tow Hyundai Matrix 2003 Workshop Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Matrix, Model: Hyundai Matrix 2003Pages: 312, PDF Size: 4.1 MB

Page 258 of 312

3-1

IN CASE OF EMERGENCY

SD000A1-E

3. IN CASE OF

EMERGENCY

SD020A1-E

IF THE ENGINE WILL NOT START Seek assistance from the nearest Hyundai dealer with regard to the method of ignition andfuel system diagnosis.

CAUTION:If the engine refuses to start, no attempt

should be made to push or tow start thevehicle. Vehicles with automatic transaxleor fuel injection will not be able to bestarted in this manner since no drive istransmitted through the automatic transaxlewhilst the engine is not running, and in thecase of fuel injected derivatives, the fuelpump will not operate under tow start con-ditions. In addition, if the vehicle isequipped with an exhaust catalyst, dam-age to the catalyst may result if the vehicleis tow started. SD020B1-E

IF THE ENGINE CANNOT BE

CRANKED SD020C1-F

If Engine Turns Over Normally but Does Not Start

SSA3020C

1. Check fuel Level

2. Check all connectors at ignition coil and spark plugs.Replace any that may be disconnected or loose.

3. Check fuel line in the engine room.

4. If engine still refuses to start, call a Hyundai dealer or seek other qualified assistance.

1. If the vehicle is fitted with manual transaxle,

ensure that the clutch pedal is depressed whilst cranking the engine. If the vehicle isfitted with automatic transaxle, ensurethat the transaxle selector is at the "P"or"N" position.

2. Check the battery terminals and connec- tions to ensure that these are clean andalso tight.

3. If the ignition warning lights dim when the engine is cranked and the battery termi-nals have been checked, a dischargedbattery is indicated.

4. Do not attempt to push or tow start the vehicle, refer to "Jump Starting" for infor-mation regarding engine starting when thebattery is discharged. AD020D1-A

If Engine Stalls While Driving

1. Reduce your speed gradually, keeping a straight line. Move cautiously off the road to a safe place.

2. Turn on your emergency flashers.

3. Try starting the engine again. If your ve- hicle will not start, see "IF THE ENGINE WILL NOT START"

3

D010B01FC

Page 264 of 312

3-7

IN CASE OF EMERGENCY

SD070J1-E

8. Lower Vehicle and Tighten Nuts

Lower the car to the ground turning the wheel

nut wrench counterclockwise. When the ve- hicle is firmly on the ground, remove the jackand tighten the wheel nuts securely. At thefirst available opportunity, the wheel nut torqueshould be checked with a suitable torquewrench.

Wheel nut tightening torque Steel wheel & aluminium alloy wheel:900-1,100 kg.cm (65-80 lb.ft) SD070K1-E AFTER CHANGING WHEELS

SD080A1-E

VEHICLE TOWING OR RECOVERY

The pressure of the spare tyre should be checked at the first available opportunity. Ifany doubt exists as to the tyre pressure, thevehicle should be driven slowly to the nearestservice station and the tyre pressure checkedand adjusted as required. If the valve cap is lost from any of the valves, a replacement should be obtained and fittedat the first available opportunity. The valvecap prevents the ingress of dirt which maycause the valve to stick and therefore leakand is part of the valve sealing function. Ensure that the spare wheel, jack and wheel nut wrench as well tools are correctly locatedin the boot of the vehicle to prevent damageand noise. CAUTION:

An incorrect tow or recovery could result

in serious damage to the vehicle. If anydamage to the suspension, steering ortransaxle is apparent or suspected, a tow-ing ambulance must be used.

D060I01FC-DD060B01FC

o OK FOR AUTOMATIC OR MANUAL

TRANSAXLE EQUIPPED VEHICLE D080A01FC

Page 265 of 312

IN CASE OF EMERGENCY

3-8 The vehicle may be towed by the conven-

tional method using the towing eye at the front of the vehicle as an attachment point. Inaddition, a suspended tow with or without anambulance may be used with either the frontor the rear wheels being suspended, providedthe above caution is observed. In addition, the following points must be noted:

o If towing by conventional means, the ignition key must be at the "ACC" posi- tion, otherwise the steering lock will beactivated.

o Because the brake system and steering system power assistance is derived fromthe engine, the amount of effort re-quired to stop or steer the vehicle willbe greater than normal. o If a suspended tow is being given to the

rear, the ignition key must be at the"ACC" position since the steering lockis not designed to withstand the forcerequired to hold the front wheels straightduring the tow.

o The vehicle must not be towed with the front wheels on the ground for morethan thirty miles.

o OK FOR AUTOMATIC OR MANUAL

TRANSAXLE EQUIPPED VEHICLE

SD100A2-E

Automatic Transaxle Vehicle

o NOT OK FOR AUTOMATIC TRANSAXLE EQUIPPED VEHICLE

o OK FOR MANUAL TRANSAXLE

The vehicle may be towed by the conven- tional method using the towing eye at the frontof the vehicle as an attachment point. In addition, a suspended tow may be given to the front of the vehicle without an ambulance.In the event of a suspended tow being givento the rear of the vehicle, the use of anambulance is imperative. D120A01A-EAT

IF YOU LOSE YOUR KEYS

Information about the key of immobilizer sys-tem will be found on page 1-2.

CAUTION: The following restriction must be observed in order to avoid serious damage to thetransaxle . The vehicle must never be towed from the rear with the front wheels on the ground. The vehicle must not be towed until transaxle fluid has been added to bringthe level up to the "HOT" marking on thedipstick. (The level will need to be reducedagain after towing). The vehicle must not be towed at speeds faster than 25 mph. or distances greaterthan fifty miles. The general points regard-ing the steering lock etc. described in thepreceding section (Manual transaxle ve-hicle) should be observed.

SD090A1-E

Manual Transaxle Vehicle

o OK FOR AUTOMATIC OR MANUAL TRANSAXLE EQUIPPED VEHICLE WITH NO DAMAGE

D080C01FC

D080B01FC

D080C02FC

Page 272 of 312

VEHICLE MAINTENANCE REQUIREMENTS 5-5

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the

appropriate maintenance intervals.

R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

F040A04E-EAT

SEVERE DRIVING CONDITIONS

A - Repeated short distance driving

B - Extensive idling

C - Driving in dusty, rough roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in sandy areas ENGINE OIL AND FILTER AIR CLEANER FILTERSPARK PLUGSTIMING BELT BRAKE PADS REAR BRAKE LININGS AND CYLINDERSSUSPENSION AND STEERING SYSTEMMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDPOLLEN FILTER(IN FRONT OF BLOWER UNIT)

EVERY 4,500MILES OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLY EVERY 37,000MILES OR 48 MONTHS

MORE FREQUENTLY

MORE FREQUENTLY MORE FREQUENTLY EVERY 60,000MILESEVERY 27,000MILES MORE FREQUENTLY

MAINTENANCE OPERATIONMAINTENANCE ITEM

R R R RII I

R R R A, B, C, F, H C, E B, H D, E, F, GC, D, G, HC, D, G, H C, D, E, F A, C, D, E, F, G, H, I, JA, C, E, F, G, H, I C,E

MAINTENANCE INTERVALS

DRIVING

CONDITION

F - More than 50% driving in heavy city traffic during hot weather above 90°F (32°C)

G - Driving in mountainous areas

H - Towing a trailer

I - Driving for patrol car, taxi, commercial car or vehicle towing

J - Driving over 100MPH

Page 284 of 312

OWNER MAINTENANCE 6-9

SG060A1-E

SPARKING PLUG REPLACEMENT

SSA6060A

0.039 ~ 0.043 in. (1.0 ~ 1.1 mm)

This operation should only be performed when

the engine is cold.

1. Remove the centre cover from the engine rocker cover.

2. Remove plug lead from the sparking plug to be replaced, pulling the lead by the rubber cap. (Pulling the lead may damage the car-bon conductor).SSA6061CSSA6060B

Prior to installing a sparking plug, the gap between the centre and outer electrodes mustbe checked and adjusted as necessary.Adjustment is facilitated by bending the outerelectrode towards or away from the centreelectrode. Under no circumstances should at-tempts be made to adjust the position of thecentre electrode.

4. Insert the sparking plug into the cylinder head and screw by the wrench and until theplug contacts the seating area. Tighten theplug with the socket by a further 1/2 to 3/4 ofa turn only.

3. Clean around the base of the plug to be

removed, and install the plug socket ensur-ing that the ceramic insulator does not be-come damaged. Turn the socket counter-clockwise to remove the plug.

CAUTION: Sparking plugs must only be cleaned using

purpose designed equipment. Wire brush- ing may damage the centre electrodein-sulator causing misfiring to occur. Only thecorrect grade of sparking plug should beused. Use of an incorrect grade may resultin serious engine damage.

you are not injured by a rotating fan blade.As the engine coolant temperature decreas-es, the fan will automatically shut off. Thisis a normal condition.

Page 302 of 312

EMISSION CONTROL SYSTEM

7-2

It is of the utmost importance that the following information is read and understood by thevehicle operator in order to prevent operationalproblems arising from damage to the catalyst.Damage to the catalyst will result if contamina-tion occurs through the use of leaded fuel.Whilst the vehicle is fitted with a reduced diam-eter filler neck to prevent charging of the fueltank with a leaded fuel pump nozzle, it ispossible that the use of funnels or jerry cans willpermit leaded fuel to be introduced into the fueltank.The catalyst is intolerant of unburnt fuel andtherefore if an engine misfire condition exists,damage to the catalyst will occur. It is impera-tive that if a misfire condition develops, thevehicle is immediately presented to a Hyundaidealer for rectification. Similarly, the practice ofcertain ignition system diagnosis procedureswhich involve inducing a misfire (cylinder powerbalance tests for example) may result in cata-lyst damage.For these reasons, it is advisable that theexhaust gas emission be tested at each routineservice with a gas analyzer having a Hydrocar-bon measuring facility to ensure continuedreliability of the catalyst.Push or tow starting of the vehicle is to beavoided since unburnt fuel may be enter thecatalyst and result in damage. (Note, it isimpossible to push or tow start a Hyundaimodel equipped with fuel injection since thefuel pump safety interlock will prevent the pumpfrom operating under these conditions).

Operation of the catalyst involves extremelyhigh temperatures being attained within thecatalytic convertor, and although the convertoris fitted with heat shields, it is important that thevehicle is not parked over combustible or vola-tile material which may result in fire.If the above precautions are not adhered to andthe catalyst becomes inoperative, the resultantincrease in core temperature will result in a"melt down" where the catalyst core will meltand subsequently may block the exhaust sys-tem.Due to the fragile nature of the catalyst ele-ment, it is important that damage does notoccur when the vehicle is raised by means of agarage jack. Care must also be exercised toavoid driving over road hazards or debris whichmay cause damage to the catalyst element.

H020D01S-GAT CATALYTIC CONVERTER ; For a diesel engine All Hyundai vehicles are equipped with oxida- tion type catalytic converter to reduce the car-bon monoxide, hydrocarbons and particulatecontained in the exhaust gas.

H020C01S-GAT EGR SYSTEM ; For a diesel engine This system helps control oxides of nitrogen by recirculating a part of the exhaust gas into theengine.

Page 304 of 312

CONSUMER INFORMATION

8-2 NOTE:

o Do not use the temporary spare tyre for tyre rotation.

o Aluminium wheels which are not sup- plied as Original Equipment should not be mixed on the same vehicle withthe original steel wheels. However, it isacceptable that the steel spare wheelbe used in conjunction with OriginalEquipment aluminium wheels since theoffset of both wheels is compatible.Radial and cross ply tyres should notbe mixed on the same vehicle.

I060A01FC-EAT

TYRE ROTATION

The tyre wear characteristics will vary be-

tween each tyre dependant upon the condi-tions of use. It is normal for the front tyres towear more rapidly than those fitted to the rearof the vehicle and therefore tyre rotation willprovide a means of helping to ensure an evenwear rate across the tyre set. For vehiclesfitted with radial ply tyres, rotation should beconfined to front to rear tyre alternation. It isnot recommended that radial ply tyres berotated from side to side. SI060A1-E

TYRE BALANCING Incorrect tyre balance will cause steering

vibration and uneven tyre wear. The vehicletyres are balanced during production but mayneed further balancing throughout the life ofthe tyres.

It is recommended that the tyres be balanced

on the car for best results and that the tyres arebalanced whenever they have been removedfrom the wheel for repair.

SI030A2-E

SNOW TYRES If it is desired to fit snow tyres to the vehicle,

it must be ascertained that the original sizeand load carrying capacity are met by thereplacement tyres. When using snow tyres,the vehicle should not be driven at speeds inexcess of 60 MPH.

SI040A1-E

TYRE CHAINS

Tyre chains, if necessary, should be installed

on the front wheels. Be sure that the chains arethe proper size and that they are installed inaccordance with the manufacturer's instruc-tions.

To minimize tyre and chain wear, do not contin-

ue to use tyre chains when they are no longerneeded.

CAUTION:When driving on roads covered with snow

or ice, drive at less than 20 mph (30 km/h). Tyre pressures should be increased by 3 psi

when the vehicle is driven fully laden or underconditions of sustained high speed motoring.

HA1409Spare tyre

Page 312 of 312

INDEX

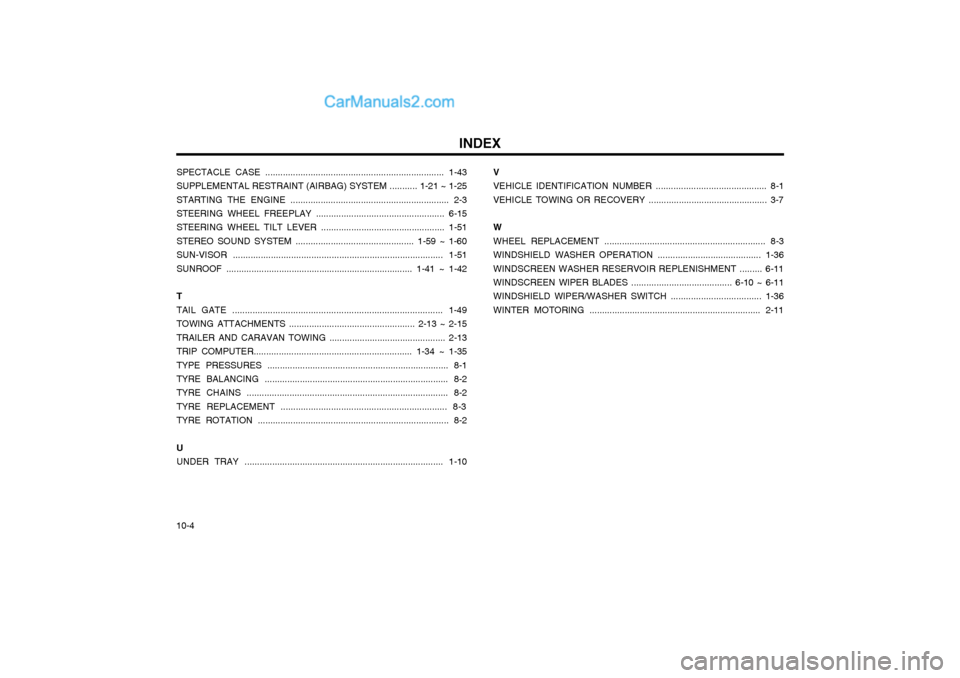

10-4 SPECTACLE CASE ....................................................................... 1-43 SUPPLEMENTAL RESTRAINT (AIRBAG) SYSTEM ........... 1-21 ~ 1-25STARTING THE ENGINE ............................................................... 2-3 STEERING WHEEL FREEPLAY ................................................... 6-15 STEERING WHEEL TILT LEVER ................................................. 1-51STEREO SOUND SYSTEM ............................................... 1-59 ~ 1-60SUN-VISOR ................................................................................... 1-51SUNROOF .......................................................................... 1-41 ~ 1-42 T TAIL GATE ................................................................................... 1-49TOWING ATTACHMENTS .................................................. 2-13 ~ 2-15TRAILER AND CARAVAN TOWING .............................................. 2-13TRIP COMPUTER............................................................... 1-34 ~ 1-35TYPE PRESSURES ........................................................................ 8-1 TYRE BALANCING ......................................................................... 8-2 TYRE CHAINS ................................................................................ 8-2TYRE REPLACEMENT .................................................................. 8-3TYRE ROTATION ............................................................................ 8-2 U UNDER TRAY ............................................................................... 1-10

V VEHICLE IDENTIFICATION NUMBER ............................................ 8-1VEHICLE TOWING OR RECOVERY ............................................... 3-7 W WHEEL REPLACEMENT ................................................................ 8-3WINDSHIELD WASHER OPERATION ......................................... 1-36WINDSCREEN WASHER RESERVOIR REPLENISHMENT ......... 6-11WINDSCREEN WIPER BLADES ........................................ 6-10 ~ 6-11 WINDSHIELD WIPER/WASHER SWITCH .................................... 1-36 WINTER MOTORING .................................................................... 2-11