Fuel filter Hyundai Terracan 2004 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Terracan, Model: Hyundai Terracan 2004Pages: 361, PDF Size: 4.69 MB

Page 174 of 361

DO-IT-YOURSELF MAINTENANCE

6-22

G350B01HP-GAT

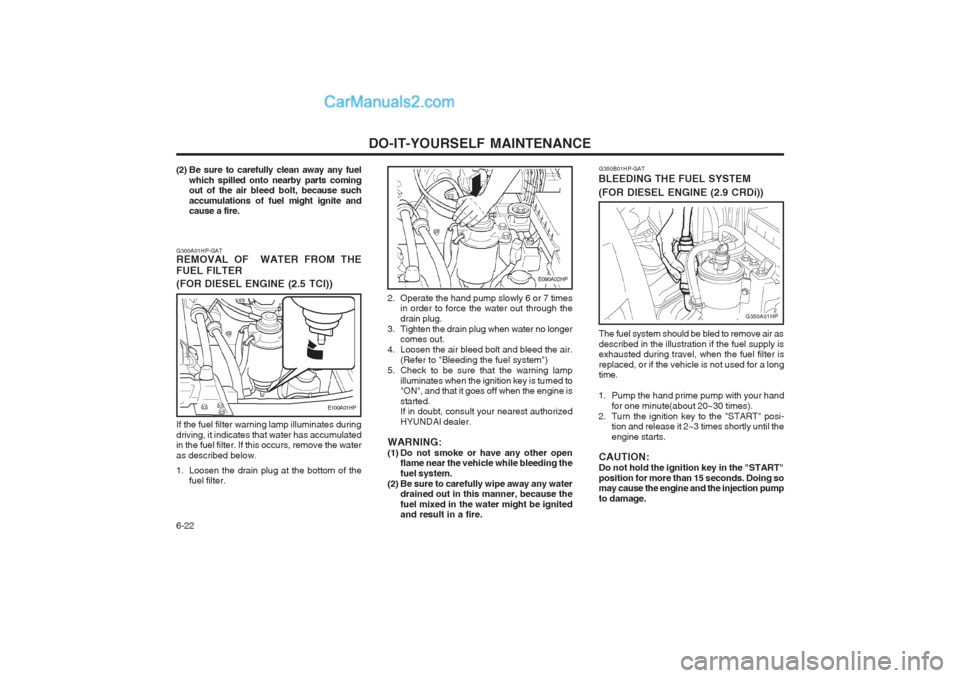

BLEEDING THE FUEL SYSTEM

(FOR DIESEL ENGINE (2.9 CRDi))

The fuel system should be bled to remove air as described in the illustration if the fuel supply is exhausted during travel, when the fuel filter is replaced, or if the vehicle is not used for a long time.

1. Pump the hand prime pump with your hand for one minute(about 20~30 times).

2. Turn the ignition key to the "START" posi- tion and release it 2~3 times shortly until the engine starts.

CAUTION:Do not hold the ignition key in the "START"position for more than 15 seconds. Doing so may cause the engine and the injection pump to damage.

G350A01HP

E090A02HP

2. Operate the hand pump slowly 6 or 7 times in order to force the water out through the drain plug.

3. Tighten the drain plug when water no longer comes out.

4. Loosen the air bleed bolt and bleed the air. (Refer to "Bleeding the fuel system")

5. Check to be sure that the warning lamp

illuminates when the ignition key is turned to "ON", and that it goes off when the engine is started. If in doubt, consult your nearest authorized HYUNDAI dealer.

WARNING:

(1) Do not smoke or have any other open flame near the vehicle while bleeding thefuel system.

(2) Be sure to carefully wipe away any water drained out in this manner, because thefuel mixed in the water might be ignited and result in a fire.

G300A01HP-GATREMOVAL OF WATER FROM THE FUEL FILTER (FOR DIESEL ENGINE (2.5 TCI))

E100A01HP

If the fuel filter warning lamp illuminates during driving, it indicates that water has accumulated in the fuel filter. If this occurs, remove the water as described below.

1. Loosen the drain plug at the bottom of the fuel filter.

(2) Be sure to carefully clean away any fuel

which spilled onto nearby parts coming out of the air bleed bolt, because such

accumulations of fuel might ignite andcause a fire.

Page 175 of 361

DO-IT-YOURSELF MAINTENANCE 6-23

G260A01HP-GAT

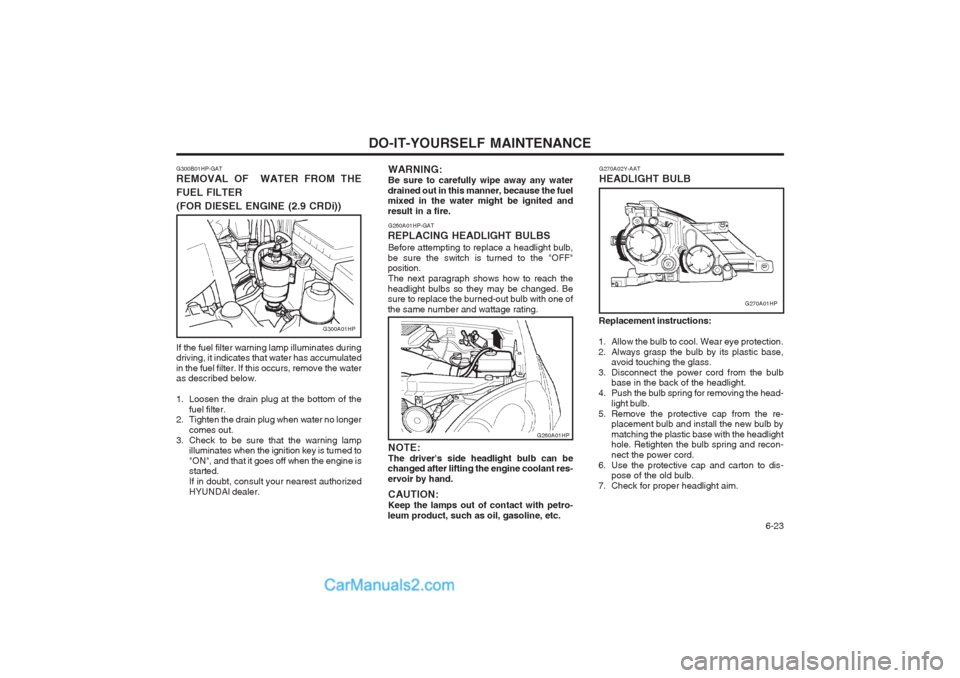

REPLACING HEADLIGHT BULBS Before attempting to replace a headlight bulb,

be sure the switch is turned to the "OFF" position. The next paragraph shows how to reach the

headlight bulbs so they may be changed. Besure to replace the burned-out bulb with one of the same number and wattage rating. WARNING:Be sure to carefully wipe away any water

drained out in this manner, because the fuel mixed in the water might be ignited and result in a fire.

NOTE:The driver's side headlight bulb can be

changed after lifting the engine coolant res-ervoir by hand.

CAUTION:Keep the lamps out of contact with petro-

leum product, such as oil, gasoline, etc.

G260A01HP Replacement instructions:

1. Allow the bulb to cool. Wear eye protection.

2. Always grasp the bulb by its plastic base, avoid touching the glass.

3. Disconnect the power cord from the bulb base in the back of the headlight.

4. Push the bulb spring for removing the head-

light bulb.

5. Remove the protective cap from the re- placement bulb and install the new bulb bymatching the plastic base with the headlight hole. Retighten the bulb spring and recon- nect the power cord.

6. Use the protective cap and carton to dis- pose of the old bulb.

7. Check for proper headlight aim. G270A02Y-AAT HEADLIGHT BULB

G270A01HP

G300B01HP-GAT REMOVAL OF WATER FROM THE FUEL FILTER

(FOR DIESEL ENGINE (2.9 CRDi))

G300A01HP

If the fuel filter warning lamp illuminates during driving, it indicates that water has accumulated in the fuel filter. If this occurs, remove the water as described below.

1. Loosen the drain plug at the bottom of the fuel filter.

2. Tighten the drain plug when water no longer

comes out.

3. Check to be sure that the warning lamp illuminates when the ignition key is turned to "ON", and that it goes off when the engine is started. If in doubt, consult your nearest authorizedHYUNDAI dealer.

Page 179 of 361

EMISSION CONTROL SYSTEMS 7-1

7. EMISSION

CONTROL SYSTEMS

H010A01A-GAT EMISSION CONTROL SYSTEMS (If installed) Your Hyundai is equipped with an emission control system to meet all requirements of the Emission prohibition rules of your province. There are three emission control systems which are as follows. (1) Crankcase emission control system (For a Gasoline Engine)

(2) Evaporative emission control system (For a Gasoline Engine)

(3) Exhaust emission control system In order to assure the proper function of the emission control systems, it is recommended that you have your car inspected and main- tained by an authorized Hyundai dealer in ac- cordance with the maintenance schedule in this manual. H010C02Y-GAT 2. Evaporative Emission Control

System; For a Gasoline Engine

The Evaporative Emission Control System is

designed to prevent fuel vapors from escaping into the atmosphere. Canister While the engine is inoperative, fuel vapors

generated inside the fuel tank are absorbed and stored in the canister. When the engine is

running, the fuel vapors absorbed in the canis- ter are drawn into the induction system through the purge control solenoid valve. Purge Control Solenoid Valve The purge control solenoid valve is controlled

by the ECM; when the engine coolant tempera- ture is low, and during idling, it closes, so that evaporated fuel is not taken into the surge tank.

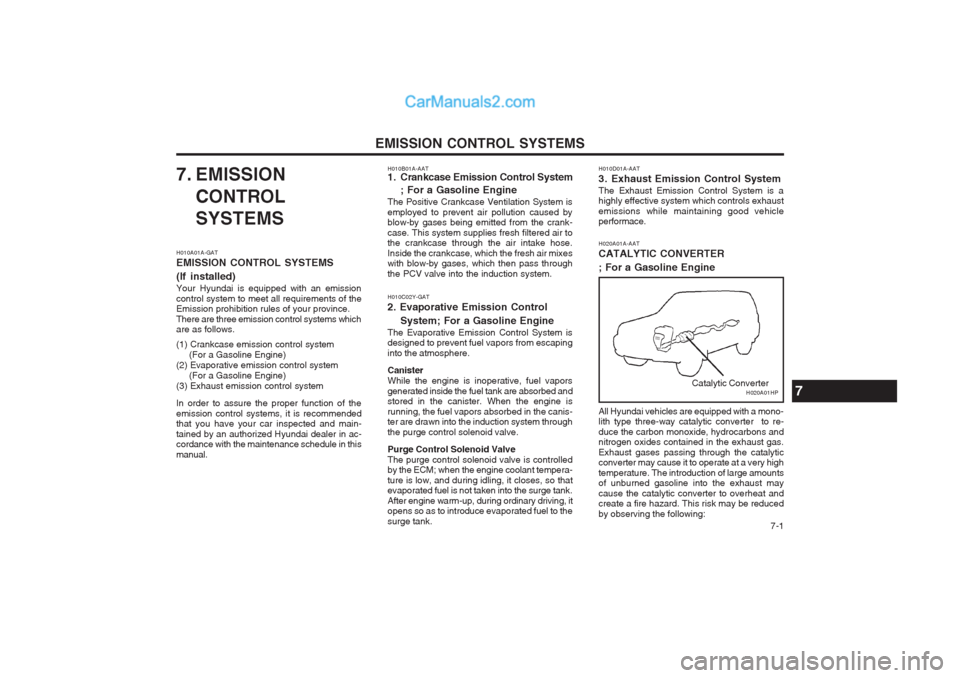

After engine warm-up, during ordinary driving, it opens so as to introduce evaporated fuel to the surge tank. H020A01A-AAT CATALYTIC CONVERTER ; For a Gasoline Engine

H020A01HP

Catalytic Converter

All Hyundai vehicles are equipped with a mono- lith type three-way catalytic converter to re- duce the carbon monoxide, hydrocarbons and nitrogen oxides contained in the exhaust gas. Exhaust gases passing through the catalytic converter may cause it to operate at a very high temperature. The introduction of large amounts of unburned gasoline into the exhaust may cause the catalytic converter to overheat and create a fire hazard. This risk may be reduced by observing the following:

H010B01A-AAT

1. Crankcase Emission Control System

; For a Gasoline Engine

The Positive Crankcase Ventilation System is employed to prevent air pollution caused by blow-by gases being emitted from the crank- case. This system supplies fresh filtered air to the crankcase through the air intake hose. Inside the crankcase, which the fresh air mixes with blow-by gases, which then pass through the PCV valve into the induction system.7

H010D01A-AAT

3. Exhaust Emission Control SystemThe Exhaust Emission Control System is a highly effective system which controls exhaust emissions while maintaining good vehicle performace.

Page 237 of 361

CONTROLS AND EQUIPMENT1- 37

B260A03HP-E

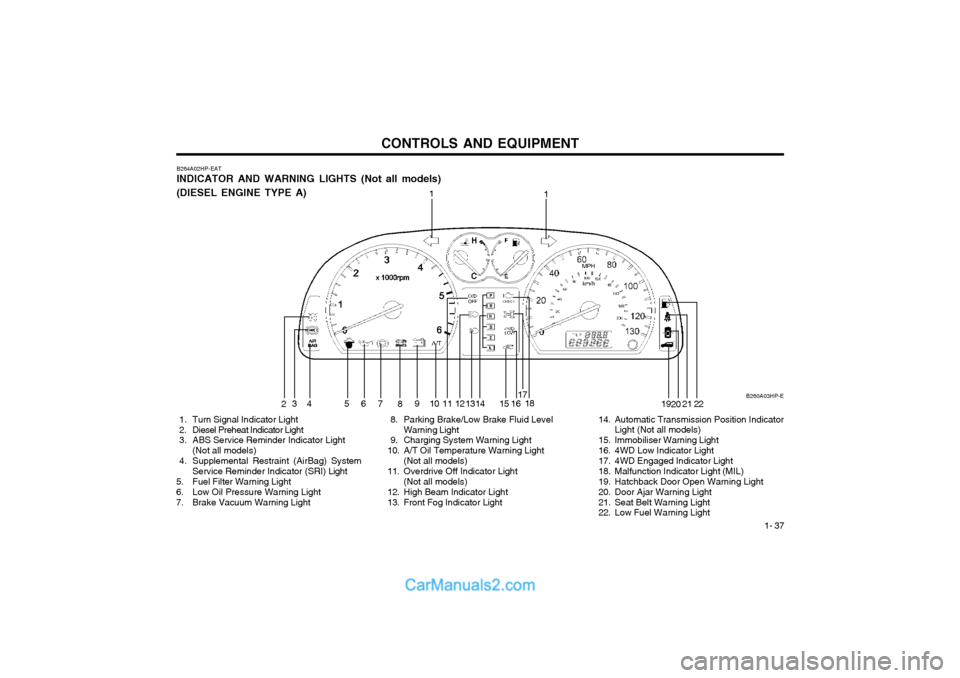

B264A02HP-EAT INDICATOR AND WARNING LIGHTS (Not all models) (DIESEL ENGINE TYPE A)

1

2 34 5 6

7

8910111213 15 17

18 192021

1

22

1416

1. Turn Signal Indicator Light

2. Diesel Preheat Indicator Light

3. ABS Service Reminder Indicator Light(Not all models)

4. Supplemental Restraint (AirBag) System Service Reminder Indicator (SRI) Light

5. Fuel Filter Warning Light

6. Low Oil Pressure Warning Light

7. Brake Vacuum Warning Light 8. Parking Brake/Low Brake Fluid Level

Warning Light

9. Charging System Warning Light

10. A/T Oil Temperature Warning Light

(Not all models)

11. Overdrive Off Indicator Light (Not all models)

12. High Beam Indicator Light

13. Front Fog Indicator Light 14. Automatic Transmission Position Indicator

Light (Not all models)

15. Immobiliser Warning Light

16. 4WD Low Indicator Light

17. 4WD Engaged Indicator Light

18. Malfunction Indicator Light (MIL)

19. Hatchback Door Open Warning Light

20. Door Ajar Warning Light

21. Seat Belt Warning Light

22. Low Fuel Warning Light

Page 239 of 361

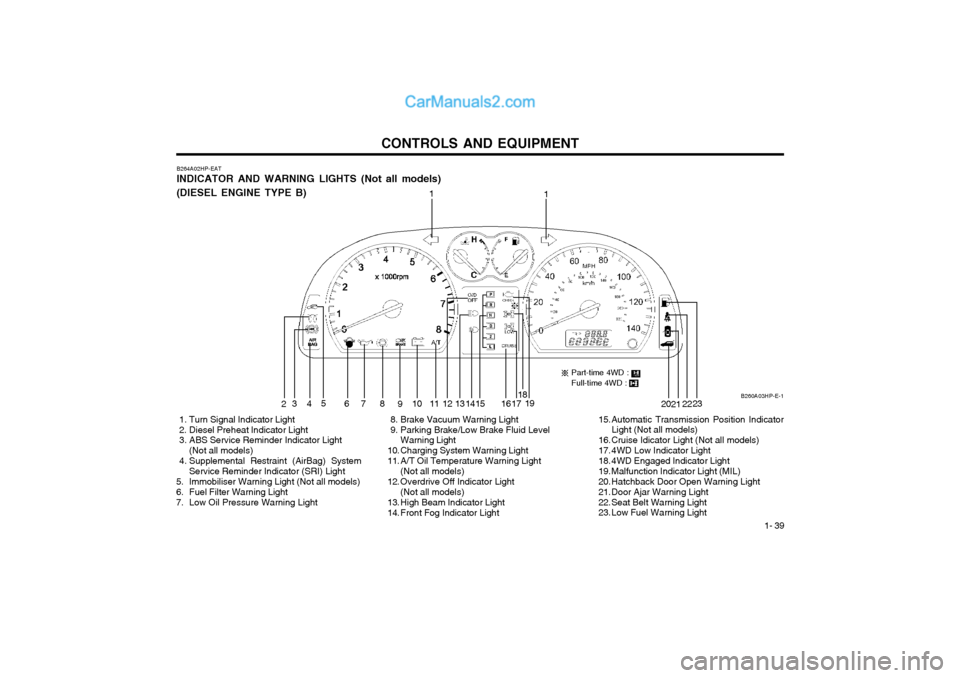

CONTROLS AND EQUIPMENT1- 39

B260A03HP-E-1

B264A02HP-EAT INDICATOR AND WARNING LIGHTS (Not all models) (DIESEL ENGINE TYPE B)

1

2 34 6 7

8

910 11 12 13 14 17 18

19 202122

1

1516

1. Turn Signal Indicator Light

2. Diesel Preheat Indicator Light

3. ABS Service Reminder Indicator Light

(Not all models)

4. Supplemental Restraint (AirBag) System Service Reminder Indicator (SRI) Light

5. Immobiliser Warning Light (Not all models)

6. Fuel Filter Warning Light

7. Low Oil Pressure Warning Light 8. Brake Vacuum Warning Light

9. Parking Brake/Low Brake Fluid Level

Warning Light

10. Charging System Warning Light

11. A/T Oil Temperature Warning Light (Not all models)

12. Overdrive Off Indicator Light (Not all models)

13. High Beam Indicator Light

14. Front Fog Indicator Light 15. Automatic Transmission Position Indicator

Light (Not all models)

16. Cruise Idicator Light (Not all models)

17. 4WD Low Indicator Light

18. 4WD Engaged Indicator Light

19. Malfunction Indicator Light (MIL)

20. Hatchback Door Open Warning Light

21. Door Ajar Warning Light

22. Seat Belt Warning Light

23. Low Fuel Warning Light

5 23

Part-time 4WD : Full-time 4WD :

Page 243 of 361

CONTROLS AND EQUIPMENT1- 43

B270A01A-EAT BRAKE PAD WEAR WARNING SOUND (Not all models) The front disc brake pads have wear indicators

that should make a high-pitched squealing or scraping noise when new pads are needed.The sound may come and go or be heard all thetime when the vehicle is moving. It may also beheard when the brake pedal is pushed downfirmly. Excessive rotor damage will result if theworn pads are not replaced. See your Hyundaidealer immediately. NOTE: If the engine were not started within 2 sec-

onds after the preheating is completed, turn the ignition key once more to the "LOCK"position during 10 seconds, and then to the"ON" position, in order to preheat again.

it to a complete stop in a safe location off theroadway.

After starting the engine, do not drive the vehi-

cle until the vacuum level is above 275 mmHgbelow atmosphere and warning light has turnedoff. If further trouble is experienced, the vehicleshould not be driven at all but taken to a dealerby a professional towing service. B265C02HP-EAT

Diesel Preheat Indication Light-amber

The indication light illuminates amber when the ignition switch is placed at the "ON" position.The engine can be started after the preheatindication light goes off. The illuminating timevaries with the water temperature.

B265A01B-EAT Fuel Filter Warning Light(Diesel Engine)

This light illuminates when the ignition switch is set to the "ON" position and goes off after theengine has started. If it lights up whilst theengine is running, it indicates that water hasaccumulated inside the fuel filter. If this hap-pens, remove the water from the fuel filter. (Refer to "Owner Maintenance") B265B01HP-GAT Brake Vacuum Warning Light(Diesel Engine)

WARNING:

If you suspect brake trouble, have your brakes checked by a Hyundai dealer as soon aspossible. Driving your car with a problem ineither the brake electrical system or brakehydraulic system is dangerous, and couldresult in serious injury or death.

The brake vacuum warning light should come onwhen the vacuum level in brake booster de-scends to about 275 mmHg or below. The brakesystem is designed to stop the vehicle withreserve assist if brake pedal is held down. Thisreserve is greatly reduced each time you releasethe brake. Without vacuum assist your vehiclecan still be stopped by pushing much harder onbrake pedal, however the stopping distance maybe much longer. If the light comes on at anyother time, you should slow the vehicle and bring

Water temperature (°F)(°C)

Below -22(-30)

-13(-25)-4(-20)

5(-15)

14(-10) 23(-5)32(0)

68(20) Illuminating time

(sec.)

26 201510

5.53.5 20

Page 318 of 361

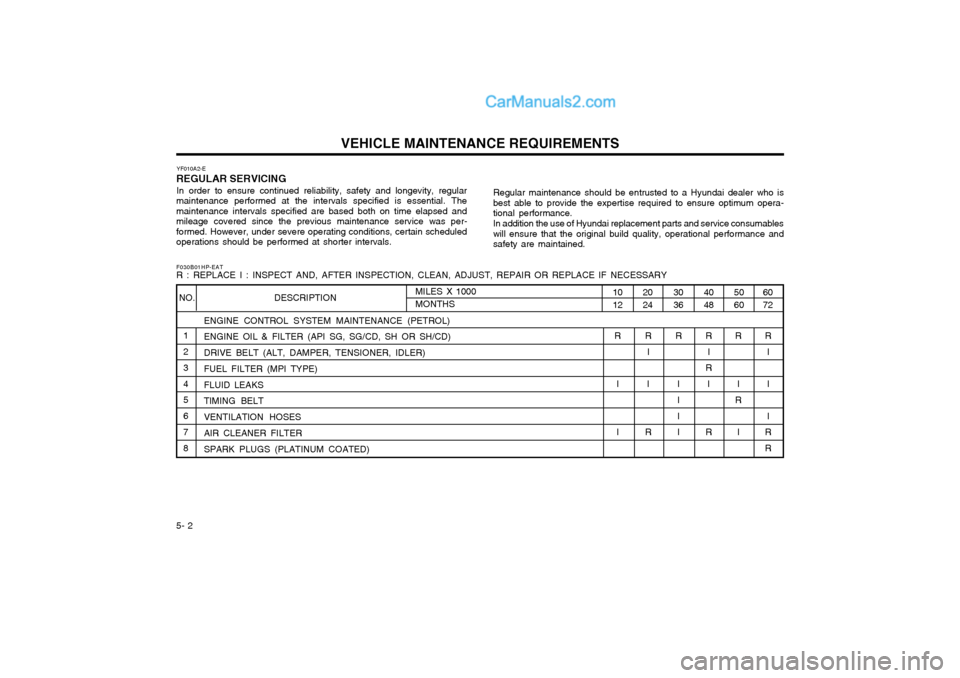

VEHICLE MAINTENANCE REQUIREMENTS

5- 2 YF010A2-E

REGULAR SERVICING

In order to ensure continued reliability, safety and longevity, regular

maintenance performed at the intervals specified is essential. The maintenance intervals specified are based both on time elapsed andmileage covered since the previous maintenance service was per-formed. However, under severe operating conditions, certain scheduledoperations should be performed at shorter intervals. Regular maintenance should be entrusted to a Hyundai dealer who is

best able to provide the expertise required to ensure optimum opera-tional performance.

In addition the use of Hyundai replacement parts and service consumables

will ensure that the original build quality, operational performance andsafety are maintained.

F030B01HP-EAT R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

ENGINE CONTROL SYSTEM MAINTENANCE (PETROL) ENGINE OIL & FILTER (API SG, SG/CD, SH OR SH/CD) DRIVE BELT (ALT, DAMPER, TENSIONER, IDLER) FUEL FILTER (MPI TYPE) FLUID LEAKS TIMING BELT VENTILATION HOSES AIR CLEANER FILTER SPARK PLUGS (PLATINUM COATED)

NO. DESCRIPTION60 72

5060

4048

3036

2024

1012

MILES X 1000 MONTHS

R

I I

l

R R

R

I

R

I

R

l

R

I

R

R

I I I I

R

l

I

R

R

I I1 2 3 4 5 6 7 8

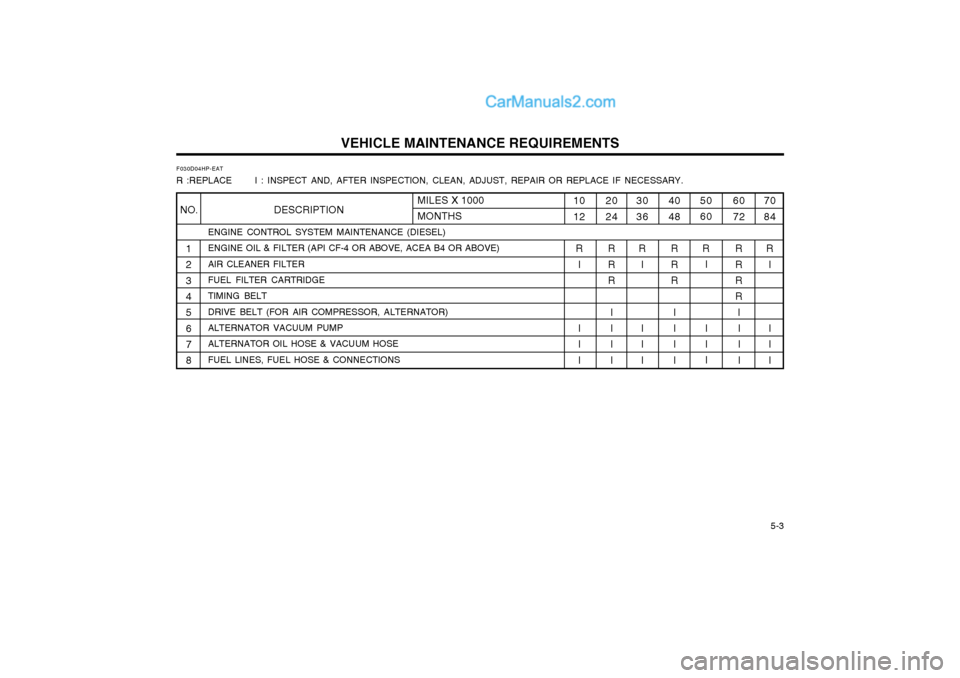

Page 319 of 361

VEHICLE MAINTENANCE REQUIREMENTS 5-3

F030D04HP-EAT R :REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL) ENGINE OIL & FILTER (API CF-4 OR ABOVE, ACEA B4 OR ABOVE) AIR CLEANER FILTERFUEL FILTER CARTRIDGE TIMING BELT DRIVE BELT (FOR AIR COMPRESSOR, ALTERNATOR)ALTERNATOR VACUUM PUMP ALTERNATOR OIL HOSE & VACUUM HOSE FUEL LINES, FUEL HOSE & CONNECTIONS

1 23 4 56 7 8

6072

RRR R l I I I

50 60

R I I I I40 48

RRR II I I20 24RRR II I IMILES X 1000 MONTHS70 84R I I I INO. DESCRIPTION 10 12

R I I I I 3036

R I I I I

Page 322 of 361

VEHICLE MAINTENANCE REQUIREMENTS

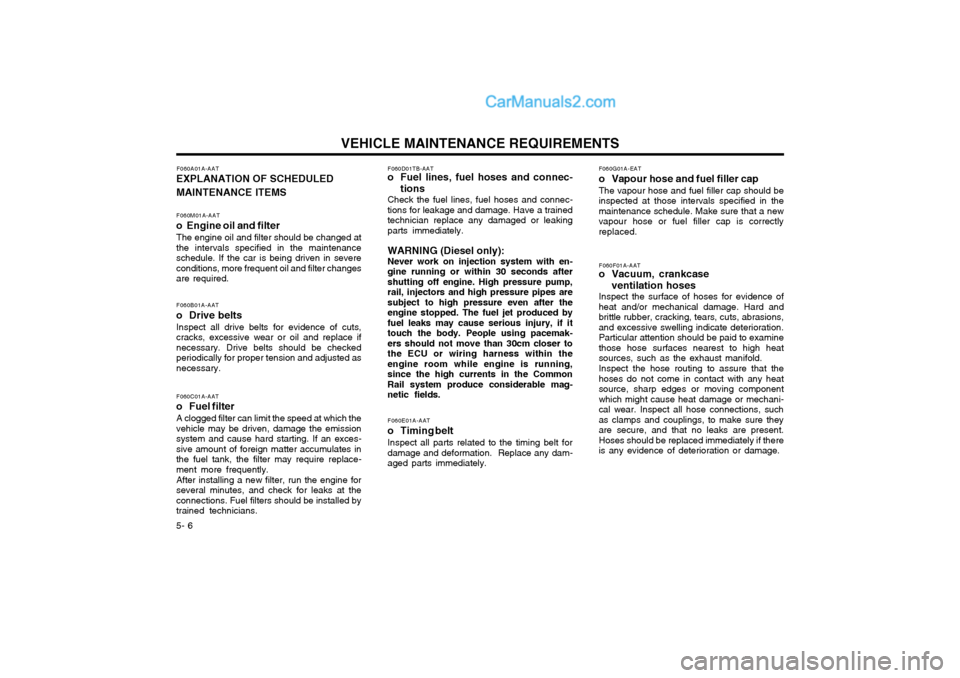

5- 6

F060B01A-AAT

o Drive belts Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil and replace ifnecessary. Drive belts should be checkedperiodically for proper tension and adjusted asnecessary. F060C01A-AAT

o Fuel filter A clogged filter can limit the speed at which the vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replace-ment more frequently. After installing a new filter, run the engine for several minutes, and check for leaks at theconnections. Fuel filters should be installed bytrained technicians.

F060M01A-AAT o Engine oil and filterThe engine oil and filter should be changed at the intervals specified in the maintenanceschedule. If the car is being driven in severeconditions, more frequent oil and filter changesare required.

F060D01TB-AAT

o Fuel lines, fuel hoses and connec-

tions

Check the fuel lines, fuel hoses and connec-tions for leakage and damage. Have a trainedtechnician replace any damaged or leakingparts immediately.

WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds aftershutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer tothe ECU or wiring harness within theengine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields. F060E01A-AAT

o Timing beltInspect all parts related to the timing belt for damage and deformation. Replace any dam-aged parts immediately. F060G01A-EAT

o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in themaintenance schedule. Make sure that a newvapour hose or fuel filler cap is correctlyreplaced.

F060F01A-AAT

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of

heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abrasions,and excessive swelling indicate deterioration.Particular attention should be paid to examinethose hose surfaces nearest to high heatsources, such as the exhaust manifold.

Inspect the hose routing to assure that the

hoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechani-cal wear. Inspect all hose connections, suchas clamps and couplings, to make sure theyare secure, and that no leaks are present.Hoses should be replaced immediately if thereis any evidence of deterioration or damage.

F060A01A-AAT

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Page 326 of 361

OWNER MAINTENANCE

6-2

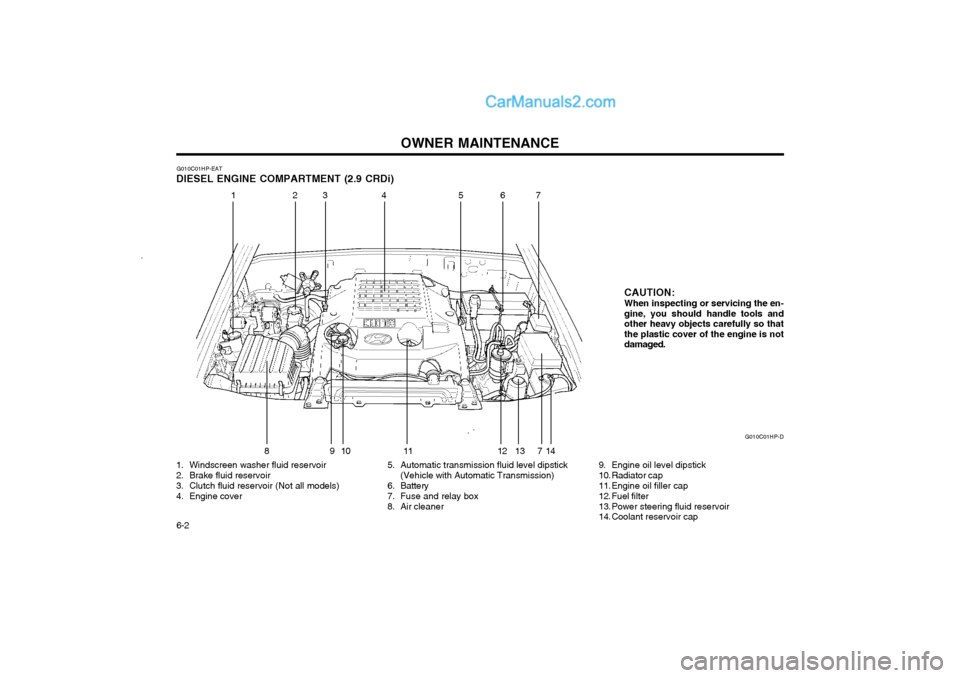

G010C01HP-EAT

DIESEL ENGINE COMPARTMENT (2.9 CRDi)

1. Windscreen washer fluid reservoir

2. Brake fluid reservoir

3. Clutch fluid reservoir (Not all models)

4. Engine cover 5. Automatic transmission fluid level dipstick

(Vehicle with Automatic Transmission)

6. Battery

7. Fuse and relay box

8. Air cleaner 9. Engine oil level dipstick

10. Radiator cap

11. Engine oil filler cap

12. Fuel filter

13. Power steering fluid reservoir

14. Coolant reservoir capG010C01HP-D

CAUTION: When inspecting or servicing the en- gine, you should handle tools andother heavy objects carefully so thatthe plastic cover of the engine is notdamaged.

12

34 56

8 9 10 11 12 7 137

14