ABS Hyundai Sonata

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: , Model line: , Model:Pages: 340, PDF Size: 18.45 MB

Page 291 of 340

Maintenance

48

7

G200700BUN-EA Wheel replacement

When replacing the metal wheels for

any reason, make sure the new

wheels are equivalent to the original

factory units in diameter, rim widthand offset. G200800AUN-EA

Tyre traction

Tyre traction can be reduced if you

drive on worn tyres, tyres that are

improperly inflated or on slippery

road surfaces. Tyres should be

replaced when tread wear indicators

appear. To reduce the possibility of

losing control, slow down whenever

there is rain, snow or ice on the road.

G200900AUN-EA

Tyre maintenance In addition to proper inflation, correct wheel alignment helps to decrease

tyre wear. If you find a tyre is worn

unevenly, have your dealer check thewheel alignment.

When you have new tyres installed,

make sure they are balanced. This

will increase vehicle ride comfort and

tyre life. Additionally, a tyre should

always be rebalanced if it is removedfrom the wheel.(Continued)

The use of any other tyre size

or type may seriously affect

ride, handling, ground clear-

ance, stopping distance, body

to tyre clearance, snow tyre

clearance, and speedometer

reliability.

It is best to replace all four tyres at the same time. If that

is not possible, or necessary,

then replace the two front or

two rear tyres as a pair.Replacing just one tyre can

seriously affect your vehicle’shandling.

The ABS works by comparing the speed of the wheels. Tyre

size can affect wheel speed.

When replacing tyres, all 4

tyres must use the same size

originally supplied with the

vehicle. Using tyres of a dif-

ferent size can cause the ABS

(Anti-lock Brake System) and

ESP (Electronic Stability

Program) (if equipped) to

work irregularly.

WARNING

A wheel that is not the correct

size may adversely affect wheel

and bearing life, braking and

stopping abilities, handling

characteristics, ground clear-

ance, body-to-tyre clearance,

snow chain clearance,speedometer and odometer cal-

ibration, headlight aim and

bumper height.

Page 303 of 340

Maintenance

60

7

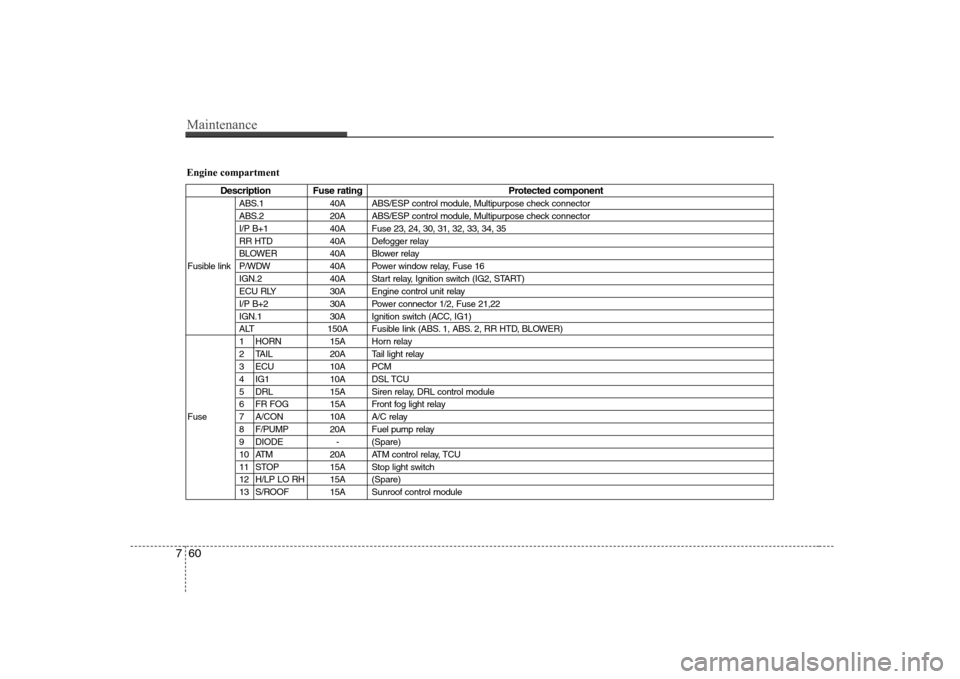

Engine compartment

Description Fuse rating Protected component

ABS.1 40A ABS/ESP control module, Multipurpose check connector

ABS.2 20A ABS/ESP control module, Multipurpose check connector

I/P B+1 40A Fuse 23, 24, 30, 31, 32, 33, 34, 35

RR HTD 40A Defogger relay

BLOWER 40A Blower relay

Fusible link P/WDW 40A Power window relay, Fuse 16 IGN.2 40A Start relay, Ignition switch (IG2, START)

ECU RLY 30A Engine control unit relay

I/P B+2 30A Power connector 1/2, Fuse 21,22

IGN.1 30A Ignition switch (ACC, IG1)

ALT 150A Fusible Iink (ABS. 1, ABS. 2, RR HTD, BLOWER)

1 HORN 15A Horn relay

2 TAIL 20A Tail light relay

3 ECU 10A PCM

4 IG1 10A DSL TCU

5 DRL 15A Siren relay, DRL control module

6 FR FOG 15A Front fog light relay

Fuse 7 A/CON 10A A/C relay 8 F/PUMP 20A Fuel pump relay

9 DIODE - (Spare)

10 ATM 20A ATM control relay, TCU

11 STOP 15A Stop light switch

12 H/LP LO RH 15A (Spare)

13 S/ROOF 15A Sunroof control module

Page 304 of 340

761

Maintenance

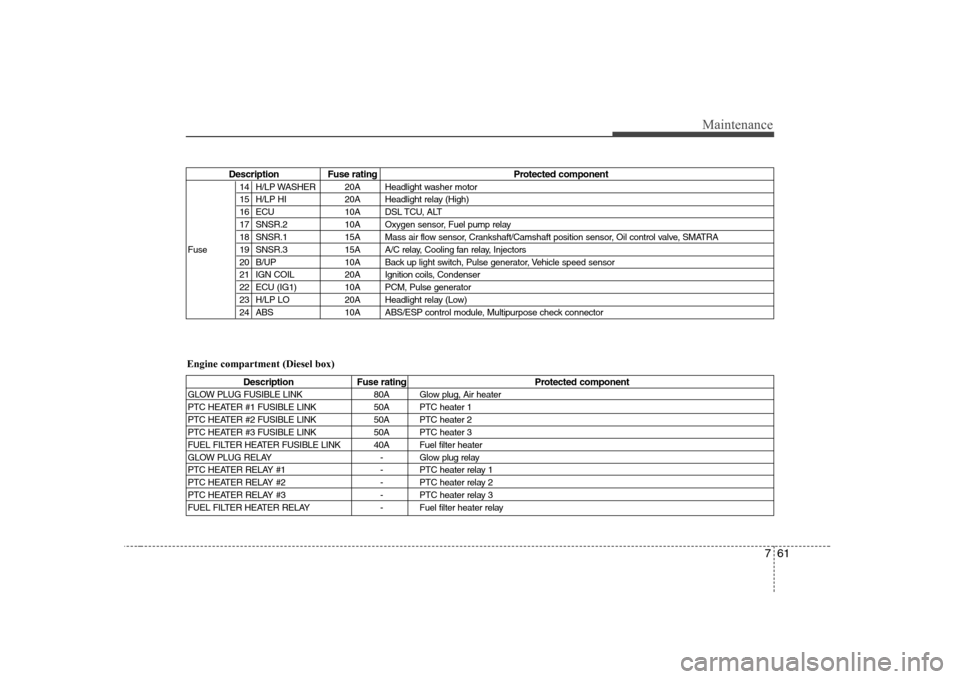

Description Fuse rating Protected component14 H/LP WASHER 20A Headlight washer motor

15 H/LP HI 20A Headlight relay (High)

16 ECU 10A DSL TCU, ALT

17 SNSR.2 10A Oxygen sensor, Fuel pump relay

18 SNSR.1 15A Mass air flow sensor, Crankshaft/Camshaft position sensor, Oil control valve, SMATRA

Fuse 19 SNSR.3 15A A/C relay, Cooling fan relay, Injectors 20 B/UP 10A Back up light switch, Pulse generator, Vehicle speed sensor

21 IGN COIL 20A Ignition coils, Condenser

22 ECU (IG1) 10A PCM, Pulse generator

23 H/LP LO 20A Headlight relay (Low)

24 ABS 10A ABS/ESP control module, Multipurpose check connector

Description Fuse rating Protected component

GLOW PLUG FUSIBLE LINK 80A Glow plug, Air heater

PTC HEATER #1 FUSIBLE LINK 50A PTC heater 1

PTC HEATER #2 FUSIBLE LINK 50A PTC heater 2

PTC HEATER #3 FUSIBLE LINK 50A PTC heater 3

FUEL FILTER HEATER FUSIBLE LINK 40A Fuel filter heater

GLOW PLUG RELAY - Glow plug relay

PTC HEATER RELAY #1 - PTC heater relay 1

PTC HEATER RELAY #2 - PTC heater relay 2

PTC HEATER RELAY #3 - PTC heater relay 3

FUEL FILTER HEATER RELAY - Fuel filter heater relay

Engine compartment (Diesel box)

Page 307 of 340

Maintenance

64

7

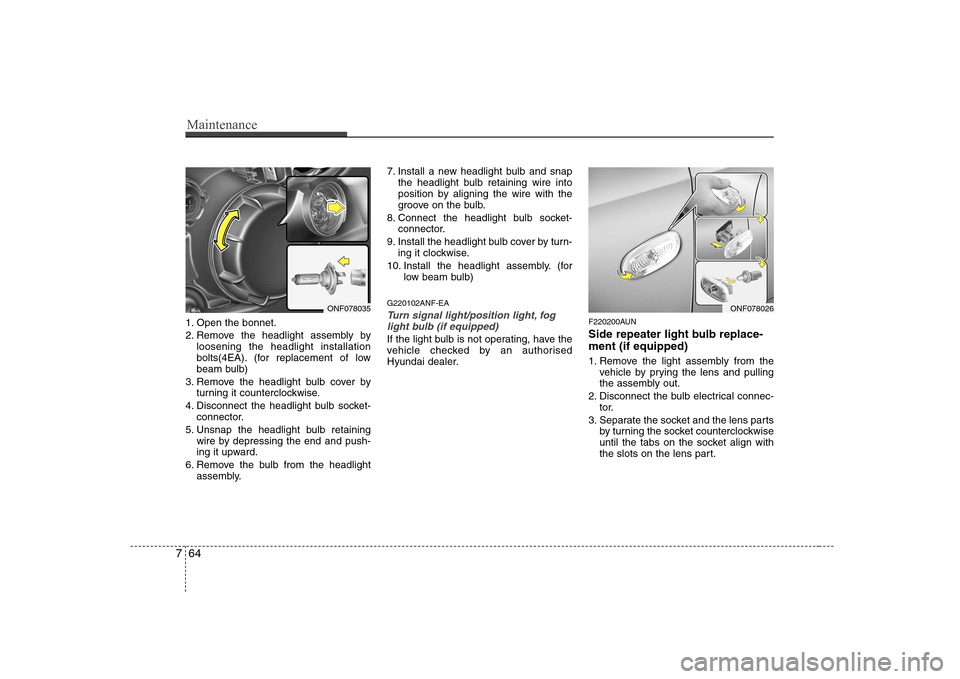

1. Open the bonnet.

2. Remove the headlight assembly by

loosening the headlight installation

bolts(4EA). (for replacement of low

beam bulb)

3. Remove the headlight bulb cover by turning it counterclockwise.

4. Disconnect the headlight bulb socket- connector.

5. Unsnap the headlight bulb retaining wire by depressing the end and push-

ing it upward.

6. Remove the bulb from the headlight assembly. 7. Install a new headlight bulb and snap

the headlight bulb retaining wire into

position by aligning the wire with the

groove on the bulb.

8. Connect the headlight bulb socket- connector.

9. Install the headlight bulb cover by turn- ing it clockwise.

10. Install the headlight assembly. (for low beam bulb)

G220102ANF-EATurn signal light/position light, fog light bulb (if equipped)

If the light bulb is not operating, have the

vehicle checked by an authorised

Hyundai dealer. F220200AUN

Side repeater light bulb replace- ment (if equipped)

1. Remove the light assembly from the

vehicle by prying the lens and pulling

the assembly out.

2. Disconnect the bulb electrical connec- tor.

3. Separate the socket and the lens parts by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the lens part.

ONF078035ONF078026

Page 309 of 340

Maintenance

66

7

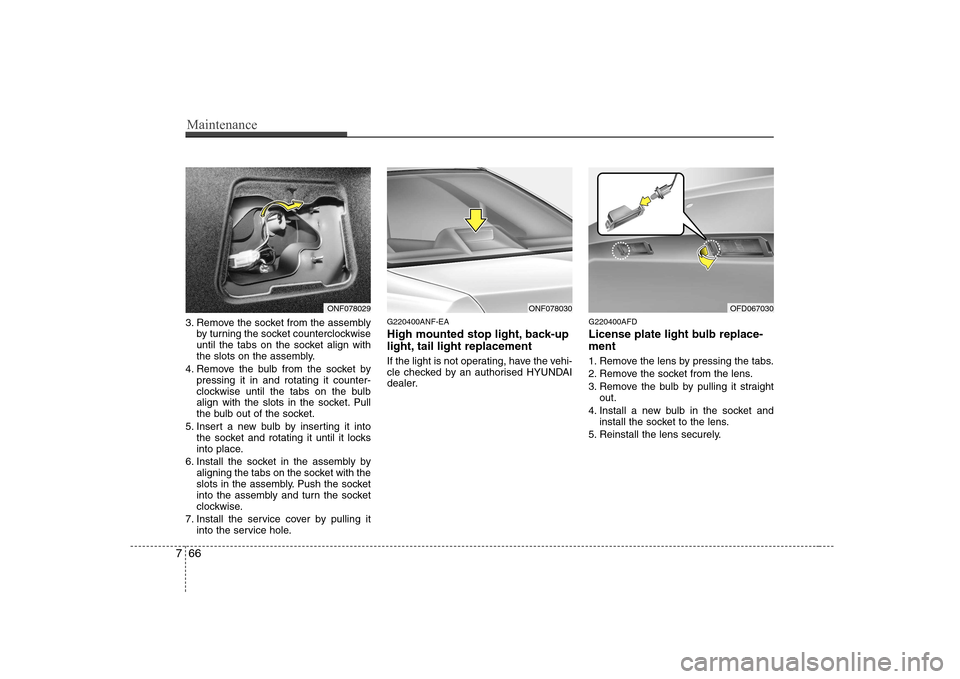

3. Remove the socket from the assembly

by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly.

4. Remove the bulb from the socket by pressing it in and rotating it counter-

clockwise until the tabs on the bulb

align with the slots in the socket. Pull

the bulb out of the socket.

5. Insert a new bulb by inserting it into the socket and rotating it until it locks

into place.

6. Install the socket in the assembly by aligning the tabs on the socket with the

slots in the assembly. Push the socket

into the assembly and turn the socket

clockwise.

7. Install the service cover by pulling it into the service hole. G220400ANF-EA

High mounted stop light, back-up

light, tail light replacement

If the light is not operating, have the vehi-

cle checked by an authorised HYUNDAI

dealer.

G220400AFD

License plate light bulb replace- ment

1. Remove the lens by pressing the tabs.

2. Remove the socket from the lens.

3. Remove the bulb by pulling it straight

out.

4. Install a new bulb in the socket and install the socket to the lens.

5. Reinstall the lens securely.

ONF078029ONF078030OFD067030

Page 310 of 340

767

Maintenance

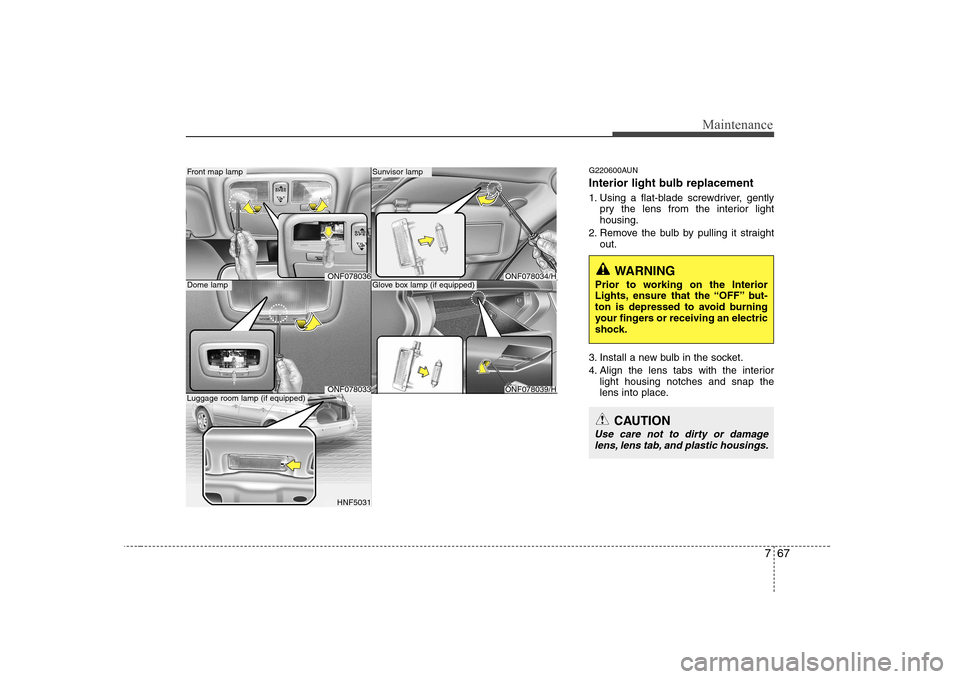

G220600AUN

Interior light bulb replacement

1. Using a flat-blade screwdriver, gentlypry the lens from the interior light housing.

2. Remove the bulb by pulling it straight out.

3. Install a new bulb in the socket.

4. Align the lens tabs with the interior light housing notches and snap the

lens into place.

WARNING

Prior to working on the Interior

Lights, ensure that the “OFF” but-

ton is depressed to avoid burning

your fingers or receiving an electric

shock.

CAUTION

Use care not to dirty or damage lens, lens tab, and plastic housings.

Front map lamp

Dome lamp

Sunvisor lamp

ONF078039/H

Glove box lamp (if equipped)

HNF5031

Luggage room lamp (if equipped)

ONF078036

ONF078033

ONF078034/H

Page 319 of 340

Maintenance

76

7

EMISSION CONTROL SYSTEM

G270000AFD-EA

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Service Passport

in your vehicle.

Your vehicle is equipped with an emis-

sion control system to meet all Australian

Design Rules (ADR) requirements. There are three emission control sys-

tems which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system(3) Exhaust emission control system In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by an autho-

rised HYUNDAI dealer in accordancewith the maintenance schedule in this

manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Program (ESP) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability

Program (ESP) system off by press-

ing the ESP switch.

After dynamometer testing is com- pleted, turn the ESP system back on

by pressing the ESP switch again.

G270100AUN

1. Crankcase emission control system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valveinto the induction system. G270200AFD-EA

2. Evaporative emission control

System

The Evaporative Emission Control

System is designed to prevent fuel

vapours from escaping into the atmos-

phere.

G270201AUN-EA

Canister

Fuel vapours generated inside the fuel tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapours absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.