU

HORN & A/C

H/LP (HI)

H/LP (LO)

FUSIBLE

LINK

FUSE

DESCRIPTION

Page 256 of 277

6

DO-IT-YOURSELF MAINTENANCE

47

G280C01E

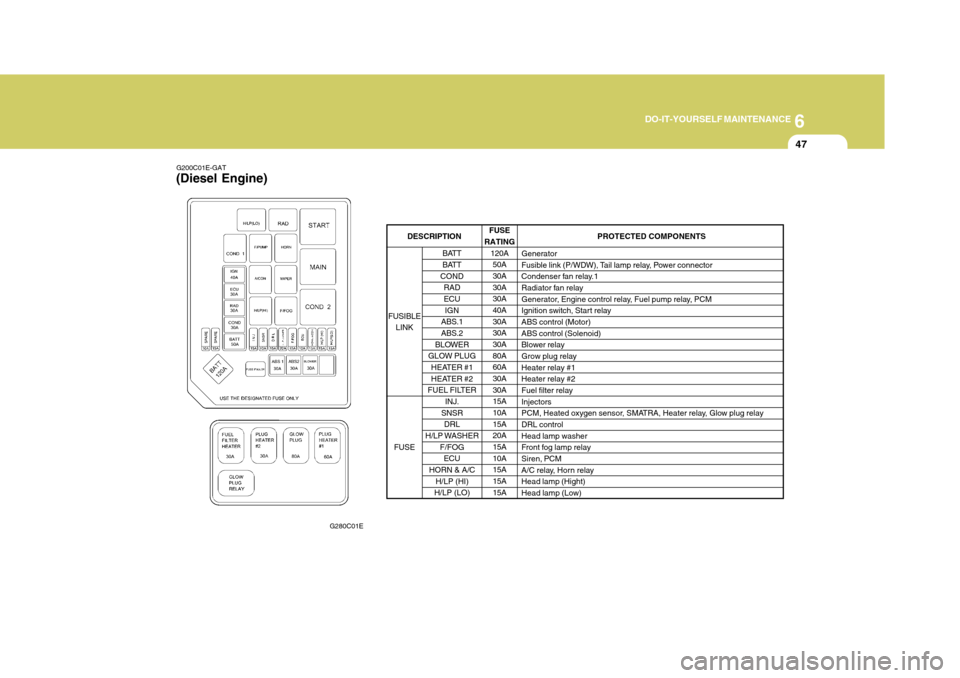

G200C01E-GAT

(Diesel Engine)

FUSE

RATING 120A50A 30A 30A30A 40A 30A30A 30A 80A60A 30A 30A15A 10A 15A20A 15A 10A15A 15A 15A PROTECTED COMPONENTS

Generator

Fusible link (P/WDW), Tail lamp relay, Power connector

Condenser fan relay.1

Radiator fan relay

Generator, Engine control relay, Fuel pump relay, PCM

Ignition switch, Start relay ABS control (Motor) ABS control (Solenoid)

Blower relay

Grow plug relay

Heater relay #1

Heater relay #2

Fuel filter relay Injectors

PCM, Heated oxygen sensor, SMATRA, Heater relay, Glow plug relay DRL control Head lamp washer

Front fog lamp relay Siren, PCM

A/C relay, Horn relayHead lamp (Hight)

Head lamp (Low)

BATT

BATT

COND RADECU

IGN

ABS.1

ABS.2

BLOWER

GLOW PLUG HEATER #1

HEATER #2

FUEL FILTER

INJ.

SNSR DRL

H/LP WASHER

F/FOGECU

HORN & A/C

H/LP (HI)

H/LP (LO)

FUSIBLE

LINK

FUSE

DESCRIPTION