oil change Hyundai Matrix 2003 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Matrix, Model: Hyundai Matrix 2003Pages: 312, PDF Size: 4.1 MB

Page 155 of 312

DO-IT-YOURSELF MAINTENANCE

6-22 G260A03A-GAT

REPLACING HEADLIGHT BULBS Before attempting to replace a headlight bulb, be sure the switch is turned to the "OFF"position. The next paragraph shows how to reach the headlight bulbs so they may be changed. Besure to replace the burned-out bulb with one ofthe same number and wattage rating. CAUTION: Keep the lamps out of contact with petro- leum products, such as oil, gasoline, etc.

G240A01A-AAT

POWER STEERING HOSES

It is suggested that you check the power steer-

ing hose connections for fluid leakage at regular intervals. The power steering hoses should bereplaced if there is severe surface cracking,scuffing or worn spots. Deterioration of thehose could cause premature failure. NOTE: Grinding noise from the power steering

pump may be heard immediately after the engine is started in extremely cold condi-tions (below - 20°C). If the noise stops dur-ing warm up, there is no abnormal functionin the system. It is due to a power steeringfluid characteristic in extremely cold condi-tions.

Recommended Fluid Use PSF-3 type fluid NOTE: Do not start the engine when the power

steering oil reservoir is empty. G300A01B-GAT

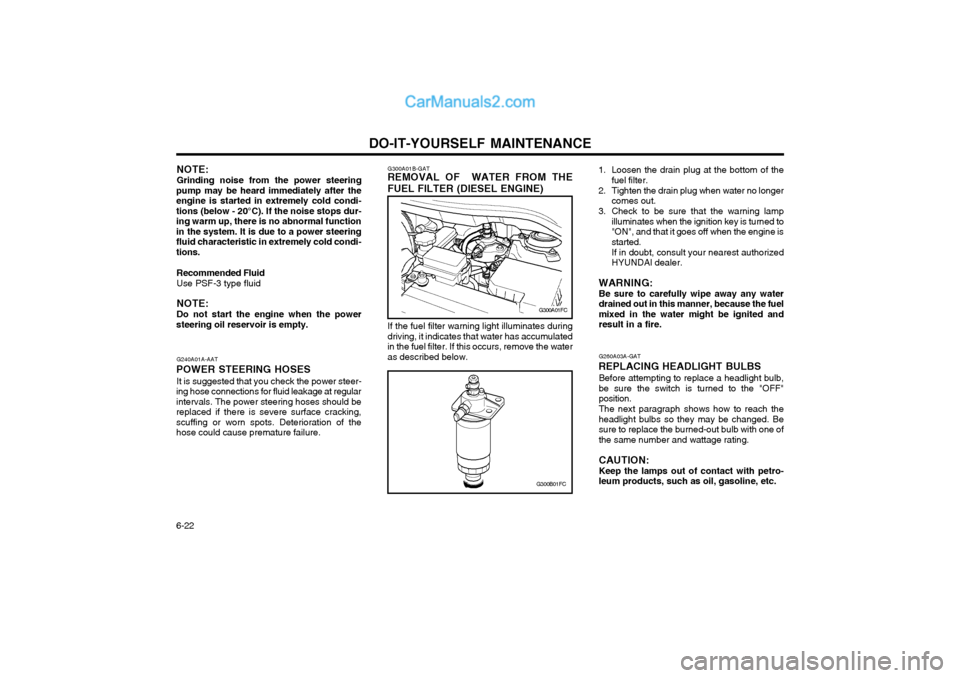

REMOVAL OF WATER FROM THE FUEL FILTER (DIESEL ENGINE)

If the fuel filter warning light illuminates during driving, it indicates that water has accumulatedin the fuel filter. If this occurs, remove the wateras described below. 1. Loosen the drain plug at the bottom of the

fuel filter.

2. Tighten the drain plug when water no longer comes out.

3. Check to be sure that the warning lamp illuminates when the ignition key is turned to"ON", and that it goes off when the engine isstarted. If in doubt, consult your nearest authorized HYUNDAI dealer.

WARNING: Be sure to carefully wipe away any waterdrained out in this manner, because the fuelmixed in the water might be ignited andresult in a fire.

G300A01FC

G300B01FC

Page 255 of 312

DRIVING YOUR HYUNDAI 2- 13

SC200B3-E TOWING ATTACHMENTS It is strongly recommended that only an Hyundai Approved towing attachment is usedto ensure that the loads placed upon the bodystructure are correctly distributed. The use ofa non approved attachment will result in theinvalidation of the vehicle warranty. Hyundaitowing attachments are designed and con-structed to ensure maximum towing perfor-mance and ease of fitment. A range of acces-sories including electrical kits are availablethrough the Hyundai dealer network. It is of the utmost importance that those areas of the vehicle which are subjected to greaterstress during towing are maintained in accor-dance with the recommendations given at theend of this book. In addition, the daily operatingchecks relating to engine oil, transmission oiland tyres must be performed at each refuellingto ensure maximum reliability and safety. The use of a proprietary stabiliser will assist in achieving an inherently stable outfit but whilstthe use of such equipment will improve thecharacteristics of a balanced outfit, it will notcompensate for a badly loaded and thereforeunstable outfit. The tyres and braking equipment fitted to the trailer or caravan must be maintained in ac-cordance with the recommendations of themanufacturer. Special attention should be paidto tyres which deteriorate through time and

WARNING:

It is not recommended that the vehicle be

used for towing until the first 1,000 milesof Running In has been completed. AllHyundai MATRIX models are suited to tow-ing trailers and caravans up to the limitsindicated below. MATRIX models fitted withautomatic transaxle have a transaxle oilcooler and further transaxle cooling shouldnot be required. C190E01FC-EAT

TRAILER AND CARAVAN TOWING

Tongue loadSSA2200B

Total trailer weight

exposure rather than as a result of the dis- tances towed. The inside walls of the tyresshould be inspected along with the outsidewalls for cracking and damage. The trailerwheel nut torque must be checked on a regularbasis, preferably before each towing session.

The trailer hitch and the safety catch mecha-

nism must be maintained in good workingorder. The trailer break away cable or chainshould be inspected for damage and shouldbe attached to the vehicle towing attachmenteach and every time the trailer is hitched tothe vehicle.

Whilst towing, the performance of the vehicle

will be reduced in terms of acceleration, brak-ing and handling due to the increased loadsplaced upon the vehicle. The driver shouldanticipate the change in characteristics andadjust the driving style in keeping with thesechanges. Care should be exercised whencornering and braking to prevent the outfitbecoming uncontrollable by reducing corner-ing speeds and allowing increased brakingdistances.

The driver should exercise care to ensure that

when pulling away from rest particularly onuphill gradients the clutch unit is not subjectedto excessive slippage which will reduce theuseful life of this component. Use of the"Overdrive Off" "2" and "L" positions whendriving vehicles with automatic transmission

Page 273 of 312

VEHICLE MAINTENANCE REQUIREMENTS

5- 6 6ZF060D2-A

o Fuel lines, fuel hoses and

connections

Check the fuel lines, fuel hoses and connec- tions for leakage and damage. Replace anydamaged or leaking parts immediately.

WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds aftershutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer tothe ECU or wiring harness within theengine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields. 6ZF060E1-A

o Timing belt Replace timimg belt and inspect all associated parts related for damage and deformation.Replace any damaged parts immediately. 6ZF060G1-A

o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in themaintenance schedule. Make sure that a newvapour hose or fuel filler cap is correctlyreplaced. 6ZF060F1-A

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abra-sions, and excessive swelling indicate dete-rioration. Particular attention should be paid toexamining those hose surfaces nearest tohigh heat sources, such as the exhaustmanifold.Inspect the hose routing to assure that thehoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechani-cal wear. Inspect all hose connections, suchas clamps and couplings, to make sure theyare secure, and that no leaks are present.Hoses should be replaced immediately if thereis any evidence of deterioration or damage.

6ZF060A1-A

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

6ZF060M1-A

o Engine oil and filter The engine oil and filter should be changed at

the intervals specified in the maintenance schedule. If the car is being driven in severeconditions, more frequent oil and filter changesare required.

6ZF060B1-A

o Drive belts Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation andreplace if necessary. Drive belts should bechecked periodically for proper tension andadjusted as necessary.

6ZF060C1-A

o Fuel filter A clogged filter can limit the speed at which the

vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replace-ment more frequently.

After installing a new filter, run the engine for

several minutes, and check for leaks at theconnections.

Page 274 of 312

VEHICLE MAINTENANCE REQUIREMENTS 5-7

6ZF070D1-A

o Manual transaxle oil Inspect the manual transaxle oil according to

the maintenance schedule. NOTE: If the oil level is low, check for possible

leaks before adding oil. Do not overfill.

6ZF070H1-A

o Rear brake drums and linings/ parking brake

Check the rear brake drums and linings for

scoring, burning, leaking fluid, broken parts, and excessive wear. Inspect the parkingbrake system including the parking brakelever and cables. For detailed service proce-dures, refer to the Shop Manual.

6ZF070J1-A

o Brake pads, calipers and rotors Check the pads for excessive wear, discs for

run out and wear, and calipers for fluid leak-age.

6ZF070K1-A

o Exhaust pipe and muffler Visually inspect the exhaust pipes, mufflerand hangers for cracks, deterioration, or dam-age. Start the engine and listen carefully forany exhaust gas leakage. Tighten connec-tions or replace parts as necessary.

F070E03A-AAT

o Automatic transaxle fluid The fluid level should be in the "HOT" range

of the dipstick, after engine and transaxle areat normal operating temperature. Check theAutomatic Transaxle Fluid level with the en-gine running and the transaxle in neutral, withthe parking brake properly applied. Use DIA-MOND ATF SP- III or SK ATF SP- III when

adding or changing fluid. 6ZF070F1-A

o Brake hoses and lines Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replaceany deteriorated or damaged parts immediately.

6ZF060H1-A

o Air cleaner filter A Genuine Hyundai air cleaner filter is recom-

mended when filter is replaced.

6ZF060J1-A

o Spark plugs Make sure to install new spark plugs of the

correct heat range.

6ZF070B1-A

o Cooling system Check the cooling system part, such asradiator, coolant reservoir, hoses and con-nections for leakage and damage. Replaceany damaged parts. 6ZF070G2-A

o Brake fluid Check brake fluid level in the brake fluidreservoir. The level should be between "MIN"and "MAX" marks on the side of the reservoir.Use only hydraulic brake fluid conforming toDOT 3 or DOT 4.

6ZF070C1-A

o Engine coolant The coolant should be changed at theintervals specified in the maintenance sched-ule.

F060N01E-AAT

o Valve Clearance Inspect excessive valve noise and/or enginevibration and adjust if necessary. A qualifiedtechnician should perform the operation.

Valve Clearance

Intake valves: 0.0067 ~ 0.0091 in. (0.17 ~ 0.23mm)

Exhaust valves: 0.0098 ~ 0.0122 in. (0.25 ~ 0.31mm)

Page 281 of 312

OWNER MAINTENANCE

6-6 the level again, allow several minutes for the oil to drain into the sump. Replace the oil fillercap rotating it in a clockwise direction untiltight. The quantity of oil required to raise the level from the minimum to maximum level is approx-imately 1 litre. The distance between the "F" and "L" marks is equal to about 1 liter(Gasoline Engine)/1.2liter(Diesel Engine) of oil.

o The engine oil consumption is strongly

effected by the viscosity and quality of oil,engine rpm and driving condition etc. The engine oil is more consumed under severe driving conditions such as highspeeds and frequent acceleration and de-celeration than normal driving condition.

ZG030E1-A

ENGINE OIL CONSUMPTION Function of engine oil

Engine oil has the primary function of lubricat-

ing and cooling the inside of the engine. Engine oil consumption

It is normal that an engine should consume

some engine oil while normal driving. The cause of oil consumption in a normal engine are asfollows;

o Engine oil is used to lubricate pistons, piston rings and cylinders. A thin film of oil is left on the cylinder wallwhen a piston moves downwards in thecylinder. High negative pressure generatedduring engine operation sucks some of theoil into the combustion chamber. This oil with some oil of the cylinder wall is burned by the high temperature combustiongases during the combustion process. SG040A1-E

ENGINE OIL AND FILTER

REPLACEMENT

SSA6040A

Oil filler cap

Drain plug

Oil filter The engine oil and filter must be changed at

the time or mileage interval specified in the maintenance schedule. If the vehicle is oper-ated under severe or adverse conditions, theoil and filter must be replaced more frequently.

To replace the oil and filter, proceed as fol-

lows:

1. Ensure that the engine is at normal operat- ing temperature and park the vehicle on level ground with the parking brake se-curely applied and the engine turned off.

2. Open the bonnet and remove the oil filler cap.

3. Prepare a suitable receptacle to collect the displaced oil and remove the drain plugfrom the sump.

CAUTION: The oil being drained from the engine will

be hot. Care should be exercised to pre- vent scalding.

Diesel engine

Gasoline engine Drain plug

Oil filter

KCHB001A-1

Page 286 of 312

OWNER MAINTENANCE 6-11

specified in the maintenance schedule. Only those lubricants specified below should beused in order to prevent gear shifting difficul-ties or transaxle damage.

WARNING: The transaxle lubricant level should only

be checked when the engine is cold to preclude the possibility of personal injuryby contact with hot components. Recommended Oil

Use only the approved transaxle lubricant.

The recommended lubricants are complete in themselves and the use of additives is neitherrequired nor recommended. The use of addi-tives may invalidate the vehicle warranty. Transaxle Lubricant Level

Checking

SSA6100B

SG090A2-E

WINDSCREEN WASHER RESERVOIR REPLENISHMENT

and water. If the wipers continue to streak or smear the glass, replace them with genuineHyundai replacement.

CAUTION:

o Do not operate the wipers on dry glass since rapid wear and damage to thewindscreen glass may result.

o Keep the blade rubber out of contact with petroleum products such as en-gine oil, gasoline, etc.

The level of windscreen washer fluid available

should be checked on a daily basis. The levelof fluid will be visible through the side of thereservoir. When the fluid is to be replenished,only a proprietary screen wash additive shouldbe used and in the concentration recommended SG100A1-E

MANUAL TRANSAXLE LUBRICANT The manual transaxle lubricant must be

checked and or changed at the intervals

G110A01EDrain plug

Filler plug

HFC5010 by the manufacturer. The windscreen washer reservoir has a total capacity of 3 litres.

CAUTION: Engine coolant anti freeze must not be

used in the windscreen washer system since damage to the paintwork may result.

Undiluted windscreen washer additive must

not be allowed to come into contact with thepaintwork. If spillage occurs, flush the af-fected area immediately with water. Do notoperate the windscreen washer for morethan 15 seconds continuously or whenthe reservoir is empty since damage tothe washer pump will result.