Hyundai Matrix 2005 Owners Manual

Manufacturer: HYUNDAI, Model Year: 2005, Model line: Matrix, Model: Hyundai Matrix 2005Pages: 407, PDF Size: 10.31 MB

Page 91 of 407

IN CASE OF EMERGENCY

3-4

SD070A1-E

CHANGING A FLAT TYRE

It is of the utmost importance that care is

exercised when changing road wheels. En- sure that the parking brake is set and that the gear shift lever is in reverse (P, if the vehicle has automatic transaxle).

D060A01FC-D

SD050A2-E SPARE WHEEL (Not all models) The spare wheel is stored under the luggage compartment floor and is accessed from within the luggage compartment by lifting the carpet and the floor panel.To remove the spare wheel, unscrew the retainer, rotating this in an anti clockwise direction and lift out the wheel. To replace the wheel, screw the retainer by hand until tight having located the wheel in the luggage com- partment floor well. The inflation pressure of the spare wheel should be checked at least monthly and whenever the wheel is fitted to the vehicle. Spare Tyre Pressure

CAUTION:

o Do not use snow chains with your

temporary spare tyre.

o Do not use more than one temporary

spare tyre at a time. SD060A1-E

IN THE EVENT OF A PUNCTURE If a puncture occurs whilst driving the vehicle:

1. Bring the car to rest as soon as it is safe to do so and with the minimum amount of braking required which will assist in main- taining the maximum amount of control. The vehicle should be parked wherever possible upon firm level ground to facilitate wheel changing.

2. If the vehicle is creating a hazard and the road conditions do not permit the wheel tobe changed safely, assistance should be sought.

3. Passengers must not be allowed to remain inside the vehicle during wheel changing.If a puncture occurs whilst the vehicle is on a motorway, the passengers should take refuge on the motorway embankment to avoid the possibility of injury occurring should the vehicle be struck by other motorway traffic.

4. Wheel changing should be performed ac- cording to the following instructions.

Type Inflation Pressure Full Size210 kPa (30 psi)

Page 92 of 407

3-5

IN CASE OF EMERGENCY

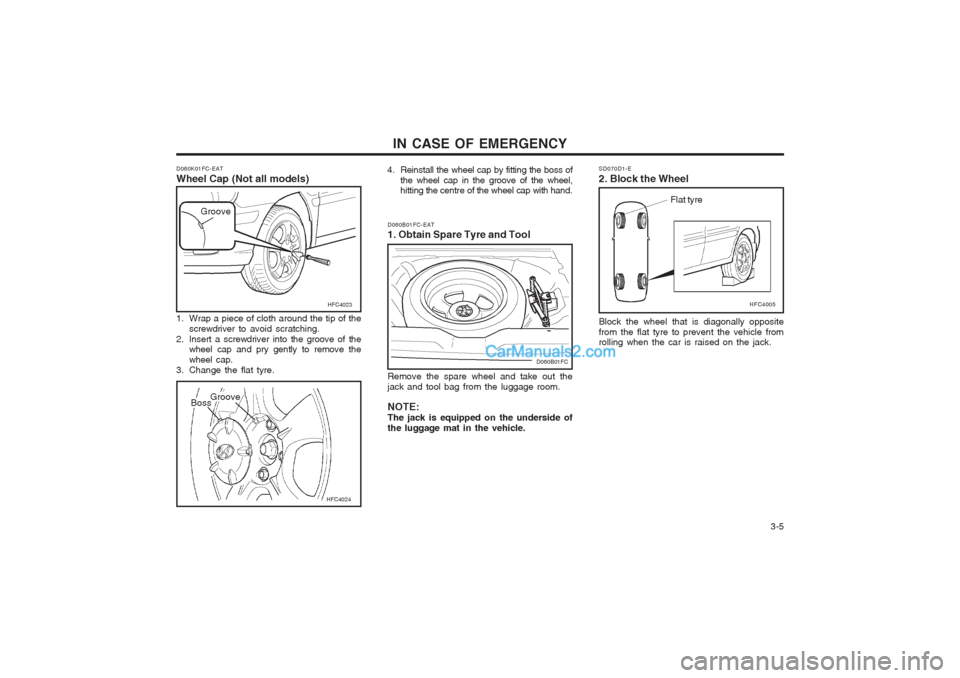

D060K01FC-EAT Wheel Cap (Not all models)

HFC4024

1. Wrap a piece of cloth around the tip of the

screwdriver to avoid scratching.

2. Insert a screwdriver into the groove of the wheel cap and pry gently to remove the wheel cap.

3. Change the flat tyre. HFC4023

Groove

BossGroove

Remove the spare wheel and take out the jack and tool bag from the luggage room. NOTE: The jack is equipped on the underside ofthe luggage mat in the vehicle.

D060B01FC-EAT 1. Obtain Spare Tyre and Tool

4. Reinstall the wheel cap by fitting the boss of

the wheel cap in the groove of the wheel,

hitting the centre of the wheel cap with hand.

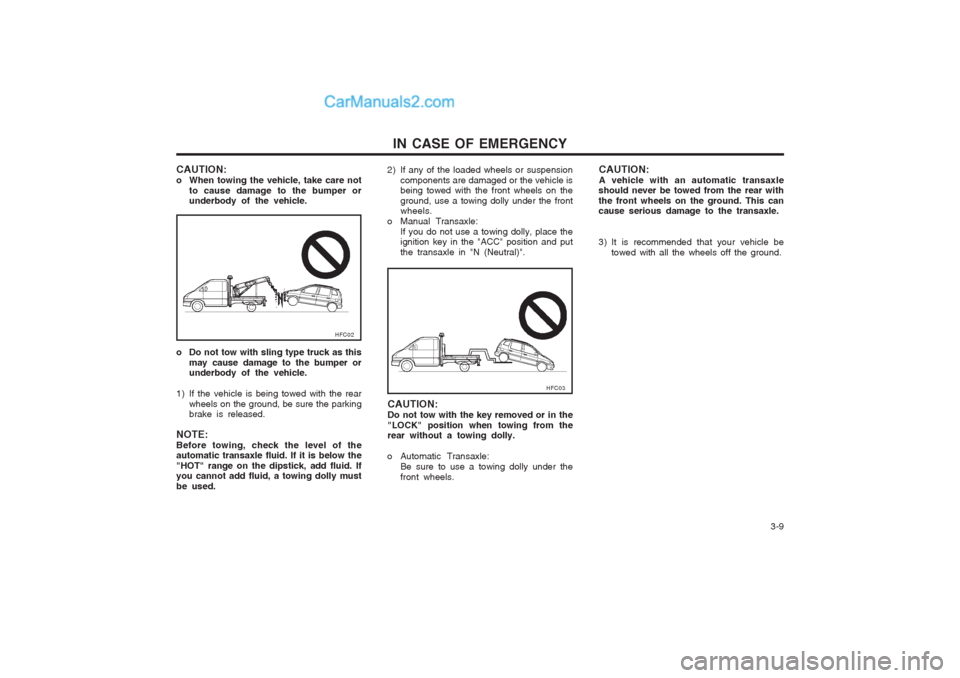

D060B01FC Block the wheel that is diagonally opposite from the flat tyre to prevent the vehicle from rolling when the car is raised on the jack.

SD070D1-E 2. Block the Wheel

Flat tyre

HFC4005

Page 93 of 407

IN CASE OF EMERGENCY

3-6 SD070G1-E

5. Raising the Car

After inserting a wrench bar into the wheel nut

wrench, install the wrench bar into the jack as shown in the drawing. To raise the vehicle, turn the wheel nut wrench clockwise. As the jack begins to raise the vehicle, double check that it is properly positioned and will not slip. If the jack is on soft ground or sand, it may be necessary to place a stout piece of timber under the base of the jack to prevent it from sinking.

Raise the car high enough so that the fully

inflated spare wheel can be installed.

WARNING: Do not get under the car when it is support-

ed by the jack! The jack is solely designedfor wheel changing and is not intended to support the vehicle for other purposes. The use of purpose designed supports is neces- sary whilst the vehicle is raised and the operator is required to get underneath.

HFC4022

Wrench bar

Wheel nut wrench

SD070E1-E 3. Loosen Wheel Nuts The wheel nuts should be loosened slightly before raising the car. To loosen the nuts, turn the wheel brace counterclockwise. Ensure that the wheel brace socket is seated properly on the nut and that it cannot slip. Do not remove the nuts at this stage. SD070F1-F

4. Put the Jack in Place

The base of the jack should be placed on firm,level ground. The jack should be positioned as shown in the drawing.

D060D01FC-DHFC4006

Page 94 of 407

3-7

IN CASE OF EMERGENCY

WARNING: It is important that the faces of the wheeland hub are clean prior to installing the wheel. The prescence of dirt or other mat- ter in the wheel or hub faces could result in the wheel nuts becoming loose whilst the vehicle is being driven. SD070I1-E

7. Re-install Wheel Nuts

Fit the wheel nuts onto the studs and tighten with the wheel brace.

SD070H1-E 6. Changing Wheels Using the wheel brace, remove the nuts and slide the wheel off the hub and wheel studs. Lie the wheel flat to prevent it from rolling. Ensure that the faces of the wheel and hub are clean. Position the spare wheel over the studs and slide it up to the hub.

STA3071H

D060H01FC-D

D060G01FC

SD070J1-E

8. Lower Vehicle and Tighten Nuts

Lower the car to the ground turning the wheel

nut wrench counterclockwise. When the ve- hicle is firmly on the ground, remove the jack and tighten the wheel nuts securely. At the first available opportunity, the wheel nut torque should be checked with a suitable torque wrench.

Wheel nut tightening torqueSteel wheel & aluminium alloy wheel: 90-110 Nm (65-80 lb.ft)

D060I01FC-D

Page 95 of 407

IN CASE OF EMERGENCY

3-8

SD070K1-E AFTER CHANGING WHEELS The pressure of the spare tyre should be checked at the first available opportunity. If any doubt exists as to the tyre pressure, the vehicle should be driven slowly to the nearest service station and the tyre pressure checked and adjusted as required. If the valve cap is lost from any of the valves, a replacement should be obtained and fitted at the first available opportunity. The valve cap prevents the ingress of dirt which may cause the valve to stick and therefore leak and is part of the valve sealing function. Ensure that the spare wheel, jack and wheel nut wrench as well tools are correctly located in the boot of the vehicle to prevent damage and noise.

D060B01FC

HFC01

D080A01O-GAT

IF YOUR VEHICLE MUST BE TOWED If your vehicle has to be towed, it should be done by your Hyundai authorised repairer or a commercial tow truck service. This will help assure that your vehicle is not damaged in towing. Also, professionals are generally aware of local laws governing towing. In any case, rather than risk damage to your car, it is suggested that you show this information to the tow truck operator. Be sure that a safety chain system is used and that all local laws are observed. It is recommended that your vehicle be towed with a wheel lift and dollies or flatbed equip- ment with all the wheels off the ground. CAUTION:

o Your vehicle can be damaged if towed incorrectly!

o Be sure the transaxle is in neutral.

o When the engine will not start, be sure the steering is unlocked by placing thekey in the "ACC" position. D080B01O-GAT

Towing the Vehicle

Your vehicle can be towed by wheel lift typetruck (1), (2) or flatbed equipment (3).

dolly

(1)

(2)

(3)

Page 96 of 407

3-9

IN CASE OF EMERGENCY

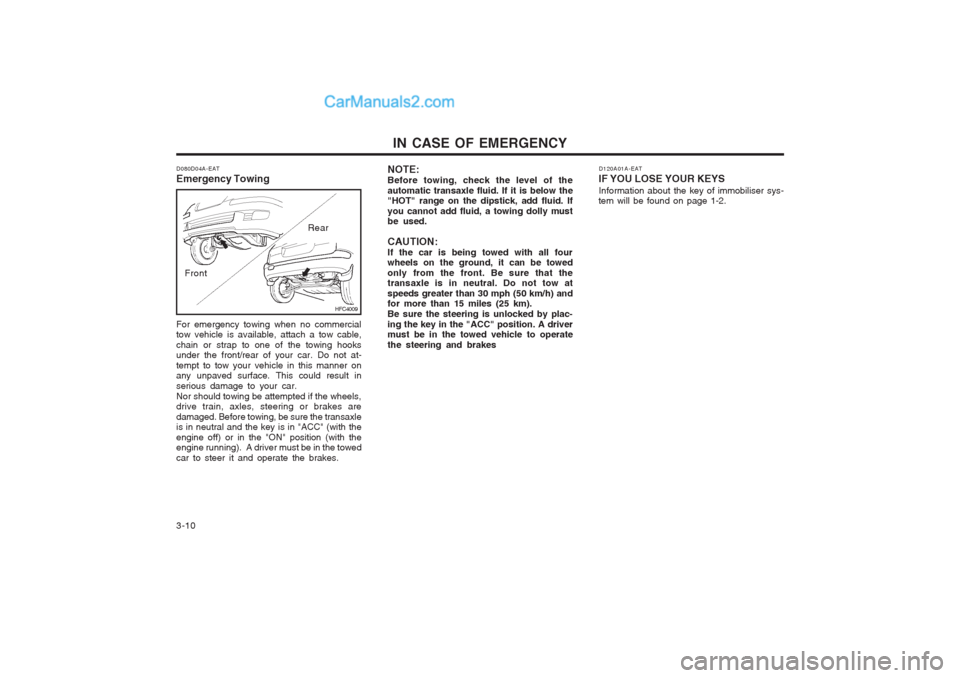

CAUTION:

o When towing the vehicle, take care not to cause damage to the bumper or underbody of the vehicle.

o Do not tow with sling type truck as this may cause damage to the bumper orunderbody of the vehicle.

1) If the vehicle is being towed with the rear wheels on the ground, be sure the parkingbrake is released.

NOTE: Before towing, check the level of the automatic transaxle fluid. If it is below the "HOT" range on the dipstick, add fluid. If you cannot add fluid, a towing dolly must be used.

HFC02

2) If any of the loaded wheels or suspension components are damaged or the vehicle is being towed with the front wheels on the ground, use a towing dolly under the front wheels.

o Manual Transaxle:

If you do not use a towing dolly, place theignition key in the "ACC" position and put the transaxle in "N (Neutral)".

HFC03

CAUTION: Do not tow with the key removed or in the"LOCK" position when towing from the rear without a towing dolly.

o Automatic Transaxle: Be sure to use a towing dolly under the front wheels. CAUTION:A vehicle with an automatic transaxle

should never be towed from the rear withthe front wheels on the ground. This can cause serious damage to the transaxle.

3) It is recommended that your vehicle be

towed with all the wheels off the ground.

Page 97 of 407

IN CASE OF EMERGENCY

3-10 D120A01A-EAT

IF YOU LOSE YOUR KEYS Information about the key of immobiliser sys-

tem will be found on page 1-2.

NOTE: Before towing, check the level of theautomatic transaxle fluid. If it is below the "HOT" range on the dipstick, add fluid. If you cannot add fluid, a towing dolly must be used. CAUTION: If the car is being towed with all four wheels on the ground, it can be towed only from the front. Be sure that the transaxle is in neutral. Do not tow at speeds greater than 30 mph (50 km/h) and for more than 15 miles (25 km). Be sure the steering is unlocked by plac-ing the key in the "ACC" position. A driver must be in the towed vehicle to operate the steering and brakes

D080D04A-EAT Emergency Towing

HFC4009

Front

Rear

For emergency towing when no commercial tow vehicle is available, attach a tow cable, chain or strap to one of the towing hooks under the front/rear of your car. Do not at- tempt to tow your vehicle in this manner on any unpaved surface. This could result in serious damage to your car.Nor should towing be attempted if the wheels, drive train, axles, steering or brakes are damaged. Before towing, be sure the transaxle is in neutral and the key is in "ACC" (with the engine off) or in the "ON" position (with the engine running). A driver must be in the towed car to steer it and operate the brakes.

Page 98 of 407

APPEARANCE CARE 4-1

garding the retreatment programme must be observed in accordance with the Terms and Conditions outlined in the separate Anti Per- foration Warranty Booklet. NOTE: The underbody should never be steamcleaned since the underbody coating may be removed by this process. During the interim period between powerwashing the underbody, the more vulnera- ble areas such as wheel arches should be hosed off particularly during the winter sea- son to prevent prolonged contact with road salts.Ensure that the various drain points located at the bottom of the door panels and sills are kept clear to prevent water from becom- ing trapped within the cavities. Wherever possible, the parking of the vehicle in a confined, poorly ventilated location (a ga- rage for example) should be avoided when the vehicle is wet or is covered with snow or ice. Under these conditions, the internal cavities of the vehicle will remain damp for prolonged periods of time which will en- courage corrosion. Parking the vehicle where good ventilation exists (outside for example) is preferable.

SE040A1-E VALETING Regular cleaning of the exterior paintwork serves two important functions. Firstly, the removal of abrasive dirt and contaminants will maintain the lustre of the paintwork and will prevent discolouration and dulling due to prolonged con- tact. Secondly, the presence of damage through im- pact or abrasion will be apparent allowing early rectification to be made thus preventing corro- sion from becoming established and spreading beneath the paint film. To avoid "water spotting" the vehicle should not be washed in direct sun- light particularly in the case of vehicles having dark body colours. The heat from the sun rays is absorbed by the paint film increasing the surface temperature. This action causes water used for washing to evaporate quickly leaving behind the deposits from the water and the shampoo used. Use only a shampoo intended for the purpose and ensure that the body work is thoroughly wetted to soften the dirt film prior to attempting to remove this. After removing the dirt film with a soft sponge, the body work should be thoroughly rinsed and then dried with a good quality chamois leather to prevent streaking or spotting of the paint work. Household detergents, solvents and abrasive cleaning materials should not be used in order to avoid damaging the paint film.

SE030A1-E UNDERBODY COATINGSEvery Hyundai passenger car receives a full underbody and cavity injection treatment during production. In order that this treatment may retain maximum effectiveness it is recommend- ed that the underbody receives a power wash and a thorough inspection after each winter season. In doing so any accumulations of mud, which act as moisture traps and com- bine with road salts to accelerate corrosion will be removed. In order to maintain the Anti Perforation Warranty, the requirements re-

SE000A1-E

4. APPEARANCE

CARE

SE020A1-E PROTECTING YOUR HYUNDAI FROM CORROSION By using the most advanced design and con- struction practices, every Hyundai is built to retain the original factory finish for many years. However, long term durability is also greatly dependant upon maintaining the various protec- tion systems and coatings used in manufacture since constant, exposure to the elements will result in a breakdown and loss of effectiveness. The following suggestions are made to assist in the maintenance of the vehicle bodywork.

4

Page 99 of 407

APPEARANCE CARE

4-2

Plastic wheel covers should be cleaned using a sponge and water. Cast alloy wheels should be cleaned using a mild soap or neutral deter- gent. Abrasive compounds must not be used since in the event of these damaging the lac- quer coating, oxidization of the aluminium wheel will occur, spoiling the appearance. The use of an a toothbrush will facilitate cleaning between the wheel "spokes".

ensure that accidental spillages are immediately flushed with water. Do not use abrasive cleaning materials which may damage the bumpers. Avoid subjecting the bumpers to high tempera- tures such as may be encountered in high bake paint ovens.

SE040B1-E STAIN/SPOT REMOVAL Should tree sap, dead insects or tar prove to be difficult to remove from the paint film, turpentine or a proprietary paint cutting compound may be used. Ensure that the area to be cleaned is not rubbed intensively to prevent breaking through the colour coat and exposing the under coat. SE040C1-E POLISHINGThe exterior paint work should be polished with a proprietary wax polish when water no longer collects in bead form on the paint work. The instructions of the product manufacturer should be adhered to. SE040E1-E BUMPER MAINTENANCEThe special material from which the bumpers are manufactured warrants special attention to pre- serve the appearance of the bumpers. Avoid contact with battery electrolyte or brake fluid and SE040F1-E ACCIDENT REPAIRSIn the event of the body work sustaining damage, the following points should be noted prior to repairs being undertaken. If body panels are replaced or repaired, anti corrosion treatment must be applied to the repair area. The product used must be compatible withthose used in manufacture. It is recommended that repairs are entrusted to a Hyundai authorised repairer to ensure that replacement parts used are of the same high quality as those used in manufacture of the vehicle and that the correct repair methods and materials will en- sure adequate levels of corrosion protection and the continued validity of the Anti Perforation Warranty. SE050A1-E INTERIORDuring the winter period, it is possible that the passenger compartment flooring may become wet from damp footwear or quantities of snow adhering to footwear. The carpet should not be allowed to remain in this condition since the carpet may begin to create musty smells and will

SE050D1-E SEAT BELTS Seat belts should be cleaned only with a mild soap solution. Strong detergents, solvents or bleaches may damage the belt webbing and therefore reduce the effectiveness of the belt. Belts which display signs of fraying, wear of cuts should be replaced. SE050E1-E WINDOWS A proprietary glass cleaner should be used to clean the inside of the windows. However, the rear heated windshield must only be cleaned using a light horizontal cleaning action. Care should be exercised to avoid the use of abrasive cleaners or contact with items of jewellery which may damage the heating elements.

promote corrosion of the floor pan in addition tothe carpet and under felt beginning to rot. SE050C1-E INTERIOR VALETING The soft trim and carpets should be maintained with the regular use of a vacuum cleaner. Heavy soiling should be removed with a dry cleaning agent recommended for this purpose following the instructions of the product manufacturer. Paint thinner, solvents or other such cleaning materials should not be used since damage to the upholstery may result.

Page 100 of 407

VEHICLE MAINTENANCE REQUIREMENTS 5-1

SF020A1-E

MAINTENANCE AND SERVICING REQUIREMENTS To ensure the continued reliability and safety

of the vehicle, certain routine maintenance operations are required at specific mileage ortime intervals.

It is the responsibility of the vehicle owner to

ensure that the maintenance schedules shownin both this Owners Manual and the Warrantyand Service Passport are adhered to.

The new vehicle warranty may be invalidated

if the routine maintenance operations are notperformed in line with the recommendationsoutlined and the safety and durability of thevehicle adversely affected.

It is recommended that all maintenance op-

erations with the exception of the daily oper-ating checks are entrusted to a Hyundaiauthorised repairer to ensure that the latestrepair and maintenance procedures andspecialised servicing tools are employed. In addition, the use of genuine Hyundai re-

placement parts will ensure that the vehiclesafety and performance will not be compro-mised. NOTE: The inspection and testing of certain elec-

tronic fuel injection/engine management and automatic transmission control sys-tems require specialised electronic equip-ment specifically designed for Hyundaivehicles. The use of general purpose elec-trical test equipment may result in dam-age to the control unit microprocessors.

SF000A1-E

5. VEHICLE

MAINTENANCE REQUIREMENTS

SF020C2-E

Specified Scheduled Procedures The Specified scheduled procedures are listed

in the maintenance charts beginning at page 5-2. The operations specified must be per-formed at the time or mileage intervals shownirrespective of whether the mileage intervalhas been reached before the specified timeinterval.

Certain lubricants and components degrade

with both time and mileage (e.g. engine oil andbrake fluid) and therefore it is not permissableto base the maintenance schedule upon mile-age alone. It is strongly recommended thatthe maintenance operations are performed bythe factory-trained or distributor-trained tech-nicians at your Hyundai authorised repairer because of the need for specialised knowl-edge and tooling and to ensure that no pos-sibility of invalidating the manufacturers war-ranty exists.

The maintenance schedules relate to ve-

hicles operated under normal conditions, ve-hicles which are operated under adverseconditions will require more frequent mainte-nance which is described at page 5-5. NOTE:

Service schedules may change depend-

ing on individual country needs. Please ask your local Hyundai authorised re-pairer for a copy of the service schedulethat relates to that country.

SF030B1-E

SERVICE HISTORY It is important that all scheduled maintenanceservices are recorded in the warranty andservice passport to ensure that proof of main-tenance is available when warranty service isrequired.

5