Battery Hyundai Matrix 2005 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2005, Model line: Matrix, Model: Hyundai Matrix 2005Pages: 407, PDF Size: 10.31 MB

Page 89 of 407

IN CASE OF EMERGENCY

3-2

CAUTION: Personal injury and damage to the vehicle may occur if jump starting is not per- formed correctly. If any doubt exists as to how this operation should be performed, seek assistance from qualified personnel. WARNING: Motor vehicle batteries contain sulphuric acid and emit hydrogen gas. Protective clothing should be worn and care exer- cised to prevent the acid from coming into contact with skin or clothing and the ve- hicle. Naked lights should not be permitted in the vicinity of the battery. Care should be exercised to prevent sparks occurring during connection. If acid accidentally comes into contact with skin or eyes, the affected area should immediately be flushed CAUTION: If the jump cable are incorrectly installed,

damage to the vehicle electrical system may occur, in particular the electronic components such as the Fuel Injection system computer and the Automatic

Transaxle computer. The battery must never be disconnected whilst the engine is running. SD040A2-E IF THE ENGINE OVERHEATS

If the temperature gauge indicates overheat- ing:

1. Pull off the road and stop as soon as it is safe to do so.

2. Place the gear selector lever in "P" (auto- matic), or neutral (manual transaxle) and set the parking brake. If the air condition- ing is on, turn it off.

3. If coolant is running out under the car or

steam is coming out from under the bonnet stop the engine. Do not open the bonnet until the coolant has stopped running or the steaming has stopped. If there is no visible loss of coolant and no steam, leave the engine running and check to be sure the engine cooling fan is operating.If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is broken. If it is not missing, check to seethat it is tight.

SD030A2-E Jump Starting

with copious amounts of water and medi- cal assistance sought.

1. Ensure that the booster battery is 12 volt

type. If the booster battery is installed in another vehicle, ensure that the two vehi- cles are not touching.

2. Turn off all unnecessary electrical equip- ment in both vehicles.

3. Ensure that the engine of the vehicle pro- viding the jump start is running prior to connection of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the booster battery and theother end to the positive (+) terminal of the discharged battery.

5. Attach the black jump cable to the nega- tive (-) terminal of the booster battery, andthe other end to a ground point within the engine compartment of the vehicle with the flat battery. Do not connect to the negative battery terminal of the flat battery since sparks may be generated with the subsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start the engine of thevehicle with the flat battery.

7. Switch "ON" the main beam headlamps before carefully removing the jumper cables in the reverse order of attachment. Once the jumper cables have been re- moved, switch "OFF" the main beam headlamps.

HFC4002

Booster battery Discharged battery

Page 99 of 407

APPEARANCE CARE

4-2

Plastic wheel covers should be cleaned using a sponge and water. Cast alloy wheels should be cleaned using a mild soap or neutral deter- gent. Abrasive compounds must not be used since in the event of these damaging the lac- quer coating, oxidization of the aluminium wheel will occur, spoiling the appearance. The use of an a toothbrush will facilitate cleaning between the wheel "spokes".

ensure that accidental spillages are immediately flushed with water. Do not use abrasive cleaning materials which may damage the bumpers. Avoid subjecting the bumpers to high tempera- tures such as may be encountered in high bake paint ovens.

SE040B1-E STAIN/SPOT REMOVAL Should tree sap, dead insects or tar prove to be difficult to remove from the paint film, turpentine or a proprietary paint cutting compound may be used. Ensure that the area to be cleaned is not rubbed intensively to prevent breaking through the colour coat and exposing the under coat. SE040C1-E POLISHINGThe exterior paint work should be polished with a proprietary wax polish when water no longer collects in bead form on the paint work. The instructions of the product manufacturer should be adhered to. SE040E1-E BUMPER MAINTENANCEThe special material from which the bumpers are manufactured warrants special attention to pre- serve the appearance of the bumpers. Avoid contact with battery electrolyte or brake fluid and SE040F1-E ACCIDENT REPAIRSIn the event of the body work sustaining damage, the following points should be noted prior to repairs being undertaken. If body panels are replaced or repaired, anti corrosion treatment must be applied to the repair area. The product used must be compatible withthose used in manufacture. It is recommended that repairs are entrusted to a Hyundai authorised repairer to ensure that replacement parts used are of the same high quality as those used in manufacture of the vehicle and that the correct repair methods and materials will en- sure adequate levels of corrosion protection and the continued validity of the Anti Perforation Warranty. SE050A1-E INTERIORDuring the winter period, it is possible that the passenger compartment flooring may become wet from damp footwear or quantities of snow adhering to footwear. The carpet should not be allowed to remain in this condition since the carpet may begin to create musty smells and will

SE050D1-E SEAT BELTS Seat belts should be cleaned only with a mild soap solution. Strong detergents, solvents or bleaches may damage the belt webbing and therefore reduce the effectiveness of the belt. Belts which display signs of fraying, wear of cuts should be replaced. SE050E1-E WINDOWS A proprietary glass cleaner should be used to clean the inside of the windows. However, the rear heated windshield must only be cleaned using a light horizontal cleaning action. Care should be exercised to avoid the use of abrasive cleaners or contact with items of jewellery which may damage the heating elements.

promote corrosion of the floor pan in addition tothe carpet and under felt beginning to rot. SE050C1-E INTERIOR VALETING The soft trim and carpets should be maintained with the regular use of a vacuum cleaner. Heavy soiling should be removed with a dry cleaning agent recommended for this purpose following the instructions of the product manufacturer. Paint thinner, solvents or other such cleaning materials should not be used since damage to the upholstery may result.

Page 108 of 407

OWNER MAINTENANCE 6-1

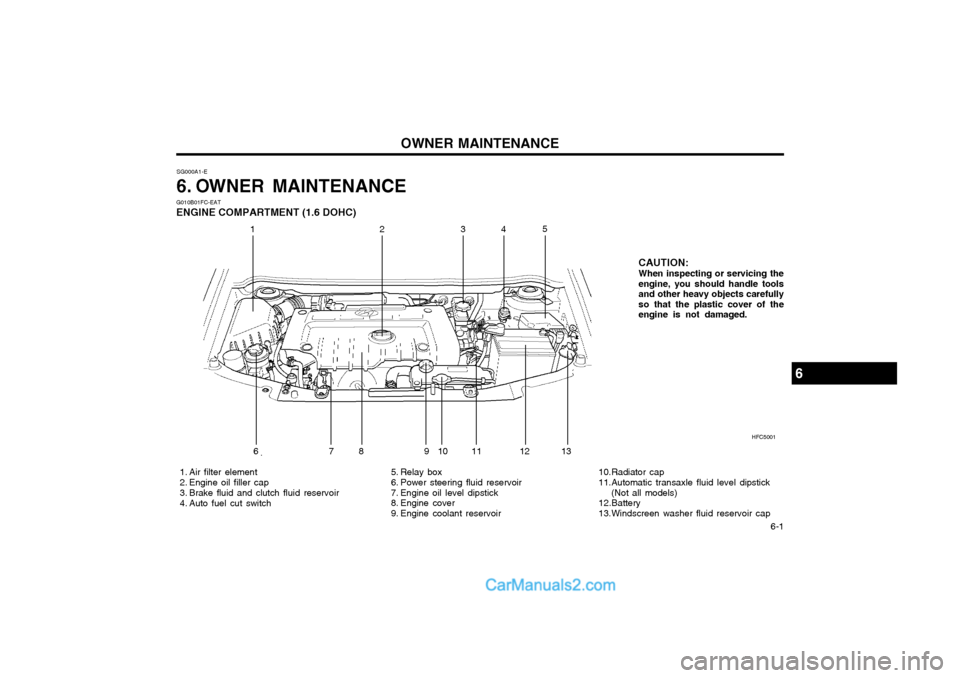

SG000A1-E

6. OWNER MAINTENANCE

6

HFC5001

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Auto fuel cut switch 5. Relay box

6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine cover

9. Engine coolant reservoir10.Radiator cap

11.Automatic transaxle fluid level dipstick

(Not all models)

12.Battery

13.Windscreen washer fluid reservoir cap CAUTION:When inspecting or servicing the engine, you should handle toolsand other heavy objects carefullyso that the plastic cover of theengine is not damaged.

G010B01FC-EAT ENGINE COMPARTMENT (1.6 DOHC)

12

34 5

6 7 8 9 10 11 12 13

Page 109 of 407

OWNER MAINTENANCE

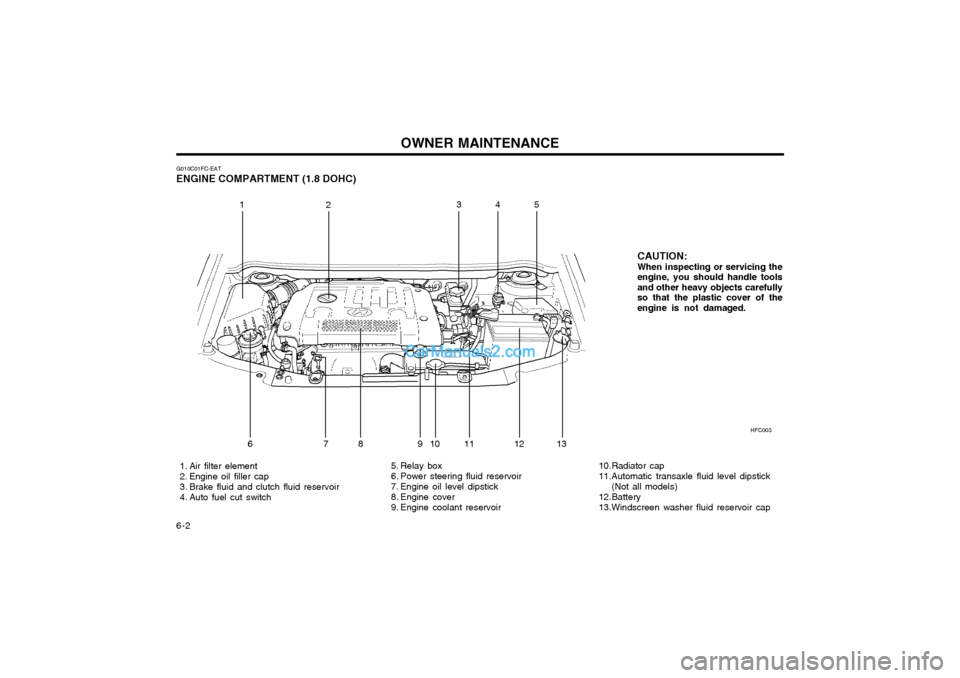

6-2 HFC003

CAUTION: When inspecting or servicing the engine, you should handle toolsand other heavy objects carefullyso that the plastic cover of theengine is not damaged.

G010C01FC-EAT ENGINE COMPARTMENT (1.8 DOHC)

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Auto fuel cut switch

5. Relay box

6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine cover

9. Engine coolant reservoir10.Radiator cap

11.Automatic transaxle fluid level dipstick

(Not all models)

12.Battery

13.Windscreen washer fluid reservoir cap

1 2 345

6 7 8 9 10 11 12 13

Page 110 of 407

OWNER MAINTENANCE 6-3

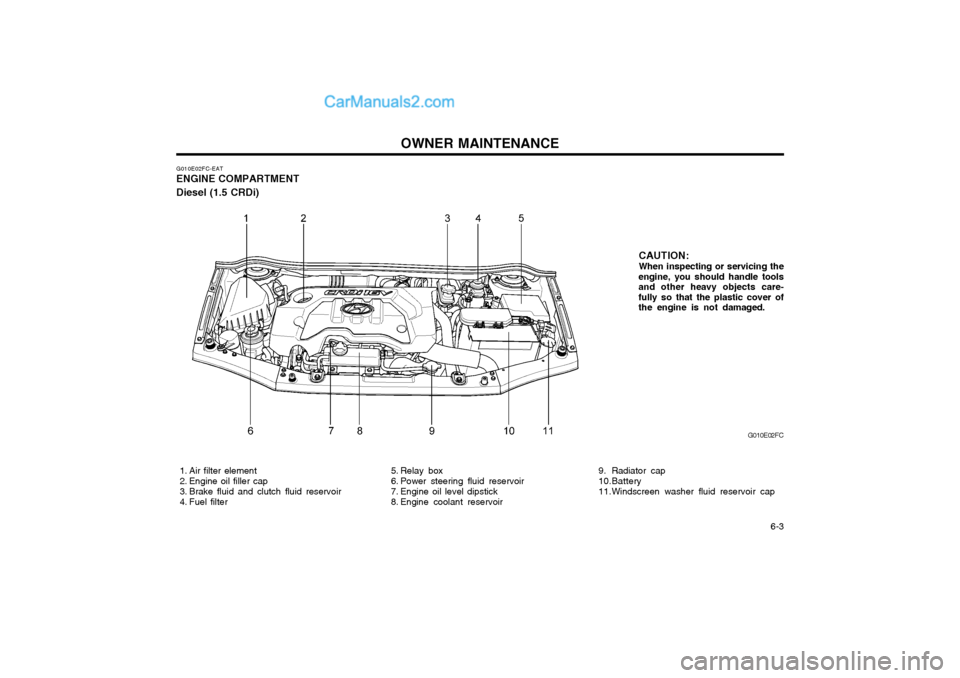

G010E02FC

G010E02FC-EAT

ENGINE COMPARTMENT Diesel (1.5 CRDi)

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Fuel filter 5. Relay box

6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine coolant reservoir

9. Radiator cap

10.Battery

11.Windscreen washer fluid reservoir capCAUTION:When inspecting or servicing the

engine, you should handle tools and other heavy objects care-fully so that the plastic cover ofthe engine is not damaged.

Page 111 of 407

OWNER MAINTENANCE

6-4 SG020B1-E

DAILY OPERATING CHECKS

The following items should be checked on a

daily basis or whenever the vehicle is refuelled, whichever occurs sooner.

o Engine oil level.

o Engine coolant level.

o Power steering fluid level.

o Brake fluid level.

o Windscreen washer fluid level.

o Battery condition.

o Tyre condition and pressures.

o Operation and cleanliness of all lighting equipment.

o Windscreen wiper and washer operation.

o Horn operation.

o Warning light operation.

o Adjustment and cleanliness of mirrors.

o Seat and seat belt adjustment and opera- tion.

o Fluid leakage.

The vehicle must not be driven if the daily

operating checks indicate that any item of equip- ment related to the safety or roadworthiness ofthe vehicle is not functioning correctly. G030A01FC-EAT

ENGINE OIL

The correct engine oil level is of paramount

importance. An excessively high or low oil levelmay result in irreparable damage being sus-tained by the engine. The engine oil levelmust be checked on a daily basis, wheneverthe vehicle is refuelled or before starting along trip, whichever occurs sooner.

In addition, it is imperative that only an ap-

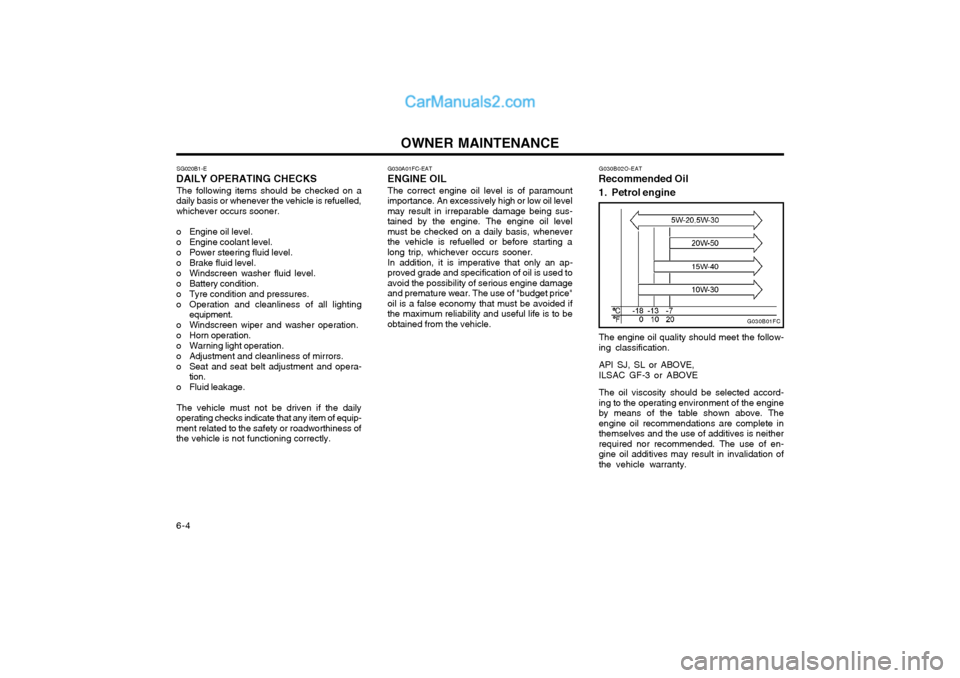

proved grade and specification of oil is used toavoid the possibility of serious engine damageand premature wear. The use of "budget price"oil is a false economy that must be avoided ifthe maximum reliability and useful life is to beobtained from the vehicle. G030B02O-EAT

Recommended Oil

1. Petrol engine

G030B01FC

The engine oil quality should meet the follow- ing classification. API SJ, SL or ABOVE, ILSAC GF-3 or ABOVE The oil viscosity should be selected accord- ing to the operating environment of the engineby means of the table shown above. Theengine oil recommendations are complete inthemselves and the use of additives is neitherrequired nor recommended. The use of en-gine oil additives may result in invalidation ofthe vehicle warranty.

Page 128 of 407

OWNER MAINTENANCE 6-21

G200B01E-EAT

INDIVIDUAL CIRCUIT FUSES

The fuse box containing the individual circuit fuses will be found in the backside of multi boxlocated in the right side of driver. The multi boxis removed by pulling lightly and then releasingthe lid. A fuse rating grid will be found on thereverse side of the cover. In the event of fusefailure, the fuse should be replaced with one ofequivalent rating. A fuse removal tool is pro-vided within the fuse box to facilitate replace-ment. In the event of a replacement fuse failing shortly after installation a malfunction within the circuitprotected by that fuse is indicated. The circuitshould be checked by a Hyundai authorisedrepairer at the first available opportunity.

HFC4010-D

AXA6201B

WARNING: The use of replacement fuses having a higher rating than specified or other meansof connecting the circuit will create a po-tential fire hazard. NOTE: See page 6-28 for the fuse pannel descrip- tions.

SG210A1-E

BATTERY MAINTENANCE

D010B01FC

WARNING:

Motor vehicle batteries contain sulphuric

acid which is corrosive and poisonous. Hy- drogen gas is emitted from the battery whichis explosive when combined with oxygen.The following precautions must be strictlyobserved to avoid personal injury or dam-age to the vehicle.

o If battery electrolyte is spilled onto skin or

into eyes, the effected area must be flushed with copious amounts of water and medicalassistance sought.

o If battery electrolyte is ingested, copious amounts of water or milk followed by an ant-acid (raw egg or milk of magnesia) must bedrunk. Vomiting should not be induced andmedical assistance must be sought.

Page 129 of 407

OWNER MAINTENANCE

6-22 SG230A1-E POWER STEERING FLUID LEVEL

HFC5004

G230A02FC

Petrol engine

Diesel engine

The power steering fluid level should be checked daily.

SG220A1-E ELECTRIC COOLING FANS WARNING: The cooling fan is controlled by engine coolant temperature and may sometimesoperate even when the engine is not run-ning. Use extreme caution when workingnear the blades of the cooling fan so thatyou are not injured by a rotating fan blade.As the engine coolant temperature decreas-es, the fan will automatically shut off. Thisis a normal condition. The engine cooling fan should operate before the temperature gauge reaches the upper por-tion of the scale and the condenser fan shouldoperate whenever the air conditioning is in use.

o Batteries must only be charged in well

ventilated areas from which naked lights orsources of sparks are excluded.

o Ensure that children, pets or other unauthorised persons are kept away frombatteries.

o Do not allow anything to bridge the positive (+) and negative (-) terminals of the battery.

o Never invert the battery. The battery fitted during production is of the "Maintenance Free" type.

Page 144 of 407

VEHICLE SPECIFICATIONS 9-1

Litre

55 Imp.gal

12

SJ000A1-F

9. VEHICLE SPECIFICATIONS

Fuel tank capacity

Type Wheel free playRack strokeOil pump type

J010A01FC-EAT MEASUREMENT

in. (mm)

Item BatteryGeneratorDiesel

CMF 68 AH 120A (12V)

Petrol

MF45AH

90A (13.5V)

9

J040A02FC-EAT ELECTRICAL

SJ030A1-FFUEL SYSTEM

J020A01FC-EAT POWER STEERING

US.gal14.5

Rack and pinion 0 ~ 1.18 in. (0 ~ 30 mm)5.7±0.04 in. (146±1mm)Vane type J030A01FC-DAT

TYRE

185/65 R14 195/55 R15205/55 R15 (1.8 DOHC only)

StandardOption

Type Front brake typeRear brake typeParking brake Dual hydraulic with brake boosterVentilated discDrum Cable

J050A01FC-GAT BRAKE

Front Rear

Overall lengthOverall widthOverall height (unladen) Wheel base Wheel tread

158.4 (4,025)

68.5 (1,740)64.3 (1,635)

*66.3 (1,685)

102.3 (2,600) 58.5 (1,485)58.5 (1,485)

*If installed roof rack

Standard Option

J030B01FC-EAT SPARE TYRE Space-saver Full size

Page 147 of 407

INDEX10-1

A ACCESSORY TRAY

........................................................................ 1-50

AIR CONDITIONING SWITCH ........................................................ 1-60

AIR CONDITIONING SYSTEM MAINTENANCE ...........................6-18

AIR CLEANER ELEMENT REPLACEMENT ..................................6-12

ANTENNA ......................................................................................... 1-64

ANTI-THEFT ALARM SYSTEM .... .......................................... 1-5 ~ 1-7

AUTO FUEL CUT SWITCH ............................................................. 1-53

AUTOMATIC TRANSAXLE ............................................................... 2-6

AUTOMATIC TRANSAXLE FLUID ................................................ 6-14

B BATTERY MAINTENANCE ............................................................. 6-21

BEFORE STARTING THE ENGINE ................................................. 2-2

BLEEDING THE FUEL SYSTEM ....................................................6-23

BONNET RELEASE ......................................................................... 1-51

BRAKE PEDAL FREEPLAY .................................... ........................ 6-19

BRAKE TRACTION CONTROL SYSTEM ................... ................... 2-10

BRAKE SYSTEM CHECKING ........................................................ 6-16CCARE OF SEAT

BELTS ................................................................. 1-14

CARGO AREA COVER ................................................................... 1-53

CATALYTIC CONVERTOR OPERATING PRECAUTIONS ............. 7-1

CENTRE VENTILATOR ................................................................... 1-55

CENTRAL DOOR LOCKS ................................................................. 1-5

CHANGING A FLAT TYRE ............................................................... 3-4

CHECKING THE CLUTCH FLUID.................................................. 6-17

CHILD-PROOF REAR DOOR LOCK ................................................ 1-4

CHILD RESTRAINT SYSTEM ............................................. 1-17 ~ 1-22

CIGAR LIGHTER ............................................................................. 1-42

CLUTCH PEDAL FREEPLAY ......................................................... 6-19

COMBINATION IGNITION SWITCH AND STEERING LOCK ........ 2-2

COOLANT TEMPERATURE GAUGE .............................................1-35

D DAILY OPERATING CHECKS .......................................................... 6-4

DIGITAL CLOCK .............................................................................. 1-42

DOOR LOCKS ................................................................................... 1-3

DOOR WINDOWS ............................................................................. 1-7 DRINK HOLDER .............................................................................. 1-43

DRIVE BELTS .................................................................................. 6-20

DRIVING FOR ECONOMY ............................................................. 2-11

JK000A1-A 10. INDEX

10