ECU Hyundai Matrix 2005 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2005, Model line: Matrix, Model: Hyundai Matrix 2005Pages: 407, PDF Size: 10.31 MB

Page 87 of 407

DRIVING YOUR HYUNDAI 2- 15

YC200E2-E

Trailer or Vehicle Towing Tips

1. Before towing, check towbar ball and safe- ty cable connections as well as proper operation of the trailer running lights, brake lights, and turn signals.

2. Always drive your vehicle at a moderate speed (Less than 60 MPH)

3. Trailer towing requires more fuel than nor- mal conditions.

4. To maintain engine braking efficiency and electrical charging performance, do not usefifth gear (manual transaxle) or overdrive (automatic transaxle). 5. Always secure items in the trailer to pre-

vent load shift whilst driving.

6. Check the condition and air pressure of all tyres on the trailer and your car. Low tyrepressure can seriously affect the handling. Also check the spare tyre.

7. The vehicle/trailer combination is more af- fected by crosswind and buffeting. When being passed by a large vehicle,keep a constant speed and steer straight ahead. If there is too much wind buffeting slow down to get out of the other vehicle's air turbulence.

8. When parking your car and trailer, espe- cially on a hill, be sure to follow all thenormal precautions. Turn your front wheels into the curb, set the parking brake firmly, and put the transaxle in 1st or Reverse (manual) or Park (automatic). In addition, place wheel chocks at each of the trailer's tyres.

9. If the trailer has electric brakes, start your vehicle and trailer moving, and then applythe trailer brake controller by hand to be sure the brakes are working. This lets you check your electrical connection at the same time.

10.During your trip, check occasionally to be sure that the load is secure, and that thelights and any trailer brakes are still work- ing. 11.Avoid jerky starts, sudden acceleration or

sudden stops.

12.Avoid sharp turns and rapid lane changes.

13.Avoid holding the brake pedal down too long or too frequently. This could causethe brakes to overheat, resulting in re- duced braking efficiency.

14.When going down a hill, shift into a lower gear and use the engine braking effect. When ascending a long grade, downshiftthe transaxle to a lower gear and reduce speed to reduce chances of engine over- loading and/or overheating.

15.If you have to stop whilst going uphill, do not hold the vehicle in place by pressing onthe accelerator. This can cause the auto- matic transaxle to overheat. Use the park- ing brake or footbrake.

NOTE:When towing check transaxle fluid more

frequently.

CAUTION:If overheating should occur when towing,

(temperature gauge reads near red zone), taking the following action may reduce or eliminate the problem.

1. Turn off the air conditioner.

2. Reduce highway speed.

3. Select a lower gear when going uphill.

4. While in stop and go traffic, place the gear selection in park or neutral andidle the engine at a higher speed.

Towing BracketAttachment Location

o The maximum permissible static verti-

cal load on the coupling device : 52kg

o The maximum permissible overhang of the coupling point : 760 mm.

C190E01FC

Page 90 of 407

3-3

IN CASE OF EMERGENCY

If the drive belt seems to be satisfactory, check for coolant leaking from the radiator, hoses or under the car. (If the air condi- tioning had been in use, it is normal for cold water to be draining from it).

WARNING: Whilst the engine is running, keep hands and clothing away from moving parts such as the fan and drive belts to prevent injury. WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds after shutting off engine. High pressure pump, rail, injectors and high pressure pipes are subject to high pressure even after the engine stopped. The fuel jet produced by fuel leaks may cause serious injury, if it touch the body. People using pacemak- ers should ensure that they keep a dis- tance of 30cm from the ECU or wiring harness within the engine room whilst engine is running, since the high currents in the Common Rail system produce con- siderable magnetic fields.

5. If the water pump drive belt is broken or coolant is leaking out, stop the engine immediately and call the nearest Hyundai authorised repairer for assistance. WARNING:Do not remove the radiator cap when theengine is hot since steam and boiling water may be ejected from the radiator resulting in burns or scalding.

6. If the cause of the overheating cannot be found, wait until the engine temperature has returned to normal. Then, if coolant has been lost, carefully remove the radia- tor cap and add water to bring the fluid level in the reservoir up to the base of the radiator fill opening. Fill the coolant expan- sion tank to the halfway mark.

7. Proceed with caution until it is established that the engine is operating normally. If theengine overheats repeatedly, the advice of a Hyundai authorised repairer should be sought.

CAUTION:Serious loss of coolant indicates there is a leak in the cooling system and this should be checked as soon as possible by a Hyundai authorised repairer. D040A01FC-EAT

TEMPORARY SPARE TYRE The following instructions for the temporary

spare tyre should be observed:

1. Check inflation pressure as soon as pos-

sible after installing the spare tyre, and adjust to the specified pressure. The tyre pressure should be periodically checked and maintained at the specified pressure whilst the tyre is stored.

2. The spare tyre should only be used tem- porarily and should be returned to the luggage compartment as soon as the origi- nal tyre can be repaired or replaced.

3. Continuous use at speeds of over 80 km/h

(50 mph) is not recommended.

4. As the temporary spare tyre is specifically designed for your car, it should not beused on any other vehicle.

5. The temporary spare tyre should not be used on any other wheels, nor shouldstandard tyre, snow tyre, wheel covers or trim rings be used with the temporary spare wheel. If such use is attempted, damage to these items or other car com- ponents may occur.

6. The temporary spare tyre pressure should be checked once a month whilst the tyreis stored.

Spare Tyre Pressure

Type Size Inflation Pressure T115/70R(D)15420 kPa (60 psi)

Page 94 of 407

3-7

IN CASE OF EMERGENCY

WARNING: It is important that the faces of the wheeland hub are clean prior to installing the wheel. The prescence of dirt or other mat- ter in the wheel or hub faces could result in the wheel nuts becoming loose whilst the vehicle is being driven. SD070I1-E

7. Re-install Wheel Nuts

Fit the wheel nuts onto the studs and tighten with the wheel brace.

SD070H1-E 6. Changing Wheels Using the wheel brace, remove the nuts and slide the wheel off the hub and wheel studs. Lie the wheel flat to prevent it from rolling. Ensure that the faces of the wheel and hub are clean. Position the spare wheel over the studs and slide it up to the hub.

STA3071H

D060H01FC-D

D060G01FC

SD070J1-E

8. Lower Vehicle and Tighten Nuts

Lower the car to the ground turning the wheel

nut wrench counterclockwise. When the ve- hicle is firmly on the ground, remove the jack and tighten the wheel nuts securely. At the first available opportunity, the wheel nut torque should be checked with a suitable torque wrench.

Wheel nut tightening torqueSteel wheel & aluminium alloy wheel: 90-110 Nm (65-80 lb.ft)

D060I01FC-D

Page 105 of 407

VEHICLE MAINTENANCE REQUIREMENTS

5- 6 6ZF060D2-A

o Fuel lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and connec- tions for leakage and damage. Replace anydamaged or leaking parts immediately.

WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds aftershutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if itcontacts the body. People using pace-makers should ensure that they keep adistance of 30cm from the ECU or wiringharness within the engine room whilstengine is running, since the high currentsin the Common Rail system produce con-siderable magnetic fields. 6ZF060E1-A

o Timing Belt Replace timimg belt and inspect all associated parts related for damage and deformation.Replace any damaged parts immediately. 6ZF060G1-A

o Vapour Hose and Fuel Filler Cap The vapour hose and fuel filler cap should be inspected at those intervals specified in themaintenance schedule. Make sure that a newvapour hose or fuel filler cap is correctlyreplaced. 6ZF060F1-A

o Vacuum, Crankcase

Ventilation Hoses

Inspect the surface of hoses for evidence of heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abra-sions, and excessive swelling indicate dete-rioration. Particular attention should be paid toexamining those hose surfaces nearest tohigh heat sources, such as the exhaustmanifold.Inspect the hose routing to assure that thehoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechani-cal wear. Inspect all hose connections, suchas clamps and couplings, to make sure theyare secure, and that no leaks are present.Hoses should be replaced immediately if thereis any evidence of deterioration or damage.

6ZF060A1-A

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

6ZF060M1-A

o Engine Oil and Filter The engine oil and filter should be changed at

the intervals specified in the maintenance schedule. If the car is being driven in severeconditions, more frequent oil and filter changesare required.

6ZF060B1-A

o Drive Belts Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil contaminationand replace if necessary. Drive belts shouldbe checked periodically for proper tensionand adjusted as necessary.

6ZF060C1-A

o Fuel Filter A clogged filter can limit the speed at which the

vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replace-ment more frequently.

After installing a new filter, run the engine for

several minutes, and check for leaks at theconnections.

Page 123 of 407

OWNER MAINTENANCE

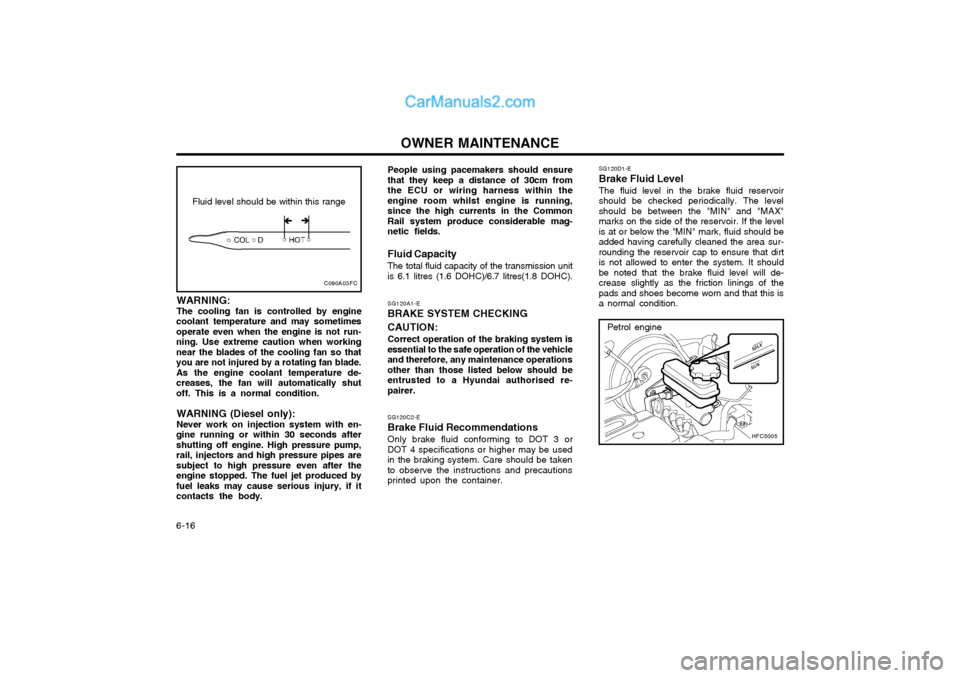

6-16 SG120D1-E Brake Fluid Level The fluid level in the brake fluid reservoir should be checked periodically. The levelshould be between the "MIN" and "MAX"marks on the side of the reservoir. If the levelis at or below the "MIN" mark, fluid should beadded having carefully cleaned the area sur-rounding the reservoir cap to ensure that dirtis not allowed to enter the system. It shouldbe noted that the brake fluid level will de-crease slightly as the friction linings of thepads and shoes become worn and that this isa normal condition.

SG120A1-E

BRAKE SYSTEM CHECKING CAUTION:

Correct operation of the braking system is

essential to the safe operation of the vehicle and therefore, any maintenance operationsother than those listed below should beentrusted to a Hyundai authorised re-pairer.

SG120C2-E

Brake Fluid Recommendations

Only brake fluid conforming to DOT 3 or

DOT 4 specifications or higher may be usedin the braking system. Care should be takento observe the instructions and precautionsprinted upon the container.

HFC5005

Petrol engine

People using pacemakers should ensure that they keep a distance of 30cm fromthe ECU or wiring harness within theengine room whilst engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields. Fluid Capacity The total fluid capacity of the transmission unit is 6.1 litres (1.6 DOHC)/6.7 litres(1.8 DOHC).

Fluid level should be within this range

C090A03FC

�Î�Î

WARNING: The cooling fan is controlled by engine

coolant temperature and may sometimes operate even when the engine is not run-ning. Use extreme caution when workingnear the blades of the cooling fan so thatyou are not injured by a rotating fan blade.As the engine coolant temperature de-creases, the fan will automatically shutoff. This is a normal condition.

WARNING (Diesel only): Never work on injection system with en-

gine running or within 30 seconds after shutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if itcontacts the body.

Page 135 of 407

OWNER MAINTENANCE

6-28

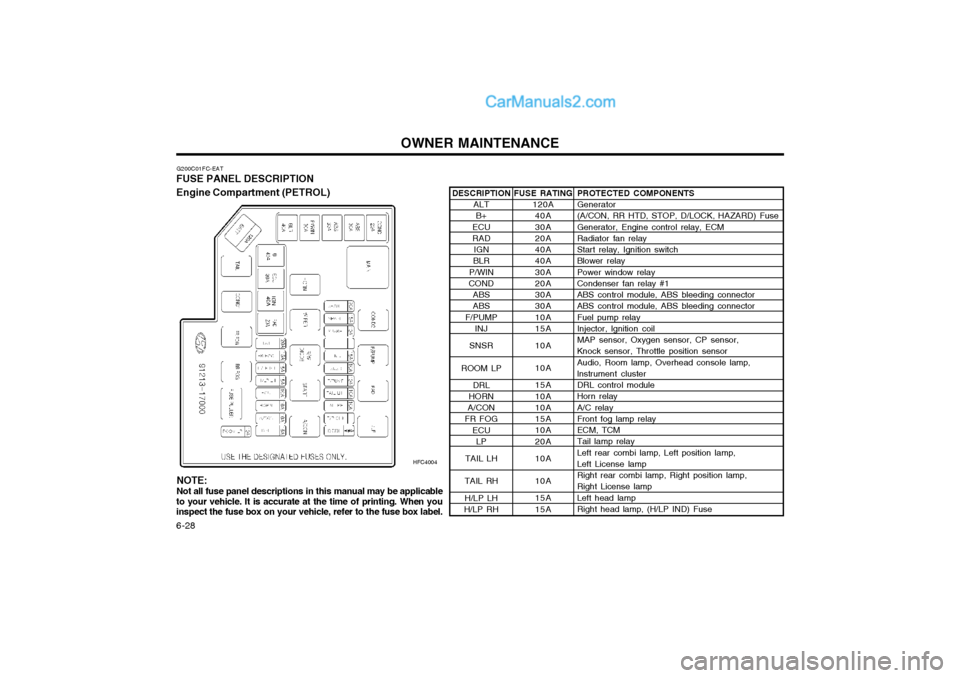

G200C01FC-EAT

FUSE PANEL DESCRIPTION Engine Compartment (PETROL)

HFC4004PROTECTED COMPONENTS Generator (A/CON, RR HTD, STOP, D/LOCK, HAZARD) Fuse Generator, Engine control relay, ECM Radiator fan relay Start relay, Ignition switch Blower relay Power window relay Condenser fan relay #1 ABS control module, ABS bleeding connector ABS control module, ABS bleeding connector Fuel pump relay Injector, lgnition coil MAP sensor, Oxygen sensor, CP sensor, Knock sensor, Throttle position sensor Audio, Room lamp, Overhead console lamp, lnstrument cluster DRL control module Horn relay A/C relay Front fog lamp relay ECM, TCM Tail lamp relay Left rear combi lamp, Left position lamp, Left License lamp Right rear combi lamp, Right position lamp, Right License lamp Left head lamp Right head lamp, (H/LP IND) Fuse

FUSE RATING

120A40A 30A 20A 40A 40A 30A 20A 30A 30A 10A 15A 10A 10A 15A 10A 10A 15A 10A 20A 10A 10A 15A 15A

DESCRIPTION

ALTB+

ECU RAD IGN

BLR

P/WIN

COND

ABSABS

F/PUMP INJ

SNSR

ROOM LP DRL

HORN

A/CON

FR FOG

ECULP

TAIL LH

TAIL RH H/LP LH

H/LP RH

NOTE: Not all fuse panel descriptions in this manual may be applicable

to your vehicle. It is accurate at the time of printing. When you inspect the fuse box on your vehicle, refer to the fuse box label.

Page 137 of 407

OWNER MAINTENANCE

6-30

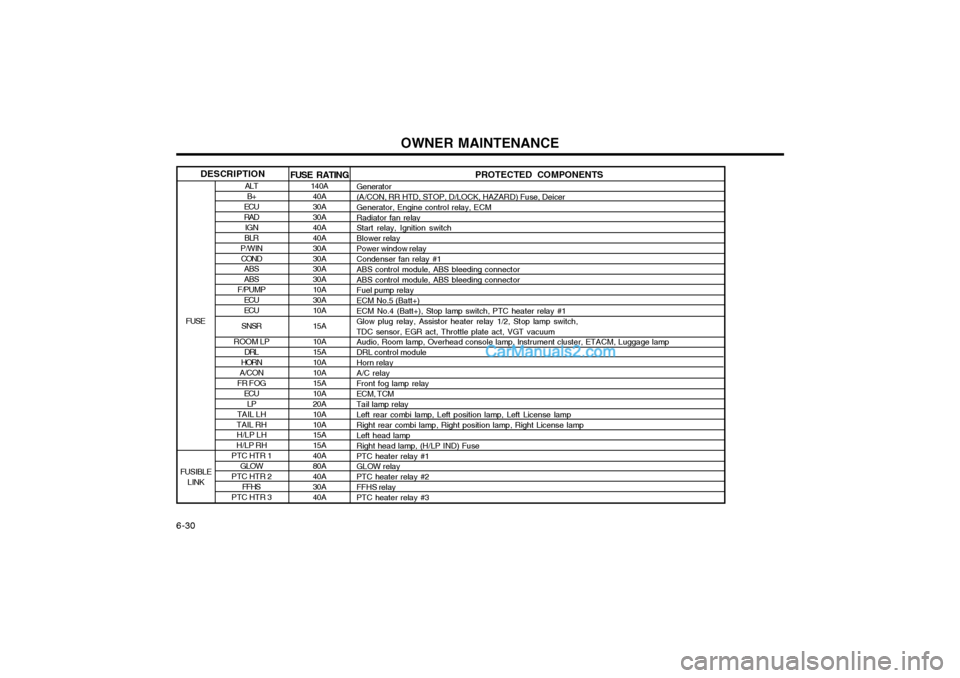

PROTECTED COMPONENTS

Generator (A/CON, RR HTD, STOP, D/LOCK, HAZARD) Fuse, DeicerGenerator, Engine control relay, ECMRadiator fan relay Start relay, Ignition switch Blower relayPower window relayCondenser fan relay #1ABS control module, ABS bleeding connectorABS control module, ABS bleeding connector Fuel pump relay ECM No.5 (Batt+)ECM No.4 (Batt+), Stop lamp switch, PTC heater relay #1Glow plug relay, Assistor heater relay 1/2, Stop lamp switch,TDC sensor, EGR act, Throttle plate act, VGT vacuum Audio, Room lamp, Overhead console lamp, lnstrument cluster, ETACM, Luggage lamp DRL control moduleHorn relayA/C relayFront fog lamp relayECM, TCM Tail lamp relay Left rear combi lamp, Left position lamp, Left License lampRight rear combi lamp, Right position lamp, Right License lampLeft head lampRight head lamp, (H/LP IND) FusePTC heater relay #1 GLOW relay PTC heater relay #2FFHS relayPTC heater relay #3

FUSE RATING

140A40A 30A 30A40A40A30A30A 30A 30A10A30A10A 15A10A 15A10A 10A 15A10A20A10A10A 15A 15A40A80A40A30A 40A

ALT

B+

ECU RAD

IGN

BLR

P/WIN COND ABSABS

F/PUMP ECUECU

SNSR

ROOM LP DRL

HORN

A/CON

FR FOG ECULP

TAIL LH

TAIL RH H/LP LH

H/LP RH

PTC HTR 1 GLOW

PTC HTR 2 FFHS

PTC HTR 3

FUSE

FUSIBLE LINK DESCRIPTION

Page 138 of 407

OWNER MAINTENANCE 6-31

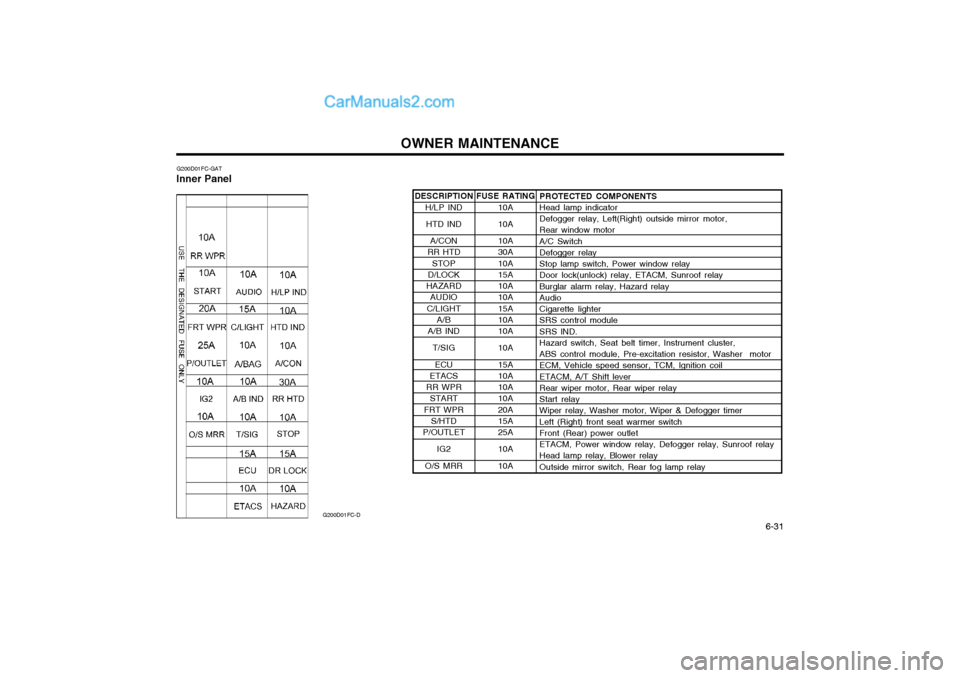

DESCRIPTION

H/LP IND

HTD IND

A/CON

RR HTD

STOP

D/LOCK

HAZARD AUDIO

C/LIGHT A/B

A/B IND

T/SIG

ECU

ETACS

RR WPR START

FRT WPR S/HTD

P/OUTLET

IG2

O/S MRR

G200D01FC-GAT

Inner Panel

G200D01FC-D

PROTECTED COMPONENTS Head lamp indicator Defogger relay, Left(Right) outside mirror motor, Rear window motor A/C Switch Defogger relay Stop lamp switch, Power window relay Door lock(unlock) relay, ETACM, Sunroof relay Burglar alarm relay, Hazard relay Audio Cigarette lighter SRS control module SRS IND. Hazard switch, Seat belt timer, Instrument cluster, ABS control module, Pre-excitation resistor, Washer motor ECM, Vehicle speed sensor, TCM, Ignition coil ETACM, A/T Shift lever Rear wiper motor, Rear wiper relay Start relay Wiper relay, Washer motor, Wiper & Defogger timer Left (Right) front seat warmer switch Front (Rear) power outlet ETACM, Power window relay, Defogger relay, Sunroof relay Head lamp relay, Blower relay Outside mirror switch, Rear fog lamp relay

FUSE RATING

10A 10A 10A 30A 10A 15A 10A 10A 15A 10A 10A 10A 15A 10A 10A 10A 20A 15A 25A 10A 10A

Page 139 of 407

EMISSION CONTROL SYSTEM 7-1

SH000A1-E

7. EMISSION

CONTROL SYSTEM

SH010A1-E EMISSION CONTROL SYSTEMS (Not all models) Depending upon the market for which the ve-hicle is destined, the emission control systemwill comprise one or more of the followingemission control devices. (1) Crankcase emission control system (2) Evaporative emission control system (3) Exhaust emission control system In order that the proper functioning of the emis- sion control systems may be ensured, it isrecommended that the vehicle is inspected andmaintained by an Hyundai authorised repairerin accordance with the maintenance schedulein this manual. SH010B1-E 1. CRANKCASE EMISSION CONTROL SYSTEM

The positive crankcase ventilation system is employed to prevent air pollution caused byblow-by gases being emitted from the crank-case by introducing fresh air to the crankcase through the air cleaner where this mixes withblow-by gases and then passes through thePCV valve into the intake manifold from whereit subsequently enters the combustion cham-ber and is burned.

SH010D1-E 3. EXHAUST EMISSION CONTROL SYSTEM The exhaust emission control system is a highlyeffective system which controls exhaust emis-sion whilst maintaining good vehicle perfor-mance.

SH010C1-E

2. EVAPORATIVE EMISSION

CONTROL SYSTEM

The Evaporative Emission Control System is designed to prevent fuel vapours from escap-ing into the atmosphere through the fuel tankventilation system.Whilst the engine is not running, fuel vapoursgenerated inside the fuel tank are absorbedand stored in a charcoal canister. When theengine is started, the vapours stored in thecanister are drawn into the induction systemthrough the purge control solenoid valve andare subsequently burned.The purge control solenoid valve is controlledby the ECU; when the engine coolant tempera-ture is low or the engine is idling, the purgecontrol valve is closed and fuel vapours remainstored in the canister. Under normal runningconditions when the engine is warm, the valveopens and the vapours are drawn into the inlettract and subsequently burned in the combus-tion chamber. SH020A1-E

Catalytic Convertor Operation Precautions; For a petrol engine Hyundai Matrix models are fitted with catalytic convertors which require special operatingconsiderations. The catalytic convertor servesto oxidize certain noxious elements of theexhaust gases leaving the engine to reduce thelevel of pollutants emitted from the vehicle and,provided that care is exercised to prevent dam-age, the catalyst will operate efficiently for thelife of the vehicle.

7HFC5013

Catalytic Converter

Page 170 of 407

1FEATURES OF YOUR HYUNDAI

6

B880D02A-GAT Limp home procedures

The key number should be recorded and kept in a safe place in case theneed to order further keys arises. New keys are available from any Hyundai dealer by quoting the relevant keynumber. In the interest of security, the metal tag attached to the keys which bears thekey number should be removed from the key ring after you receive your new vehicle. In addition, key numbers can-not be provided by Hyundai for secu- rity reasons. If you need additional keys or if youshould lose your keys, your authorized Hyundai dealer can make new keys. In case the immobilizer warning indi-cator blinks for five seconds when the ignition key is turned to "ON" position,this indicates that the immobilizer sys- tem is out of order. And you cannot start the engine without the limp homeprocedures with ignition key. The following procedure is how to start the engine with the function of the limphome. (0, 1, 2, 3 as a sample pass- word).B880D01FCNOTE: You can get the limp home pass- word when the vehicle is first deliv- ered to you. If you do not have thepassword, consult your authorized Hyundai dealer.

1. To set the password you may turn

the ignition key "ON" and then turn it "OFF" according to the digit num-bers, then the immobilizer indicator will blink along with the operation of the ignition key. For example, turnthe ignition key once for digit num- ber "1", and twice for "2", and so on. However, for the digit number "0",you must turn the ignition key for 10 times.

2. Wait for 3~10 seconds.

3. You may set the remaining number of digits by following the same pro-cedures 1 and 2.

4. If all of four digits have been tried successfully, turn the ignition key"ON" and check that the immobi-lizer indicator illuminates. From this time, you have to start your engine within 30 seconds. If you start yourengine after 30 seconds, your en- gine will not start.