engine Hyundai Getz 2007 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2007, Model line: Getz, Model: Hyundai Getz 2007Pages: 463, PDF Size: 11.14 MB

Page 426 of 463

DO-IT-YOURSELF MAINTENANCE 6- 15

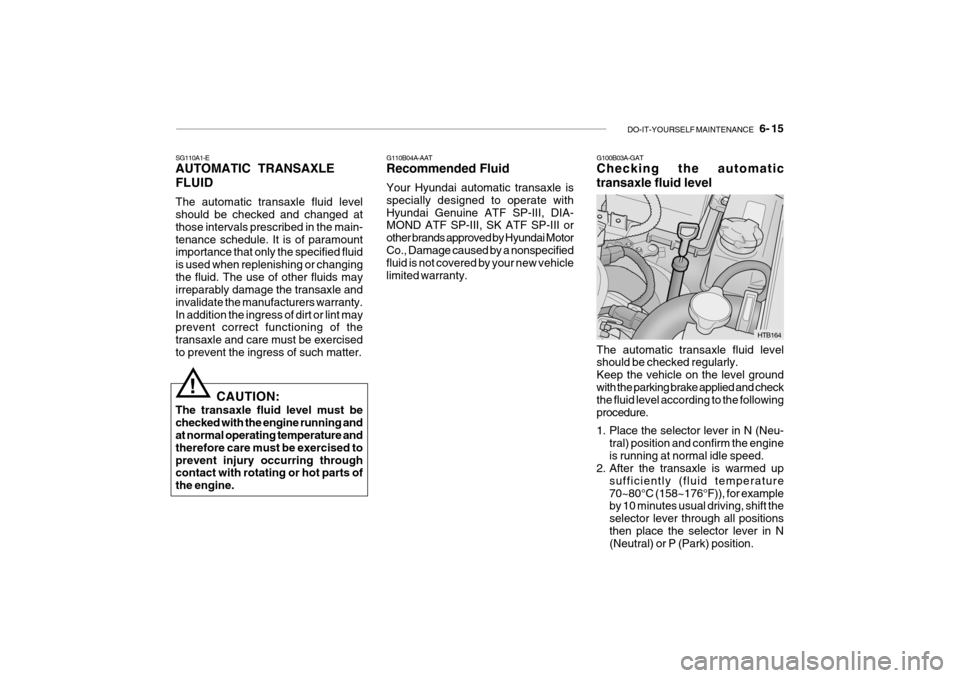

G100B03A-GAT Checking the automatic transaxle fluid level

SG110A1-E AUTOMATIC TRANSAXLE FLUID The automatic transaxle fluid level should be checked and changed at those intervals prescribed in the main-tenance schedule. It is of paramount importance that only the specified fluid is used when replenishing or changingthe fluid. The use of other fluids may irreparably damage the transaxle and invalidate the manufacturers warranty.In addition the ingress of dirt or lint may prevent correct functioning of the transaxle and care must be exercisedto prevent the ingress of such matter.

CAUTION:

The transaxle fluid level must bechecked with the engine running and at normal operating temperature and therefore care must be exercised toprevent injury occurring through contact with rotating or hot parts of the engine.

! G110B04A-AAT Recommended Fluid Your Hyundai automatic transaxle is specially designed to operate withHyundai Genuine ATF SP-III, DIA- MOND ATF SP-III, SK ATF SP-III or other brands approved by Hyundai MotorCo., Damage caused by a nonspecified fluid is not covered by your new vehicle limited warranty.

The automatic transaxle fluid level should be checked regularly. Keep the vehicle on the level groundwith the parking brake applied and check the fluid level according to the following procedure.

1. Place the selector lever in N (Neu-tral) position and confirm the engine is running at normal idle speed.

2. After the transaxle is warmed up

sufficiently (fluid temperature70~80°C (158~176°F)), for example by 10 minutes usual driving, shift the selector lever through all positionsthen place the selector lever in N (Neutral) or P (Park) position.

HTB164

Page 427 of 463

6- 16 DO-IT-YOURSELF MAINTENANCE

if it touch the body. People using pacemakers should not move than 30cm closer to the ECU or wiringharness within the engine room while engine is running, since the high currents in the Common Rail systemproduce considerable magnetic fields.

!

CAUTION:

The automatic transaxle unit is a precision engineered assembly and correct operation is dependant uponthe exclusion of dirt and lint from the unit. Therefore, it is imperative that only lint free cloth (eg nylon) is usedfor wiping the dipstick and that the area around the dipstick is thor- oughly clean prior to level checkingor adding fluid. Fluid Capacity The total fluid capacity of the transaxle unit is 6.1 litres.

!

!

C090A03FC

Fluid level should be within "HOT" range

3. Confirm that the fluid level is in “HOT” range on the level gauge. If the fluid level is lower, add the specified fluid from the fill hole. If the fluid level is higher, drain the fluid from the drainhole.

4. If the fluid level is checked in cold

condition (fluid temperature 20~30°C(68~86°F)) add the fluid to “COLD” line and then recheck the fluid level according to the above step 2. WARNING:

The cooling fan is controlled by en-gine coolant temperature and maysometimes operate even when the engine is not running. Use extreme caution when working near theblades of the cooling fan so that you are not injured by a rotating fan blade. As the engine coolant tem-perature decreases, the fan will auto- matically shut off. This is a normal condition.

WARNING (Diesel only):

Never work on injection system withengine running or within 30 seconds after shutting off engine. High pres- sure pump, rail, injectors and highpressure pipes are subject to high pressure even after the engine stopped. The fuel jet produced byfuel leaks may cause serious injury,

Page 429 of 463

6- 18 DO-IT-YOURSELF MAINTENANCE

SG140C1-E Checking the Refrigerant

1. Start the engine and run at idle for

several minutes with the refrigera- tion system running at the coldest setting.

2. Open the bonnet and inspect the

sight glass on the top of the receiverdryer.

3. If the refrigerant charge is insuffi- cient, a flow of bubbles will be ob-served through the sight glass.

4. If the refrigerant charge is satisfac- tory, no bubbles will be observedthrough the sight glass.

CAUTION:

Running the air conditioning systemwith a low refrigerant level may dam- age the compressor.

!

!WARNING:

Brake fluid is hygroscopic and should never be stored in an un-sealed container. The presence of water in the braking system will cause vapour locks and increase the possi-bility of brake fade along with pro- moting corrosion within the braking system. The brake fluid must bechanged at the specified time or mile- age interval to ensure continued safe operation of the system. Brake fluid will cause rapid and serious damage to paintwork. If accidental spillageoccurs, the affected area must be rinsed with water immediately. Do not allow brake fluid to come intocontact with the eyes or to be in- gested and ensure that fluid is safely stored away form the reach of chil-dren. SG140A1-E AIR CONDITIONING SYSTEM MAINTENANCECondenser Ensure that the condenser is periodi- cally inspected and that accumulations of dirt, dead insects and leaves etc, areremoved to ensure that the efficiency of the system is not impaired. Care must be exercised to ensure that the con-denser fins are not damaged during cleaning.

Page 431 of 463

6- 20 DO-IT-YOURSELF MAINTENANCE

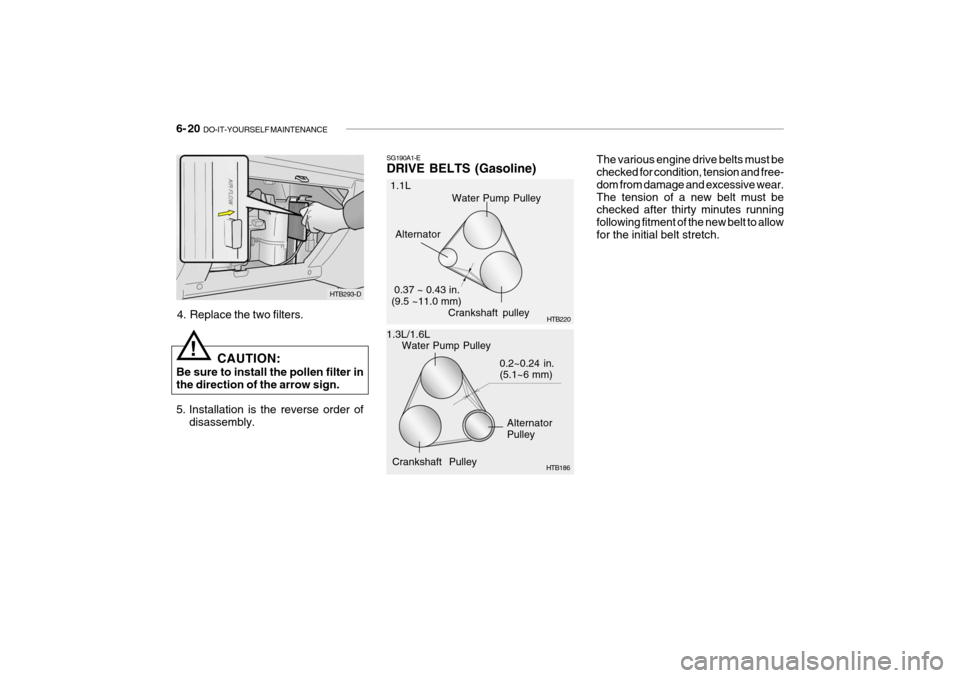

The various engine drive belts must be checked for condition, tension and free- dom from damage and excessive wear.The tension of a new belt must be checked after thirty minutes running following fitment of the new belt to allowfor the initial belt stretch.

Crankshaft Pulley

SG190A1-E DRIVE BELTS (Gasoline)

1.1L

1.3L/1.6L Alternator

0.37 ~ 0.43 in. (9.5 ~11.0 mm)

Water Pump Pulley

Alternator Pulley

0.2~0.24 in.(5.1~6 mm)

HTB186

Crankshaft pulley

HTB220

Water Pump Pulley

HTB293-D

4. Replace the two filters.

CAUTION:

Be sure to install the pollen filter in the direction of the arrow sign.

5. Installation is the reverse order of disassembly.

!

Page 432 of 463

DO-IT-YOURSELF MAINTENANCE 6- 21

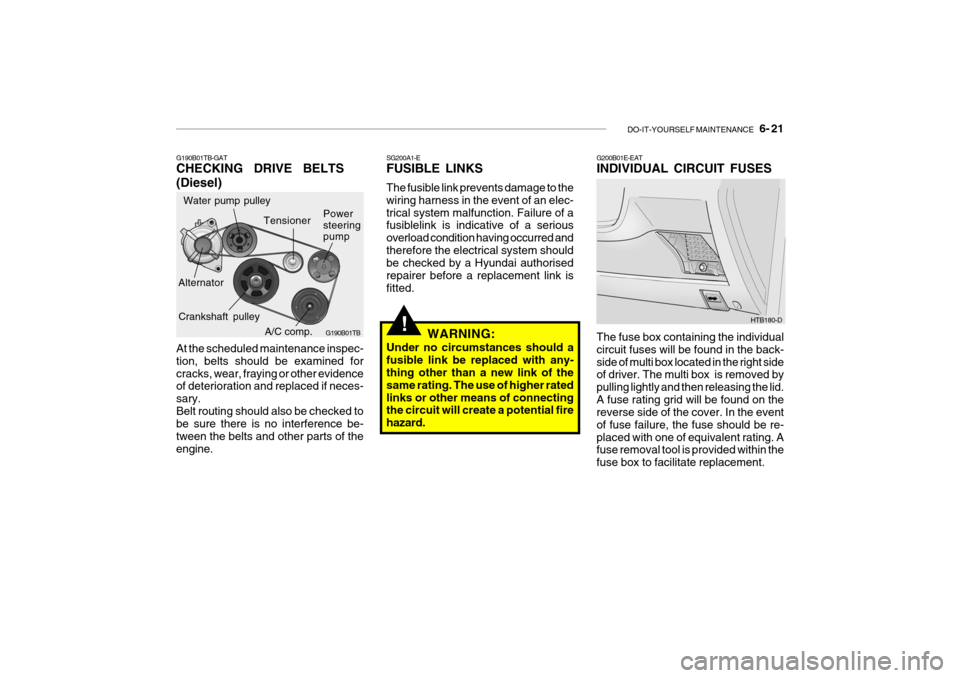

G190B01TB-GAT CHECKING DRIVE BELTS (Diesel) At the scheduled maintenance inspec- tion, belts should be examined forcracks, wear, fraying or other evidence of deterioration and replaced if neces- sary.Belt routing should also be checked to be sure there is no interference be- tween the belts and other parts of theengine.

!

SG200A1-E FUSIBLE LINKS The fusible link prevents damage to the wiring harness in the event of an elec-trical system malfunction. Failure of a fusiblelink is indicative of a serious overload condition having occurred andtherefore the electrical system should be checked by a Hyundai authorised repairer before a replacement link isfitted.

WARNING:

Under no circumstances should afusible link be replaced with any- thing other than a new link of the same rating. The use of higher ratedlinks or other means of connecting the circuit will create a potential fire hazard.G200B01E-EAT INDIVIDUAL CIRCUIT FUSES The fuse box containing the individual circuit fuses will be found in the back-side of multi box located in the right side of driver. The multi box is removed by pulling lightly and then releasing the lid.A fuse rating grid will be found on the reverse side of the cover. In the event of fuse failure, the fuse should be re-placed with one of equivalent rating. A fuse removal tool is provided within the fuse box to facilitate replacement. HTB180-D

A/C comp.

Water pump pulley

G190B01TB

Alternator Power steering pump

Tensioner

Crankshaft pulley

Page 434 of 463

DO-IT-YOURSELF MAINTENANCE 6- 23

!

SG220A1-E ELECTRIC COOLING FANS

WARNING:

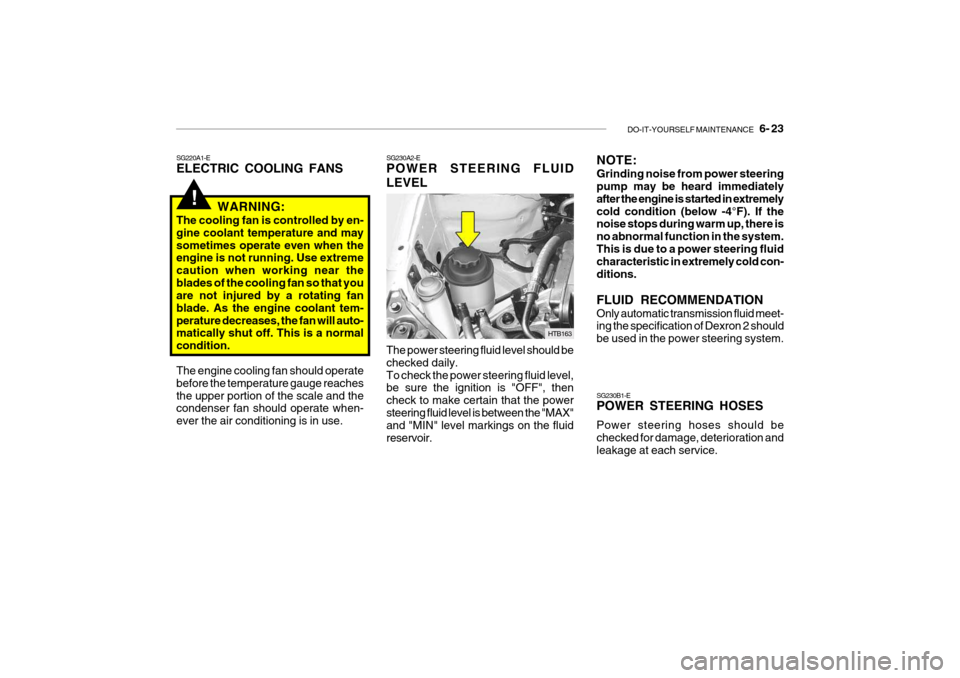

The cooling fan is controlled by en- gine coolant temperature and maysometimes operate even when the engine is not running. Use extreme caution when working near theblades of the cooling fan so that you are not injured by a rotating fan blade. As the engine coolant tem-perature decreases, the fan will auto- matically shut off. This is a normal condition. The engine cooling fan should operate before the temperature gauge reachesthe upper portion of the scale and the condenser fan should operate when- ever the air conditioning is in use. SG230B1-E POWER STEERING HOSES Power steering hoses should be checked for damage, deterioration and leakage at each service.

NOTE: Grinding noise from power steering pump may be heard immediately after the engine is started in extremelycold condition (below -4°F). If the noise stops during warm up, there is no abnormal function in the system.This is due to a power steering fluid characteristic in extremely cold con- ditions. FLUID RECOMMENDATION Only automatic transmission fluid meet- ing the specification of Dexron 2 should be used in the power steering system.SG230A2-E POWER STEERING FLUID LEVEL The power steering fluid level should be checked daily.To check the power steering fluid level, be sure the ignition is "OFF", then check to make certain that the powersteering fluid level is between the "MAX" and "MIN" level markings on the fluid reservoir.

HTB163

Page 435 of 463

6- 24 DO-IT-YOURSELF MAINTENANCE

!

G290A01FC-EAT HEADLIGHT AIMING ADJUST- MENT Before performing aiming adjustment, make sure of the following.

1. Keep all tyres inflated to the correct

pressure.

2. Place the vehicle on level ground and press the front bumper and rear bumper down several times. Place the vehicle at a distance of 118 in.(3,000 mm) from the test wall.

3. See that the vehicle is unloaded

(except for full levels of coolant,engine oil and fuel, and spare tyre, jack, and tools).

4. Clean the head lights lens and turn on the headlight (low beam).

WARNING:

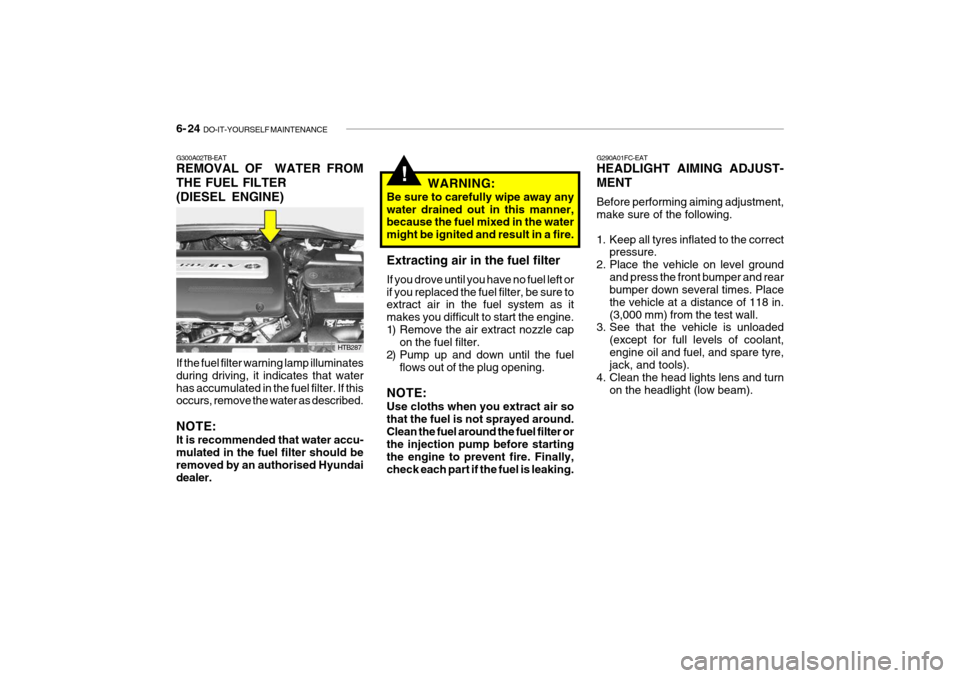

Be sure to carefully wipe away any water drained out in this manner, because the fuel mixed in the water might be ignited and result in a fire. Extracting air in the fuel filter If you drove until you have no fuel left or if you replaced the fuel filter, be sure to extract air in the fuel system as it makes you difficult to start the engine.

1) Remove the air extract nozzle cap on the fuel filter.

2) Pump up and down until the fuel flows out of the plug opening.

NOTE: Use cloths when you extract air so that the fuel is not sprayed around.Clean the fuel around the fuel filter or the injection pump before starting the engine to prevent fire. Finally,check each part if the fuel is leaking.

HTB287

G300A02TB-EAT REMOVAL OF WATER FROM THE FUEL FILTER(DIESEL ENGINE) If the fuel filter warning lamp illuminates during driving, it indicates that waterhas accumulated in the fuel filter. If this occurs, remove the water as described. NOTE: It is recommended that water accu- mulated in the fuel filter should be removed by an authorised Hyundai dealer.

Page 442 of 463

DO-IT-YOURSELF MAINTENANCE 6- 31

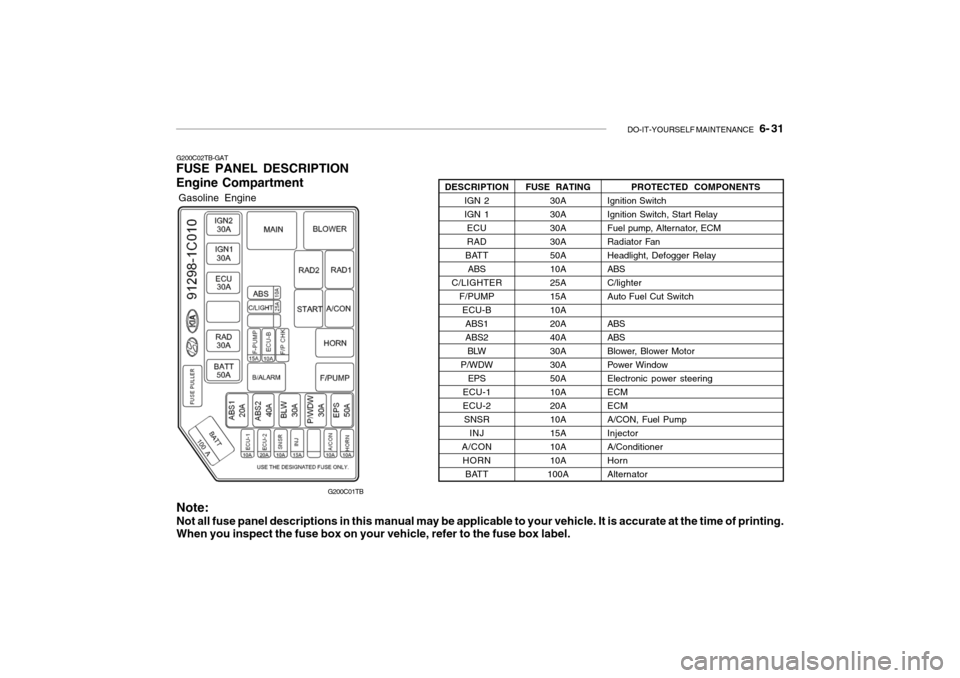

G200C02TB-GAT FUSE PANEL DESCRIPTION Engine Compartment

PROTECTED COMPONENTS

Ignition Switch Ignition Switch, Start Relay

Fuel pump, Alternator, ECM

Radiator FanHeadlight, Defogger RelayABSC/lighterAuto Fuel Cut Switch ABS ABS

Blower, Blower Motor

Power WindowElectronic power steeringECMECMA/CON, Fuel PumpInjectorA/ConditionerHornAlternator

FUSE RATING

30A30A30A30A50A10A25A15A10A20A40A30A30A50A10A20A10A15A10A10A

100A

DESCRIPTION

IGN 2IGN 1ECURAD

BATT ABS

C/LIGHTER F/PUMPECU-BABS1ABS2BLW

P/WDW EPS

ECU-1ECU-2 SNSR INJ

A/CON HORN BATT

Note: Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing. When you inspect the fuse box on your vehicle, refer to the fuse box label.

Gasoline Engine

G200C01TB

Page 443 of 463

6- 32 DO-IT-YOURSELF MAINTENANCE

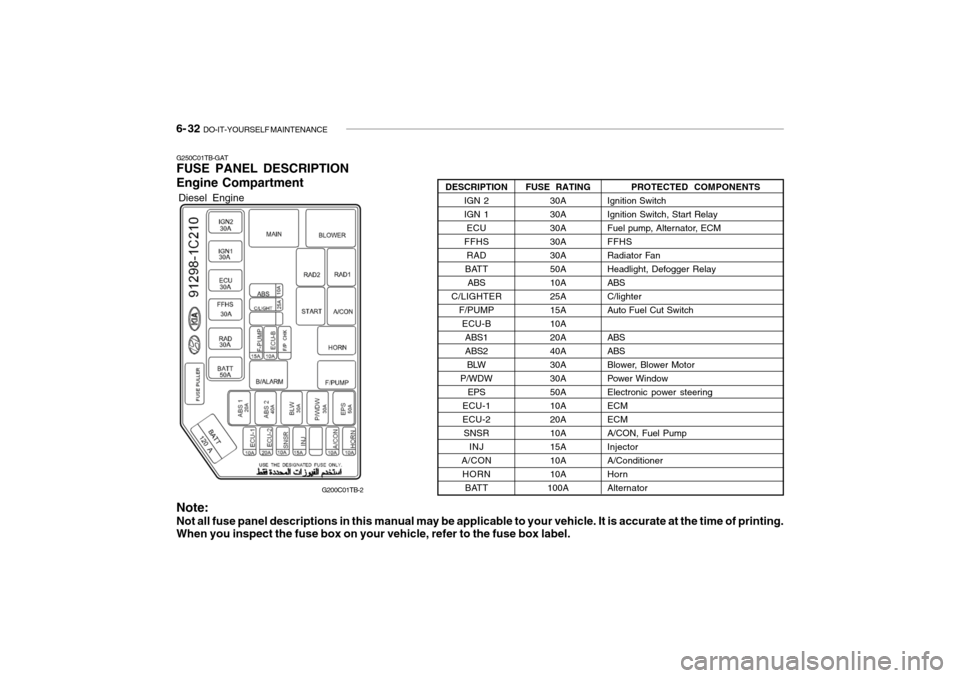

G250C01TB-GAT FUSE PANEL DESCRIPTION Engine Compartment

PROTECTED COMPONENTS

Ignition Switch Ignition Switch, Start Relay

Fuel pump, Alternator, ECMFFHS

Radiator FanHeadlight, Defogger RelayABSC/lighterAuto Fuel Cut Switch ABS ABS

Blower, Blower Motor

Power WindowElectronic power steeringECMECMA/CON, Fuel PumpInjectorA/ConditionerHornAlternator

FUSE RATING

30A30A30A30A30A50A10A25A15A10A20A40A30A30A50A10A20A10A15A10A10A

100A

DESCRIPTION

IGN 2IGN 1ECU

FFHS RAD

BATT ABS

C/LIGHTER F/PUMPECU-BABS1ABS2BLW

P/WDW EPS

ECU-1ECU-2 SNSR INJ

A/CON HORN BATT

Note: Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing. When you inspect the fuse box on your vehicle, refer to the fuse box label.

Diesel Engine

G200C01TB-2

Page 446 of 463

7- 2 EMISSION CONTROL SYSTEMS

SH010A1-E EMISSION CONTROL SYSTEMS (Not all models) Depending upon the market for which the vehicle is destined, the emissioncontrol system will comprise one or more of the following emission con- trol devices.

1) Crankcase emission control sys-

tem

2) Evaporative emission control sys-

tem

3) Exhaust emission control systemIn order that the proper functioning of the emission control systems may be ensured, it is recommended that the vehicle is inspected and maintainedby a Hyundai authorised repairer in accordance with the maintenance schedule in this manual. SH010B1-E

1. Crankcase emission

controlsystem

The positive crankcase ventilation

system is employed to prevent airpollution caused by blow-by gasesbeing emitted from the crankcase by introducing fresh air to the crankcase through the air cleaner where thismixes with blow-by gases and then passes through the PCV valve into the intake manifold from where it sub-sequently enters the combustion chamber and is burned.

SH010C1-E

2. Evaporative emission control

system

The Evaporative Emission Control

System is designed to prevent fuel vapours from escaping into the atmo- sphere through the fuel tank ventila- tion system. SH010D1-E

3. Exhaust emission con trol

system

The exhaust emission control system

is a highly effective system whichcontrols exhaust emission while main- taining good vehicle performance. Whilst the engine is not running, fuel

vapours generated inside the fuel tank are absorbed and stored in a char-coal canister. When the engine is started, the vapours stored in the canister are drawn into the inductionsystem through the purge control sole- noid valve and are subsequently burned.

The purge control solenoid valve is

controlled by the ECU; when the en-gine coolant temperature is low or the engine is idling, the purge control valve is closed and fuel vapours re-main stored in the canister. Under normal running conditions when the engine is warm, the valve opens andthe vapours are drawn into the inlet tract and subsequently burned in the combustion chamber.