ESP Hyundai Genesis 2012 Workshop Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2012, Model line: Genesis, Model: Hyundai Genesis 2012Pages: 393, PDF Size: 8.81 MB

Page 358 of 393

Maintenance

40 7

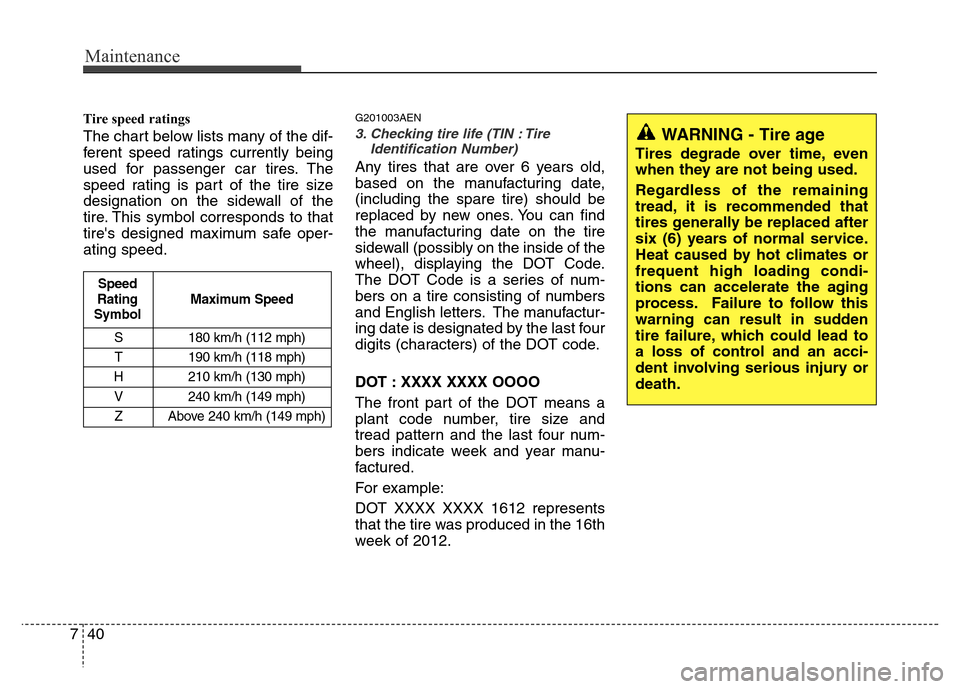

Tire speed ratings

The chart below lists many of the dif-

ferent speed ratings currently being

used for passenger car tires. The

speed rating is part of the tire size

designation on the sidewall of the

tire. This symbol corresponds to that

tire's designed maximum safe oper-

ating speed.

G201003AEN

3. Checking tire life (TIN : Tire

Identification Number)

Any tires that are over 6 years old,

based on the manufacturing date,

(including the spare tire) should be

replaced by new ones. You can find

the manufacturing date on the tire

sidewall (possibly on the inside of the

wheel), displaying the DOT Code.

The DOT Code is a series of num-

bers on a tire consisting of numbers

and English letters. The manufactur-

ing date is designated by the last four

digits (characters) of the DOT code.

DOT : XXXX XXXX OOOO

The front part of the DOT means a

plant code number, tire size and

tread pattern and the last four num-

bers indicate week and year manu-

factured.

For example:

DOT XXXX XXXX 1612 represents

that the tire was produced in the 16th

week of 2012.

S 180 km/h (112 mph)

T 190 km/h (118 mph)

H 210 km/h (130 mph)

V 240 km/h (149 mph)

Z Above 240 km/h (149 mph)

Maximum Speed Speed

Rating

Symbol

WARNING - Tire age

Tires degrade over time, even

when they are not being used.

Regardless of the remaining

tread, it is recommended that

tires generally be replaced after

six (6) years of normal service.

Heat caused by hot climates or

frequent high loading condi-

tions can accelerate the aging

process. Failure to follow this

warning can result in sudden

tire failure, which could lead to

a loss of control and an acci-

dent involving serious injury or

death.

Page 359 of 393

741

Maintenance

G201004AEN

4. Tire ply composition and material

The number of layers or plies of rub-

ber-coated fabric in the tire. Tire

manufacturers also must indicate the

materials in the tire, which include

steel, nylon, polyester, and others.

The letter "R" means radial ply con-

struction; the letter "D" means diago-

nal or bias ply construction; and the

letter "B" means belted-bias ply con-

struction.

G201005AUN

5. Maximum permissible inflation

pressure

This number is the greatest amount

of air pressure that should be put in

the tire. Do not exceed the maximum

permissible inflation pressure. Refer

to the Tire and Loading Information

label for recommended inflation

pressure.

G201006AUN

6. Maximum load rating

This number indicates the maximum

load in kilograms and pounds that

can be carried by the tire. When

replacing the tires on the vehicle,

always use a tire that has the same

load rating as the factory installed

tire.

G2010007BEN

7. Uniform tire quality grading

Quality grades can be found where

applicable on the tire sidewall

between tread shoulder and maxi-

mum section width.

For example:

TREADWEAR 200

TRACTION AA

TEMPERATURE A

Tr e a d w e a r

The tread wear grade is a compara-

tive rating based on the wear rate of

the tire when tested under controlled

conditions on a specified govern-

ment test course. For example, a tire

graded 150 would wear one-and-a-

half times (1½) as well on the gov-

ernment course as a tire graded 100.

The relative performance of tires

depends upon the actual conditions

of their use, however, and may

depart significantly from the norm

due to variations in driving habits,

service practices and differences in

road characteristics and climate.

These grades are molded on the

side-walls of passenger vehicle tires.

The tires available as standard or

optional equipment on your vehicle

may vary with respect to grade.

Page 366 of 393

Maintenance

48 7

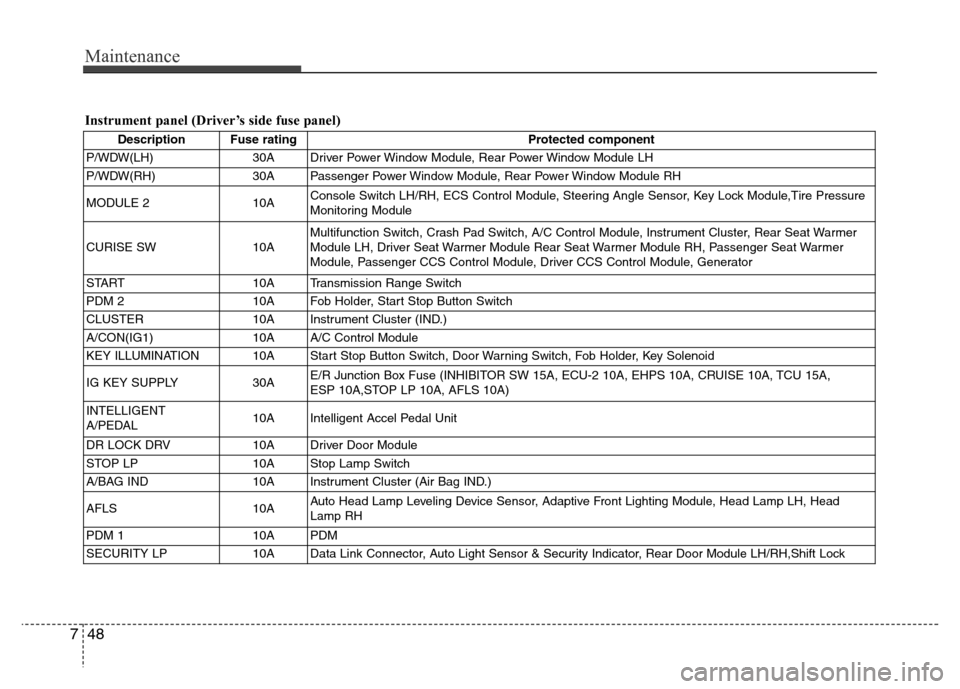

Instrument panel (Driver’s side fuse panel)

Description Fuse rating Protected component

P/WDW(LH) 30A Driver Power Window Module, Rear Power Window Module LH

P/WDW(RH) 30A Passenger Power Window Module, Rear Power Window Module RH

MODULE 2 10AConsole Switch LH/RH, ECS Control Module, Steering Angle Sensor, Key Lock Module,Tire Pressure

Monitoring Module

CURISE SW 10AMultifunction Switch, Crash Pad Switch, A/C Control Module, Instrument Cluster, Rear Seat Warmer

Module LH, Driver Seat Warmer Module Rear Seat Warmer Module RH, Passenger Seat Warmer

Module, Passenger CCS Control Module, Driver CCS Control Module, Generator

START 10A Transmission Range Switch

PDM 2 10A Fob Holder, Start Stop Button Switch

CLUSTER 10A Instrument Cluster (IND.)

A/CON(IG1) 10A A/C Control Module

KEY ILLUMINATION 10A Start Stop Button Switch, Door Warning Switch, Fob Holder, Key Solenoid

IG KEY SUPPLY 30AE/R Junction Box Fuse (INHIBITOR SW 15A, ECU-2 10A, EHPS 10A, CRUISE 10A, TCU 15A,

ESP 10A,STOP LP 10A, AFLS 10A)

INTELLIGENT

A/PEDAL10A Intelligent Accel Pedal Unit

DR LOCK DRV 10A Driver Door Module

STOP LP 10A Stop Lamp Switch

A/BAG IND 10A Instrument Cluster (Air Bag IND.)

AFLS 10AAuto Head Lamp Leveling Device Sensor, Adaptive Front Lighting Module, Head Lamp LH, Head

Lamp RH

PDM 1 10A PDM

SECURITY LP 10A Data Link Connector, Auto Light Sensor & Security Indicator, Rear Door Module LH/RH,Shift Lock

Page 369 of 393

751

Maintenance

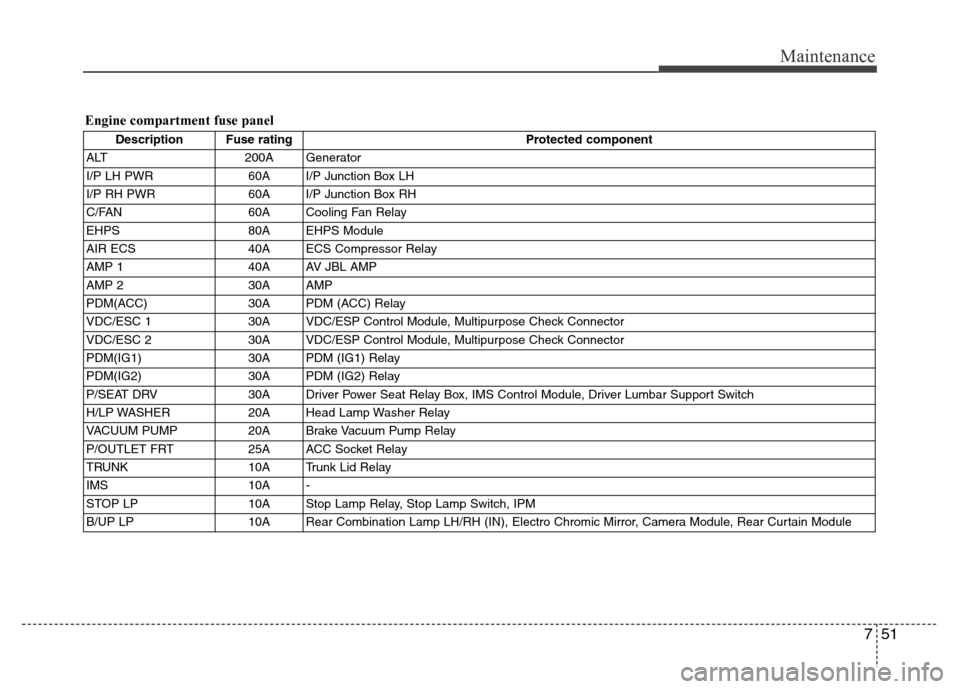

Description Fuse rating Protected component

ALT 200A Generator

I/P LH PWR 60A I/P Junction Box LH

I/P RH PWR 60A I/P Junction Box RH

C/FAN 60A Cooling Fan Relay

EHPS 80A EHPS Module

AIR ECS 40A ECS Compressor Relay

AMP 1 40A AV JBL AMP

AMP 2 30A AMP

PDM(ACC) 30A PDM (ACC) Relay

VDC/ESC 1 30A VDC/ESP Control Module, Multipurpose Check Connector

VDC/ESC 2 30A VDC/ESP Control Module, Multipurpose Check Connector

PDM(IG1) 30A PDM (IG1) Relay

PDM(IG2) 30A PDM (IG2) Relay

P/SEAT DRV 30A Driver Power Seat Relay Box, IMS Control Module, Driver Lumbar Support Switch

H/LP WASHER 20A Head Lamp Washer Relay

VACUUM PUMP 20A Brake Vacuum Pump Relay

P/OUTLET FRT 25A ACC Socket Relay

TRUNK 10A Trunk Lid Relay

IMS 10A -

STOP LP 10A Stop Lamp Relay, Stop Lamp Switch, IPM

B/UP LP 10A Rear Combination Lamp LH/RH (IN), Electro Chromic Mirror, Camera Module, Rear Curtain Module

Engine compartment fuse panel

Page 370 of 393

Maintenance

52 7

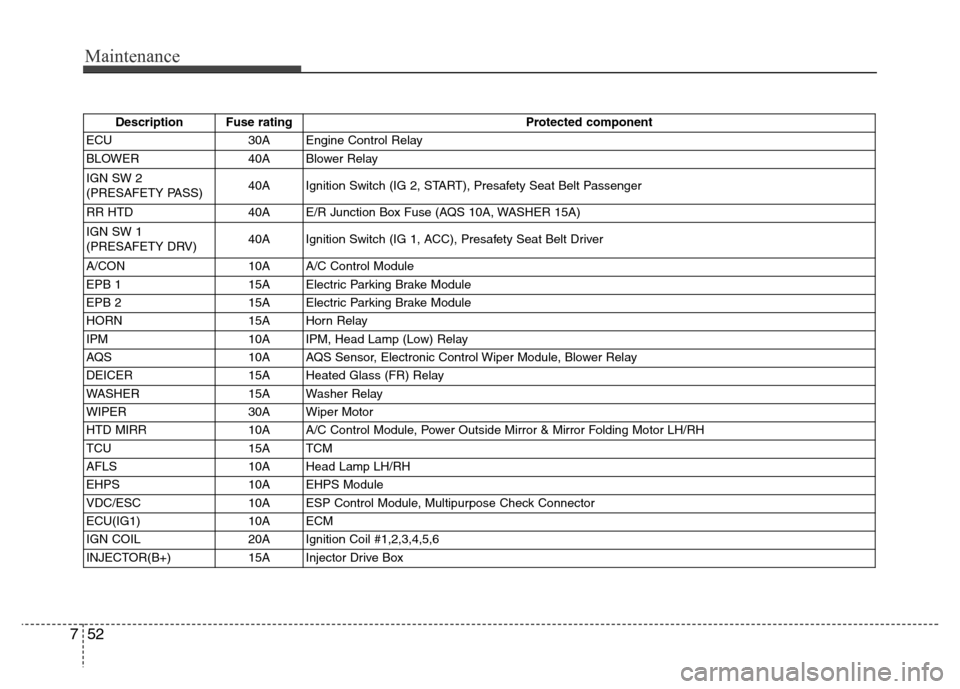

Description Fuse rating Protected component

ECU 30A Engine Control Relay

BLOWER 40A Blower Relay

IGN SW 2

(PRESAFETY PASS)40A Ignition Switch (IG 2, START), Presafety Seat Belt Passenger

RR HTD 40A E/R Junction Box Fuse (AQS 10A, WASHER 15A)

IGN SW 1

(PRESAFETY DRV)40A Ignition Switch (IG 1, ACC), Presafety Seat Belt Driver

A/CON 10A A/C Control Module

EPB 1 15A Electric Parking Brake Module

EPB 2 15A Electric Parking Brake Module

HORN 15A Horn Relay

IPM 10A IPM, Head Lamp (Low) Relay

AQS 10A AQS Sensor, Electronic Control Wiper Module, Blower Relay

DEICER 15A Heated Glass (FR) Relay

WASHER 15A Washer Relay

WIPER 30A Wiper Motor

HTD MIRR 10A A/C Control Module, Power Outside Mirror & Mirror Folding Motor LH/RH

TCU 15A TCM

AFLS 10A Head Lamp LH/RH

EHPS 10A EHPS Module

VDC/ESC 10A ESP Control Module, Multipurpose Check Connector

ECU(IG1) 10A ECM

IGN COIL 20A Ignition Coil #1,2,3,4,5,6

INJECTOR(B+) 15A Injector Drive Box

Page 372 of 393

Maintenance

54 7

LIGHT BULBS

G220000AEN

Use only the bulbs of the specified

wattage.

✽NOTICE

After heavy, driving rain or washing,

headlight and taillight lenses could

appear frosty. This condition is caused by

the temperature difference between the

lamp inside and outside. This is similar

to the condensation on your windows

inside your vehicle during the rain and

doesn’t indicate a problem with your

vehicle. If the water leaks into the lamp

bulb circuitry, have the vehicle checked

by an authorized HYUNDAI dealer.

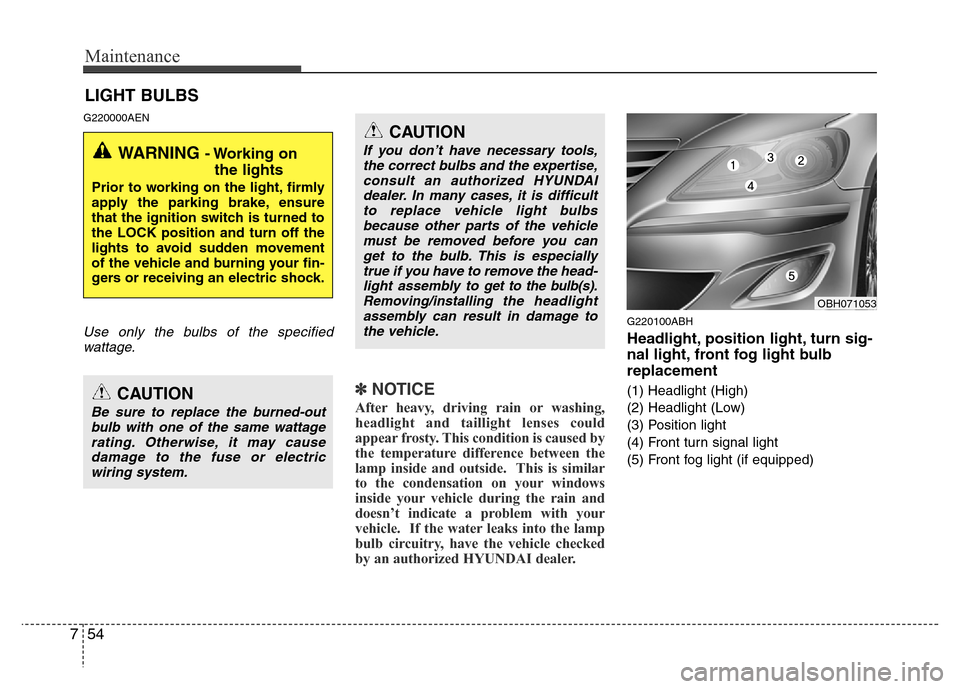

G220100ABH

Headlight, position light, turn sig-

nal light, front fog light bulb

replacement

(1) Headlight (High)

(2) Headlight (Low)

(3) Position light

(4) Front turn signal light

(5) Front fog light (if equipped)

WARNING - Working on

the lights

Prior to working on the light, firmly

apply the parking brake, ensure

that the ignition switch is turned to

the LOCK position and turn off the

lights to avoid sudden movement

of the vehicle and burning your fin-

gers or receiving an electric shock.

CAUTION

Be sure to replace the burned-out

bulb with one of the same wattage

rating. Otherwise, it may cause

damage to the fuse or electric

wiring system.

CAUTION

If you don’t have necessary tools,

the correct bulbs and the expertise,

consult an authorized HYUNDAI

dealer. In many cases, it is difficult

to replace vehicle light bulbs

because other parts of the vehicle

must be removed before you can

get to the bulb. This is especially

true if you have to remove the head-

light assembly to

get to the bulb(s).

Removing/installingthe headlight

assembly can result in damage to

the vehicle.OBH071053

Page 378 of 393

Maintenance

60 7

Exterior care

G230101AUN

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning and

caution statements that appear on the

label.

G230102ABH

Finish maintenance

Washing

To help protect your vehicle’s finish from

rust and deterioration, wash it thoroughly

and frequently at least once a month with

lukewarm or cold water.

If you use your vehicle for off-road driv-

ing, you should wash it after each off-

road trip. Pay special attention to the

removal of any accumulation of salt, dirt,

mud, and other foreign materials. Make

sure the drain holes in the lower edges of

the doors and rocker panels are kept

clear and clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar deposits

can damage your vehicle’s finish if not

removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used.After washing, rinse the vehicle thor-

oughly with lukewarm or cold water. Do

not allow soap to dry on the finish.

APPEARANCE CARE

CAUTION

• Do not use strong soap, chemical

detergents or hot water, and do

not wash the vehicle in direct

sunlight or when the body of the

vehicle is warm.

• Be careful when washing the side

windows of your vehicle.

Especially, with high-pressure

water, water may leak through the

windows and wet the interior.

• To prevent damage to the plastic

parts and lamps, do not clean

with chemical solvents or strong

detergents.

WARNING - Wet brakes

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

CAUTION

• Water washing in the engine com-

partment including high pressure

water washing may cause the fail-

ure of electrical circuits or engine

and related part located in the

engine compartment.

• Never allow water or other liquids

to come in contact with electri-

cal/electronic components and

air duct inside the vehicle as this

may damage them.

OJB037800

Page 384 of 393

Maintenance

66 7

EMISSION CONTROL SYSTEM (IF EQUIPPED)

G270000AEN

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Service Passport

in your vehicle.

Your vehicle is equipped with an emis-

sion control system to meet all applicable

emission regulations.

There are three emission control sys-

tems, as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system

(3) Exhaust emission control system

In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by an author-

ized HYUNDAI dealer in accordance with

the maintenance schedule in this manu-

al.Caution for the Inspection and

Maintenance Test (With Electronic

Stability Program (ESP) system)

• To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability

Program (ESP) system off by press-

ing the ESP switch.

• After dynamometer testing is com-

pleted, turn the ESP system back on

by pressing the ESP switch again.

G270100AUN

1. Crankcase emission control

system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valve

into the induction system.

G270200AEN

2. Evaporative emission control

system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

Page 391 of 393

85

Specifications & Consumer information

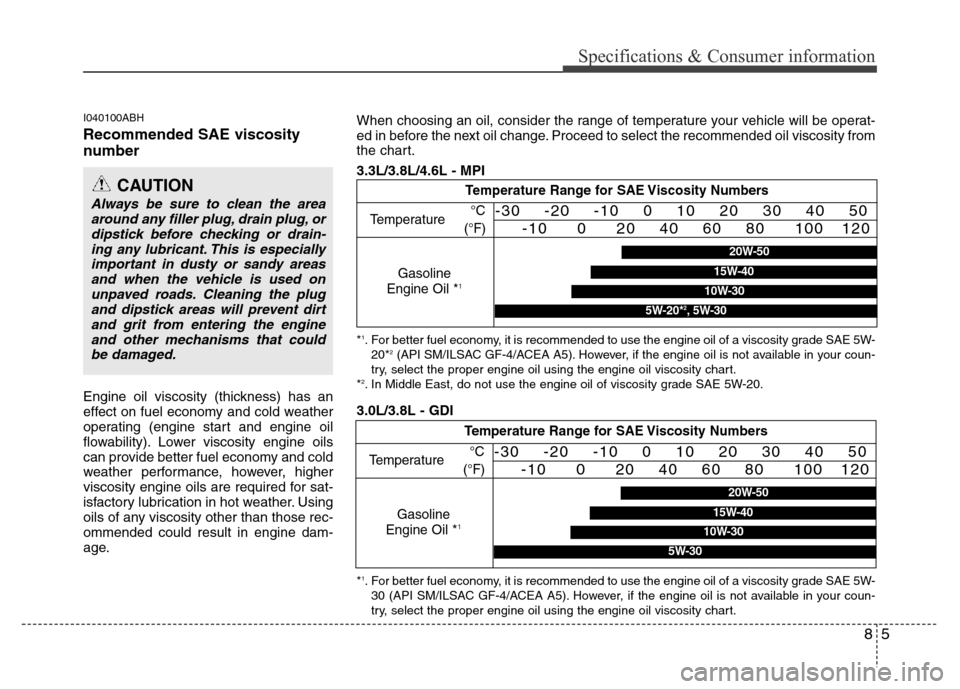

I040100ABH

Recommended SAE viscosity

number

Engine oil viscosity (thickness) has an

effect on fuel economy and cold weather

operating (engine start and engine oil

flowability). Lower viscosity engine oils

can provide better fuel economy and cold

weather performance, however, higher

viscosity engine oils are required for sat-

isfactory lubrication in hot weather. Using

oils of any viscosity other than those rec-

ommended could result in engine dam-

age.

CAUTION

Always be sure to clean the area

around any filler plug, drain plug, or

dipstick before checking or drain-

ing any lubricant. This is especially

important in dusty or sandy areas

and when the vehicle is used on

unpaved roads. Cleaning the plug

and dipstick areas will prevent dirt

and grit from entering the engine

and other mechanisms that could

be damaged.Temperature Range for SAE Viscosity Numbers

Temperature

Gasoline

Engine Oil *

1

°C

(°F)-30 -20 -10 0 10 20 30 40 50

-10 0 20 40 60 80 100 120

*1. For better fuel economy, it is recommended to use the engine oil of a viscosity grade SAE 5W-

30 (API SM/ILSAC GF-4/ACEA A5). However, if the engine oil is not available in your coun-

try, select the proper engine oil using the engine oil viscosity chart.

20W-50

10W-30

15W-40

5W-20*2, 5W-30

Temperature Range for SAE Viscosity Numbers

Temperature

Gasoline

Engine Oil *

1

°C

(°F)-30 -20 -10 0 10 20 30 40 50

-10 0 20 40 60 80 100 120

20W-50

10W-30

15W-40

5W-30

3.3L/3.8L/4.6L - MPI When choosing an oil, consider the range of temperature your vehicle will be operat-

ed in before the next oil change. Proceed to select the recommended oil viscosity from

the chart.

3.0L/3.8L - GDI

*1. For better fuel economy, it is recommended to use the engine oil of a viscosity grade SAE 5W-

20*2(API SM/ILSAC GF-4/ACEA A5). However, if the engine oil is not available in your coun-

try, select the proper engine oil using the engine oil viscosity chart.

*

2. In Middle East, do not use the engine oil of viscosity grade SAE 5W-20.