warning Hyundai Terracan 2004 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Terracan, Model: Hyundai Terracan 2004Pages: 361, PDF Size: 4.69 MB

Page 301 of 361

DRIVING YOUR HYUNDAI

2- 18 NOTE:

1. Never load the trailer with more weight in the back than in the front. About 60% of the trailer load should be in the front halfon the trailer and the remaining 40% inthe rear.

2. The total gross vehicle weight with trailer must not exceed the Gross Vehicle WeightRating (GVWR) shown on the vehicleidentification plate (see page 8-1). Thetotal gross vehicle weight is the com-bined weight of the vehicle, driver, allpassengers and their luggage, cargo,towbar hitch, trailer nose weight and otheroptional equipment.

3. The front or rear axle weight must not exceed the Gross Axle Weight Rating(GAWR) shown on the vehicle identifica-tion plate (see page 8-1). It is possiblethat your towing package does not ex-ceed the GVWR but exceeds the GAWR. Improper trailer loading and/or too much luggage in the trunk can overload therear axle. Redistribute the load and checkthe axle weight again.

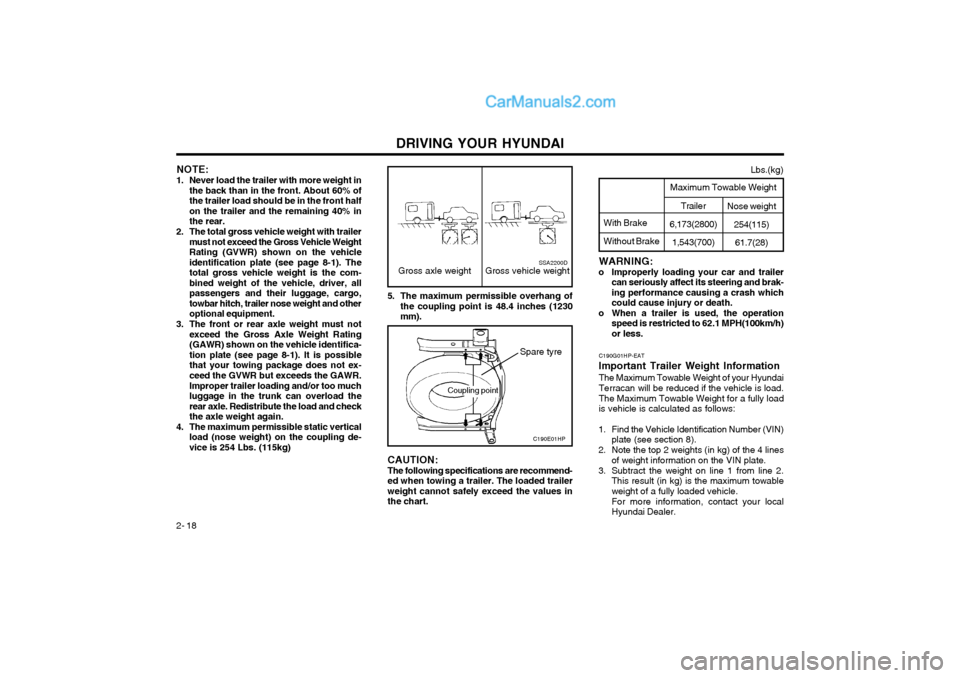

4. The maximum permissible static vertical load (nose weight) on the coupling de-vice is 254 Lbs. (115kg) 5. The maximum permissible overhang of

the coupling point is 48.4 inches (1230mm).

Gross axle weight Gross vehicle weightSSA2200D

CAUTION: The following specifications are recommend-ed when towing a trailer. The loaded trailerweight cannot safely exceed the values inthe chart.

Lbs.(kg)

Maximum Towable Weight

With Brake Without Brake Trailer

6,173(2800) 1,543(700) Nose weight

254(115)61.7(28)

WARNING:

o Improperly loading your car and trailer can seriously affect its steering and brak- ing performance causing a crash whichcould cause injury or death.

o When a trailer is used, the operation speed is restricted to 62.1 MPH(100km/h)or less.

C190E01HP

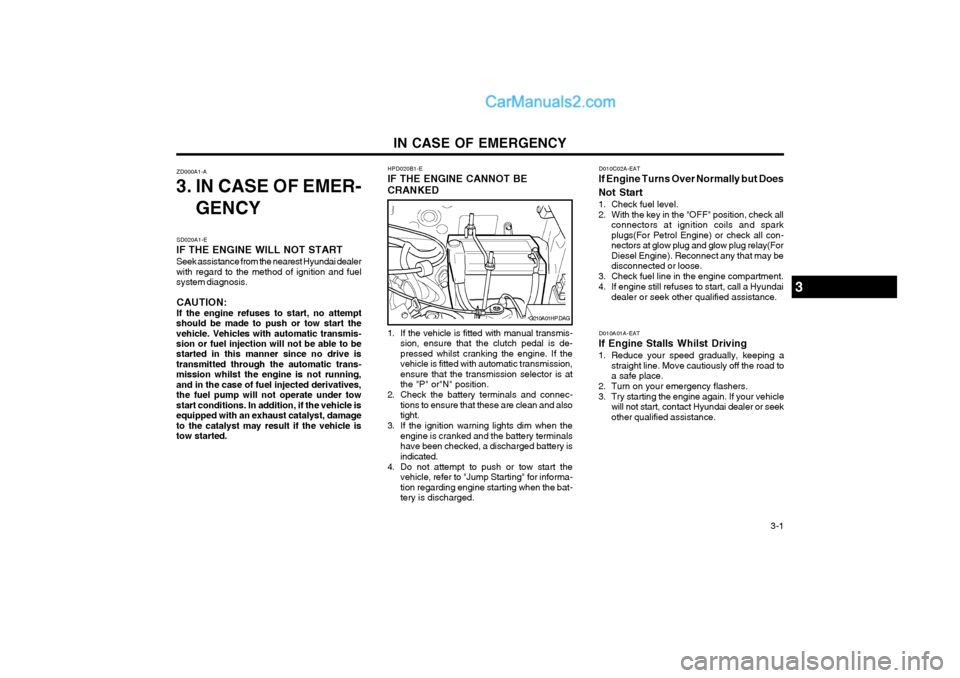

Spare tyre

Coupling point

C190G01HP-EAT

Important Trailer Weight Information

The Maximum Towable Weight of your Hyundai Terracan will be reduced if the vehicle is load. The Maximum Towable Weight for a fully load is vehicle is calculated as follows:

1. Find the Vehicle Identification Number (VIN) plate (see section 8).

2. Note the top 2 weights (in kg) of the 4 lines of weight information on the VIN plate.

3. Subtract the weight on line 1 from line 2. This result (in kg) is the maximum towableweight of a fully loaded vehicle. For more information, contact your local Hyundai Dealer.

Page 303 of 361

IN CASE OF EMERGENCY 3-1

ZD000A1-A

3. IN CASE OF EMER-

GENCY

D010A01A-EAT

If Engine Stalls Whilst Driving

1. Reduce your speed gradually, keeping a straight line. Move cautiously off the road to a safe place.

2. Turn on your emergency flashers.

3. Try starting the engine again. If your vehicle will not start, contact Hyundai dealer or seek other qualified assistance.

SD020A1-E

IF THE ENGINE WILL NOT START Seek assistance from the nearest Hyundai dealer with regard to the method of ignition and fuelsystem diagnosis.

CAUTION: If the engine refuses to start, no attempt

should be made to push or tow start the vehicle. Vehicles with automatic transmis- sion or fuel injection will not be able to be started in this manner since no drive istransmitted through the automatic trans-mission whilst the engine is not running,and in the case of fuel injected derivatives,the fuel pump will not operate under towstart conditions. In addition, if the vehicle isequipped with an exhaust catalyst, damageto the catalyst may result if the vehicle istow started. HPD020B1-E

IF THE ENGINE CANNOT BE

CRANKED

1. If the vehicle is fitted with manual transmis- sion, ensure that the clutch pedal is de-

pressed whilst cranking the engine. If thevehicle is fitted with automatic transmission,ensure that the transmission selector is atthe "P" or"N" position.

2. Check the battery terminals and connec- tions to ensure that these are clean and alsotight.

3. If the ignition warning lights dim when the engine is cranked and the battery terminalshave been checked, a discharged battery isindicated.

4. Do not attempt to push or tow start the vehicle, refer to "Jump Starting" for informa-tion regarding engine starting when the bat-tery is discharged.

G210A01HP.DAG

3

D010C02A-EAT

If Engine Turns Over Normally but Does Not Start

1. Check fuel level.

2. With the key in the "OFF" position, check all connectors at ignition coils and spark plugs(For Petrol Engine) or check all con-nectors at glow plug and glow plug relay(ForDiesel Engine). Reconnect any that may bedisconnected or loose.

3. Check fuel line in the engine compartment.

4. If engine still refuses to start, call a Hyundai dealer or seek other qualified assistance.

Page 304 of 361

IN CASE OF EMERGENCY

3-2

CAUTION:

Personal injury and damage to the vehicle

may occur if jump starting is not performed correctly. If any doubt exists as to how thisoperation should be performed, seek assis-tance from qualified personnel. WARNING:

Motor vehicle batteries contain sulphuric

acid and emit hydrogen gas. Protective cloth- ing should be worn and care exercised toprevent the acid from coming into contactwith skin or clothing and the vehicle. Nakedlights should not be permitted in the vicinityof the battery. Care should be exercised toprevent sparks occurring during connec-tion. If acid accidentally comes into contactwith skin or eyes, the affected area shouldimmediately be flushed with copious CAUTION: If the jump cable is incorrectly installed, damage to the vehicle electrical system mayoccur, in particular the electronic compo-nents such as the Fuel Injection system

computer and the Automatic Transmissioncomputer. The battery must never be dis-connected whilst the engine is running.

SD030A1-E JUMP STARTING

amounts of water and medical assistance sought.

1. Ensure that the booster battery is 12 volt type. If the booster battery is installed inanother vehicle, ensure that the two vehi-cles are not touching.

2. Turn off all unnecessary electrical equip- ment in both vehicles.

3. Ensure that the engine of the vehicle provid- ing the jump start is running prior to connec-tion of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the booster battery and theother end to the positive (+) terminal of thedis-charged battery.

5. Attach the black jump cable to the negative (-) terminal of the booster battery, and theother end to a ground point within the enginecompartment of the vehicle with the flat bat-tery. Do not connect to the negative batteryterminal of the flat battery since sparks maybe generated with the subsequent risk ofexplosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start the engine of thevehicle with the flat battery.

7. Switch "ON" the main beam headlamps before carefully removing the jumper cablesin the reverse order of attachment. Oncethe jumper cables have been removed,switch "OFF" the main beam headlamps. HPD040A2-E IF THE ENGINE OVERHEATS If the temperature gauge indicates overheating:

1. Pull off the road and stop as soon as it is

safe to do so.

2. Place the gear selector lever in "P" (auto- matic), or neutral (manual transmission) and set the parking brake. If the air conditioningis on, turn it off.

3. If coolant is running out under the car or steam is coming out from under the bonnetstop the engine. Do not open the bonnetuntil the coolant has stopped running or thesteaming has stopped. If there is no visibleloss of coolant and no steam, leave theengine running and check to be sure theengine cooling fan is operating. If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is missing. If it is not missing, check to see that it is tight. If the drive belt seems to besatisfactory, check for coolant leaking fromthe radiator, hoses or under the car. (If theair conditioning had been in use, it is normalfor cold water to be draining from it).

AX30030A

Negative to the engine not to the battery

Positive to positive

Booster battery

�c

�e

�f �d

Discharged battery

Page 305 of 361

IN CASE OF EMERGENCY 3-3

WARNING: Whilst the engine is running, keep hands

and clothing away from moving parts such as the fan and drive belts to prevent injury.

WARNING (Diesel only): Never work on injection system with engine

running or within 30 seconds after shutting off engine. High pressure pump, rail, injec-tors and high pressure pipes are subject tohigh pressure even after the engine stopped.The fuel jet produced by fuel leaks maycause serious injury, if it touch the body.People using pacemakers should not movethan 30cm closer to the ECU or wiring har-ness within the engine room while engine isrunning, since the high currents in the Com-mon Rail system produce considerable mag-netic fields.

5. If the water pump drive belt is broken or coolant is leaking out, stop the engine imme- diately and call the nearest Hyundai dealerfor assistance.

WARNING: Do not remove the radiator cap when the

engine is hot since steam and boiling water may be ejected from the radiator resulting inburns or scalding. YD050A1-E

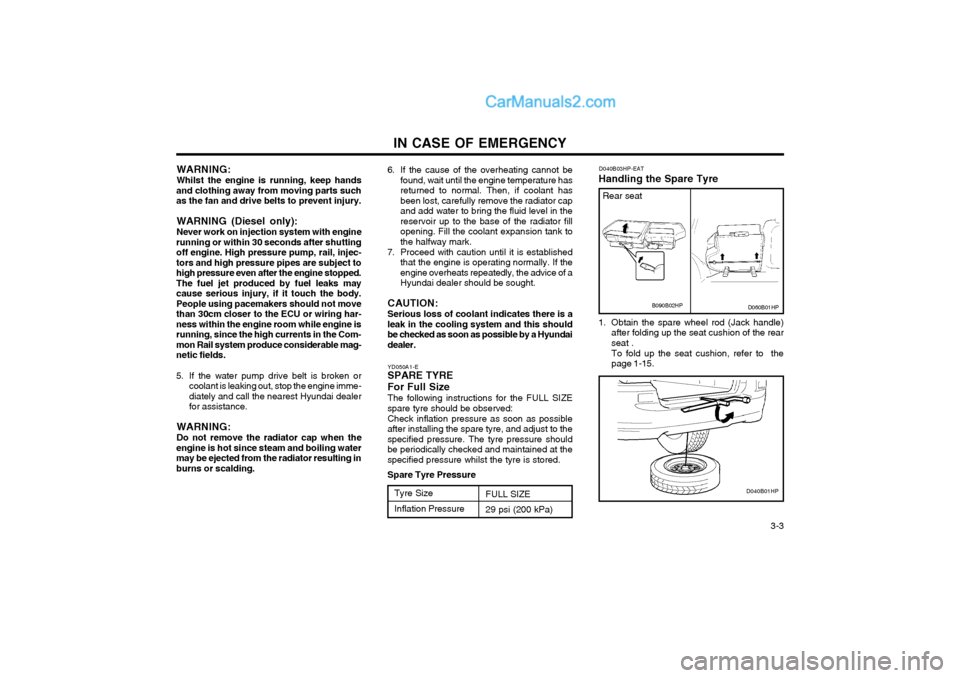

SPARE TYRE For Full Size

The following instructions for the FULL SIZE

spare tyre should be observed:

Check inflation pressure as soon as possible

after installing the spare tyre, and adjust to the specified pressure. The tyre pressure shouldbe periodically checked and maintained at thespecified pressure whilst the tyre is stored.

Spare Tyre Pressure

Inflation Pressure

Tyre Size

FULL SIZE 29 psi (200 kPa)

6. If the cause of the overheating cannot be

found, wait until the engine temperature has returned to normal. Then, if coolant hasbeen lost, carefully remove the radiator capand add water to bring the fluid level in thereservoir up to the base of the radiator fillopening. Fill the coolant expansion tank tothe halfway mark.

7. Proceed with caution until it is established that the engine is operating normally. If theengine overheats repeatedly, the advice of aHyundai dealer should be sought.

CAUTION: Serious loss of coolant indicates there is a

leak in the cooling system and this should be checked as soon as possible by a Hyundaidealer.

D040B01HP

D040B03HP-EAT

Handling the Spare Tyre

1. Obtain the spare wheel rod (Jack handle) after folding up the seat cushion of the rear seat . To fold up the seat cushion, refer to the page 1-15.

D060B01HPB090B02HP

Rear seat

Page 309 of 361

IN CASE OF EMERGENCY 3-7

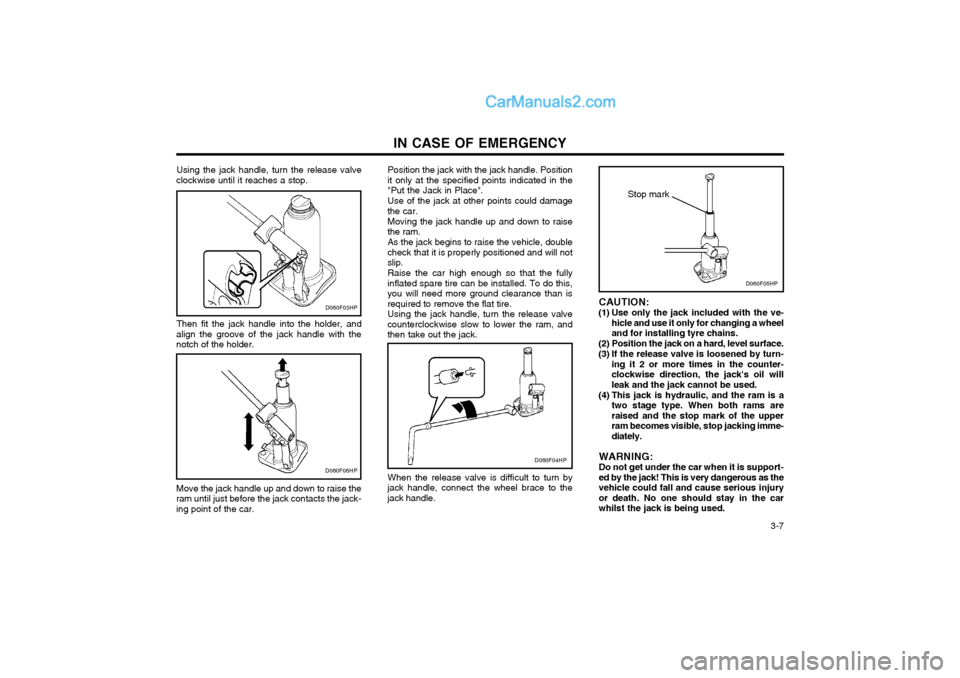

Using the jack handle, turn the release valve

clockwise until it reaches a stop.

Then fit the jack handle into the holder, and

align the groove of the jack handle with the notch of the holder.

D060F03HP

Move the jack handle up and down to raise the

ram until just before the jack contacts the jack- ing point of the car.

D060F04HP

When the release valve is difficult to turn by

jack handle, connect the wheel brace to the jack handle. CAUTION:

(1) Use only the jack included with the ve- hicle and use it only for changing a wheeland for installing tyre chains.

(2) Position the jack on a hard, level surface.

(3) If the release valve is loosened by turn- ing it 2 or more times in the counter- clockwise direction, the jack's oil willleak and the jack cannot be used.

(4) This jack is hydraulic, and the ram is a two stage type. When both rams areraised and the stop mark of the upperram becomes visible, stop jacking imme-diately.

WARNING:Do not get under the car when it is support-ed by the jack! This is very dangerous as thevehicle could fall and cause serious injuryor death. No one should stay in the carwhilst the jack is being used.

D060F05HP

D060F06HP Position the jack with the jack handle. Position

it only at the specified points indicated in the "Put the Jack in Place".

Use of the jack at other points could damage

the car.

Moving the jack handle up and down to raise

the ram.

As the jack begins to raise the vehicle, double

check that it is properly positioned and will notslip.

Raise the car high enough so that the fully

inflated spare tire can be installed. To do this,you will need more ground clearance than isrequired to remove the flat tire. Using the jack handle, turn the release valve

counterclockwise slow to lower the ram, andthen take out the jack.

Stop mark

Page 310 of 361

IN CASE OF EMERGENCY

3-8

SD070H1-E 7. Changing Wheels

Using the wheel brace, remove the nuts and

slide the wheel off the hub and wheel studs. Lie the wheel flat to prevent it from rolling. Ensurethat the faces of the wheel and hub are clean.Position the spare wheel over the studs andslide it up to the hub.

D060G01HP

SD070I1-E

8. Re-install Wheel Nuts

WARNING: It is important that the faces of the wheel

and hub are clean prior to installing the wheel. The prescence of dirt or other matter in the wheel or hub faces could result in the wheel nuts becoming loose whilst the vehi-cle is being driven.

D060I01HP

D060H01HP

D060G02HP

D060I01HP-EAT

9. Lower Vehicle and Tighten Nuts Fit the wheel nuts onto the studs and tighten with the wheel brace.

Page 322 of 361

VEHICLE MAINTENANCE REQUIREMENTS

5- 6

F060B01A-AAT

o Drive belts Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil and replace ifnecessary. Drive belts should be checkedperiodically for proper tension and adjusted asnecessary. F060C01A-AAT

o Fuel filter A clogged filter can limit the speed at which the vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replace-ment more frequently. After installing a new filter, run the engine for several minutes, and check for leaks at theconnections. Fuel filters should be installed bytrained technicians.

F060M01A-AAT o Engine oil and filterThe engine oil and filter should be changed at the intervals specified in the maintenanceschedule. If the car is being driven in severeconditions, more frequent oil and filter changesare required.

F060D01TB-AAT

o Fuel lines, fuel hoses and connec-

tions

Check the fuel lines, fuel hoses and connec-tions for leakage and damage. Have a trainedtechnician replace any damaged or leakingparts immediately.

WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds aftershutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer tothe ECU or wiring harness within theengine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields. F060E01A-AAT

o Timing beltInspect all parts related to the timing belt for damage and deformation. Replace any dam-aged parts immediately. F060G01A-EAT

o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in themaintenance schedule. Make sure that a newvapour hose or fuel filler cap is correctlyreplaced.

F060F01A-AAT

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of

heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abrasions,and excessive swelling indicate deterioration.Particular attention should be paid to examinethose hose surfaces nearest to high heatsources, such as the exhaust manifold.

Inspect the hose routing to assure that the

hoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechani-cal wear. Inspect all hose connections, suchas clamps and couplings, to make sure theyare secure, and that no leaks are present.Hoses should be replaced immediately if thereis any evidence of deterioration or damage.

F060A01A-AAT

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Page 327 of 361

OWNER MAINTENANCE 6-3

G030A01FC-EAT

ENGINE OIL

The correct engine oil level is of paramount

importance. An excessively high or low oil level may result in irreparable damage being sus-tained by the engine. The engine oil level mustbe checked on a daily basis, whenever thevehicle is refuelled or before starting a long trip,whichever occurs sooner.

In addition, it is imperative that only an ap-

proved grade and specification of oil is used toavoid the possibility of serious engine damageand premature wear. The use of "budget price"oil is a false economy that must be avoided ifthe maximum reliability and useful life is to beobtained from the vehicle.

SG020B1-E

DAILY OPERATING CHECKS The following items should be checked on a

daily basis or whenever the vehicle is refuelled,whichever occurs sooner.

o Engine oil level.

o Coolant level.

o Power steering fluid level.

o Brake fluid level.

o Windscreen washer fluid level.

o Battery condition.

o Tyre condition and pressures.

o Operation and cleanliness of all lighting equipment.

o Windscreen wiper and washer operation.

o Horn operation.

o Warning light operation.

o Adjustment and cleanliness of mirrors.

o Seat and seat belt adjustment and opera- tion.

o Fluid leakage.

The vehicle must not be driven if the daily

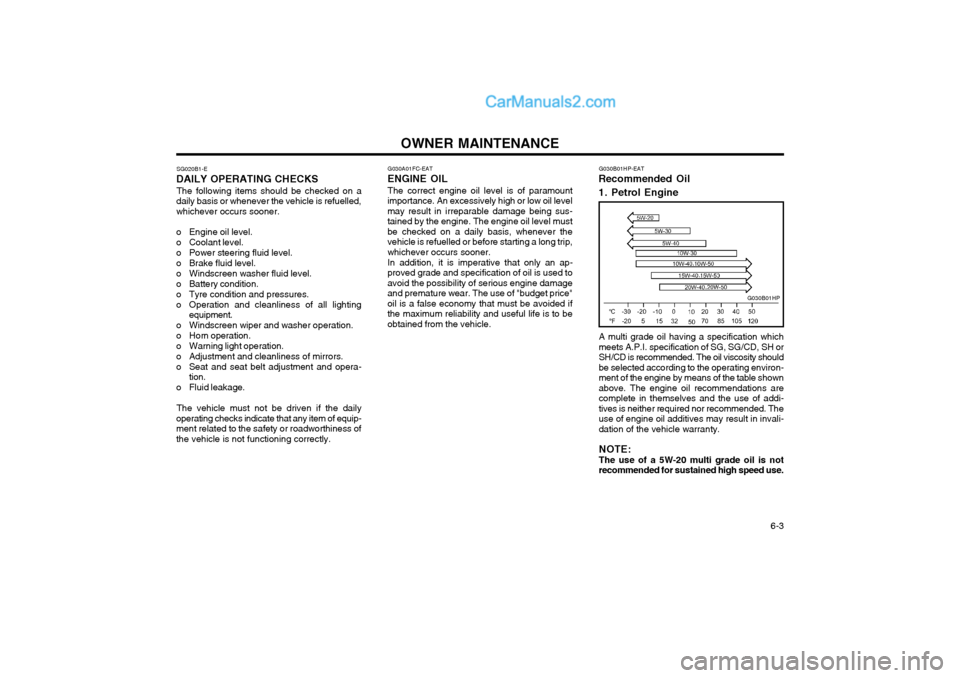

operating checks indicate that any item of equip-ment related to the safety or roadworthiness ofthe vehicle is not functioning correctly. G030B01HP-EAT

Recommended Oil

1. Petrol Engine

A multi grade oil having a specification which

meets A.P.I. specification of SG, SG/CD, SH or SH/CD is recommended. The oil viscosity shouldbe selected according to the operating environ-ment of the engine by means of the table shownabove. The engine oil recommendations arecomplete in themselves and the use of addi-tives is neither required nor recommended. Theuse of engine oil additives may result in invali-dation of the vehicle warranty.

NOTE:The use of a 5W-20 multi grade oil is not

recommended for sustained high speed use.

G030B01HP

Page 330 of 361

OWNER MAINTENANCE

6-6

To replace the oil and filter, proceed as follows:

1. Ensure that the engine is at normal operat- ing temperature and park the vehicle on level ground with the parking brake securelyapplied and the engine turned off.

2. Open the bonnet and remove the oil filler cap.

3. Prepare a suitable receptacle to collect the displaced oil and remove the drain plug fromthe sump.

CAUTION: The oil being drained from the engine will be

hot. Care should be exercised to prevent scalding.

4. When the oil has drained from the sump, replace the drain plug using a new washer ensuring that the plug is not over tightened. Tightening torque is: 3.5 ~ 4.5 kgf.m

5. Remove the oil filter by rotating counter- clockwise, using a proprietary oil filter re- moval tool if necessary. Note that the oilfilter will contain approximately 0.5 litres ofoil and this should be collected in a suitablereceptacle.

6. Install a new oil filter having smeared the sealing ring with clean oil and rotating clock-wise until the filter contacts the mountingand then a further one half turn. Do not over-tighten. Tightening torque: Petrol Engine - 1.2 ~ 1.6 kgf.mDiesel Engine - 2.3 ~ 2.5 kgf.m

7. Pour the specified quantity of the recom- mended oil into the engine and replace the filler cap. Start the engine and ensure thatno oil leaks exist. Turn off the engine andafter a couple minutes, recheck the oil level.

WARNING: Prolonged and repeated contact with used engine oils may result in serious skin disor-ders including dermatitis and cancer. Avoidcontact with skin as far as possible andalways wash thoroughly after any contact.Keep used oils out of reach of children. It isillegal to pollute drains, water courses andsoil. Use only authorized waste collectionfacilities including civic amenity sites andgarages for the disposal of used oil and oilfilters. If in doubt, contact the local authorityfor disposal instructions. SG050A1-E

ENGINE COOLANT CHECKING AND REPLACING

WARNING: Do not remove the radiator cap when the engine is hot, since the system is pressur-ized and coolant may be ejected from theradiator resulting in scalding. SG050B1-E

Coolant recommendations Only ethylene glycol based coolant with a cor- rosion inhibitor suited to aluminium alloy enginecomponents should be used in the coolingsystem. No further additives or inhibitors shouldbe used. The coolant specific gravity should bechecked as prescribed in the maintenanceschedule to ensure adequate frost and corro-sion protection. In addition, the engine coolantmust be replaced at the specified interval sincethe corrosion inhibitor properties deteriorate withtime. It is important to note that whilst an increase in the concentration of anti freeze gives an in-crease in the level of frost protection, a solutionwhich is in excess of 65% anti freeze will resultin reduced frost protection and engine over-heating. Therefore the recommended concen-tration of 50% should not be exceeded forgeneral use.The use of methanol based anti freeze com-pounds may result in engine overheating andwill invalidate the vehicle warranty.

Page 332 of 361

OWNER MAINTENANCE

6-8

G050D03HP

4. When the engine coolant has drained com- pletely, close the drain tap ensuring that this is not over tightened.

5. Prepare a suitable quantity of new engine coolant (refer to section 9) and pour this intothe radiator. 6. Start the engine with the radiator cap still

removed and continue to add coolant as thelevel decreases as air is expelled from thesystem. When the level remains constant,replace the radiator cap and replenish thecoolant reservoir.

7. When the engine is hot, check to ensure that no coolant leaks are present.

WARNING:The cooling fan is controlled by engine cool-

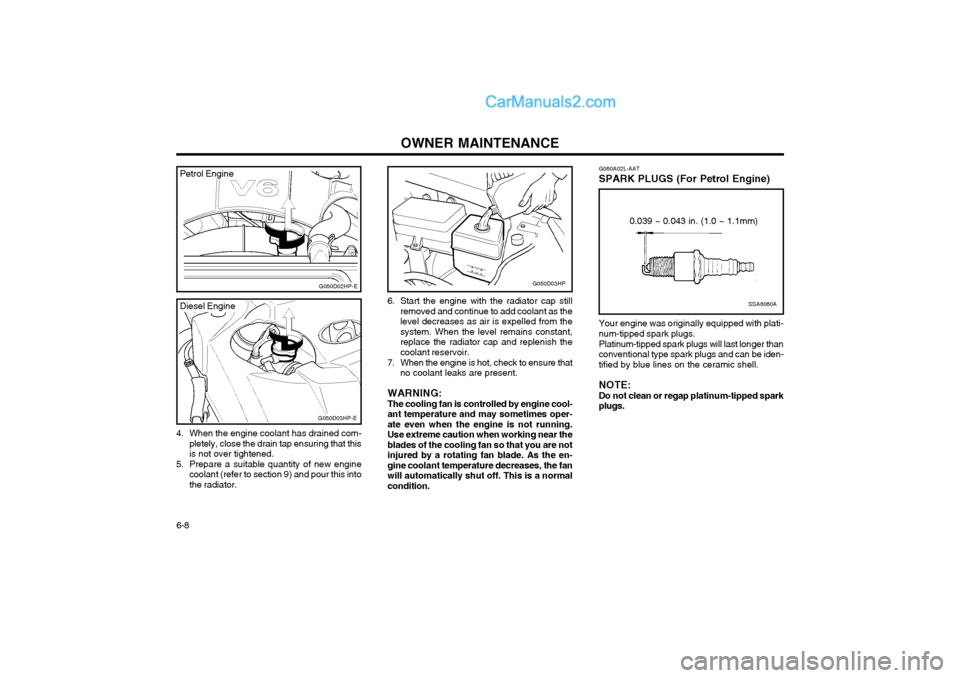

ant temperature and may sometimes oper-ate even when the engine is not running.Use extreme caution when working near theblades of the cooling fan so that you are notinjured by a rotating fan blade. As the en-gine coolant temperature decreases, the fanwill automatically shut off. This is a normalcondition. G060A02L-AAT SPARK PLUGS (For Petrol Engine)

SSA6060A

0.039 ~ 0.043 in. (1.0 ~ 1.1mm)

Your engine was originally equipped with plati- num-tipped spark plugs. Platinum-tipped spark plugs will last longer than conventional type spark plugs and can be iden-tified by blue lines on the ceramic shell. NOTE: Do not clean or regap platinum-tipped spark plugs.

G050D03HP-E

Diesel Engine

G050D02HP-E

Petrol Engine