Hyundai Matrix 2005 Owner's Manual

Manufacturer: HYUNDAI, Model Year: 2005, Model line: Matrix, Model: Hyundai Matrix 2005Pages: 407, PDF Size: 10.31 MB

Page 101 of 407

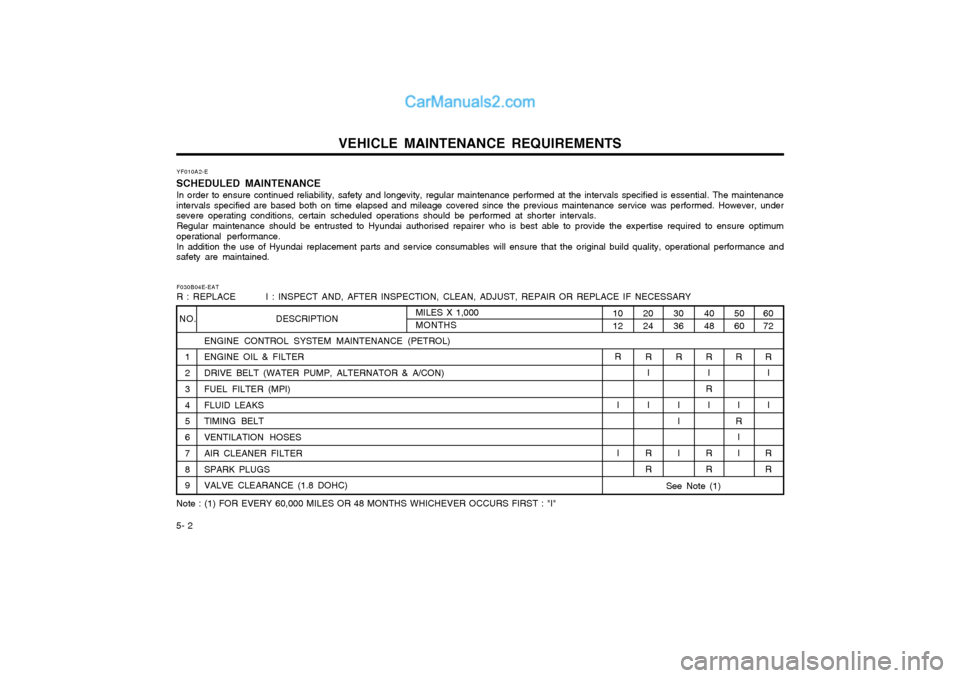

VEHICLE MAINTENANCE REQUIREMENTS

5- 2 YF010A2-E

SCHEDULED MAINTENANCE In order to ensure continued reliability, safety and longevity, regular maintenance performed at the intervals specified is essential. The maintenance

intervals specified are based both on time elapsed and mileage covered since the previous maintenance service was performed. However, under severe operating conditions, certain scheduled operations should be performed at shorter intervals.

Regular maintenance should be entrusted to Hyundai authorised repairer who is best able to provide the expertise required to ensure optimum

operational performance.

In addition the use of Hyundai replacement parts and service consumables will ensure that the original build quality, operation al performance and

safety are maintained.

F030B04E-EAT R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

Note : (1) FOR EVERY 60,000 MILES OR 48 MONTHS WHICHEVER OCCURS FIRST : "I" ENGINE CONTROL SYSTEM MAINTENANCE (PETROL)

1 ENGINE OIL & FILTER

2 DRIVE BELT (WATER PUMP, ALTERNATOR & A/CON)

3 FUEL FILTER (MPI)

4 FLUID LEAKS

5 TIMING BELT

6 VENTILATION HOSES

7 AIR CLEANER FILTER

8 SPARK PLUGS

9 VALVE CLEARANCE (1.8 DOHC)

NO. DESCRIPTION60 72

5060

4048

3036

2024

1012

MILES X 1,000 MONTHS

R

I I

R R

R

I

R I I

R

I

R I

R R

R

I I I

R

II

R R

R

I I

See Note (1)

Page 102 of 407

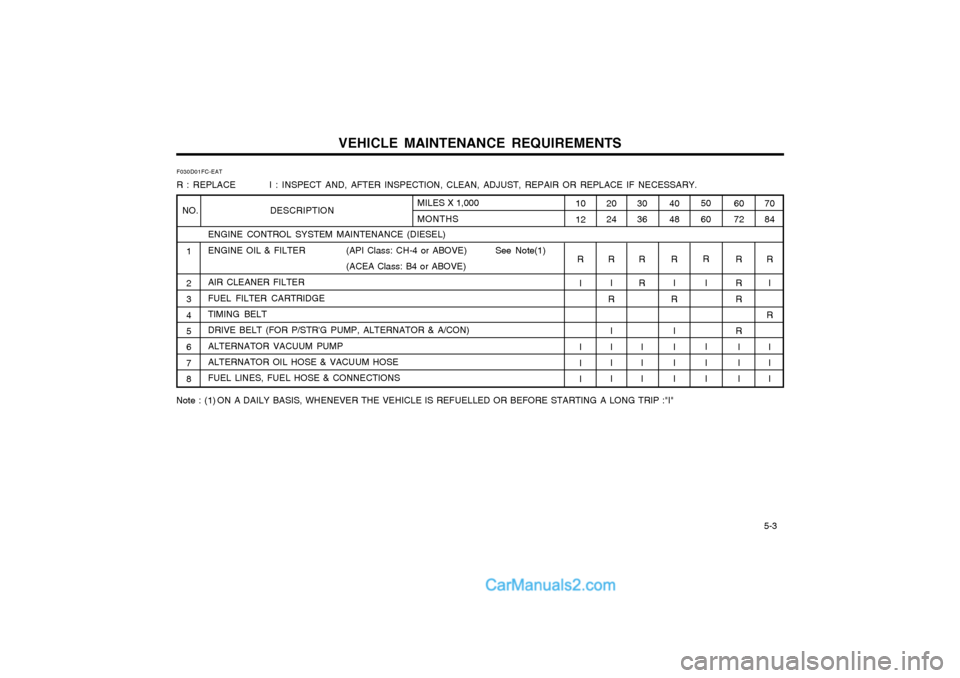

VEHICLE MAINTENANCE REQUIREMENTS 5-3

F030D01FC-EAT R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL)

ENGINE OIL & FILTER (API Class: CH-4 or ABOVE) See Note(1)

(ACEA Class: B4 or ABOVE)

AIR CLEANER FILTERFUEL FILTER CARTRIDGETIMING BELT DRIVE BELT (FOR P/STR'G PUMP, ALTERNATOR & A/CON) ALTERNATOR VACUUM PUMPALTERNATOR OIL HOSE & VACUUM HOSE FUEL LINES, FUEL HOSE & CONNECTIONS

NO. DESCRIPTION

1 2 34 5 67 8 60 72

R R R R I I I50 60

R I I I I40 48

R I

R

II I I30 36

R R

I I I20 24R I

R

II I I

1012

R I I I IMILES X 1,000 MONTHS70 84

R I

R I I I

Note : (1) ON A DAILY BASIS, WHENEVER THE VEHICLE IS REFUELLED OR BEFORE STARTING A LONG TRIP :"I"

Page 103 of 407

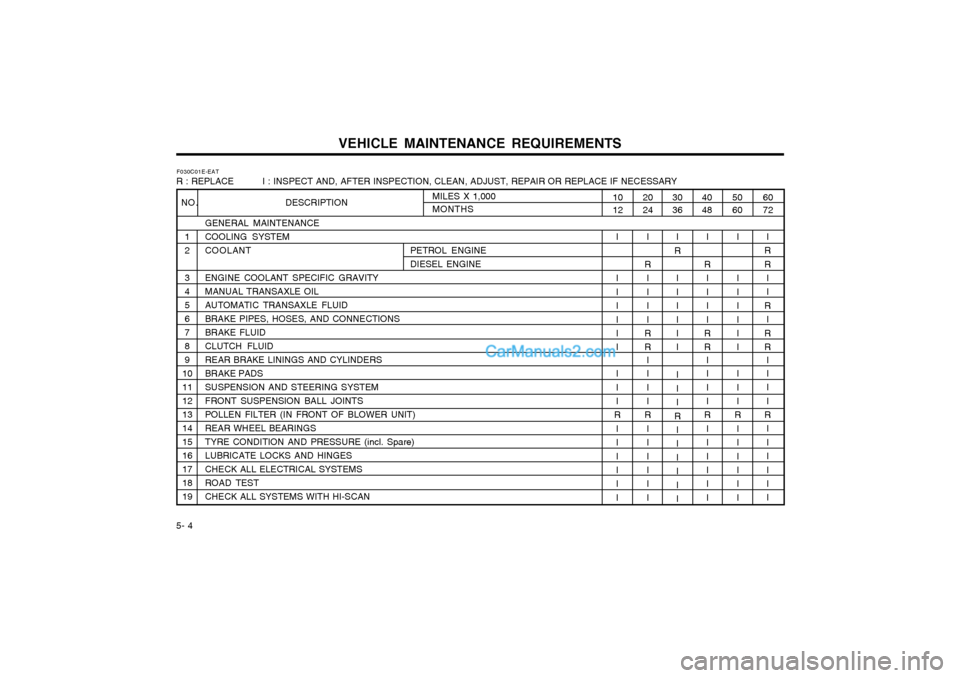

VEHICLE MAINTENANCE REQUIREMENTS

5- 4 F030C01E-EAT

R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

GENERAL MAINTENANCE COOLING SYSTEMCOOLANT PETROL ENGINEDIESEL ENGINE

ENGINE COOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDBRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUIDCLUTCH FLUIDREAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEMFRONT SUSPENSION BALL JOINTSPOLLEN FILTER (IN FRONT OF BLOWER UNIT)REAR WHEEL BEARINGSTYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGESCHECK ALL ELECTRICAL SYSTEMSROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN

60 72

50 60

4048

I

R R

I I

R I

R R I I II

R

IIIII I

I I IIII I I I I

R I III I I

I

R IIII

R R I I I I

R I III I I

30 36

2024

I

R

I IIII I I II

R IIIIII

I

R IIII

R R I I I I

R I III I I

10 12

I I IIII I I I I

R I III I I

MILES X 1,000 MONTHS

NO. DESCRIPTION

1 2 3 456789

10111213141516171819

Page 104 of 407

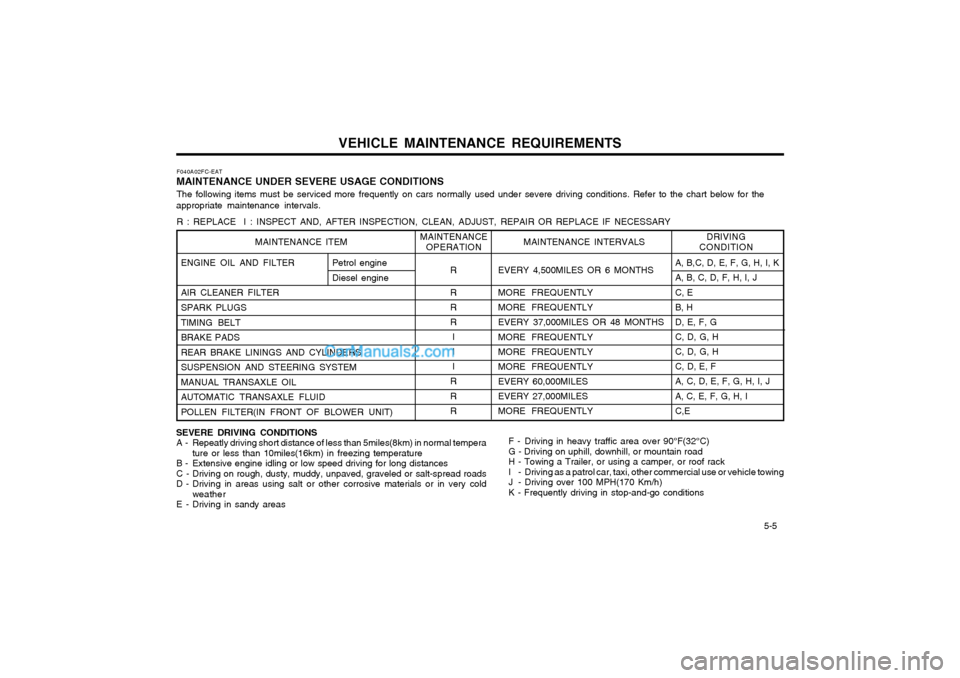

VEHICLE MAINTENANCE REQUIREMENTS 5-5

R R RR

I I I

R R R A, B,C, D, E, F, G, H, I, KA, B, C, D, F, H, I, J C, E B, HD, E, F, GC, D, G, H C, D, G, H C, D, E, FA, C, D, E, F, G, H, I, J A, C, E, F, G, H, I C,E

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the

appropriate maintenance intervals.

R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

F040A02FC-EAT

SEVERE DRIVING CONDITIONS

A - Repeatly driving short distance of less than 5miles(8km) in normal tempera ture or less than 10miles(16km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt-spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in sandy areas ENGINE OIL AND FILTER Petrol engine

Diesel engine

AIR CLEANER FILTER SPARK PLUGS TIMING BELT BRAKE PADSREAR BRAKE LININGS AND CYLINDERSSUSPENSION AND STEERING SYSTEMMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDPOLLEN FILTER(IN FRONT OF BLOWER UNIT) EVERY 4,500MILES OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLYEVERY 37,000MILES OR 48 MONTHS MORE FREQUENTLY MORE FREQUENTLYMORE FREQUENTLY EVERY 60,000MILES EVERY 27,000MILESMORE FREQUENTLY

MAINTENANCE

OPERATIONMAINTENANCE ITEM MAINTENANCE INTERVALSDRIVING

CONDITION

F - Driving in heavy traffic area over 90°F(32°C) G - Driving on uphill, downhill, or mountain roadH - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle towing

J - Driving over 100 MPH(170 Km/h)K - Frequently driving in stop-and-go conditions

Page 105 of 407

VEHICLE MAINTENANCE REQUIREMENTS

5- 6 6ZF060D2-A

o Fuel lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and connec- tions for leakage and damage. Replace anydamaged or leaking parts immediately.

WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds aftershutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if itcontacts the body. People using pace-makers should ensure that they keep adistance of 30cm from the ECU or wiringharness within the engine room whilstengine is running, since the high currentsin the Common Rail system produce con-siderable magnetic fields. 6ZF060E1-A

o Timing Belt Replace timimg belt and inspect all associated parts related for damage and deformation.Replace any damaged parts immediately. 6ZF060G1-A

o Vapour Hose and Fuel Filler Cap The vapour hose and fuel filler cap should be inspected at those intervals specified in themaintenance schedule. Make sure that a newvapour hose or fuel filler cap is correctlyreplaced. 6ZF060F1-A

o Vacuum, Crankcase

Ventilation Hoses

Inspect the surface of hoses for evidence of heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abra-sions, and excessive swelling indicate dete-rioration. Particular attention should be paid toexamining those hose surfaces nearest tohigh heat sources, such as the exhaustmanifold.Inspect the hose routing to assure that thehoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechani-cal wear. Inspect all hose connections, suchas clamps and couplings, to make sure theyare secure, and that no leaks are present.Hoses should be replaced immediately if thereis any evidence of deterioration or damage.

6ZF060A1-A

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

6ZF060M1-A

o Engine Oil and Filter The engine oil and filter should be changed at

the intervals specified in the maintenance schedule. If the car is being driven in severeconditions, more frequent oil and filter changesare required.

6ZF060B1-A

o Drive Belts Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil contaminationand replace if necessary. Drive belts shouldbe checked periodically for proper tensionand adjusted as necessary.

6ZF060C1-A

o Fuel Filter A clogged filter can limit the speed at which the

vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replace-ment more frequently.

After installing a new filter, run the engine for

several minutes, and check for leaks at theconnections.

Page 106 of 407

VEHICLE MAINTENANCE REQUIREMENTS 5-7

6ZF070D1-A

o Manual Transaxle Oil Inspect the manual transaxle oil according to

the maintenance schedule. NOTE: If the oil level is low, check for possible

leaks before adding oil. Do not overfill.

6ZF070H1-A

o Rear Brake Drums And Linings/ Parking Brake

Check the rear brake drums and linings for

scoring, burning, leaking fluid, broken parts, and excessive wear. Inspect the parkingbrake system including the parking brakelever and cables. For detailed service proce-dures, refer to the Shop Manual.

6ZF070J1-A

o Brake Pads, Calipers and Rotors Check the pads for excessive wear, discs for

run out and wear, and calipers for fluid leak-age.

6ZF070K1-A

o Exhaust Pipe and Muffler Visually inspect the exhaust pipes, silencerand hangers for cracks, deterioration, or dam-age. Start the engine and listen carefully forany exhaust gas leakage. Tighten connec-tions or replace parts as necessary.

F070E05A-AAT

o Automatic Transaxle Fluid The fluid level should be in the "HOT" range

of the dipstick, after the engine and transaxleare at normal operating temperature. Checkthe automatic transaxle fluid level with theengine running and the transaxle in neutral,with the parking brake properly applied. UseHyundai Genuine ATF SP-III, DIAMOND ATFSP-III, SK ATF SP-III or other brands ap-proved by Hyundai Motor Co., when adding orchanging fluid. 6ZF070F1-A

o Brake Hoses and Lines Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replaceany deteriorated or damaged parts immediately.

6ZF060H1-A

o Air Cleaner Filter A Genuine Hyundai air cleaner filter is recom-

mended when filter is replaced.

6ZF060J1-A

o Spark Plugs Make sure to install new spark plugs of the

correct heat range.

6ZF070B1-A

o Cooling System Check the cooling system part, such asradiator, coolant reservoir, hoses and con-nections for leakage and damage. Replaceany damaged parts. 6ZF070G2-A

o Brake Fluid Check brake fluid level in the brake fluidreservoir. The level should be between "MIN"and "MAX" marks on the side of the reservoir.Use only hydraulic brake fluid conforming toDOT 3 or DOT 4.

6ZF070C1-A

o Engine Coolant The coolant should be changed at theintervals specified in the maintenance sched-ule.

F060N02E-AAT

o Valve Clearance Inspect excessive valve noise and/or enginevibration and adjust if necessary. A qualifiedtechnician should perform the operation.

Page 107 of 407

VEHICLE MAINTENANCE REQUIREMENTS

5- 8 6ZF070P1-A

o Driveshafts and Boots Check the drive shafts, boots and clamps for cracks, deterioration, or damage. Replaceany damaged parts and, if necessary, repackthe grease. 6ZF070Q1-A

o Air conditioning Refrigerant Check the air conditioning lines and connec- tions for leakage and damage. Check airconditioning performance according to therelevant shop manual if necessary.

6ZF070L1-A

o Suspension Mounting Bolts Check the suspension connections for loose-

ness or damage. Retighten to the specifiedtorque. 6ZF070M1-A

o Steering Gear Box, Linkage & Boots/

Lower arm Ball Joint

With the vehicle stopped and engine off, check for excessive freeplay in the steering wheel. Check the linkage for bends or damage. Check the dust boots and ball joints for dete-rioration, cracks, or damage. Replace anydamaged parts. 6ZF070N1-A

o Power Steering Pump, Belt and Hoses Check the power steering pump and hoses for leakage and damage. Replace any dam-aged or leaking parts immediately. Inspect thepower steering belt for evidence of cuts,cracks, excessive wear, oil contaminationand proper tension. Replace or adjust it ifnecessary.

Page 108 of 407

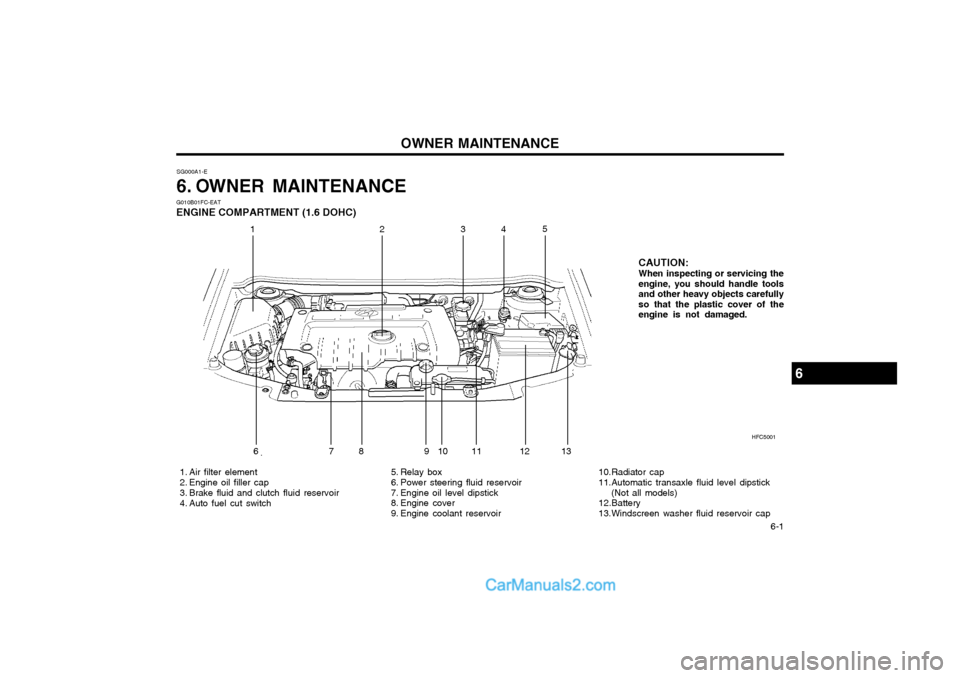

OWNER MAINTENANCE 6-1

SG000A1-E

6. OWNER MAINTENANCE

6

HFC5001

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Auto fuel cut switch 5. Relay box

6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine cover

9. Engine coolant reservoir10.Radiator cap

11.Automatic transaxle fluid level dipstick

(Not all models)

12.Battery

13.Windscreen washer fluid reservoir cap CAUTION:When inspecting or servicing the engine, you should handle toolsand other heavy objects carefullyso that the plastic cover of theengine is not damaged.

G010B01FC-EAT ENGINE COMPARTMENT (1.6 DOHC)

12

34 5

6 7 8 9 10 11 12 13

Page 109 of 407

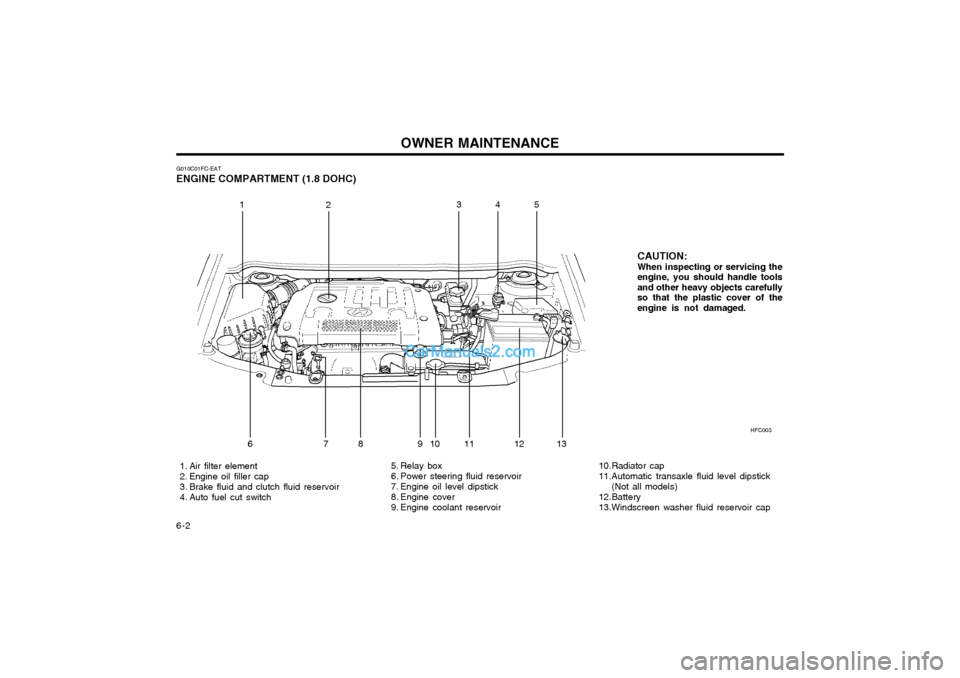

OWNER MAINTENANCE

6-2 HFC003

CAUTION: When inspecting or servicing the engine, you should handle toolsand other heavy objects carefullyso that the plastic cover of theengine is not damaged.

G010C01FC-EAT ENGINE COMPARTMENT (1.8 DOHC)

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Auto fuel cut switch

5. Relay box

6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine cover

9. Engine coolant reservoir10.Radiator cap

11.Automatic transaxle fluid level dipstick

(Not all models)

12.Battery

13.Windscreen washer fluid reservoir cap

1 2 345

6 7 8 9 10 11 12 13

Page 110 of 407

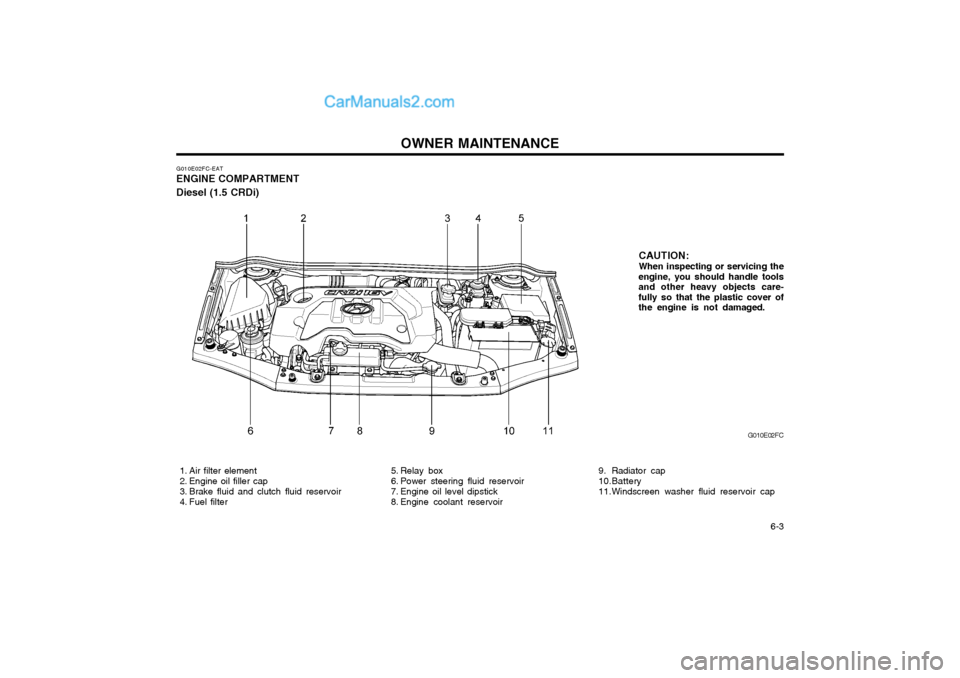

OWNER MAINTENANCE 6-3

G010E02FC

G010E02FC-EAT

ENGINE COMPARTMENT Diesel (1.5 CRDi)

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Fuel filter 5. Relay box

6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine coolant reservoir

9. Radiator cap

10.Battery

11.Windscreen washer fluid reservoir capCAUTION:When inspecting or servicing the

engine, you should handle tools and other heavy objects care-fully so that the plastic cover ofthe engine is not damaged.