belt Hyundai Matrix 2003 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Matrix, Model: Hyundai Matrix 2003Pages: 312, PDF Size: 4.1 MB

Page 259 of 312

IN CASE OF EMERGENCY

3-2

CAUTION:

Personal injury and damage to the vehicle

may occur if jump starting is not per- formed correctly. If any doubt exists as tohow this operation should be performed,seek assistance from qualified personnel. WARNING:

Motor vehicle batteries contain sulphuric

acid and emit hydrogen gas. Protective clothing should be worn and care exer-cised to prevent the acid from coming intocontact with skin or clothing and the ve-hicle. Naked lights should not be permittedin the vicinity of the battery. Care shouldbe exercised to prevent sparks occurringduring connection. If acid accidentallycomes into contact with skin or eyes, theaffected area should immediately be flushed ponents such as the Fuel Injection system

computer and the Automatic Transaxlecomputer. The battery must never be dis-connected whilst the engine is running. SD040A2-E IF THE ENGINE OVERHEATS If the temperature gauge indicates overheat- ing:

1. Pull off the road and stop as soon as it is

safe to do so.

2. Place the gear selector lever in "P" (auto- matic), or neutral (manual transaxle) and set the parking brake. If the air condition-ing is on, turn it off.

3. If coolant is running out under the car or steam is coming out from under the bonnetstop the engine. Do not open the bonnetuntil the coolant has stopped running orthe steaming has stopped. If there is novisible loss of coolant and no steam, leavethe engine running and check to be surethe engine cooling fan is operating. If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is missing. If it is not missing, check to see that it is tight. If the drive belt seems to besatisfactory, check for coolant leaking fromthe radiator, hoses or under the car. (If theair conditioning had been in use, it isnormal for cold water to be draining fromit).

SD030A1-E JUMP STARTING

with copious amounts of water and medi- cal assistance sought.

1. Ensure that the booster battery is 12 volt type. If the booster battery is installed inanother vehicle, ensure that the two vehi-cles are not touching.

2. Turn off all unnecessary electrical equip- ment in both vehicles.

3. Ensure that the engine of the vehicle pro- viding the jump start is running prior toconnection of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the booster battery and theother end to the positive (+) terminal of thedischarged battery.

5. Attach the black jump cable to the nega- tive (-) terminal of the booster battery, andthe other end to a ground point within theengine compartment of the vehicle withthe flat battery. Do not connect to thenegative battery terminal of the flat batterysince sparks may be generated with thesubsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start the engine of thevehicle with the flat battery.

7. Remove jump cables in the reverse order of installation (black cable first).

CAUTION:If the jump cable is incorrectly installed,damage to the vehicle electrical systemmay occur, in particular the electronic com-

HFC4002

Booster battery Discharged battery

Page 260 of 312

3-3

IN CASE OF EMERGENCY

WARNING: While the engine is running, keep hands

and clothing away from moving parts such as the fan and drive belts to preventinjury.

WARNING (Diesel only): Never work on injection system with en-

gine running or within 30 seconds after shutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer tothe ECU or wiring harness within theengine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields.

5. If the water pump drive belt is broken or coolant is leaking out, stop the engine immediately and call the nearest Hyundaidealer for assistance.

WARNING: Do not remove the radiator cap when the

engine is hot since steam and boiling wa- ter may be ejected from the radiator result-ing in burns or scalding. D040A01FC-EAT TEMPORARY SPARE TYREThe following instructions for the temporary spare tyre should be observed:

1. Check inflation pressure as soon as pos-

sible after installing the spare tyre, and adjust to the specified pressure. The tyrepressure should be periodically checkedand maintained at the specified pressurewhile the tyre is stored. 2. The spare tyre should only be used tem-

porarily and should be returned to theluggage compartment as soon as the origi-nal tyre can be repaired or replaced.

3. Continuous use at speeds of over 80 km/h (50 mph) is not recommended.

4. As the temporary spare tyre is specifically designed for your car, it should not beused on any other vehicle.

5. The temporary spare tyre should not be used on any other wheels, nor shouldstandard tyre, snow tyre, wheel covers ortrim rings be used with the temporaryspare wheel. If such use is attempted,damage to these items or other car com-ponents may occur.

6. The temporary spare tyre pressure should be checked once a month while the tyre isstored.

CAUTION:

o Do not use snow chains with your tem- porary spare tyre.

o Do not use more than one temporary spare tyre at a time.

Spare Tyre Pressure

Type Size Inflation Pressure T115/70R(D)15420 kPa (60 psi)6. If the cause of the overheating cannot be

found, wait until the engine temperature has returned to normal. Then, if coolanthas been lost, carefully remove the radia-tor cap and add water to bring the fluid levelin the reservoir up to the base of theradiator fill opening. Fill the coolant expan-sion tank to the halfway mark.

7. Proceed with caution until it is established that the engine is operating normally. If theengine overheats repeatedly, the advice ofa Hyundai dealer should be sought.

CAUTION: Serious loss of coolant indicates there is a leak in the cooling system and thisshould be checked as soon as possibleby a Hyundai dealer.

Page 267 of 312

APPEARANCE CARE

4-2

Plastic wheel covers should be cleaned using a sponge and water. Cast alloy wheels shouldbe cleaned using a mild soap or neutral deter-gent. Abrasive compounds must not be usedsince in the event of these damaging the lac-quer coating, oxidization of the aluminium wheelwill occur, spoiling the appearance.The use of an a toothbrush will facilitate cleaningbetween the wheel "spokes".

ensure that accidental spillages are immediatelyflushed with water.Do not use abrasive cleaning materials whichmay damage the bumpers.Avoid subjecting the bumpers to high tempera-tures such as may be encountered in high bakepaint ovens.

SE040B1-E STAIN/SPOT REMOVALShould tree sap, dead insects or tar prove to be difficult to remove from the paint film, turpentineor a proprietary paint cutting compound may beused. Ensure that the area to be cleaned is notrubbed intensively to prevent breaking throughthe colour coat and exposing the under coat. SE040C1-E POLISHINGThe exterior paint work should be polished with a proprietary wax polish when water no longercollects in bead form on the paint work. Theinstructions of the product manufacturer shouldbe adhered to. SE040E1-E BUMPER MAINTENANCE The special material from which the bumpers are manufactured warrants special attention to pre-serve the appearance of the bumpers. Avoidcontact with battery electrolyte or brake fluid and SE040F1-E ACCIDENT REPAIRS In the event of the body work sustaining damage, the following points should be noted prior torepairs being undertaken.If body panels are replaced or repaired, anticorrosion treatment must be applied to the repairarea. The product used must be compatible withthose used in manufacture. It is recommendedthat repairs are entrusted to a Hyundai dealer toensure that replacement parts used are of thesame high quality as those used in manufactureof the vehicle and that the correct repair methodsand materials will ensure adequate levels ofcorrosion protection and the continued validity ofthe Anti Perforation Warranty. SE050A1-E INTERIOR During the winter period, it is possible that the passenger compartment flooring may becomewet from damp footwear or quantities of snowadhering to footwear. The carpet should not beallowed to remain in this condition since thecarpet may begin to create musty smells and will

SE050D1-E SEAT BELTSSeat belts should be cleaned only with a mild soap solution. Strong detergents, solvens orbleaches may damage the belt webbing andtherefore reduce the effectiveness of the belt.Belts which display signs of fraying, wear of cutshould be replaced. SE050E1-E WINDOWS A proprietary glass cleaner should be used to clean the inside of the windows. However, therear heated windshield must only be cleanedusing a light horizontal cleaning action. Careshould be exercised to avoid the use of abrasivecleaners or contact with items of jewellery whichmay damage the heating elements.

promote corrosion of the floor pan in addition tothe carpet and under felt beginning to rot. SE050C1-E INTERIOR VALETINGThe soft trim and carpets should be maintained with the regular use of a vacuum cleaner. Heavysoiling should be removed with a dry cleaningagent recommended for this purpose followingthe instructions of the product manufacturer.Paint thinner, solvents or other such cleaningmaterials should not be used since damage tothe upholstery may result.

Page 269 of 312

VEHICLE MAINTENANCE REQUIREMENTS

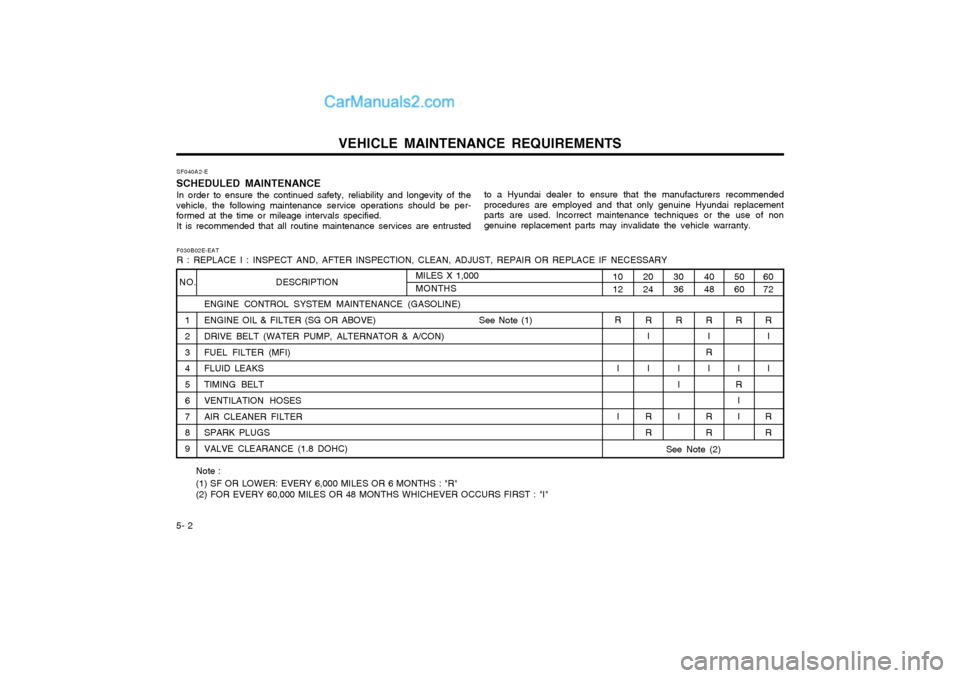

5- 2 SF040A2-E

SCHEDULED MAINTENANCE In order to ensure the continued safety, reliability and longevity of the

vehicle, the following maintenance service operations should be per- formed at the time or mileage intervals specified.

It is recommended that all routine maintenance services are entrusted to a Hyundai dealer to ensure that the manufacturers recommendedprocedures are employed and that only genuine Hyundai replacementparts are used. Incorrect maintenance techniques or the use of nongenuine replacement parts may invalidate the vehicle warranty.

F030B02E-EAT R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

Note :

(1) SF OR LOWER: EVERY 6,000 MILES OR 6 MONTHS : "R" (2) FOR EVERY 60,000 MILES OR 48 MONTHS WHICHEVER OCCURS FIRST : "I"ENGINE CONTROL SYSTEM MAINTENANCE (GASOLINE)

1 ENGINE OIL & FILTER (SG OR ABOVE) See Note (1)

2 DRIVE BELT (WATER PUMP, ALTERNATOR & A/CON)

3 FUEL FILTER (MFI)

4 FLUID LEAKS

5 TIMING BELT

6 VENTILATION HOSES

7 AIR CLEANER FILTER

8 SPARK PLUGS

9 VALVE CLEARANCE (1.8 DOHC)

NO. DESCRIPTION60 72

5060

4048

3036

2024

1012

MILES X 1,000MONTHS

R

I I

R R

R

I

R I I

R

I

R I

R R

R

I I I

R

II

R R

R

I I

See Note (2)

Page 270 of 312

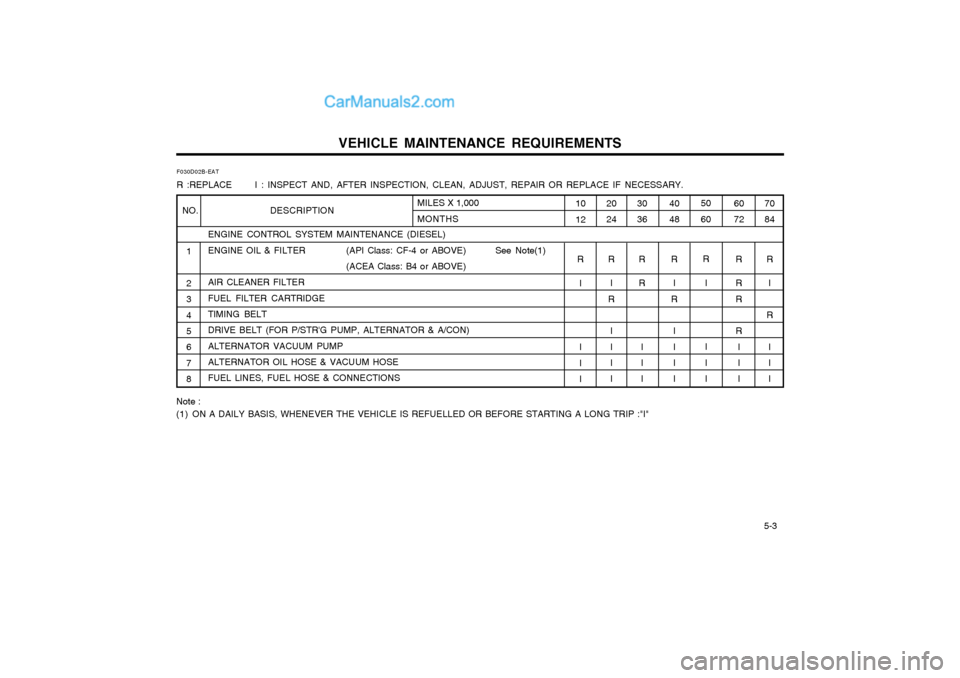

VEHICLE MAINTENANCE REQUIREMENTS 5-3

F030D02B-EAT R :REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL)

ENGINE OIL & FILTER (API Class: CF-4 or ABOVE) See Note(1)

(ACEA Class: B4 or ABOVE)

AIR CLEANER FILTERFUEL FILTER CARTRIDGETIMING BELT DRIVE BELT (FOR P/STR'G PUMP, ALTERNATOR & A/CON) ALTERNATOR VACUUM PUMPALTERNATOR OIL HOSE & VACUUM HOSE FUEL LINES, FUEL HOSE & CONNECTIONS

NO. DESCRIPTION

1 2 34 5 67 8 60 72

R R R R I I I50 60

R I I I I40 48

R I

R

II I I30 36

R R

I I I20 24R I

R

II I I

1012

R I I I IMILES X 1,000 MONTHS70 84

R I

R I I I

Note :

(1) ON A DAILY BASIS, WHENEVER THE VEHICLE IS REFUELLED OR BEFORE STARTING A LONG TRIP :"I"

Page 272 of 312

VEHICLE MAINTENANCE REQUIREMENTS 5-5

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the

appropriate maintenance intervals.

R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

F040A04E-EAT

SEVERE DRIVING CONDITIONS

A - Repeated short distance driving

B - Extensive idling

C - Driving in dusty, rough roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in sandy areas ENGINE OIL AND FILTER AIR CLEANER FILTERSPARK PLUGSTIMING BELT BRAKE PADS REAR BRAKE LININGS AND CYLINDERSSUSPENSION AND STEERING SYSTEMMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDPOLLEN FILTER(IN FRONT OF BLOWER UNIT)

EVERY 4,500MILES OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLY EVERY 37,000MILES OR 48 MONTHS

MORE FREQUENTLY

MORE FREQUENTLY MORE FREQUENTLY EVERY 60,000MILESEVERY 27,000MILES MORE FREQUENTLY

MAINTENANCE OPERATIONMAINTENANCE ITEM

R R R RII I

R R R A, B, C, F, H C, E B, H D, E, F, GC, D, G, HC, D, G, H C, D, E, F A, C, D, E, F, G, H, I, JA, C, E, F, G, H, I C,E

MAINTENANCE INTERVALS

DRIVING

CONDITION

F - More than 50% driving in heavy city traffic during hot weather above 90°F (32°C)

G - Driving in mountainous areas

H - Towing a trailer

I - Driving for patrol car, taxi, commercial car or vehicle towing

J - Driving over 100MPH

Page 273 of 312

VEHICLE MAINTENANCE REQUIREMENTS

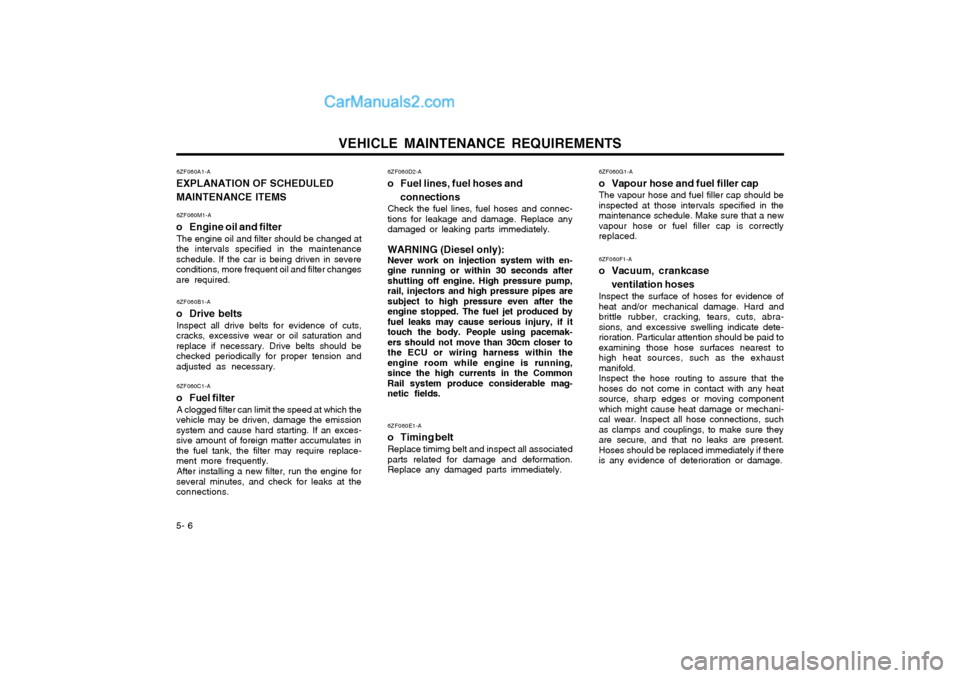

5- 6 6ZF060D2-A

o Fuel lines, fuel hoses and

connections

Check the fuel lines, fuel hoses and connec- tions for leakage and damage. Replace anydamaged or leaking parts immediately.

WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds aftershutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer tothe ECU or wiring harness within theengine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields. 6ZF060E1-A

o Timing belt Replace timimg belt and inspect all associated parts related for damage and deformation.Replace any damaged parts immediately. 6ZF060G1-A

o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in themaintenance schedule. Make sure that a newvapour hose or fuel filler cap is correctlyreplaced. 6ZF060F1-A

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abra-sions, and excessive swelling indicate dete-rioration. Particular attention should be paid toexamining those hose surfaces nearest tohigh heat sources, such as the exhaustmanifold.Inspect the hose routing to assure that thehoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechani-cal wear. Inspect all hose connections, suchas clamps and couplings, to make sure theyare secure, and that no leaks are present.Hoses should be replaced immediately if thereis any evidence of deterioration or damage.

6ZF060A1-A

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

6ZF060M1-A

o Engine oil and filter The engine oil and filter should be changed at

the intervals specified in the maintenance schedule. If the car is being driven in severeconditions, more frequent oil and filter changesare required.

6ZF060B1-A

o Drive belts Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation andreplace if necessary. Drive belts should bechecked periodically for proper tension andadjusted as necessary.

6ZF060C1-A

o Fuel filter A clogged filter can limit the speed at which the

vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replace-ment more frequently.

After installing a new filter, run the engine for

several minutes, and check for leaks at theconnections.

Page 275 of 312

VEHICLE MAINTENANCE REQUIREMENTS

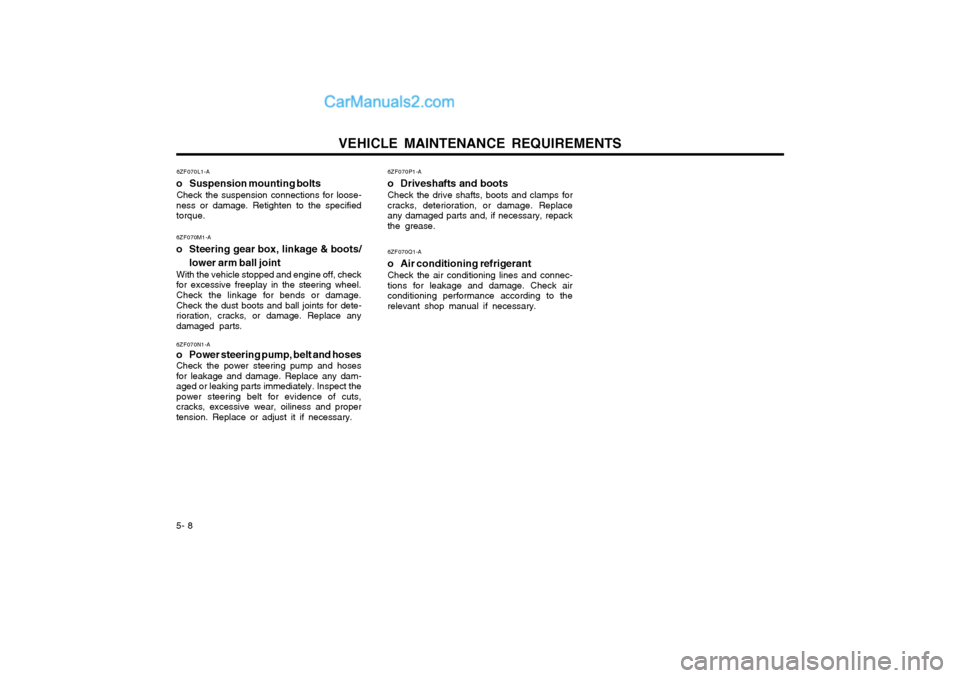

5- 8 6ZF070P1-A

o Driveshafts and boots Check the drive shafts, boots and clamps for cracks, deterioration, or damage. Replaceany damaged parts and, if necessary, repackthe grease. 6ZF070Q1-A

o Air conditioning refrigerant Check the air conditioning lines and connec- tions for leakage and damage. Check airconditioning performance according to therelevant shop manual if necessary.

6ZF070L1-A

o Suspension mounting bolts Check the suspension connections for loose-

ness or damage. Retighten to the specifiedtorque. 6ZF070M1-A

o Steering gear box, linkage & boots/

lower arm ball joint

With the vehicle stopped and engine off, check for excessive freeplay in the steering wheel. Check the linkage for bends or damage. Check the dust boots and ball joints for dete-rioration, cracks, or damage. Replace anydamaged parts. 6ZF070N1-A

o Power steering pump, belt and hoses Check the power steering pump and hoses for leakage and damage. Replace any dam-aged or leaking parts immediately. Inspect thepower steering belt for evidence of cuts,cracks, excessive wear, oiliness and propertension. Replace or adjust it if necessary.

Page 279 of 312

OWNER MAINTENANCE

6-4

SG020B1-E

DAILY OPERATING CHECKS

The following items should be checked on a

daily basis or whenever the vehicle is refuelled, whichever occurs sooner.

o Engine oil level.

o Engine coolant level.

o Power steering fluid level.

o Brake fluid level.

o Windscreen washer fluid level.

o Battery condition.

o Tyre condition and pressures.

o Operation and cleanliness of all lighting equipment.

o Windscreen wiper and washer operation.

o Horn operation.

o Warning light operation.

o Adjustment and cleanliness of mirrors.

o Seat and seat belt adjustment and opera- tion.

o Fluid leakage.

The vehicle must not be driven if the daily

operating checks indicate that any item of equip- ment related to the safety or roadworthiness ofthe vehicle is not functioning correctly. G030A01FC-EAT

ENGINE OIL

The correct engine oil level is of paramount

importance. An excessively high or low oil levelmay result in irreparable damage being sus-tained by the engine. The engine oil levelmust be checked on a daily basis, wheneverthe vehicle is refuelled or before starting along trip, whichever occurs sooner.

In addition, it is imperative that only an ap-

proved grade and specification of oil is used toavoid the possibility of serious engine damageand premature wear. The use of "budget price"oil is a false economy that must be avoided ifthe maximum reliability and useful life is to beobtained from the vehicle.

G030B02O-EAT

Recommended Oil

1. Gasoline engine

20W-40 20W-50

5W-40

SSA6030B

°C °F -25 -13 40104

2068

1050

032

-15 5 -10-14

5W-20 15W-40 15W-50

10W-30

10W-40 10W-50

5W-30

A multi grade oil having a specification which meets A.P.I. specification of SG or above isrecommended. The oil viscosity should be se-lected according to the operating environmentof the engine by means of the table shown inthe illustration. The engine oil recommenda-tions are complete in themselves and the use ofadditives is neither required nor recommended.The use of engine oil additives may result ininvalidation of the vehicle warranty. NOTE: The use of a 5W-20 multi grade oil is not recommended for sustained high speed use.

2. Diesel engine

The engine oil quality should meet the follow-

ing classification:

API class: CF-4 or ABOVEACEA class: B4 or ABOVE

G030B02B

Page 290 of 312

OWNER MAINTENANCE 6-15

SG140C1-E

Checking the Refrigerant

1. Start the engine and run at idle for several minutes with the refrigeration system run- ning at the coldest setting.

2. Open the bonnet and inspect the sight glass on the top of the receiver dryer.

3. If the refrigerant charge is insufficient, a flow of bubbles will be observed through the sightglass.

4. If the refrigerant charge is satisfactory, no bubbles will be observed through the sightglass.

CAUTION: Running the air conditioning system with a

low refrigerant level may damage the com- pressor.

SG140D1-E

Off Season Maintenance The air conditioning must be run for ten minutes

or so weekly during periods when the systemwould not normally be used to ensure that thecompressor and seals are lubricated. If thisprecaution is not observed the compressor sealsmay become stuck to the compressor shaft anddamaged when the system is next used result-ing in a loss of refrigerant and damage to thecompressor. SG150A1-E STEERING WHEEL FREEPLAY

Steering wheel freeplay should be checked to

ensure that the specified value is not exceeded.

SG160A1-E

CLUTCH PEDAL FREEPLAY

SG140B1-E

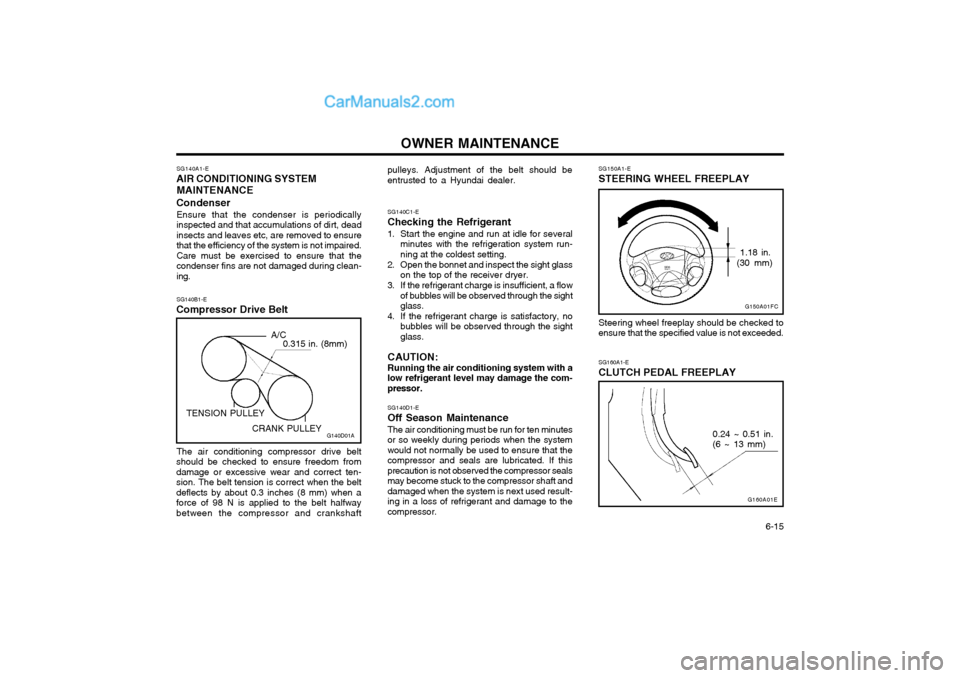

Compressor Drive Belt

The air conditioning compressor drive belt

should be checked to ensure freedom from damage or excessive wear and correct ten-sion. The belt tension is correct when the beltdeflects by about 0.3 inches (8 mm) when aforce of 98 N is applied to the belt halfwaybetween the compressor and crankshaft SG140A1-E

AIR CONDITIONING SYSTEM

MAINTENANCE

Condenser Ensure that the condenser is periodicallyinspected and that accumulations of dirt, deadinsects and leaves etc, are removed to ensurethat the efficiency of the system is not impaired.Care must be exercised to ensure that thecondenser fins are not damaged during clean-ing.

G160A01E

0.24 ~ 0.51 in. (6 ~ 13 mm)

G150A01FC

G140D01A

A/C

CRANK PULLEY

TENSION PULLEY

1.18 in. (30 mm)

0.315 in. (8mm) pulleys. Adjustment of the belt should be entrusted to a Hyundai dealer.