Hyundai Getz 2005 Owner's Manual

Manufacturer: HYUNDAI, Model Year: 2005, Model line: Getz, Model: Hyundai Getz 2005Pages: 437, PDF Size: 11.19 MB

Page 131 of 437

4. CORROSION PREVENTION &APPEARANCE CARE

Protecting Your Hyundai From Corrosion ...................................... 4-2

Underbody coatings ........................................................................ 4-2Polishing ......................................................................................... 4-3

Interior Valeting ............................................................................... 4-4

4

Page 132 of 437

4- 2 CORROSION PREVENTION AND APPEARANCE CARE

SE020A1-E PROTECTING YOUR HYUNDAI FROM CORROSION By using the most advanced design and construction practices, every Hyundai is built to retain the originalfactory finish for many years. How- ever, long term durability is also greatly dependant upon maintaining the vari-ous protection systems and coatings used in manufacture since constant, exposure to the elements will result ina breakdown and loss of effective- ness. The following suggestions are made to assist in the maintenance ofthe vehicle bodywork. SE030A1-E UNDERBODY COATINGS Every Hyundai passenger car receives a full underbody and cavity injectiontreatment during production. In order that this treatment may retain maxi- mum effectiveness it is recommendedthat the underbody receives a power wash and a thorough inspection after each winter season. In doing so anyaccumulations of mud, which act as moisture traps and combine with road salts to accelerate corrosion will beremoved. In order to maintain the Anti Perforation Warranty, the requirements regarding the retreatment programmemust be observed in accordance with the Terms and Conditions outlined in the separate Anti Perforation WarrantyBooklet. NOTE: The underbody should never be steam cleaned since the underbodycoating may be removed by this process. During the interim period betweenpower washing the underbody, the more vulnerable areas such as wheel arches should be hosed off particularly during the winter sea- son to prevent prolonged contact with road salts.Ensure that the various drain points located at the bottom of the door panels and sills are kept clear toprevent water from becoming trapped within the cavities. Wher- ever possible, the parking of thevehicle in a confined, poorly venti- lated location (a garage for example) should be avoided when the ve-hicle is wet or is covered with snow or ice. Under these conditions, the internal cavities of the vehicle willremain damp for prolonged peri- ods of time which will encourage corrosion. Parking the vehiclewhere good ventilation exists (out- side for example) is preferable.

Page 133 of 437

CORROSION PREVENTION AND APPEARANCE CARE 4- 3

SE040A1-E VALETING Regular cleaning of the exterior paintwork serves two important func-tions. Firstly, the removal of abrasive dirt and contaminants will maintain the lustre of the paintwork and will preventdiscolouration and dulling due to pro- longed contact. Secondly, the presence of damagethrough impact or abrasion will be ap- parent allowing early rectification to be made thus preventing corrosion frombecoming established and spreading beneath the paint film. To avoid "water spotting" the vehicle should not bewashed in direct sunlight particularly in the case of vehicles having dark body colours. The heat from the sun rays isabsorbed by the paint film increasing the surface temperature. This action causes water used for washing toevaporate quickly leaving behind the deposits from the water and the sham- poo used.Use only a shampoo intended for the purpose and ensure that the body work is thoroughly wetted to soften the dirtfilm prior to attempting to remove this. After removing the dirt film with a soft sponge, the body work should be thor- oughly rinsed and then dried with agood quality chamois leather to pre- vent streaking or spotting of the paint work.Household detergents, solvents and abrasive cleaning materials should not be used in order to avoid damaging thepaint film. Plastic wheel covers should be cleaned using a sponge and water. Cast alloywheels should be cleaned using a mild soap or neutral detergent. Abrasive compounds must not be used since inthe event of these damaging the lac- quer coating, oxidization of the alu- minium wheel will occur, spoiling theappearance. The use of an a toothbrush will facili- tate cleaning between the wheel"spokes".

SE040B1-E STAIN/SPOT REMOVAL Should tree sap, dead insects or tar prove to be difficult to remove from thepaint film, turpentine or a proprietary paint cutting compound may be used. Ensure that the area to be cleaned isnot rubbed intensively to prevent break- ing through the colour coat and expos- ing the under coat. SE040C1-E POLISHING The exterior paint work should be pol- ished with a proprietary wax polish when water no longer collects in bead form on the paint work. The instruc-tions of the product manufacturer should be adhered to.

Page 134 of 437

4- 4 CORROSION PREVENTION AND APPEARANCE CARE

SE040E1-E BUMPER MAINTENANCE The special material from which the bumpers are manufactured warrantsspecial attention to preserve the ap- pearance of the bumpers. Avoid con- tact with battery electrolyte or brakefluid and ensure that accidental spill- ages are immediately flushed with water.Do not use abrasive cleaning materi- als which may damage the bumpers. Avoid subjecting the bumpers to hightemperatures such as may be encoun- tered in high bake paint ovens.

SE040F1-E ACCIDENT REPAIRERS In the event of the body work sustain- ing damage, the following points should be noted prior to repairers being un- dertaken.If body panels are replaced or repairered, anti corrosion treatment must be applied to the repairer area.The product used must be compatible with those used in manufacture. It is recommended that repairers are en-trusted to a Hyundai authorised re- pairer to ensure that replacement parts used are of the same high quality as those used in manufacture of the ve-hicle and that the correct repairer meth- ods and materials will ensure adequate levels of corrosion protection and thecontinued validity of the Anti Perfora- tion Warranty. SE050A1-E INTERIOR During the winter period, it is possible that the passenger compartment floor- ing may become wet from damp foot- wear or quantities of snow adhering tofootwear. The carpet should not be allowed to remain in this condition since the carpet may begin to create mustysmells and will promote corrosion of the floor pan in addition to the carpet and under felt beginning to rot.

SE050C1-E INTERIOR VALETING The soft trim and carpets should be maintained with the regular use of avacuum cleaner. Heavy soiling should be removed with a dry cleaning agent recommended for this purpose follow-ing the instructions of the product manufacturer. Paint thinner, solvents or other such cleaning materials shouldnot be used since damage to the up- holstery may result. SE050D1-E SEAT BELTS Seat belts should be cleaned only with a mild soap solution. Strong deter- gents, solvens or bleaches may dam- age the belt webbing and thereforereduce the effectiveness of the belt. Belts which display signs of fraying, wear of cut should be replaced.

Page 135 of 437

CORROSION PREVENTION AND APPEARANCE CARE 4- 5

SE050E1-E WINDOWS A proprietary glass cleaner should be used to clean the inside of the win-dows. However, the rear heated wind- shield must only be cleaned using a light horizontal cleaning action. Careshould be exercised to avoid the use of abrasive cleaners or contact with items of jewellery which may damage theheating elements.

Page 136 of 437

5. VEHICLE MAINTENANCEREQUIREMENTS

Maintenance and Servicing Requirements ....................................... 5-2

Scheduled maintenance ................................................................... 5-3

Maintenance under severe usage conditions ................................... 5-6

Explanation of scheduled maintenance items .................................. 5-7

5

Page 137 of 437

5- 2 VEHICLE MAINTENANCE REQUIREMENTS

SF020A1-E MAINTENANCE AND SERVICING REQUIREMENTS To ensure the continued reliability and safety of the vehicle, certain routinemaintenance operations are required at specific mileage or time intervals. It is the responsibility of the vehicle owner to ensure that the maintenance schedules shown in both this OwnersManual and the Warranty and Service Passport are adhered to. The new vehicle warranty may be invalidated if the routine maintenance operations are not performed in line with the recommendations outlinedand the safety and durability of the vehicle adversely affected. It is recommended that all mainte- nance operations with the exception of the daily operating checks are en-trusted to a Hyundai authorised re- pairer to ensure that the latest repairer and maintenance procedures and spe-cialized servicing tools are employed. In addition, the use of genuine Hyundai replacement parts will ensure that thevehicle safety and performance will not be compromised. NOTE:

The inspection and testing of cer-

tain electronic fuel injection/engine management and automatic trans- mission control systems require specialised electronic equipmentspecifically designed for Hyundai vehicles. The use of general pur- pose electrical test equipment mayresult in damage to the control unit microprocessors.

SF020C2-E

Specified Scheduled Procedures

The Specified scheduled procedures

are listed in the maintenance charts beginning at page 5-3. The opera- tions specified must be performed at the time or mileage intervals shownirrespective of whether the mileage interval has been reached before the specified time interval. Certain lubricants and components

degrade with both time and mileage(e.g. engine oil and brake fluid) and therefore it is not permissable to base the maintenance schedule upon mile-age alone. It is strongly recommended that the maintenance operations are performed by the factory-trained ordistributor-trained technicians at your Hyundai authorised repairer becauseof the need for specialized knowledge and tooling and to ensure that no possibility of invalidating the manufac-turers warranty exists.

The maintenance schedules relate to

vehicles operated under normal con- ditions, vehicles which are operated under adverse conditions will requiremore frequent maintenance which is described at page 5-6. NOTE:

Service schedules may change de-

pending on individual country needs. Please ask your localHyundai authorised repairer for a copy of the service schedule that relates to that country.

SF030B1-E

SERVICE HISTORY

It is important that all scheduled main-

tenance services are recorded in thewarranty and service passport to en-sure that proof of maintenance is avail- able when warranty service is required.

Page 138 of 437

VEHICLE MAINTENANCE REQUIREMENTS 5- 3

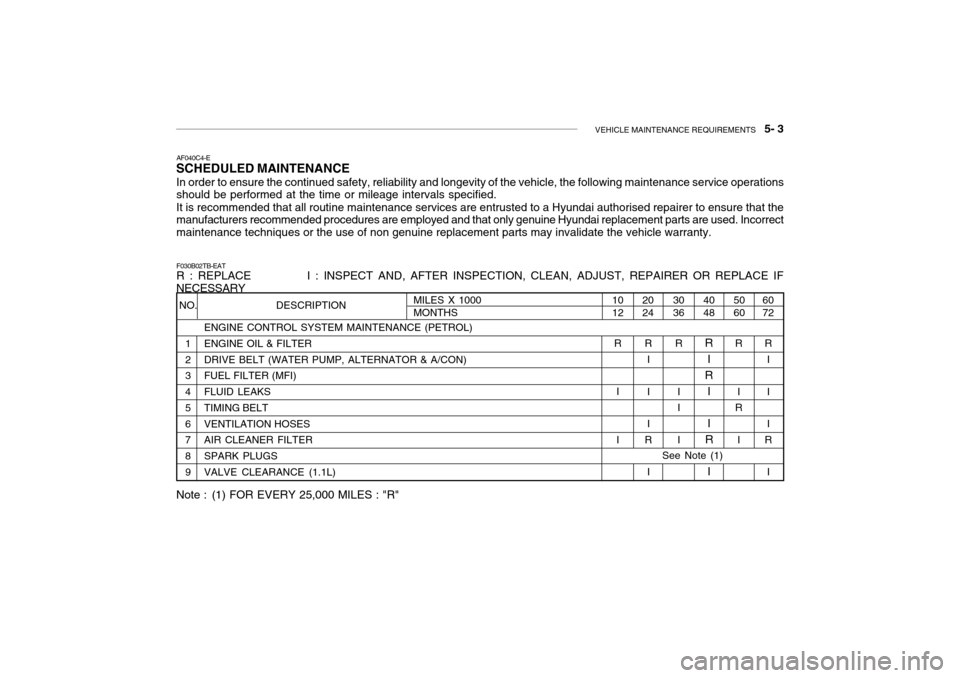

ENGINE CONTROL SYSTEM MAINTENANCE (PETROL)

1 ENGINE OIL & FILTER

2 DRIVE BELT (WATER PUMP, ALTERNATOR & A/CON)

3 FUEL FILTER (MFI)

4 FLUID LEAKS

5 TIMING BELT

6 VENTILATION HOSES

7 AIR CLEANER FILTER

8 SPARK PLUGS

9 VALVE CLEARANCE (1.1L)

AF040C4-E

SCHEDULED MAINTENANCE

In order to ensure the continued safety, reliability and longevity of the vehicle, the following maintenance service operations should be performed at the time or mileage intervals specified. It is recommended that all routine maintenance services are entrusted to a Hyundai authorised repairer to ensure that the manufacturers recommended procedures are employed and that only genuine Hyundai replacement parts are used. Incorrect maintenance techniques or the use of non genuine replacement parts may invalidate the vehicle warranty. F030B02TB-EAT R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIRER OR REPLACE IF NECESSARY

Note : (1) FOR EVERY 25,000 MILES : "R"

NO. DESCRIPTION60 72

5060

4048

3036

2024

1012

MILES X 1000 MONTHS

R

I II

R

I

R

I

R

I

R

I

R

I

I

R

I

R

I I I

R

III

R

I

R

I I

See Note (1)

Page 139 of 437

5- 4 VEHICLE MAINTENANCE REQUIREMENTS

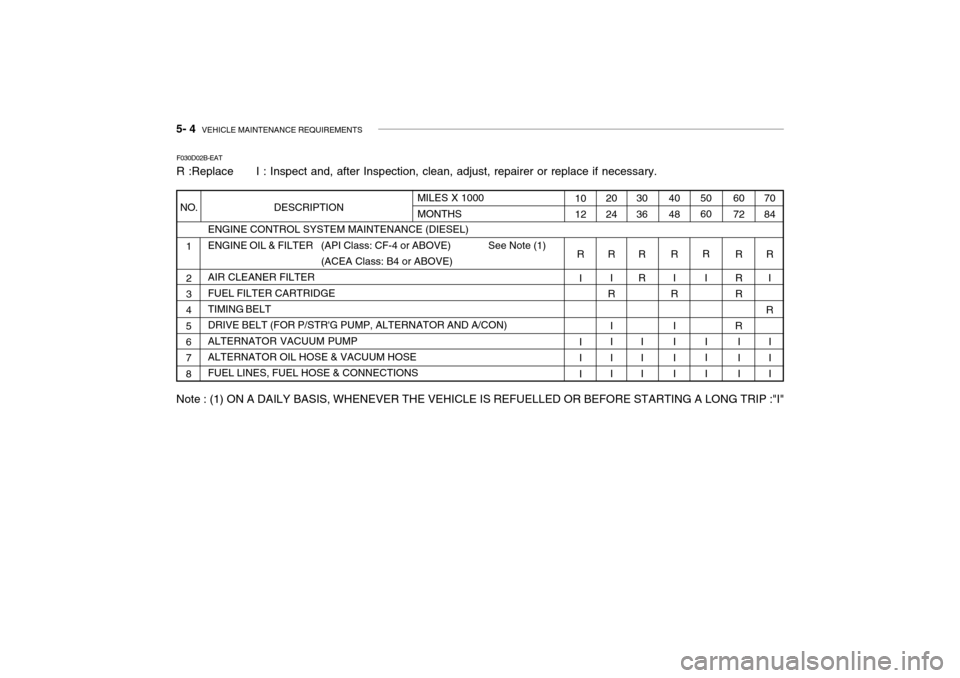

F030D02B-EAT R :Replace I : Inspect and, after Inspection, clean, adjust, repairer or replace if necessary.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL)

ENGINE OIL & FILTER (API Class: CF-4 or ABOVE) See Note (1)

(ACEA Class: B4 or ABOVE)

AIR CLEANER FILTERFUEL FILTER CARTRIDGE TIMING BELT DRIVE BELT (FOR P/STR'G PUMP, ALTERNATOR AND A/CON)ALTERNATOR VACUUM PUMP ALTERNATOR OIL HOSE & VACUUM HOSE FUEL LINES, FUEL HOSE & CONNECTIONS

1 2 3 4

5 6 7 8 6072

R R R

R I II

50 60

R I

II I40 48 R I

R

I I II30 36

R R

I II20 24R I

R

I I II

10 12

R I I I IMILES X 1000 MONTHS70 84

R I

R III

Note : (1) ON A DAILY BASIS, WHENEVER THE VEHICLE IS REFUELLED OR BEFORE STARTING A LONG TRIP :"I"

NO. DESCRIPTION

Page 140 of 437

VEHICLE MAINTENANCE REQUIREMENTS 5- 5

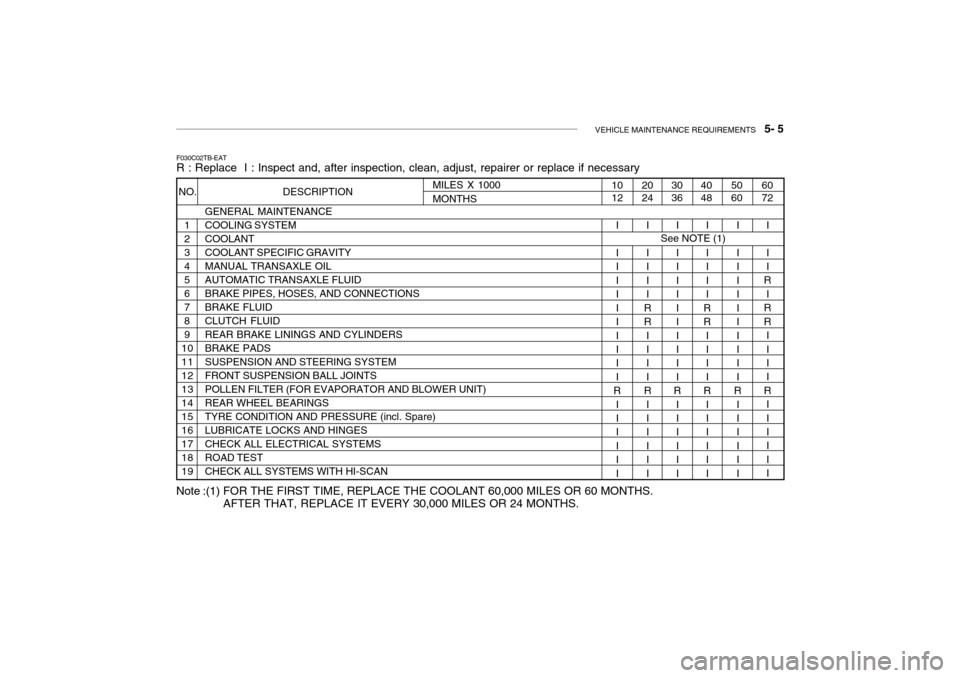

F030C02TB-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repairer or replace if necessary

GENERAL MAINTENANCE COOLING SYSTEMCOOLANTCOOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDBRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUIDCLUTCH FLUIDREAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEMFRONT SUSPENSION BALL JOINTSPOLLEN FILTER (FOR EVAPORATOR AND BLOWER UNIT)REAR WHEEL BEARINGSTYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGESCHECK ALL ELECTRICAL SYSTEMSROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN

60 72

5060

4048

I I I

R

I

RR II I I

R III I II

I I I IIIII I II

R II I III

I I I II

RR I I II

R II I III

30 36

2024

I I I IIIII I II

R II I III

I I I II

RR I I II

R II I III

10 12

I I I IIIII I II

R II I III

MILES X 1000MONTHS

NO. DESCRIPTION

1 23456789

10111213141516171819

See NOTE (1)

Note :(1) FOR THE FIRST TIME, REPLACE THE COOLANT 60,000 MILES OR 60 MONTHS. AFTER THAT, REPLACE IT EVERY 30,000 MILES OR 24 MONTHS.