ECU Hyundai Kona 2018 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2018, Model line: Kona, Model: Hyundai Kona 2018Pages: 523, PDF Size: 33.6 MB

Page 399 of 523

6-32

What to do in an emergency

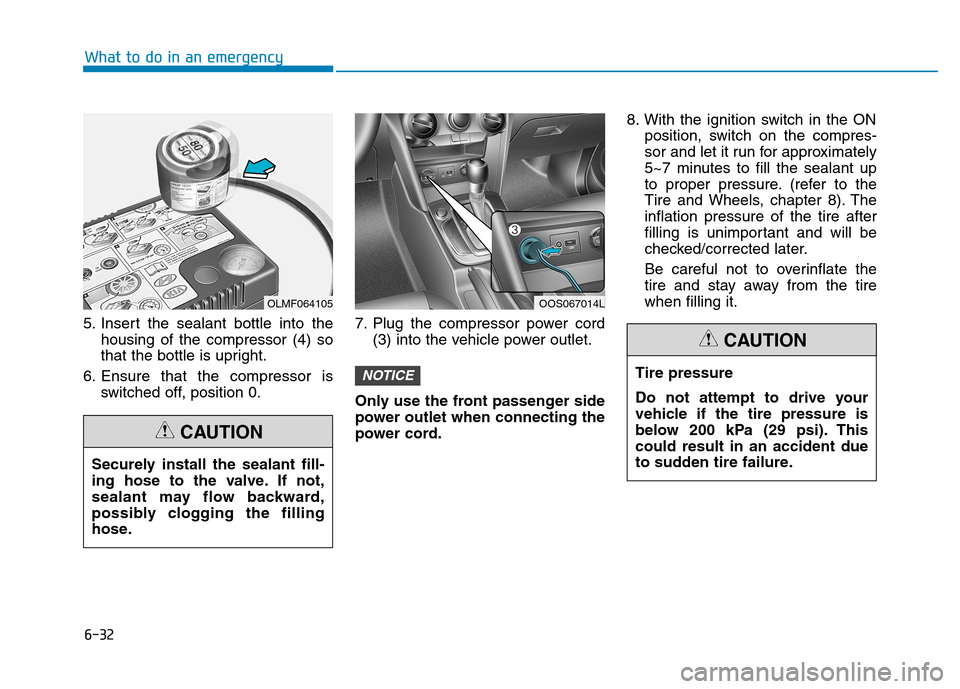

5. Insert the sealant bottle into thehousing of the compressor (4) so

that the bottle is upright.

6. Ensure that the compressor is switched off, position 0. 7. Plug the compressor power cord

(3) into the vehicle power outlet.

Only use the front passenger side

power outlet when connecting the

power cord. 8. With the ignition switch in the ON

position, switch on the compres-

sor and let it run for approximately

5~7 minutes to fill the sealant up

to proper pressure. (refer to the

Tire and Wheels, chapter 8). Theinflation pressure of the tire after

filling is unimportant and will be

checked/corrected later.

Be careful not to overinflate the

tire and stay away from the tirewhen filling it.

NOTICE

OLMF064105

Securely install the sealant fill-

ing hose to the valve. If not,

sealant may flow backward,

possibly clogging the filling

hose.

CAUTION

OOS067014L Tire pressure

Do not attempt to drive your

vehicle if the tire pressure is

below 200 kPa (29 psi). Thiscould result in an accident due

to sudden tire failure.

CAUTION

Page 405 of 523

6-38

What to do in an emergency

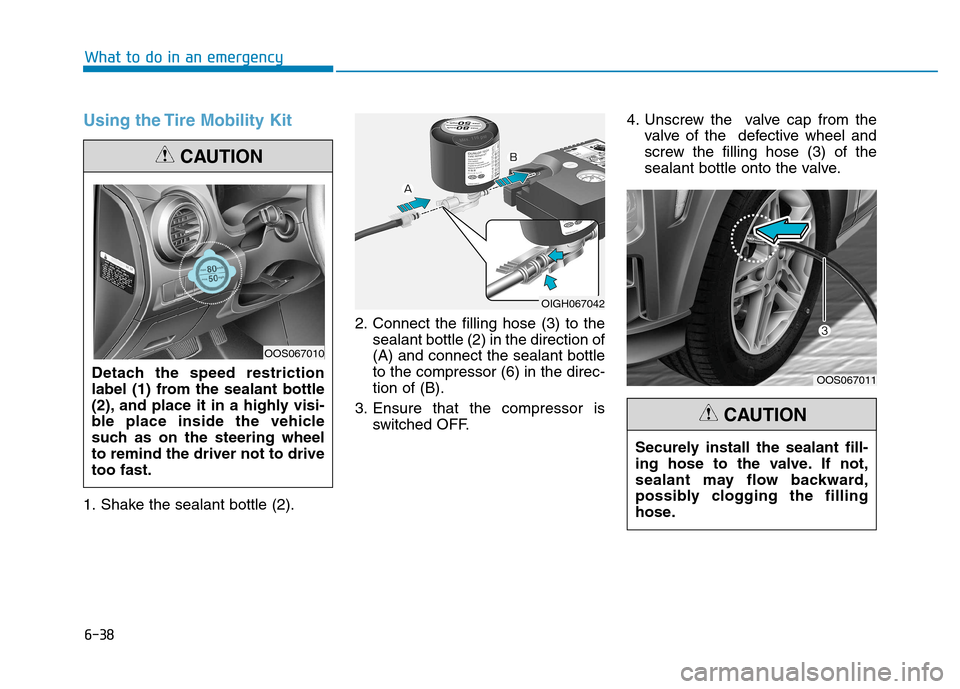

Using the Tire Mobility Kit

1. Shake the sealant bottle (2).2. Connect the filling hose (3) to the

sealant bottle (2) in the direction of (A) and connect the sealant bottleto the compressor (6) in the direc-tion of (B).

3. Ensure that the compressor is switched OFF. 4. Unscrew the valve cap from the

valve of the defective wheel and

screw the filling hose (3) of the

sealant bottle onto the valve.

Detach the speed restriction

label (1) from the sealant bottle

(2), and place it in a highly visi-

ble place inside the vehicle

such as on the steering wheelto remind the driver not to drivetoo fast.

CAUTION

OOS067010

OIGH067042

OOS067011

Securely install the sealant fill-

ing hose to the valve. If not,

sealant may flow backward,

possibly clogging the filling

hose.

CAUTION

Page 410 of 523

6-43

What to do in an emergency

6

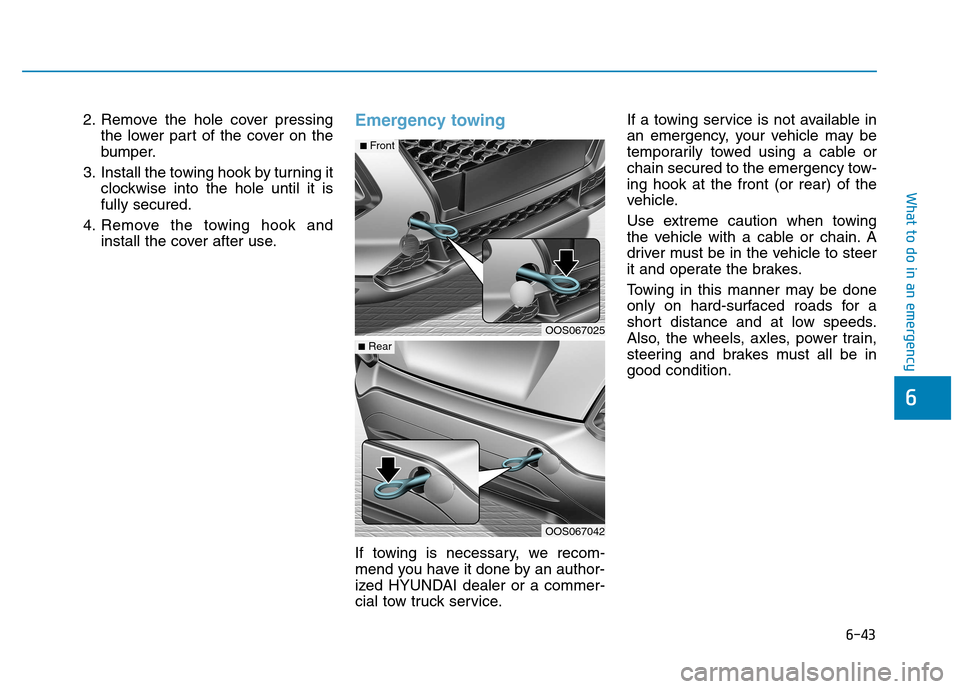

2. Remove the hole cover pressingthe lower part of the cover on the

bumper.

3. Install the towing hook by turning it clockwise into the hole until it isfully secured.

4. Remove the towing hook and install the cover after use.Emergency towing

If towing is necessary, we recom-

mend you have it done by an author-

ized HYUNDAI dealer or a commer-

cial tow truck service. If a towing service is not available in

an emergency, your vehicle may be

temporarily towed using a cable or

chain secured to the emergency tow-ing hook at the front (or rear) of the

vehicle.

Use extreme caution when towing

the vehicle with a cable or chain. A

driver must be in the vehicle to steer

it and operate the brakes.

Towing in this manner may be done

only on hard-surfaced roads for a

short distance and at low speeds.

Also, the wheels, axles, power train,

steering and brakes must all be ingood condition.

OOS067042

OOS067025

■

Rear

■Front

Page 411 of 523

6-44

What to do in an emergency

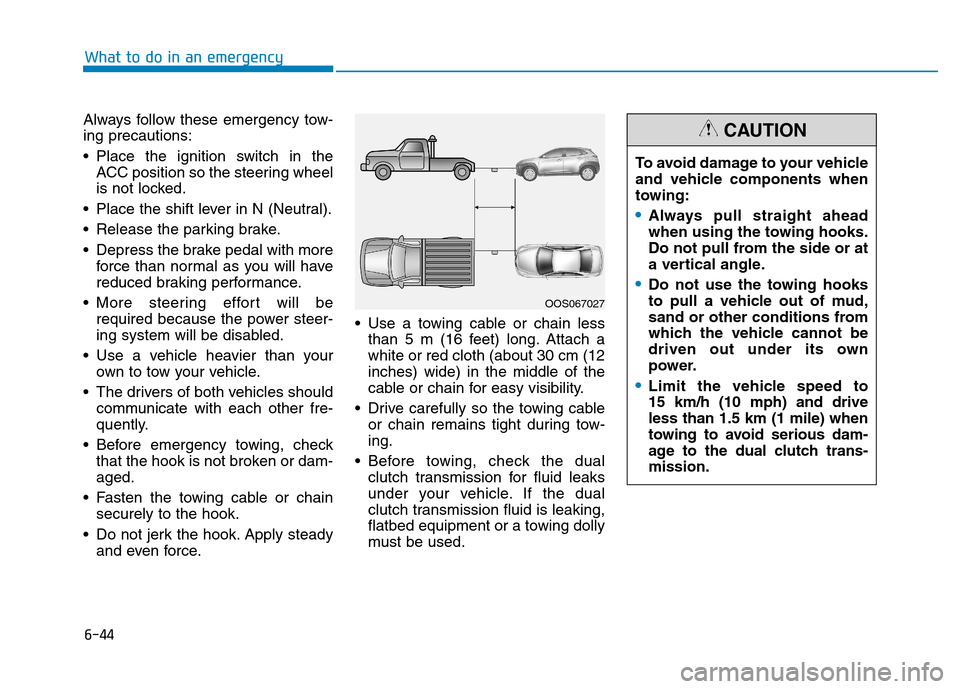

Always follow these emergency tow- ing precautions:

Place the ignition switch in theACC position so the steering wheel

is not locked.

Place the shift lever in N (Neutral).

Release the parking brake.

Depress the brake pedal with more force than normal as you will have

reduced braking performance.

More steering effort will be required because the power steer-

ing system will be disabled.

Use a vehicle heavier than your own to tow your vehicle.

The drivers of both vehicles should communicate with each other fre-

quently.

Before emergency towing, check that the hook is not broken or dam-aged.

Fasten the towing cable or chain securely to the hook.

Do not jerk the hook. Apply steady and even force. Use a towing cable or chain less

than 5 m (16 feet) long. Attach awhite or red cloth (about 30 cm (12inches) wide) in the middle of the

cable or chain for easy visibility.

Drive carefully so the towing cable or chain remains tight during tow-ing.

Before towing, check the dual clutch transmission for fluid leaks

under your vehicle. If the dual

clutch transmission fluid is leaking,

flatbed equipment or a towing dolly

must be used.

OOS067027 To avoid damage to your vehicle

and vehicle components when

towing:

Always pull straight ahead

when using the towing hooks.

Do not pull from the side or at

a vertical angle.

Do not use the towing hooks

to pull a vehicle out of mud,

sand or other conditions from

which the vehicle cannot be

driven out under its own

power.

Limit the vehicle speed to 15 km/h (10 mph) and driveless than 1.5 km (1 mile) when

towing to avoid serious dam-

age to the dual clutch trans-mission.

CAUTION

Page 431 of 523

7-19

7

Maintenance

EEXX PPLLAA NN AATTIIOO NN OO FF SS CC HH EEDD UU LLEE DD MM AAIINN TTEENN AANN CCEE IITT EEMM SS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the

vehicle is being driven in severe con-

ditions, more frequent oil and filterchanges are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. We recommend that the fuel

lines, fuel hoses and connections be

replaced by an authorized HYUNDAI

dealer.

Fuel filter (for gasoline)

HYUNDAI gasoline vehicle is

equipped a lifetime fuel filter that

integrated with the fuel tank. Regularmaintenance or replacement is not

needed but depends on fuel quality. If

there are some important safety mat-

ters like fuel flow restriction, surging,

loss of power, hard starting problem

etc, fuel filter inspection or replace is

needed. We recommend that the fuel

filter be Inspected or replaced by an

authorized HYUNDAI dealer.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-rectly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evi- dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.Inspect the hose routing to ensurethat the hoses do not come in con-

tact with any heat source, sharp

edges or moving component whichmight cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

When you are inspecting the belt,

place the ignition switch to the

LOCK/OFF or ACC position.

CAUTION

Page 439 of 523

7-27

7

Maintenance

WWAASSHH EERR FF LLUU IIDD

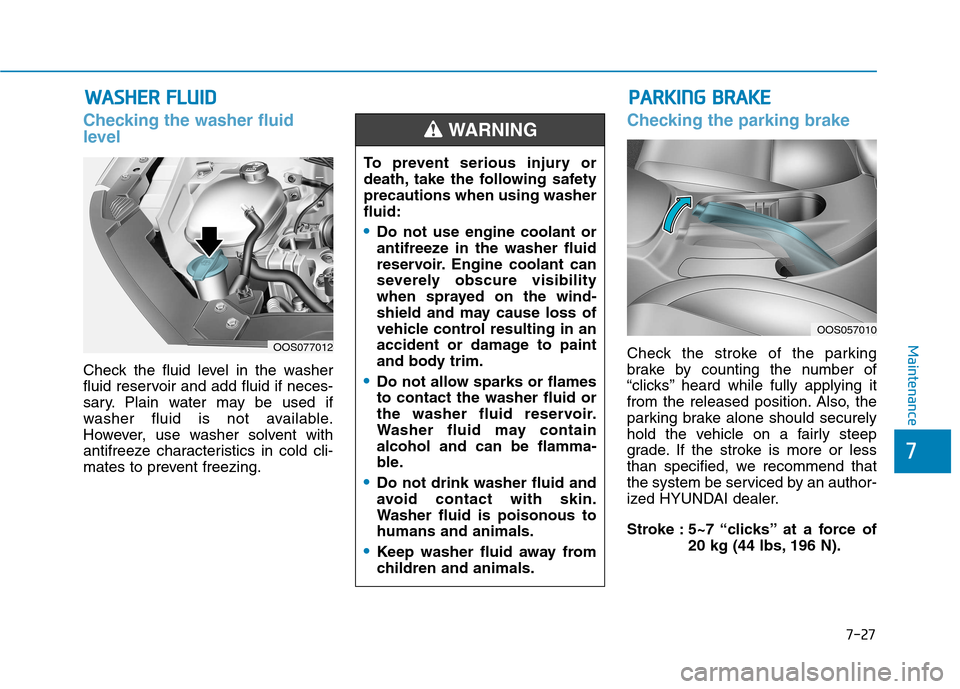

Checking the washer fluid

level

Check the fluid level in the washer

fluid reservoir and add fluid if neces-

sary. Plain water may be used if

washer fluid is not available.

However, use washer solvent with

antifreeze characteristics in cold cli-

mates to prevent freezing.

Checking the parking brake

Check the stroke of the parking

brake by counting the number of

“clicks’’ heard while fully applying it

from the released position. Also, the

parking brake alone should securely

hold the vehicle on a fairly steep

grade. If the stroke is more or less

than specified, we recommend that

the system be serviced by an author-

ized HYUNDAI dealer.

Stroke : 5~7 “clicks’’ at a force of

20 kg (44 lbs, 196 N).OOS077012

PPAA RRKK IINN GG BB RRAA KKEE

OOS057010

To prevent serious injury or

death, take the following safetyprecautions when using washerfluid:

Do not use engine coolant or

antifreeze in the washer fluid

reservoir. Engine coolant can

severely obscure visibility

when sprayed on the wind-

shield and may cause loss of

vehicle control resulting in an

accident or damage to paint

and body trim.

Do not allow sparks or flames to contact the washer fluid or

the washer fluid reservoir.

Washer fluid may containalcohol and can be flamma-

ble.

Do not drink washer fluid and

avoid contact with skin.

Washer fluid is poisonous tohumans and animals.

Keep washer fluid away from

children and animals.

WARNING

Page 445 of 523

7-33

7

Maintenance

When you do not use the vehiclefor a long time in a low tempera-

ture area, disconnect the battery

and keep it indoors.

Always charge the battery fully to prevent battery case damage

in low temperature areas.

If you connect unauthorized elec-

tronic devices to the battery, the

battery may be discharged. Never

use unauthorized devices.

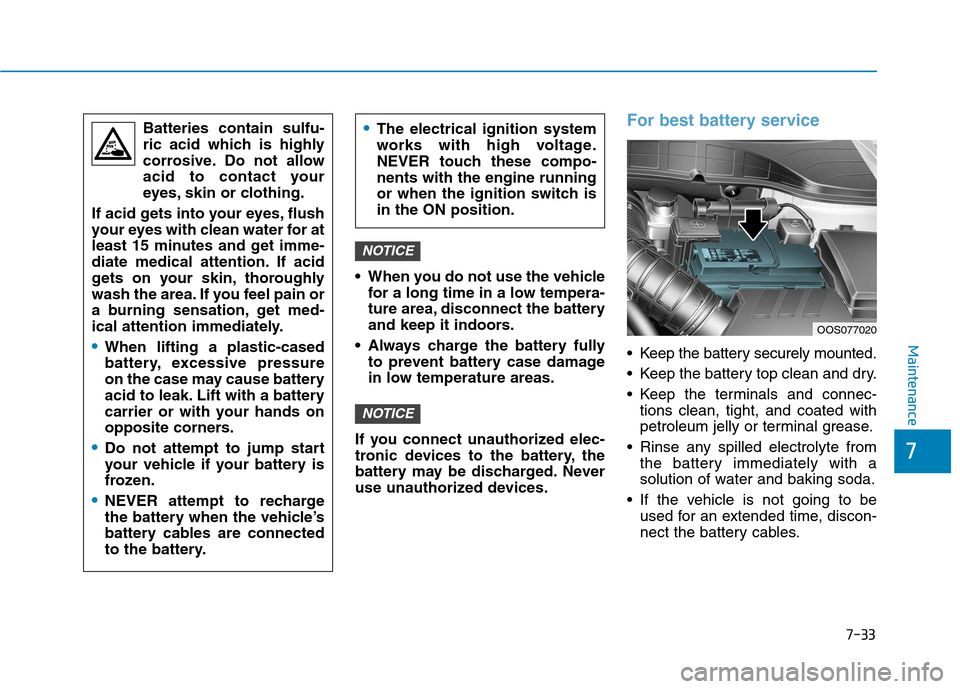

For best battery service

Keep the battery securely mounted.

Keep the battery top clean and dry.

Keep the terminals and connec- tions clean, tight, and coated with

petroleum jelly or terminal grease.

Rinse any spilled electrolyte from the battery immediately with a

solution of water and baking soda.

If the vehicle is not going to be used for an extended time, discon-

nect the battery cables.

NOTICE

NOTICE

Batteries contain sulfu-

ric acid which is highly

corrosive. Do not allow

acid to contact your

eyes, skin or clothing.

If acid gets into your eyes, flush

your eyes with clean water for at

least 15 minutes and get imme-

diate medical attention. If acid

gets on your skin, thoroughly

wash the area. If you feel pain or

a burning sensation, get med-

ical attention immediately.

When lifting a plastic-cased

battery, excessive pressure

on the case may cause battery

acid to leak. Lift with a battery

carrier or with your hands on

opposite corners.

Do not attempt to jump start

your vehicle if your battery is

frozen.

NEVER attempt to recharge

the battery when the vehicle’s

battery cables are connected

to the battery.

The electrical ignition system

works with high voltage.

NEVER touch these compo-nents with the engine running

or when the ignition switch isin the ON position.

OOS077020

Page 461 of 523

7-49

7

Maintenance

4. Check the removed fuse; replace itif it is blown. To remove or insert

the fuse, use the fuse puller in the

engine compartment fuse panel.

5. Push in a new fuse of the same rating, and make sure it fits tightly

in the clips. If it fits loosely, consult

an authorized HYUNDAI dealer.

After checking the fuse panel in

the engine compartment, securely

install the fuse panel cover. You

may hear a clicking sound if the

cover is securely latched. If it is

not securely latched, electrical

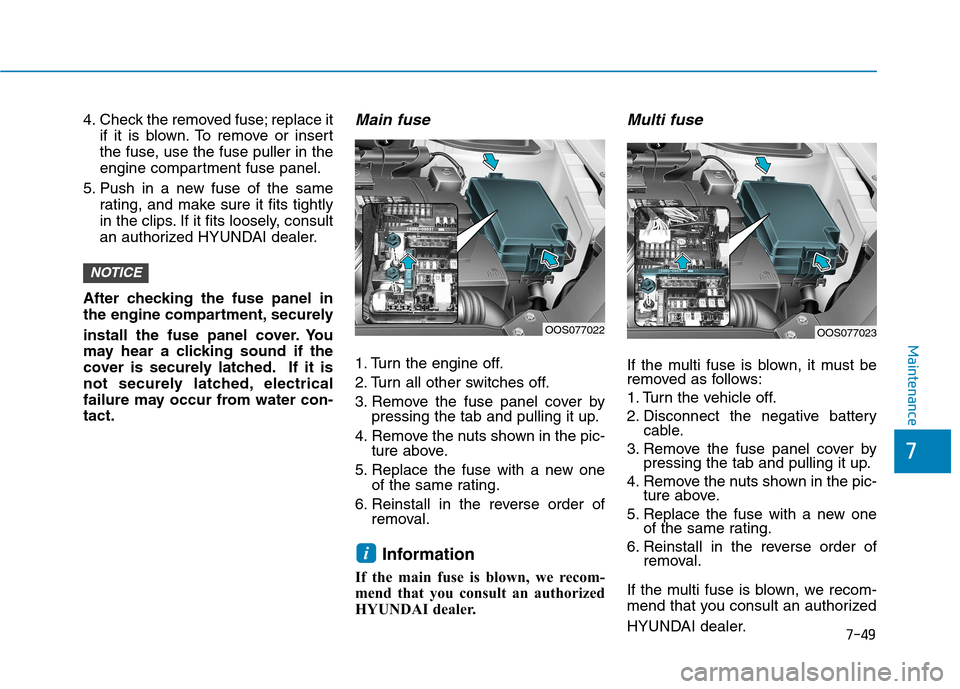

failure may occur from water con-tact.Main fuse

1. Turn the engine off.

2. Turn all other switches off.

3. Remove the fuse panel cover by pressing the tab and pulling it up.

4. Remove the nuts shown in the pic- ture above.

5. Replace the fuse with a new one of the same rating.

6. Reinstall in the reverse order of removal.

Information

If the main fuse is blown, we recom-

mend that you consult an authorized

HYUNDAI dealer.

Multi fuse

If the multi fuse is blown, it must be

removed as follows:

1. Turn the vehicle off.

2. Disconnect the negative battery cable.

3. Remove the fuse panel cover by pressing the tab and pulling it up.

4. Remove the nuts shown in the pic- ture above.

5. Replace the fuse with a new one of the same rating.

6. Reinstall in the reverse order of removal.

If the multi fuse is blown, we recom-

mend that you consult an authorized

HYUNDAI dealer.

i

NOTICE

OOS077022OOS077023

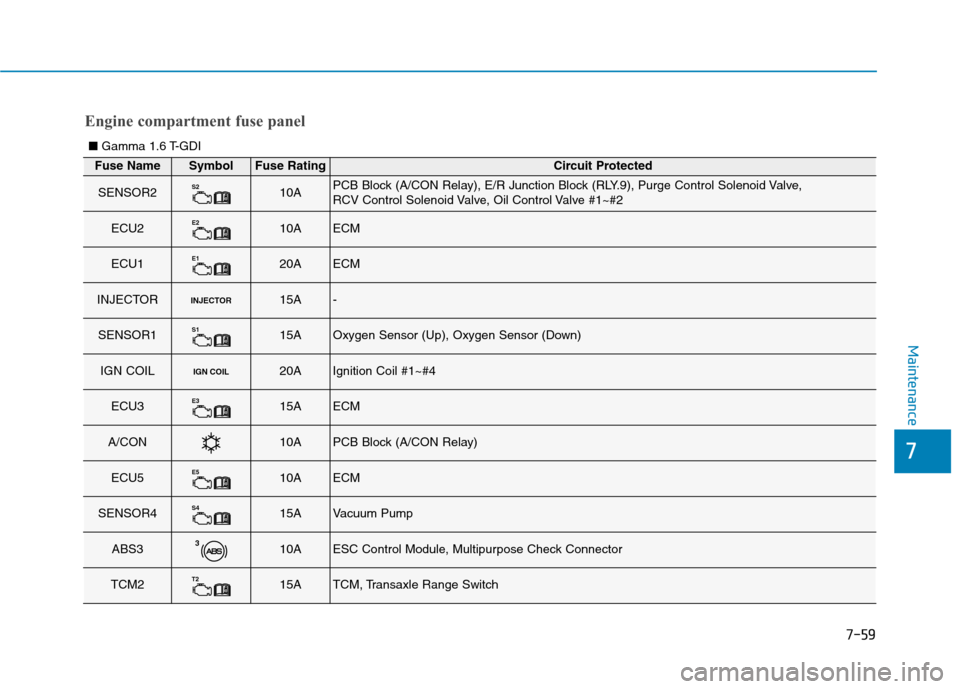

Page 471 of 523

7-59

7

Maintenance

Fuse NameSymbolFuse RatingCircuit Protected

SENSOR2S210APCB Block (A/CON Relay), E/R Junction Block (RLY.9), Purge Control Solenoid Valve,

RCV Control Solenoid Valve, Oil Control Valve #1~#2

ECU2E210AECM

ECU1E120AECM

INJECTORINJECTOR15A-

SENSOR1S115AOxygen Sensor (Up), Oxygen Sensor (Down)

IGN COILIGN COIL20AIgnition Coil #1~#4

ECU3E315AECM

A/CON10APCB Block (A/CON Relay)

ECU5E510AECM

SENSOR4S415AVacuum Pump

ABS3310AESC Control Module, Multipurpose Check Connector

TCM2T215ATCM, Transaxle Range Switch

Engine compartment fuse panel

■ Gamma 1.6 T-GDI

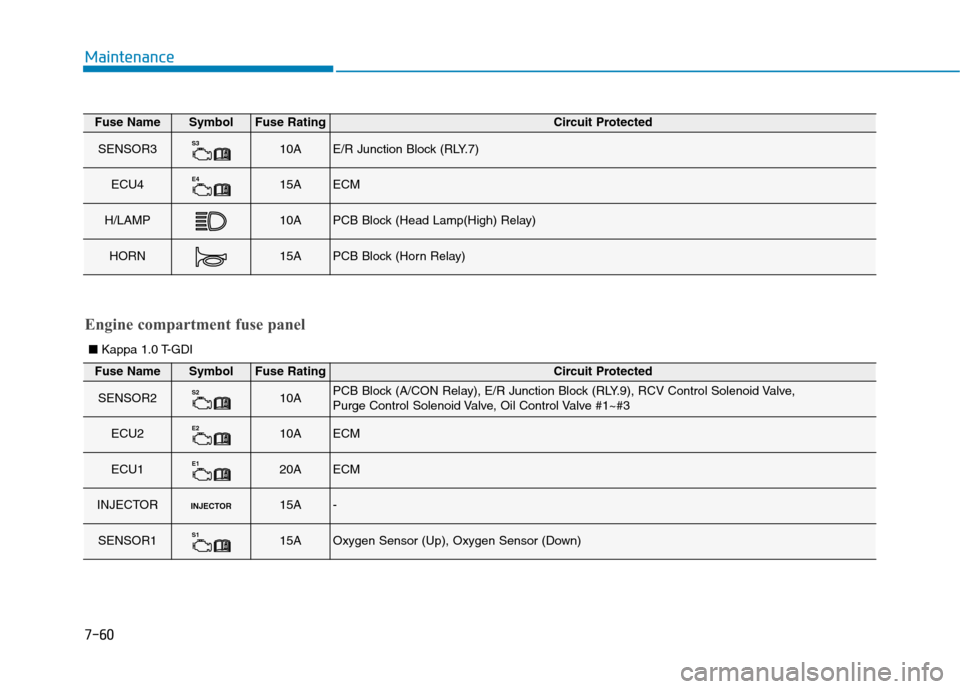

Page 472 of 523

7-60

Maintenance

Fuse NameSymbolFuse RatingCircuit Protected

SENSOR3S310AE/R Junction Block (RLY.7)

ECU4E415AECM

H/LAMP10APCB Block (Head Lamp(High) Relay)

HORN15APCB Block (Horn Relay)

Engine compartment fuse panel

■ Kappa 1.0 T-GDI

Fuse NameSymbolFuse RatingCircuit Protected

SENSOR2S210APCB Block (A/CON Relay), E/R Junction Block (RLY.9), RCV Control Solenoid Valve,

Purge Control Solenoid Valve, Oil Control Valve #1~#3

ECU2E210AECM

ECU1E120AECM

INJECTORINJECTOR15A-

SENSOR1S115AOxygen Sensor (Up), Oxygen Sensor (Down)