check engine Hyundai Terracan 2004 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Terracan, Model: Hyundai Terracan 2004Pages: 361, PDF Size: 4.69 MB

Page 302 of 361

DRIVING YOUR HYUNDAI 2- 19

CAUTION: If overheating should occur when towing,

(temperature gauge reads near red zone), taking the following action may reduce oreliminate the problem.

1. Turn off the air conditioner.

2. Reduce highway speed.

3. Select a lower gear when going uphill.

4. Whilst in stop and go traffic, place the gear selector in park or neutral and idle the engine at a higher speed.

HPC200E1-E

Trailer or Vehicle Towing Tips

1. Before towing, check towbar and safety cable connections as well as proper operation of the trailer running lights, brake lights, andturn signals.

2. Always drive your vehicle at a moderate speed (Less than 60 mph)

3. Trailer towing requires more fuel than nor- mal conditions.

4. To maintain engine braking efficiency and electrical charging performance, do not usefifth gear (manual transmission).

5. Always secure items in the trailer to prevent load shift whilst driving.

6. Check the condition and air pressure of all tyres on the trailer and your car. Low tyrepressure can seriously affect the handling.Also check the spare tyre.

7. The vehicle/trailer combination is more af- fected by crosswind and buffeting. When being passed by a large vehicle, keep a constant speed and steer straight ahead.If there is too much wind buffeting slowdown to get out of the other vehicle's airturbulence.

8. When parking your car and trailer, especial- ly on a hill, be sure to follow all the normalprecautions. Turn your front wheel into thecurb, set the parking brake firmly, and putthe transmission in 1st or Reverse (manual)or Park (automatic). In addition, place wheelchocks at each of the trailer's tyres. 9. If the trailer has electric brakes, start your

vehicle and trailer moving, and then applythe trailer brake controller by hand to besure the brakes are working. This lets youcheck your electrical connection at the sametime.

10. During your trip, check occasionally to be sure that the load is secure, and that thelights and any trailer brakes are still working.

11. Avoid jerky starts, sudden acceleration or sudden stops.

12. Avoid sharp turns and rapid lane changes.

13. Avoid holding the brake pedal down too long or too frequently. This could cause the brakes to overheat, resulting in reduced brakingefficiency.

14. When going down a hill, shift into a lower gear and use the engine braking effect. When ascending a long grade, downshift the transmission to a lower gear and reducespeed to reduce chances of engine over-loading and/or overheating.

15. If you have to stop whilst going uphill, do not hold the vehicle in place by pressing on theaccelerator. This can cause the automatictransmission to overheat. Use the parkingbrake or footbrake.

NOTE: When towing, check transmission fluid more

frequently.

Page 303 of 361

IN CASE OF EMERGENCY 3-1

ZD000A1-A

3. IN CASE OF EMER-

GENCY

D010A01A-EAT

If Engine Stalls Whilst Driving

1. Reduce your speed gradually, keeping a straight line. Move cautiously off the road to a safe place.

2. Turn on your emergency flashers.

3. Try starting the engine again. If your vehicle will not start, contact Hyundai dealer or seek other qualified assistance.

SD020A1-E

IF THE ENGINE WILL NOT START Seek assistance from the nearest Hyundai dealer with regard to the method of ignition and fuelsystem diagnosis.

CAUTION: If the engine refuses to start, no attempt

should be made to push or tow start the vehicle. Vehicles with automatic transmis- sion or fuel injection will not be able to be started in this manner since no drive istransmitted through the automatic trans-mission whilst the engine is not running,and in the case of fuel injected derivatives,the fuel pump will not operate under towstart conditions. In addition, if the vehicle isequipped with an exhaust catalyst, damageto the catalyst may result if the vehicle istow started. HPD020B1-E

IF THE ENGINE CANNOT BE

CRANKED

1. If the vehicle is fitted with manual transmis- sion, ensure that the clutch pedal is de-

pressed whilst cranking the engine. If thevehicle is fitted with automatic transmission,ensure that the transmission selector is atthe "P" or"N" position.

2. Check the battery terminals and connec- tions to ensure that these are clean and alsotight.

3. If the ignition warning lights dim when the engine is cranked and the battery terminalshave been checked, a discharged battery isindicated.

4. Do not attempt to push or tow start the vehicle, refer to "Jump Starting" for informa-tion regarding engine starting when the bat-tery is discharged.

G210A01HP.DAG

3

D010C02A-EAT

If Engine Turns Over Normally but Does Not Start

1. Check fuel level.

2. With the key in the "OFF" position, check all connectors at ignition coils and spark plugs(For Petrol Engine) or check all con-nectors at glow plug and glow plug relay(ForDiesel Engine). Reconnect any that may bedisconnected or loose.

3. Check fuel line in the engine compartment.

4. If engine still refuses to start, call a Hyundai dealer or seek other qualified assistance.

Page 304 of 361

IN CASE OF EMERGENCY

3-2

CAUTION:

Personal injury and damage to the vehicle

may occur if jump starting is not performed correctly. If any doubt exists as to how thisoperation should be performed, seek assis-tance from qualified personnel. WARNING:

Motor vehicle batteries contain sulphuric

acid and emit hydrogen gas. Protective cloth- ing should be worn and care exercised toprevent the acid from coming into contactwith skin or clothing and the vehicle. Nakedlights should not be permitted in the vicinityof the battery. Care should be exercised toprevent sparks occurring during connec-tion. If acid accidentally comes into contactwith skin or eyes, the affected area shouldimmediately be flushed with copious CAUTION: If the jump cable is incorrectly installed, damage to the vehicle electrical system mayoccur, in particular the electronic compo-nents such as the Fuel Injection system

computer and the Automatic Transmissioncomputer. The battery must never be dis-connected whilst the engine is running.

SD030A1-E JUMP STARTING

amounts of water and medical assistance sought.

1. Ensure that the booster battery is 12 volt type. If the booster battery is installed inanother vehicle, ensure that the two vehi-cles are not touching.

2. Turn off all unnecessary electrical equip- ment in both vehicles.

3. Ensure that the engine of the vehicle provid- ing the jump start is running prior to connec-tion of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the booster battery and theother end to the positive (+) terminal of thedis-charged battery.

5. Attach the black jump cable to the negative (-) terminal of the booster battery, and theother end to a ground point within the enginecompartment of the vehicle with the flat bat-tery. Do not connect to the negative batteryterminal of the flat battery since sparks maybe generated with the subsequent risk ofexplosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start the engine of thevehicle with the flat battery.

7. Switch "ON" the main beam headlamps before carefully removing the jumper cablesin the reverse order of attachment. Oncethe jumper cables have been removed,switch "OFF" the main beam headlamps. HPD040A2-E IF THE ENGINE OVERHEATS If the temperature gauge indicates overheating:

1. Pull off the road and stop as soon as it is

safe to do so.

2. Place the gear selector lever in "P" (auto- matic), or neutral (manual transmission) and set the parking brake. If the air conditioningis on, turn it off.

3. If coolant is running out under the car or steam is coming out from under the bonnetstop the engine. Do not open the bonnetuntil the coolant has stopped running or thesteaming has stopped. If there is no visibleloss of coolant and no steam, leave theengine running and check to be sure theengine cooling fan is operating. If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is missing. If it is not missing, check to see that it is tight. If the drive belt seems to besatisfactory, check for coolant leaking fromthe radiator, hoses or under the car. (If theair conditioning had been in use, it is normalfor cold water to be draining from it).

AX30030A

Negative to the engine not to the battery

Positive to positive

Booster battery

�c

�e

�f �d

Discharged battery

Page 305 of 361

IN CASE OF EMERGENCY 3-3

WARNING: Whilst the engine is running, keep hands

and clothing away from moving parts such as the fan and drive belts to prevent injury.

WARNING (Diesel only): Never work on injection system with engine

running or within 30 seconds after shutting off engine. High pressure pump, rail, injec-tors and high pressure pipes are subject tohigh pressure even after the engine stopped.The fuel jet produced by fuel leaks maycause serious injury, if it touch the body.People using pacemakers should not movethan 30cm closer to the ECU or wiring har-ness within the engine room while engine isrunning, since the high currents in the Com-mon Rail system produce considerable mag-netic fields.

5. If the water pump drive belt is broken or coolant is leaking out, stop the engine imme- diately and call the nearest Hyundai dealerfor assistance.

WARNING: Do not remove the radiator cap when the

engine is hot since steam and boiling water may be ejected from the radiator resulting inburns or scalding. YD050A1-E

SPARE TYRE For Full Size

The following instructions for the FULL SIZE

spare tyre should be observed:

Check inflation pressure as soon as possible

after installing the spare tyre, and adjust to the specified pressure. The tyre pressure shouldbe periodically checked and maintained at thespecified pressure whilst the tyre is stored.

Spare Tyre Pressure

Inflation Pressure

Tyre Size

FULL SIZE 29 psi (200 kPa)

6. If the cause of the overheating cannot be

found, wait until the engine temperature has returned to normal. Then, if coolant hasbeen lost, carefully remove the radiator capand add water to bring the fluid level in thereservoir up to the base of the radiator fillopening. Fill the coolant expansion tank tothe halfway mark.

7. Proceed with caution until it is established that the engine is operating normally. If theengine overheats repeatedly, the advice of aHyundai dealer should be sought.

CAUTION: Serious loss of coolant indicates there is a

leak in the cooling system and this should be checked as soon as possible by a Hyundaidealer.

D040B01HP

D040B03HP-EAT

Handling the Spare Tyre

1. Obtain the spare wheel rod (Jack handle) after folding up the seat cushion of the rear seat . To fold up the seat cushion, refer to the page 1-15.

D060B01HPB090B02HP

Rear seat

Page 317 of 361

VEHICLE MAINTENANCE REQUIREMENTS 5-1

NOTE:

The inspection and testing of certain elec-

tronic fuel injection/engine management and automatic transmission control sys-tems require specialised electronic equip-ment specifically designed for Hyundai ve-hicles. The use of general purpose electri-cal test equipment may result in damage tothe control unit microprocessors.

YF010A1-A

5. VEHICLE MAINTE-

NANCE REQUIRE- MENTS

DF020A1-E

MAINTENANCE AND SERVICING REQUIREMENTS To ensure the continued reliability and safety

of the vehicle, certain routine maintenance operations are required at specific mileage ortime intervals.

It is the responsibility of the vehicle owner to

ensure that the maintenance schedules shownin both this Owner's Manual and the Warrantyand Service Passport are adhered to.

The new vehicle warranty may be invalidated

if the routine maintenance operations are notperformed in line with the recommendationsoutlined and the safety and durability of thevehicle adversely affected.

It is recommended that all maintenance op-

erations with the exception of the daily oper-ating checks are entrusted to a Hyundai dealerto ensure that the latest repair and mainte-nance procedures and specialized servicingtools are employed. In addition, the use ofgenuine Hyundai replacement parts will en-sure that the vehicle safety and performancewill not be compromised. DF020C1-E

Specified Scheduled Procedures The specified scheduled procedures are listed

in the maintenance charts beginning at page5-2. The operations specified must be per-formed at the time or mileage intervals shownirrespective of whether the mileage interval has been reached before the specified time interval.

Certain lubricants and components degrade

with both time and mileage (eg, engine oil andbrake fluid) and therefore it is not permissableto base the maintenance schedule upon mile-age alone. It is strongly recommended thatthe maintenance operations are performed bya Hyundai dealer because of the need forspecialized knowledge and tooling and to en-sure that no possibility of invalidating themanufacturers warranty exists.

The maintenance schedules relate to vehicles

operated under normal conditions, vehicleswhich are operated under adverse conditionswill require more frequent maintenance whichis described at page 5-5. DF020F1-E

SERVICE HISTORY

It is important that all scheduled maintenance

services are recorded in the warranty andservice passport to ensure that proof of main-tenance is available when warranty service isrequired.

5

Page 320 of 361

VEHICLE MAINTENANCE REQUIREMENTS

5- 4

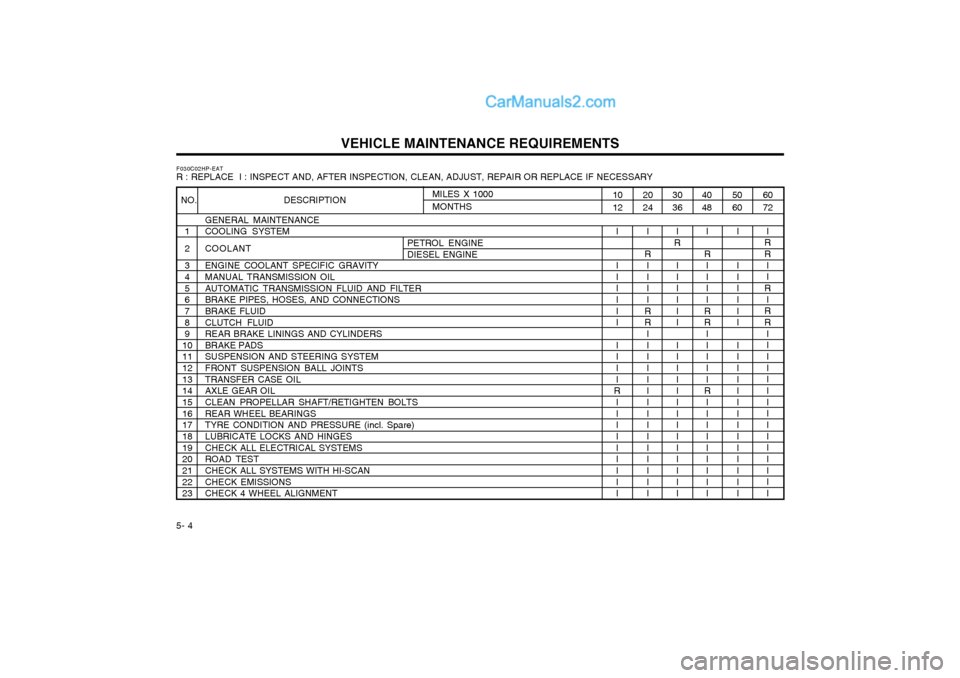

F030C02HP-EAT R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

GENERAL MAINTENANCE COOLING SYSTEM COOLANTENGINE COOLANT SPECIFIC GRAVITY MANUAL TRANSMISSION OIL AUTOMATIC TRANSMISSION FLUID AND FILTER BRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUID CLUTCH FLUID REAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEM FRONT SUSPENSION BALL JOINTS TRANSFER CASE OILAXLE GEAR OIL CLEAN PROPELLAR SHAFT/RETIGHTEN BOLTS REAR WHEEL BEARINGSTYRE CONDITION AND PRESSURE (incl. Spare) LUBRICATE LOCKS AND HINGES CHECK ALL ELECTRICAL SYSTEMSROAD TEST CHECK ALL SYSTEMS WITH HI-SCAN CHECK EMISSIONSCHECK 4 WHEEL ALIGNMENT

60 72

50 60

4048

I

R R

II

R

I

RR

III I II I II I II I II

I I I II I I I II I II I II I II I I

I

R I I II

RR I I II I

R II II I II I I

30 36

2024

I

R

I I II I I I II I II I II I II I I

I

R I I II

RR I I II I II I II I II I I

10 12

I I I II I I I II I

R

II II I II I I

MILES X 1000 MONTHS

NO. DESCRIPTION

1 23 4 5 67 8 9

1011 12 1314 15 1617 18 1920 21

22 23

PETROL ENGINE DIESEL ENGINE

Page 321 of 361

VEHICLE MAINTENANCE REQUIREMENTS 5-5

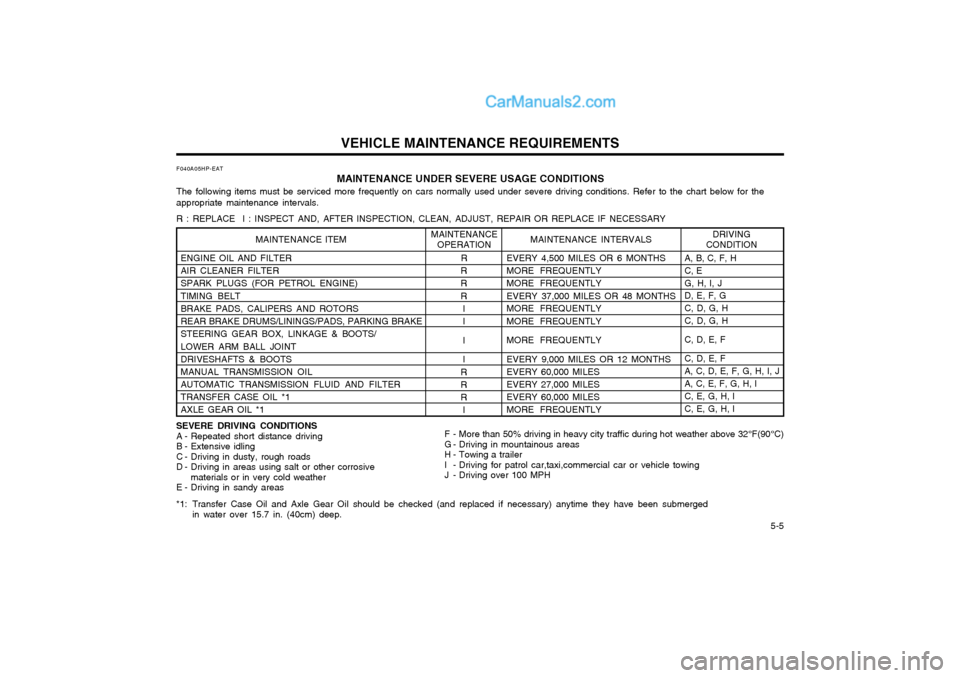

F040A05HP-EAT

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals. R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

SEVERE DRIVING CONDITIONS

A - Repeated short distance driving

B - Extensive idling

C - Driving in dusty, rough roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in sandy areas ENGINE OIL AND FILTER AIR CLEANER FILTER SPARK PLUGS (FOR PETROL ENGINE) TIMING BELT BRAKE PADS, CALIPERS AND ROTORS REAR BRAKE DRUMS/LININGS/PADS, PARKING BRAKE STEERING GEAR BOX, LINKAGE & BOOTS/ LOWER ARM BALL JOINT DRIVESHAFTS & BOOTS MANUAL TRANSMISSION OIL AUTOMATIC TRANSMISSION FLUID AND FILTERTRANSFER CASE OIL *1AXLE GEAR OIL *1

EVERY 4,500 MILES OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLY EVERY 37,000 MILES OR 48 MONTHS MORE FREQUENTLY MORE FREQUENTLY MORE FREQUENTLYEVERY 9,000 MILES OR 12 MONTHS EVERY 60,000 MILESEVERY 27,000 MILESEVERY 60,000 MILES MORE FREQUENTLY

MAINTENANCE

OPERATIONMAINTENANCE ITEM

R

R R R II II

R R R I A, B, C, F, H C, EG, H, I, J D, E, F, G C, D, G, HC, D, G, H C, D, E, FC, D, E, F A, C, D, E, F, G, H, I, JA, C, E, F, G, H, I C, E, G, H, I C, E, G, H, I

MAINTENANCE INTERVALS

DRIVING

CONDITION

F - More than 50% driving in heavy city traffic during hot weather above 32°F(90°C)

G - Driving in mountainous areas

H - Towing a trailer

I - Driving for patrol car,taxi,commercial car or vehicle towing

J - Driving over 100 MPH

*1: Transfer Case Oil and Axle Gear Oil should be checked (and replaced if necessary) anytime they have been submerged in water over 15.7 in. (40cm) deep.

Page 322 of 361

VEHICLE MAINTENANCE REQUIREMENTS

5- 6

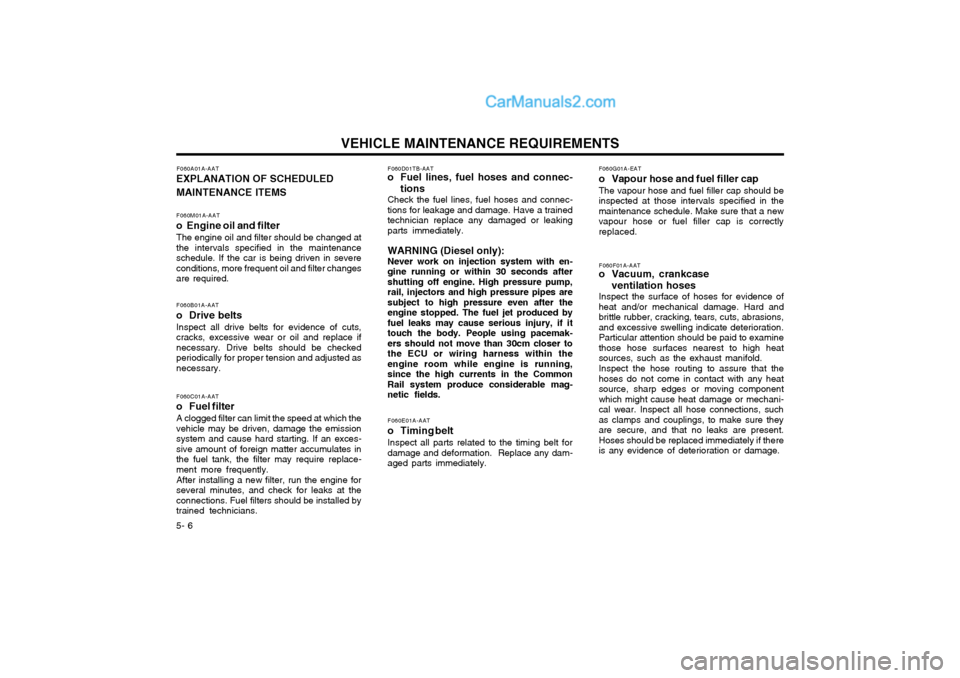

F060B01A-AAT

o Drive belts Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil and replace ifnecessary. Drive belts should be checkedperiodically for proper tension and adjusted asnecessary. F060C01A-AAT

o Fuel filter A clogged filter can limit the speed at which the vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replace-ment more frequently. After installing a new filter, run the engine for several minutes, and check for leaks at theconnections. Fuel filters should be installed bytrained technicians.

F060M01A-AAT o Engine oil and filterThe engine oil and filter should be changed at the intervals specified in the maintenanceschedule. If the car is being driven in severeconditions, more frequent oil and filter changesare required.

F060D01TB-AAT

o Fuel lines, fuel hoses and connec-

tions

Check the fuel lines, fuel hoses and connec-tions for leakage and damage. Have a trainedtechnician replace any damaged or leakingparts immediately.

WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds aftershutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer tothe ECU or wiring harness within theengine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields. F060E01A-AAT

o Timing beltInspect all parts related to the timing belt for damage and deformation. Replace any dam-aged parts immediately. F060G01A-EAT

o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in themaintenance schedule. Make sure that a newvapour hose or fuel filler cap is correctlyreplaced.

F060F01A-AAT

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of

heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abrasions,and excessive swelling indicate deterioration.Particular attention should be paid to examinethose hose surfaces nearest to high heatsources, such as the exhaust manifold.

Inspect the hose routing to assure that the

hoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechani-cal wear. Inspect all hose connections, suchas clamps and couplings, to make sure theyare secure, and that no leaks are present.Hoses should be replaced immediately if thereis any evidence of deterioration or damage.

F060A01A-AAT

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Page 323 of 361

VEHICLE MAINTENANCE REQUIREMENTS 5-7

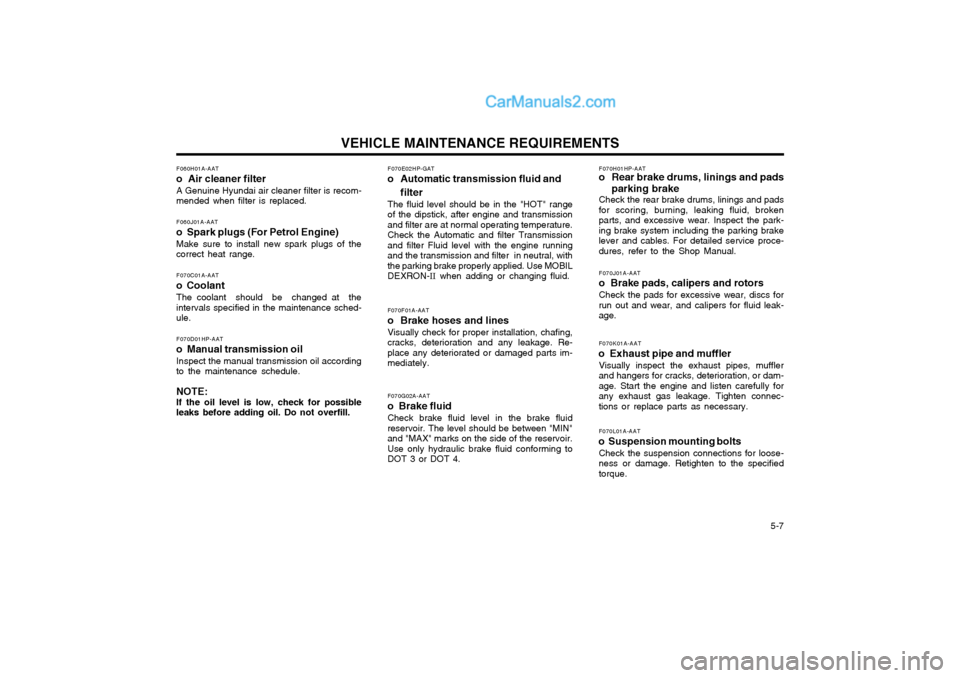

F070E02HP-GAT

o Automatic transmission fluid and

filter

The fluid level should be in the "HOT" range of the dipstick, after engine and transmissionand filter are at normal operating temperature.Check the Automatic and filter Transmissionand filter Fluid level with the engine runningand the transmission and filter in neutral, withthe parking brake properly applied. Use MOBILDEXRON- �� when adding or changing fluid.

F070F01A-AAT

o Brake hoses and lines Visually check for proper installation, chafing, cracks, deterioration and any leakage. Re-place any deteriorated or damaged parts im-mediately. F070G02A-AAT o Brake fluidCheck brake fluid level in the brake fluid reservoir. The level should be between "MIN"and "MAX" marks on the side of the reservoir.Use only hydraulic brake fluid conforming toDOT 3 or DOT 4. F070H01HP-AAT

o Rear brake drums, linings and pads

parking brake

Check the rear brake drums, linings and pads

for scoring, burning, leaking fluid, brokenparts, and excessive wear. Inspect the park-ing brake system including the parking brakelever and cables. For detailed service proce-dures, refer to the Shop Manual.

F070J01A-AAT

o Brake pads, calipers and rotors

Check the pads for excessive wear, discs for

run out and wear, and calipers for fluid leak-age. F070K01A-AAT

o Exhaust pipe and muffler Visually inspect the exhaust pipes, muffler and hangers for cracks, deterioration, or dam-age. Start the engine and listen carefully forany exhaust gas leakage. Tighten connec-tions or replace parts as necessary. F070L01A-AAT

o Suspension mounting bolts Check the suspension connections for loose- ness or damage. Retighten to the specifiedtorque.

F060H01A-AAT

o Air cleaner filter

A Genuine Hyundai air cleaner filter is recom-mended when filter is replaced. F060J01A-AAT

o Spark plugs (For Petrol Engine) Make sure to install new spark plugs of the

correct heat range.

F070C01A-AAT

o Coolant The coolant should be changed at the intervals specified in the maintenance sched-ule. F070D01HP-AAT

o Manual transmission oil Inspect the manual transmission oil according to the maintenance schedule.

NOTE: If the oil level is low, check for possibleleaks before adding oil. Do not overfill.

Page 324 of 361

VEHICLE MAINTENANCE REQUIREMENTS

5- 8

F070M01B-AAT

o Steering gear box, linkage & boots/

lower arm ball joint, upper arm ball joint

With the vehicle stopped and engine off, check for excessive free-play in the steering wheel. Check the linkage for bends or damage. Check the dust boots and ball joints for deterioration,cracks, or damage. Replace any damagedparts. F070N01A-AAT

o Power steering pump, belt and hoses Check the power steering pump and hoses for leakage and damage. Replace any dam-aged or leaking parts immediately. Inspect thepower steering belt for evidence of cuts,cracks, excessive wear, oiliness and propertension. Replace or adjust it if necessary. F070P01HP-AAT o Driveshafts and bootsCheck the drive shafts, boots and clamps for cracks, deterioration, or damage. Replace anydamaged parts and, if necessary, repack thegrease. F070Q01A-AAT

o Air conditioning refrigerant

Check the air conditioning lines and connec-tions for leakage and damage. Check airconditioning performance according to therelevant shop manual if necessary.