Hyundai Terracan 2006 Owner's Manual

Manufacturer: HYUNDAI, Model Year: 2006, Model line: Terracan, Model: Hyundai Terracan 2006Pages: 539, PDF Size: 18.11 MB

Page 221 of 539

5VEHICLE MAINTENANCE REQUIREMENTS

6

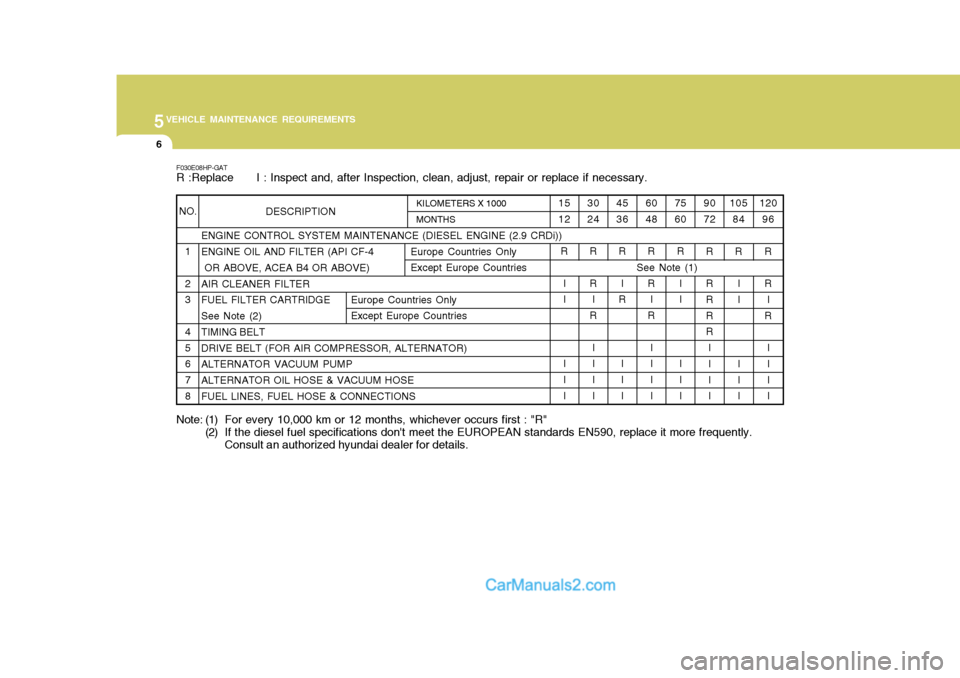

DESCRIPTION

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL ENGINE (2.9 CRDi)) ENGINE OIL AND FILTER (API CF-4 OR ABOVE, ACEA B4 OR ABOVE) AIR CLEANER FILTER FUEL FILTER CARTRIDGE See Note (2) TIMING BELT DRIVE BELT (FOR AIR COMPRESSOR, ALTERNATOR) ALTERNATOR VACUUM PUMP ALTERNATOR OIL HOSE & VACUUM HOSE FUEL LINES, FUEL HOSE & CONNECTIONS See Note (1)

Europe Countries Only Except Europe Countries

F030E08HP-GAT R :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

Note: (1)

For every 10,000 km or 12 months, whichever occurs first : "R"

(2) If the diesel fuel specifications don't meet the EUROPEAN standards EN590, replace it more frequently. Consult an authorized hyundai dealer for details.

NO.

1 2 3 4 5 6 7 8

10584

R I I I I I 120

96

R R I

R

I I I I

90 72

R R R R R II I I

75 60

R I I I I I

60 48

R R I

R

I I I I

45 36

R I

R

II I

30 24

R R I

R

I I I I

15 12

R

I I I I I

KILOMETERS X 1000 MONTHS

Europe Countries Only Except Europe Countries

Page 222 of 539

5

VEHICLE MAINTENANCE REQUIREMENTS

7

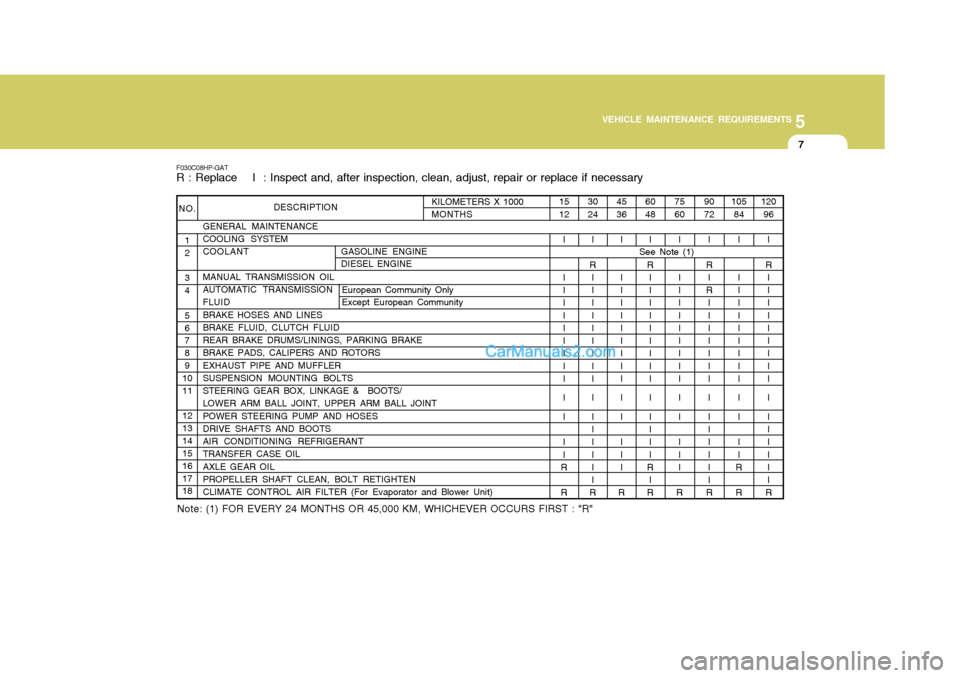

F030C08HP-GAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

Note: (1) FOR EVERY 24 MONTHS OR 45,000 KM, WHICHEVER OCCURS FIRST : "R" DESCRIPTION

GENERAL MAINTENANCE COOLING SYSTEM COOLANT MANUAL TRANSMISSION OIL AUTOMATIC TRANSMISSION FLUID BRAKE HOSES AND LINES BRAKE FLUID, CLUTCH FLUID REAR BRAKE DRUMS/LININGS, PARKING BRAKE BRAKE PADS, CALIPERS AND ROTORS EXHAUST PIPE AND MUFFLER SUSPENSION MOUNTING BOLTS STEERING GEAR BOX, LINKAGE & BOOTS/ LOWER ARM BALL JOINT, UPPER ARM BALL JOINT POWER STEERING PUMP AND HOSES DRIVE SHAFTS AND BOOTS AIR CONDITIONING REFRIGERANT TRANSFER CASE OIL AXLE GEAR OIL PROPELLER SHAFT CLEAN, BOLT RETIGHTEN CLIMATE CONTROL AIR FILTER (For Evaporator and Blower Unit)

NO.

1

2 3 4 5 6 7 89

1011 12 1314 15 1617 18

120

96

I

R I I I I I I I I I II I I I I I

R

105

84

I I I I I I I I I I II I I

R R

90 72

I

R I

R II I I I I I II I I I I I

R

7560

I I I I I I I I I I II I I I

R

60 48

I

R II I I I I I I I II I I I

R

I

R

4536

I I I I I I I I I I II I I I

R

30 24

I

R II I I I I I I I II I I I I I

R

1512

I I I I I I I I I I II I I

R R

KILOMETERS X 1000 MONTHS

European Community Only Except European Community

See Note (1)GASOLINE ENGINE DIESEL ENGINE

Page 223 of 539

5VEHICLE MAINTENANCE REQUIREMENTS

8

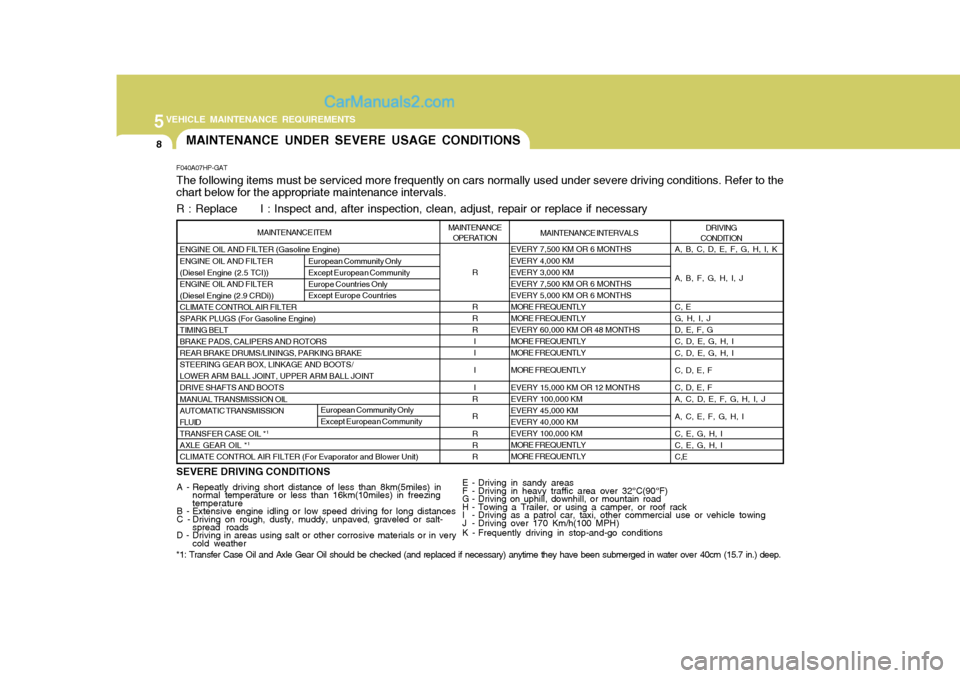

A, B, C, D, E, F, G, H, I, K A, B, F, G, H, I, JC, E G, H, I, JD, E, F, GC, D, E, G, H, I C, D, E, G, H, I C, D, E, F C, D, E, F A, C, D, E, F, G, H, I, J A, C, E, F, G, H, I C, E, G, H, I C, E, G, H, I C,E

ENGINE OIL AND FILTER (Gasoline Engine) ENGINE OIL AND FILTER (Diesel Engine (2.5 TCI))ENGINE OIL AND FILTER(Diesel Engine (2.9 CRDi))CLIMATE CONTROL AIR FILTERSPARK PLUGS (For Gasoline Engine) TIMING BELT BRAKE PADS, CALIPERS AND ROTORSREAR BRAKE DRUMS/LININGS, PARKING BRAKESTEERING GEAR BOX, LINKAGE AND BOOTS/LOWER ARM BALL JOINT, UPPER ARM BALL JOINTDRIVE SHAFTS AND BOOTS MANUAL TRANSMISSION OIL AUTOMATIC TRANSMISSIONFLUIDTRANSFER CASE OIL *

1

AXLE GEAR OIL * 1

CLIMATE CONTROL AIR FILTER (For Evaporator and Blower Unit)

European Community Only Except European Community

F040A07HP-GAT The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals. R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

R R R R

I I I I

RRR RR

EVERY 7,500 KM OR 6 MONTHS EVERY 4,000 KM EVERY 3,000 KMEVERY 7,500 KM OR 6 MONTHSEVERY 5,000 KM OR 6 MONTHSMORE FREQUENTLYMORE FREQUENTLY EVERY 60,000 KM OR 48 MONTHS MORE FREQUENTLYMORE FREQUENTLY MORE FREQUENTLY EVERY 15,000 KM OR 12 MONTHS EVERY 100,000 KMEVERY 45,000 KM EVERY 40,000 KM EVERY 100,000 KMMORE FREQUENTLYMORE FREQUENTLY

SEVERE DRIVING CONDITIONS

A - Repeatly driving short distance of less than 8km(5miles) in normal temperature or less than 16km(10miles) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very

cold weather

DRIVING

CONDITION

MAINTENANCE INTERVALS

MAINTENANCE

OPERATION

MAINTENANCE ITEM

E - Driving in sandy areas

F - Driving in heavy traffic area over 32°C(90°F)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle towing

J - Driving over 170 Km/h(100 MPH)

K - Frequently driving in stop-and-go conditions

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

European Community Only Except European Community Europe Countries Only Except Europe Countries

*1: Transfer Case Oil and Axle Gear Oil should be checked (and replaced if necessary) anytime they have been submerged in water

over 40cm (15.7 in.) deep.

Page 224 of 539

5

VEHICLE MAINTENANCE REQUIREMENTS

9EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

!

F060M01A-AAT

o Engine Oil and Filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. F060B01A-AAT

o Drive belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil saturation and replace if necessary. Drive belts should be checked periodi-cally for proper tension and adjusted as necessary. F060C01A-AAT

o Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam-age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently. After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections. Fuel fil- ters should be installed by trained technicians. WARNING (Diesel only):

Never work on injection system with

engine running or within 30 sec- onds after shutting off engine. High pressure pump, rail, injectors andhigh pressure pipes are subjected to high pressure even after the en- gine has been switched off. The fueljet produced by fuel leaks may cause serious injury, if it contacts with the body. People using pacemakersshould not move closer than 30cm to the ECU or wiring harness within the engine room with the enginerunning, since the high currents in the Common Rail system produce considerable magnetic fields.

F060D01TB-GAT

o Fuel Lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and connections for leakage and damage. Have a trained technician replace any damaged or leaking parts immediately.

Page 225 of 539

5VEHICLE MAINTENANCE REQUIREMENTS

10

F060H01A-AAT

o Air Cleaner Filter

A Genuine Hyundai air cleaner filter is

recommended when the filter is re- placed. F060J01A-AAT

o Spark Plugs

(For Gasoline Engine)

Make sure to install new spark plugs of the correct heat range.

F060E01A-AAT

o Timing belt Inspect all parts related to the timing belt for damage and deformation. Re- place any damaged parts immediately. F060G01A-AAT

o Vapor Hose and Fuel Filler Cap The vapor hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched-ule. Make sure that a new vapor hose or fuel filler cap is correctly replaced. F060F0HP-AAT

o Crankcase Ventilation Hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Particu- lar attention should be paid to examine those hose surfaces nearest to highheat sources, such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with any heat source, sharp edges or mov-ing component which might cause heat damage or mechanical wear. Inspect all hose connections, such as clampsand couplings, to make sure they are secure, and that no leaks are present. Hoses should be replaced immedi-ately if there is any evidence of dete- rioration or damage.

F070C01A-AAT

o Coolant

The coolant should be changed atthe intervals specified in the mainte- nance schedule. F070B01A-GAT

o Cooling System

Check the cooling system part, such

as radiator, coolant reservoir, hosesand connections for leakage and dam-age. Replace any damaged parts.

Page 226 of 539

5

VEHICLE MAINTENANCE REQUIREMENTS

11

F070E03HP-GAT

o Automatic Transmission Fluid

The fluid level should be in the "HOT" range of the dipstick, after the engine and transmission are at normal operat- ing temperature. Check the automatictransmission fluid level with the engine running and the transmission in neu- tral, with the parking brake properlyapplied. Use MOBIL DEXRON-II when adding or changing fluid.

F070D01A-AAT

o Manual Transmission Oil

Inspect the manual transmission oil according to the maintenance sched- ule.

NOTE: If the oil level is low, check for possible leaks before adding oil. Donot overfill. F070F01A-AAT

o Brake Hoses and Lines

Visually check for proper installation,

chafing, cracks, deterioration and any leakage. Replace any deteriorated or damaged parts immediately.

F070G02A-AAT

o Brake Fluid

Check brake fluid level in the brake

fluid reservoir. The level should bebetween "MIN" and "MAX" marks on the side of the reservoir. Use only hydraulic brake fluid conforming to DOT3 or DOT 4.

F070H01A-AAT

o Rear Brake Drums/ Linings

Parking Brake

Check the rear brake drums and lin-

ings for scoring, burning, leaking fluid,broken parts, and excessive wear. In-spect the parking brake system in- cluding the parking brake lever and cables. For detailed service proce-dures, refer to the Shop Manual. F070J01A-AAT

o Brake Pads, Calipers and

Rotors

Check the pads for excessive wear, discs for run out and wear, and cali- pers for fluid leakage. F070K01A-AAT o Exhaust Pipe and Muffler Visually inspect the exhaust pipes, muffler and hangers for cracks, dete- rioration, or damage. Start the engine and listen carefully for any exhaustgas leakage. Tighten connections or replace parts as necessary. F070L01A-AAT o Suspension Mounting Bolts Check the suspension connections for looseness or damage. Retighten to the specified torque.

Page 227 of 539

5VEHICLE MAINTENANCE REQUIREMENTS

12

F070M01B-AAT

o Steering Gear Box, Linkage &Boots/Lower Arm Ball Joint, Upper Arm Ball Joint

With the vehicle stopped and engine off, check for excessive free-play inthe steering wheel.Check the linkage for bends or dam-age. Check the dust boots and ball joints for deterioration, cracks, or dam- age. Replace any damaged parts. F070N01A-AAT

o Power Steering Pump, Belt and Hoses

Check the power steering pump and hoses for leakage and damage. Re- place any damaged or leaking partsimmediately. Inspect the power steer- ing belt for evidence of cuts, cracks, excessive wear, oiliness and propertension. Replace or adjust it if neces- sary. F070P01A-AAT

o Drive Shafts and Boots

Check the drive shafts, boots and

clamps for cracks, deterioration, ordamage. Replace any damaged parts and, if necessary, repack the grease.

F070Q01A-AAT

o Air Conditioning Refrigerant

Check the air conditioning lines and

connections for leakage and damage. Check air conditioning performance according to the relevant shop manualif necessary.

Page 228 of 539

Engine Compartment .................................................... 6-2

General Checks ........................................................... 6-5

Checking the Engine Oil .............................................. 6-6 Changing the Engine Oil and Filter ............................. 6-10

Checking and Changing the Engine Coolant ..............6-11

Changing the Air Cleaner Filte r ...................................6-14

Checking the Transmission Oil (Manual)................... 6-17

Checking the Transmission Fluid (Automatic)............6-18

Checking the Brakes .................................................. 6-21

Checking the Clutch Fluid ........................................... 6-22

Air Conditioning Care .................................................. 6-23

Changing the Climate Control Air Filter .. ....................6-24

Checking Drive Belts .................................................. 6-27

Checking and Replacing Fuses ..................................6-28

Checking The Battery ................................................. 6-31

Checking The Electric Cooling Fans ..........................6-33

Power Steering Fluid Level ......................................... 6-33

Fuel Filter ..................................................................... 6-34

Replacement of Headlight Bulbs ................................. 6-38

Headlight Aiming Adjustment ...................................... 6-39

Bulb Wattages ............................................................. 6-42

Fuse Panel D escription ............................................... 6-43

DO-IT-YOURSELF MAINTENANCE

6

6

Page 229 of 539

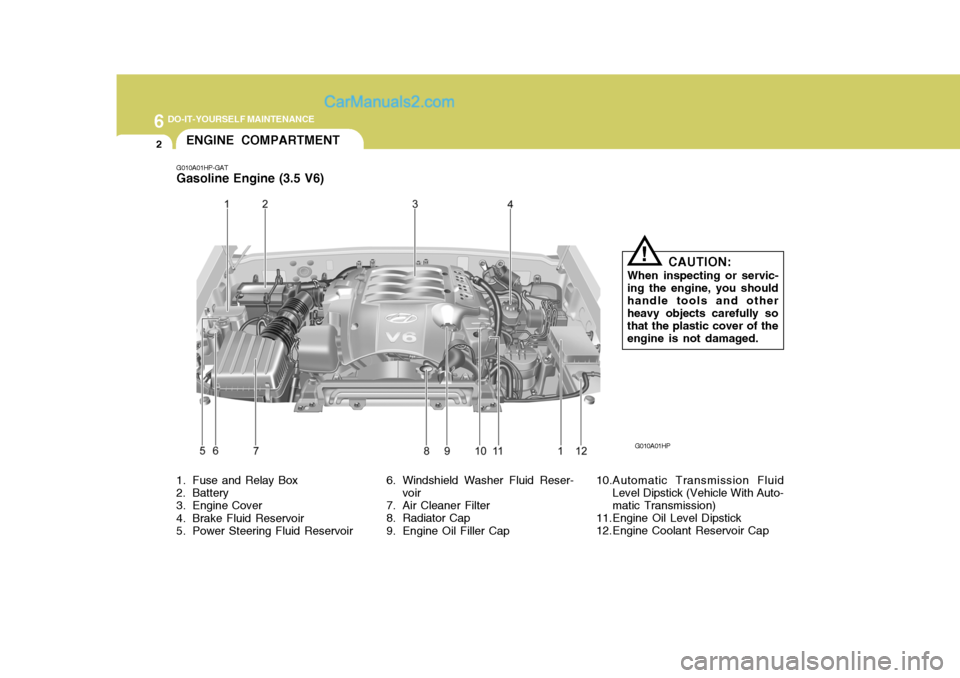

6 DO-IT-YOURSELF MAINTENANCE

2

1. Fuse and Relay Box

2. Battery

3. Engine Cover

4. Brake Fluid Reservoir

5. Power Steering Fluid Reservoir 6. Windshield Washer Fluid Reser-

voir

7. Air Cleaner Filter

8. Radiator Cap

9. Engine Oil Filler Cap 10.Automatic Transmission Fluid

Level Dipstick (Vehicle With Auto- matic Transmission)

11.Engine Oil Level Dipstick

12.Engine Coolant Reservoir Cap G010A01HP

G010A01HP-GAT Gasoline Engine (3.5 V6)

CAUTION:

When inspecting or servic-

ing the engine, you should handle tools and other heavy objects carefully so that the plastic cover of theengine is not damaged.

!

ENGINE COMPARTMENT

Page 230 of 539

6

DO-IT-YOURSELF MAINTENANCE

3

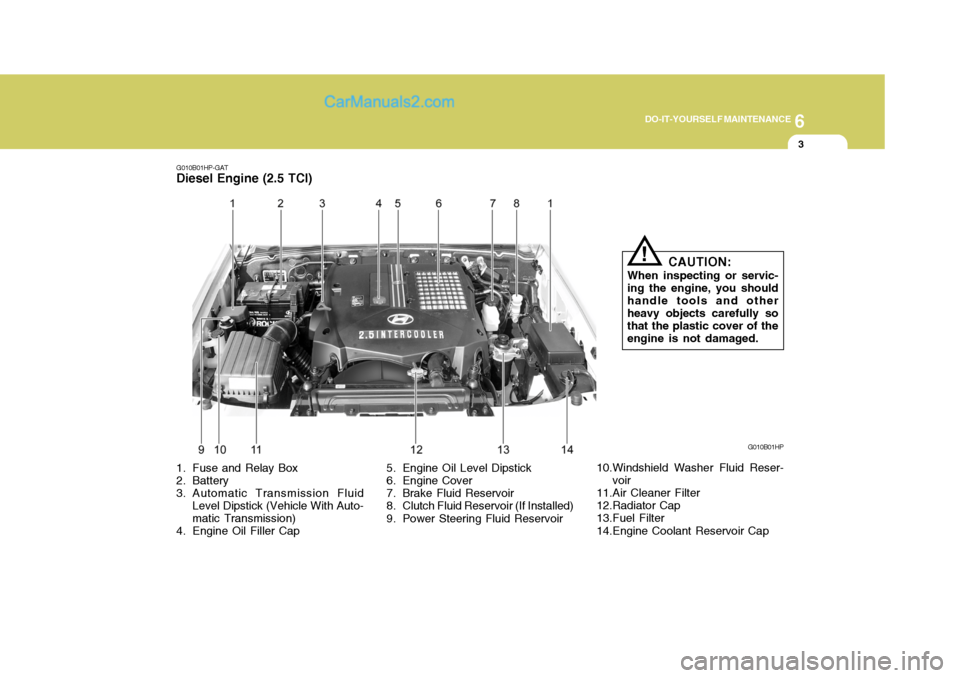

G010B01HP-GAT

Diesel Engine (2.5 TCI)

G010B01HP

1. Fuse and Relay Box

2. Battery

3. Automatic Transmission Fluid Level Dipstick (Vehicle With Auto- matic Transmission)

4. Engine Oil Filler Cap 5. Engine Oil Level Dipstick

6. Engine Cover

7. Brake Fluid Reservoir

8. Clutch Fluid Reservoir (If Installed)

9. Power Steering Fluid Reservoir

10.Windshield Washer Fluid Reser-

voir

11.Air Cleaner Filter

12.Radiator Cap

13.Fuel Filter

14.Engine Coolant Reservoir Cap CAUTION:

When inspecting or servic- ing the engine, you shouldhandle tools and other heavy objects carefully so that the plastic cover of theengine is not damaged.

!