fuel Hyundai Sonata

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: , Model line: , Model:Pages: 340, PDF Size: 18.45 MB

Page 259 of 340

Maintenance

16

7

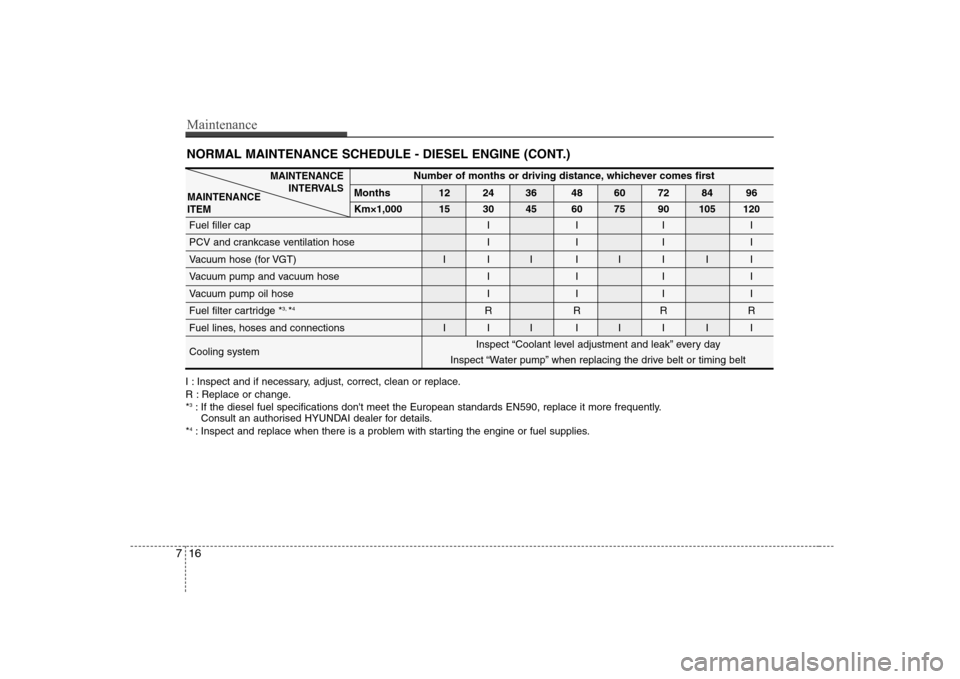

NORMAL MAINTENANCE SCHEDULE - DIESEL ENGINE (CONT.)

MAINTENANCE

INTERVALS

MAINTENANCE ITEMNumber of months or driving distance, whichever comes first

Months 12 24 36 48 60 72 84 96 Km×1,000

15 30 45 60 75 90 105 120

Fuel filler cap I I I I

PCV and crankcase ventilation hose I I I I

Vacuum hose (for VGT) I I I I I I I I

Vacuum pump and vacuum hose I I I I

Vacuum pump oil hose I I I I

Fuel filter cartridge * 3,

*4

RRRR

Fuel lines, hoses and connections I I I I I I I I Cooling system Inspect “Coolant level adjustment and leak” every day

Inspect “Water pump” when replacing the drive belt or timing belt

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.* 3

: If the diesel fuel specifications don't meet the European standards EN590, replace it more frequently.

Consult an authorised HYUNDAI dealer for details.

* 4

: Inspect and replace when there is a problem with starting the engine or fuel supplies.

Page 264 of 340

721

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

G050100AUN Engine oil and filter The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-quent oil and filter changes are required.

G050200AUN Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically forproper tension and adjusted as neces-

sary. G050300AFD-EA

Fuel filter (cartridge) A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by an authorised HYUNDAI

dealer.

G050400AFD-EA

Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

an authorised HYUNDAI dealer replace

any damaged or leaking parts immedi-

ately.

WARNING -

Diesel only

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High pressure pump, rail, injectorsand high pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touch the body.

People using pacemakers should

not move than 30cm closer to theECU or wiring harness within the

engine room while engine is run-

ning, since the high currents in the

Common Rail system produce con-

siderable magnetic fields.

Page 265 of 340

Maintenance

22

7

G050500AUN Timing belt (if equipped)

Inspect all parts related to the timing belt

for damage and deformation. Replace

any damaged parts immediately.

G050600AUN-EA

Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervals

specified in the maintenance schedule.

Make sure that a new vapour hose or fuelfiller cap is correctly replaced. G050700AUN

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.G050800AFD

Air cleaner filter

A Genuine HYUNDAI air cleaner filter is recommended when the filter isreplaced.

G050900AUN-EA

Spark plugs (for petrol engine)

Make sure to install new spark plugs of

the correct heat range. G051000AFD-EA

Valve clearance (if equipped)

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorised HYUNDAI dealer should

perform the operation.

G051100AUN Cooling system

Check the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.

G051200AUN Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

Page 276 of 340

733

Maintenance

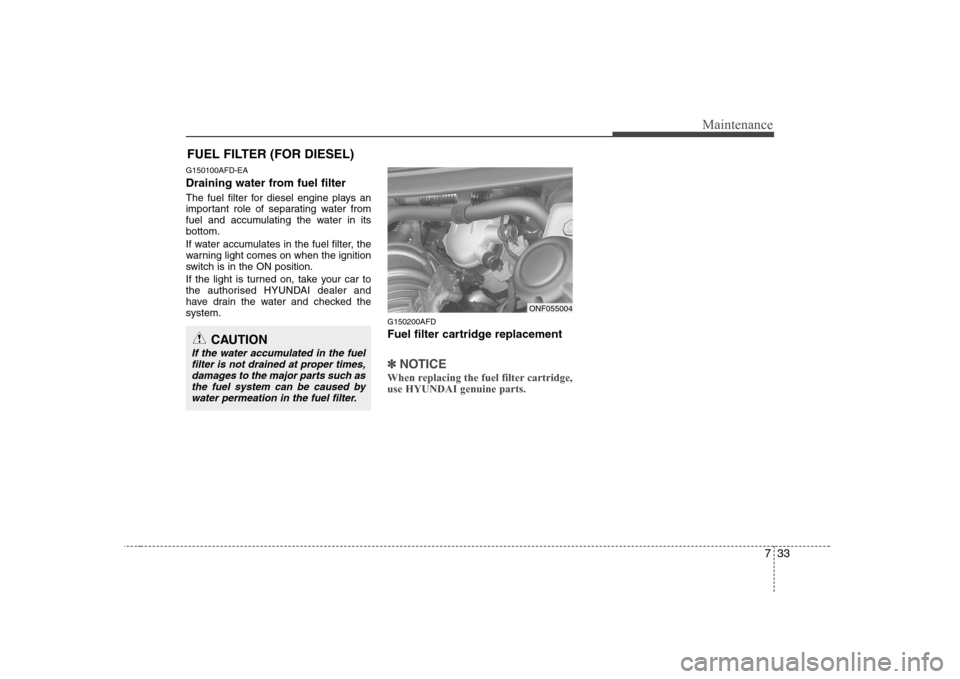

FUEL FILTER (FOR DIESEL)

G150100AFD-EA

Draining water from fuel filter

The fuel filter for diesel engine plays an

important role of separating water from

fuel and accumulating the water in itsbottom.

If water accumulates in the fuel filter, the

warning light comes on when the ignition

switch is in the ON position.

If the light is turned on, take your car to

the authorised HYUNDAI dealer and

have drain the water and checked thesystem. G150200AFD

Fuel filter cartridge replacement

✽✽NOTICE

When replacing the fuel filter cartridge, use HYUNDAI genuine parts.

ONF055004

CAUTION

If the water accumulated in the fuel filter is not drained at proper times,

damages to the major parts such asthe fuel system can be caused bywater permeation in the fuel filter.

Page 286 of 340

743

Maintenance

TYRES AND WHEELS

G200100AUN-EA

Tyre care

For proper maintenance, safety, and

maximum fuel economy, you must

always maintain recommended tyre

inflation pressures and stay within

the load limits and weight distribution

recommended for your vehicle. G200200AFD-EA Recommended cold tyre inflation pressures All tyre pressures (including the

spare) should be checked when the

tyres are cold. “Cold Tyres” means

the vehicle has not been driven for at

least three hours or driven less than1.6 km (one mile).

Recommended pressures must be

maintained for the best ride, top vehi-

cle handling, and minimum tyre

wear.

For recommended inflation pressure

refer to “Tyre and wheels” in section9. All specifications (sizes and pres-

sures) can be found on a label

attached to the vehicle.

WARNING - Tyre underin-

flation

Severe underinflation (70 kPa (10 psi) or more) can lead to

severe heat build-up, causing

blowouts, tread separation andother tyre failures that can

result in the loss of vehicle con-

trol leading to severe injury or

death. This risk is much higher

on hot days and when driving

for long periods at high speeds.

OHD086003R

Page 287 of 340

Maintenance

44

7

WARNING - Tyre inflation

Overinflation or underinflation

can reduce tyre life, adversely

affect vehicle handling, and

lead to sudden tyre failure. This

could result in loss of vehicle

control and potential injury.

CAUTION - Tyre pressure

Always observe the following:

Check tyre pressure when the tyres are cold. (After vehiclehas been parked for at leastthree hours or hasn't been driven more than 1.6 km (onemile) since startup.)

Check the pressure of your spare tyre each time youcheck the pressure of other tyres.

Never overload your vehicle. Be careful not to overload avehicle luggage rack if yourvehicle is equipped with one.

Worn, old tyres can cause accidents. If your tread isbadly worn, or if your tyreshave been damaged, replacethem.

CAUTION

Underinflation also results in excessive wear, poor handlingand reduced fuel economy. Wheel deformation also ispossible. Keep your tyre pres-sures at the proper levels. If a tyre frequently needs refilling,have it checked by an autho-rised HYUNDAI dealer.

Overinflation produces a harsh ride, excessive wear atthe centre of the tyre tread,and a greater possibility ofdamage from road hazards.

CAUTION

Warm tyres normally exceed recommended cold tyre pres-sures by 28 to 41 kPa (4 to 6 psi). Do not release air fromwarm tyres to adjust the pres-sure or the tyres will be under- inflated.

Be sure to reinstall the tyre inflation valve caps. Withoutthe valve cap, dirt or moisturecould get into the valve core and cause air leakage. If avalve cap is missing, install anew one as soon as possible.

Page 302 of 340

759

Maintenance

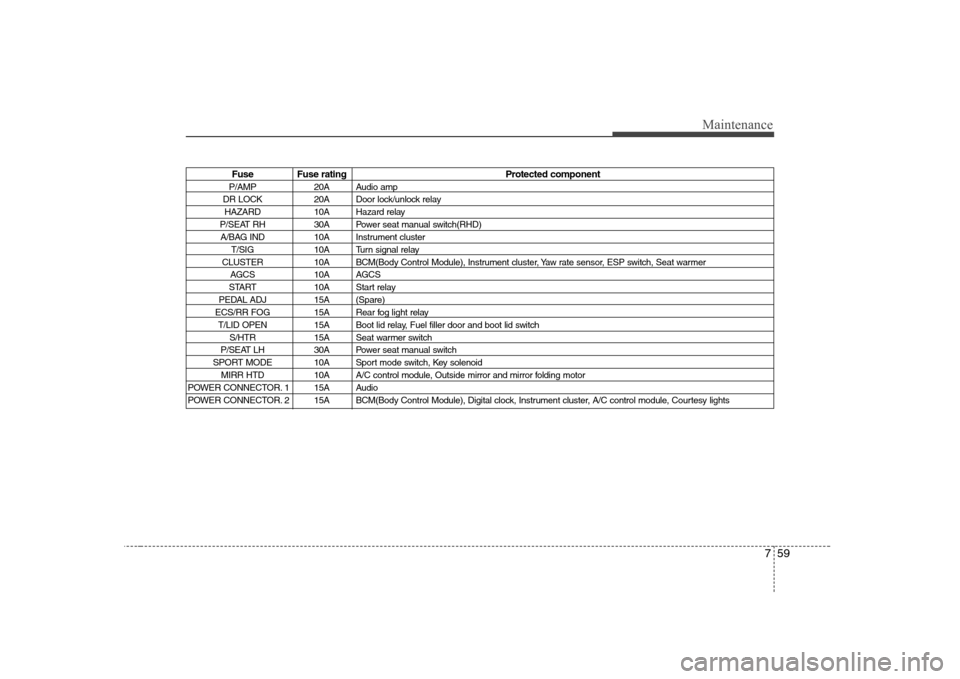

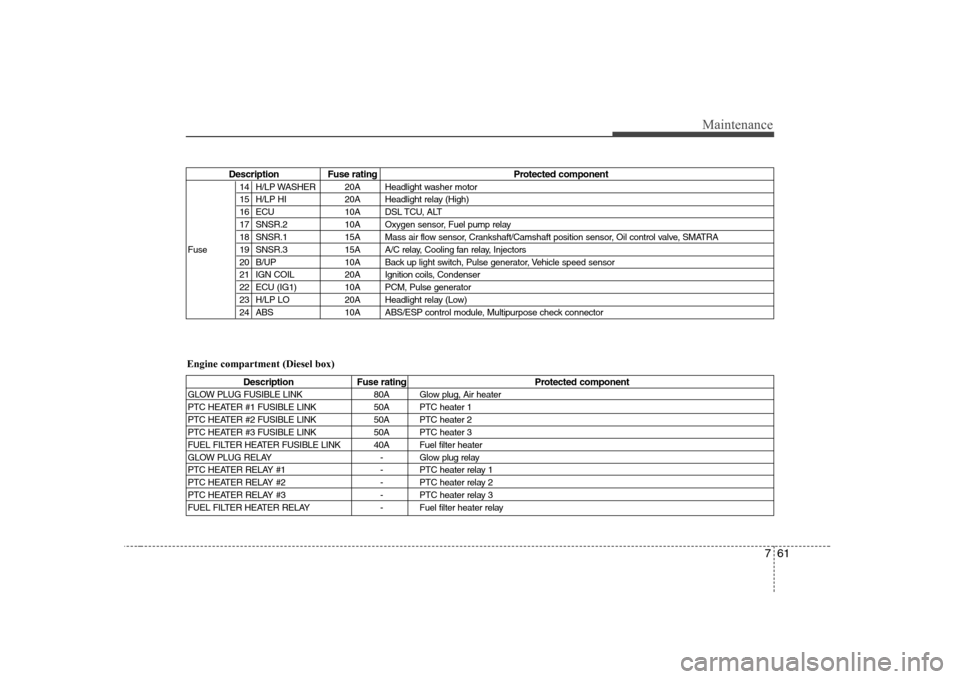

Fuse Fuse ratingProtected component

P/AMP 20A Audio amp

DR LOCK 20A Door lock/unlock relay HAZARD 10A Hazard relay

P/SEAT RH 30A Power seat manual switch(RHD) A/BAG IND 10A Instrument cluster T/SIG 10A Turn signal relay

CLUSTER 10A BCM(Body Control Module), Instrument cluster, Yaw rate sensor, ESP switch, Seat warmer AGCS 10A AGCS

START 10A Start relay

PEDAL ADJ 15A (Spare)

ECS/RR FOG 15A Rear fog light relay T/LID OPEN 15A Boot lid relay, Fuel filler door and boot lid switch S/HTR 15A Seat warmer switch

P/SEAT LH 30A Power seat manual switch

SPORT MODE 10A Sport mode switch, Key solenoid MIRR HTD 10A A/C control module, Outside mirror and mirror folding motor

POWER CONNECTOR. 1 15A Audio

POWER CONNECTOR. 2 15A BCM(Body Control Module), Digital clock, Instrument cluster, A/C control module, Courtesy lights

Page 303 of 340

Maintenance

60

7

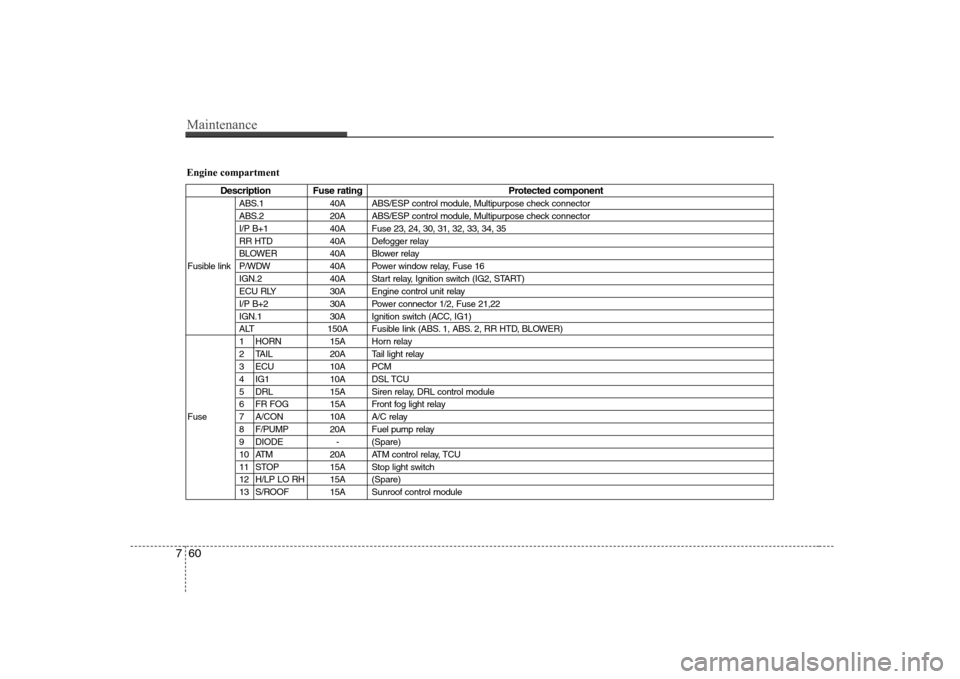

Engine compartment

Description Fuse rating Protected component

ABS.1 40A ABS/ESP control module, Multipurpose check connector

ABS.2 20A ABS/ESP control module, Multipurpose check connector

I/P B+1 40A Fuse 23, 24, 30, 31, 32, 33, 34, 35

RR HTD 40A Defogger relay

BLOWER 40A Blower relay

Fusible link P/WDW 40A Power window relay, Fuse 16 IGN.2 40A Start relay, Ignition switch (IG2, START)

ECU RLY 30A Engine control unit relay

I/P B+2 30A Power connector 1/2, Fuse 21,22

IGN.1 30A Ignition switch (ACC, IG1)

ALT 150A Fusible Iink (ABS. 1, ABS. 2, RR HTD, BLOWER)

1 HORN 15A Horn relay

2 TAIL 20A Tail light relay

3 ECU 10A PCM

4 IG1 10A DSL TCU

5 DRL 15A Siren relay, DRL control module

6 FR FOG 15A Front fog light relay

Fuse 7 A/CON 10A A/C relay 8 F/PUMP 20A Fuel pump relay

9 DIODE - (Spare)

10 ATM 20A ATM control relay, TCU

11 STOP 15A Stop light switch

12 H/LP LO RH 15A (Spare)

13 S/ROOF 15A Sunroof control module

Page 304 of 340

761

Maintenance

Description Fuse rating Protected component14 H/LP WASHER 20A Headlight washer motor

15 H/LP HI 20A Headlight relay (High)

16 ECU 10A DSL TCU, ALT

17 SNSR.2 10A Oxygen sensor, Fuel pump relay

18 SNSR.1 15A Mass air flow sensor, Crankshaft/Camshaft position sensor, Oil control valve, SMATRA

Fuse 19 SNSR.3 15A A/C relay, Cooling fan relay, Injectors 20 B/UP 10A Back up light switch, Pulse generator, Vehicle speed sensor

21 IGN COIL 20A Ignition coils, Condenser

22 ECU (IG1) 10A PCM, Pulse generator

23 H/LP LO 20A Headlight relay (Low)

24 ABS 10A ABS/ESP control module, Multipurpose check connector

Description Fuse rating Protected component

GLOW PLUG FUSIBLE LINK 80A Glow plug, Air heater

PTC HEATER #1 FUSIBLE LINK 50A PTC heater 1

PTC HEATER #2 FUSIBLE LINK 50A PTC heater 2

PTC HEATER #3 FUSIBLE LINK 50A PTC heater 3

FUEL FILTER HEATER FUSIBLE LINK 40A Fuel filter heater

GLOW PLUG RELAY - Glow plug relay

PTC HEATER RELAY #1 - PTC heater relay 1

PTC HEATER RELAY #2 - PTC heater relay 2

PTC HEATER RELAY #3 - PTC heater relay 3

FUEL FILTER HEATER RELAY - Fuel filter heater relay

Engine compartment (Diesel box)

Page 311 of 340

Maintenance

68

7

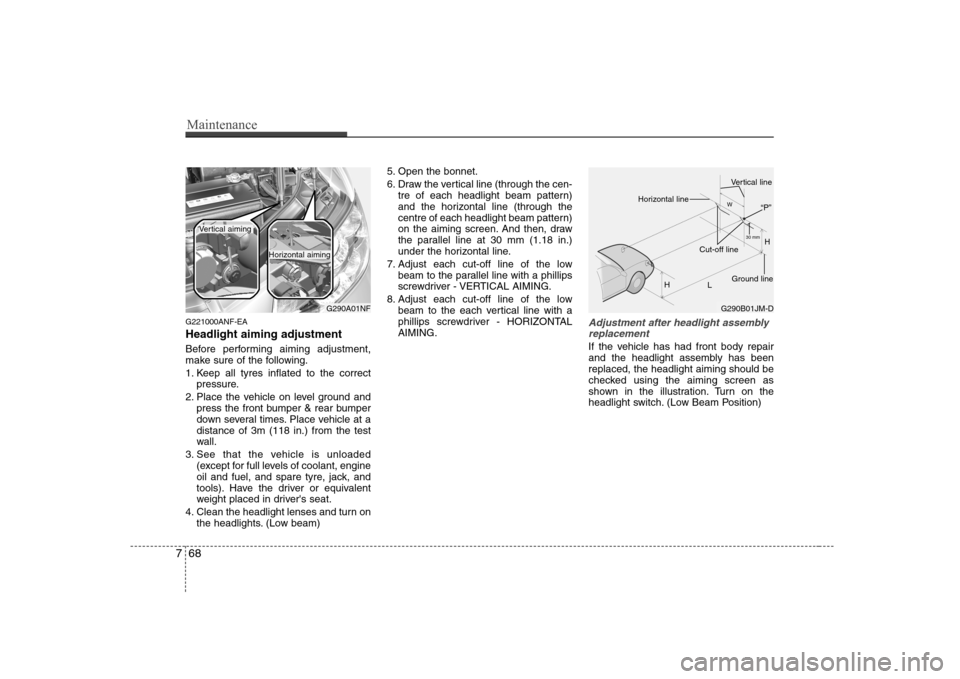

G221000ANF-EA Headlight aiming adjustment

Before performing aiming adjustment,

make sure of the following.

1. Keep all tyres inflated to the correct

pressure.

2. Place the vehicle on level ground and press the front bumper & rear bumper

down several times. Place vehicle at adistance of 3m (118 in.) from the test

wall.

3. See that the vehicle is unloaded (except for full levels of coolant, engine

oil and fuel, and spare tyre, jack, and

tools). Have the driver or equivalent

weight placed in driver's seat.

4. Clean the headlight lenses and turn on the headlights. (Low beam) 5. Open the bonnet.

6. Draw the vertical line (through the cen-

tre of each headlight beam pattern)

and the horizontal line (through the

centre of each headlight beam pattern)

on the aiming screen. And then, draw

the parallel line at 30 mm (1.18 in.)

under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips

screwdriver - VERTICAL AIMING.

8. Adjust each cut-off line of the low beam to the each vertical line with a

phillips screwdriver - HORIZONTALAIMING.Adjustment after headlight assembly

replacement

If the vehicle has had front body repair

and the headlight assembly has beenreplaced, the headlight aiming should be

checked using the aiming screen as

shown in the illustration. Turn on the

headlight switch. (Low Beam Position)

G290A01NF

Vertical aiming

Horizontal aiming

G290B01JM-D H

H L30 mm

W

Horizontal line

Vertical line

“P”

Ground line

Cut-off line