diagram INFINITI FX35 2004 Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2004, Model line: FX35, Model: INFINITI FX35 2004Pages: 4449, PDF Size: 99.66 MB

Page 1280 of 4449

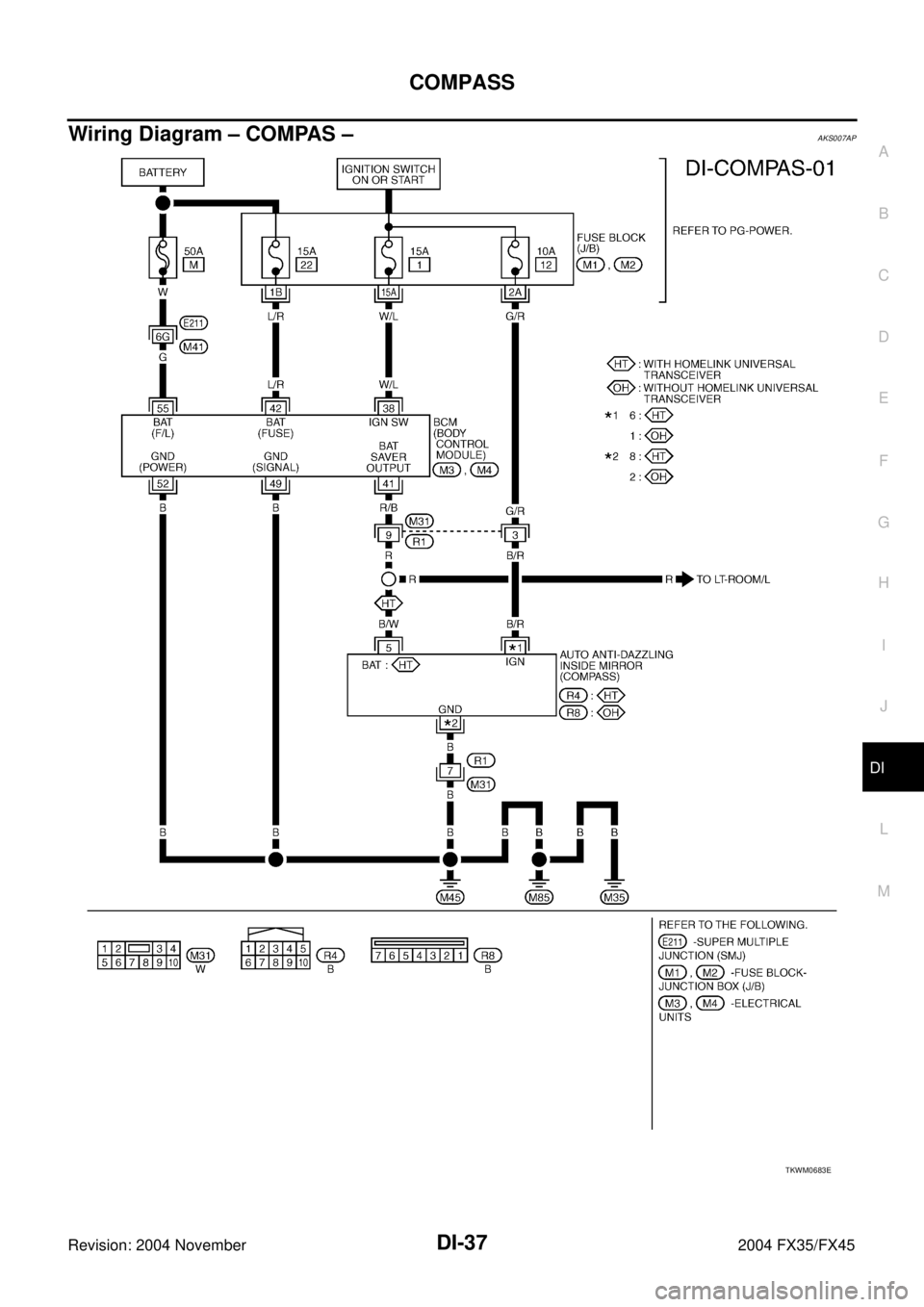

COMPASS

DI-37

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2004 November 2004 FX35/FX45

Wiring Diagram – COMPAS –AKS007AP

TKWM0683E

Page 1283 of 4449

DI-40

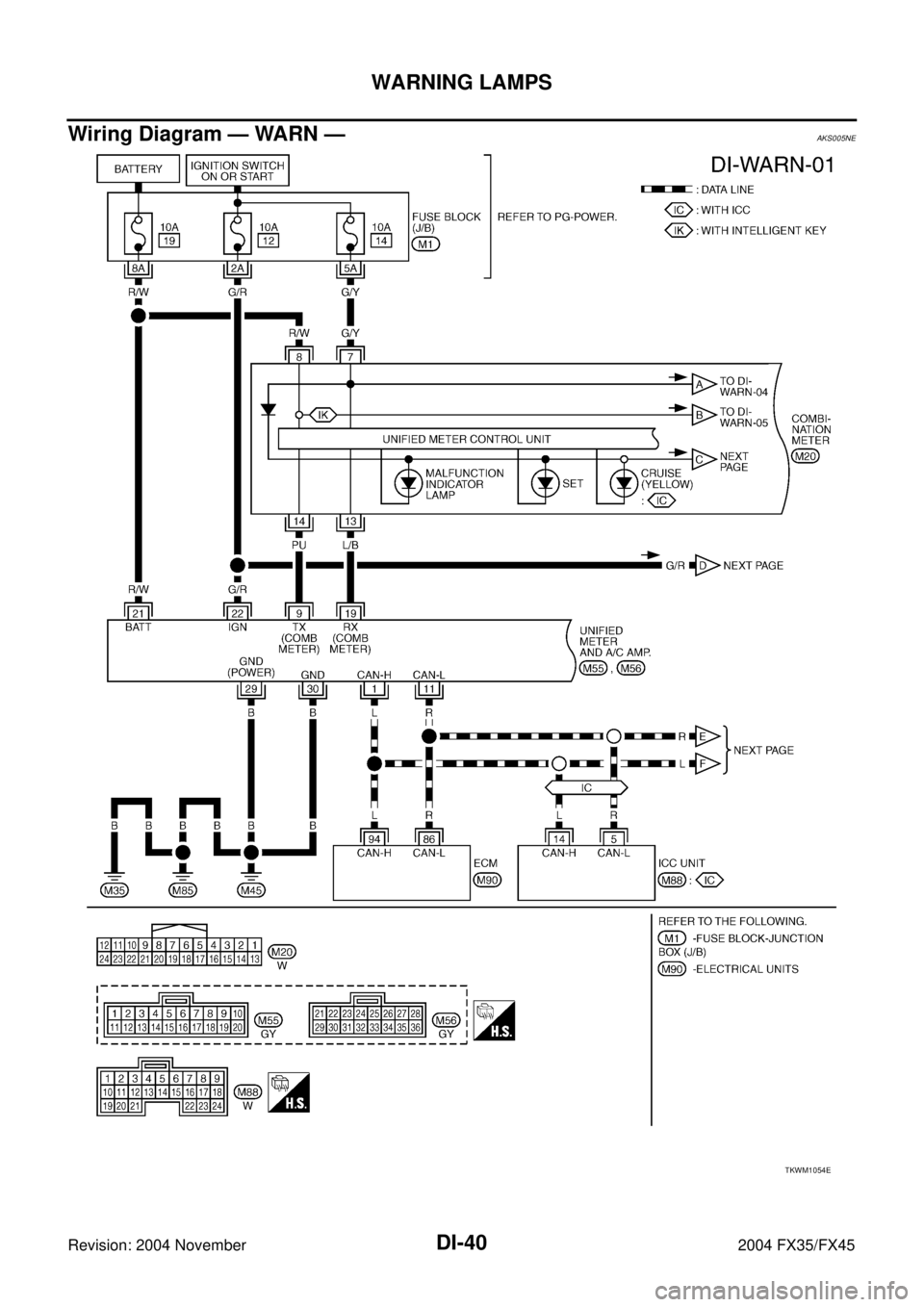

WARNING LAMPS

Revision: 2004 November 2004 FX35/FX45

Wiring Diagram — WARN —AKS005NE

TKWM1054E

Page 1294 of 4449

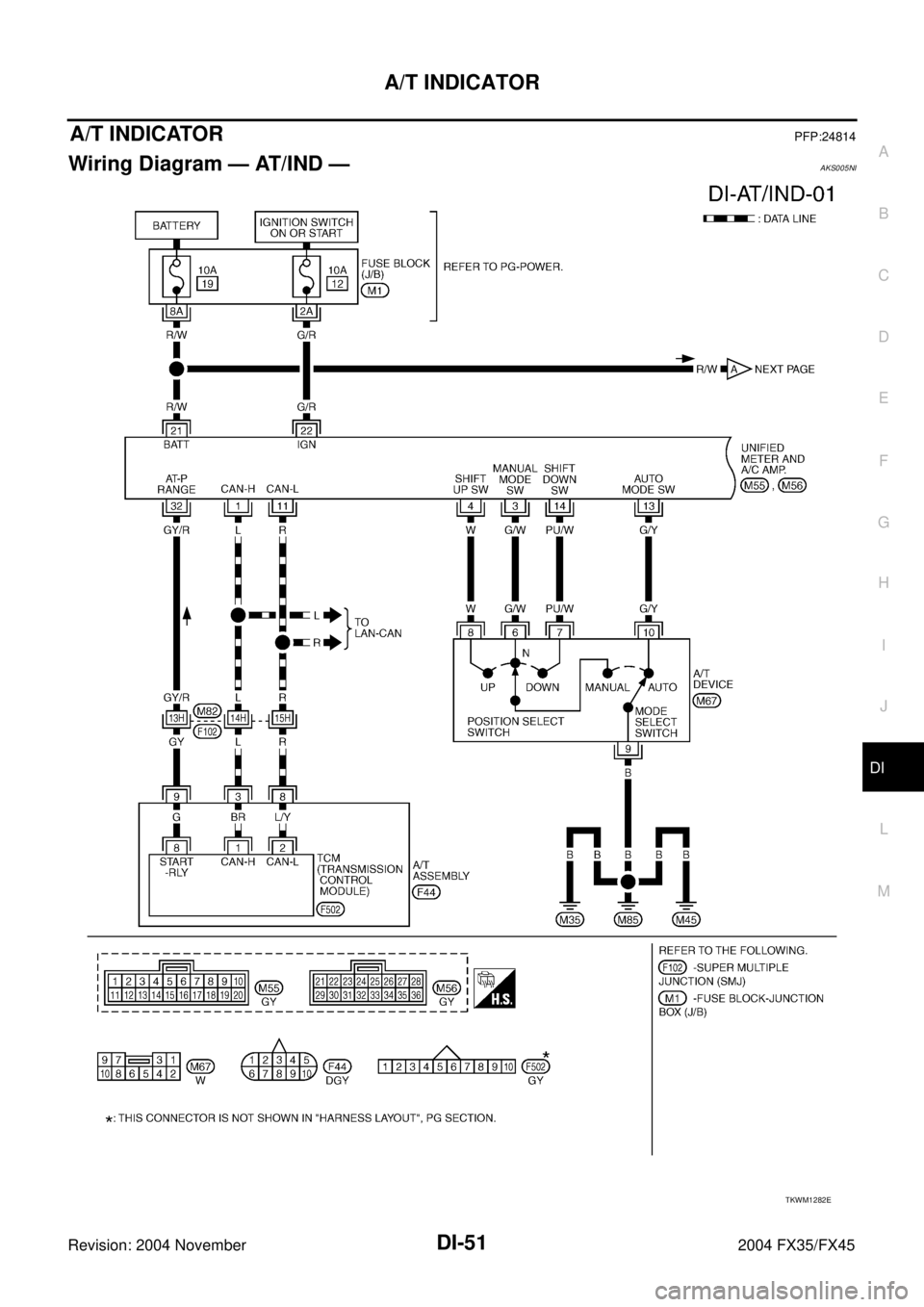

A/T INDICATOR

DI-51

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2004 November 2004 FX35/FX45

A/T INDICATORPFP:24814

Wiring Diagram — AT/IND —AKS005NI

TKWM1282E

Page 1302 of 4449

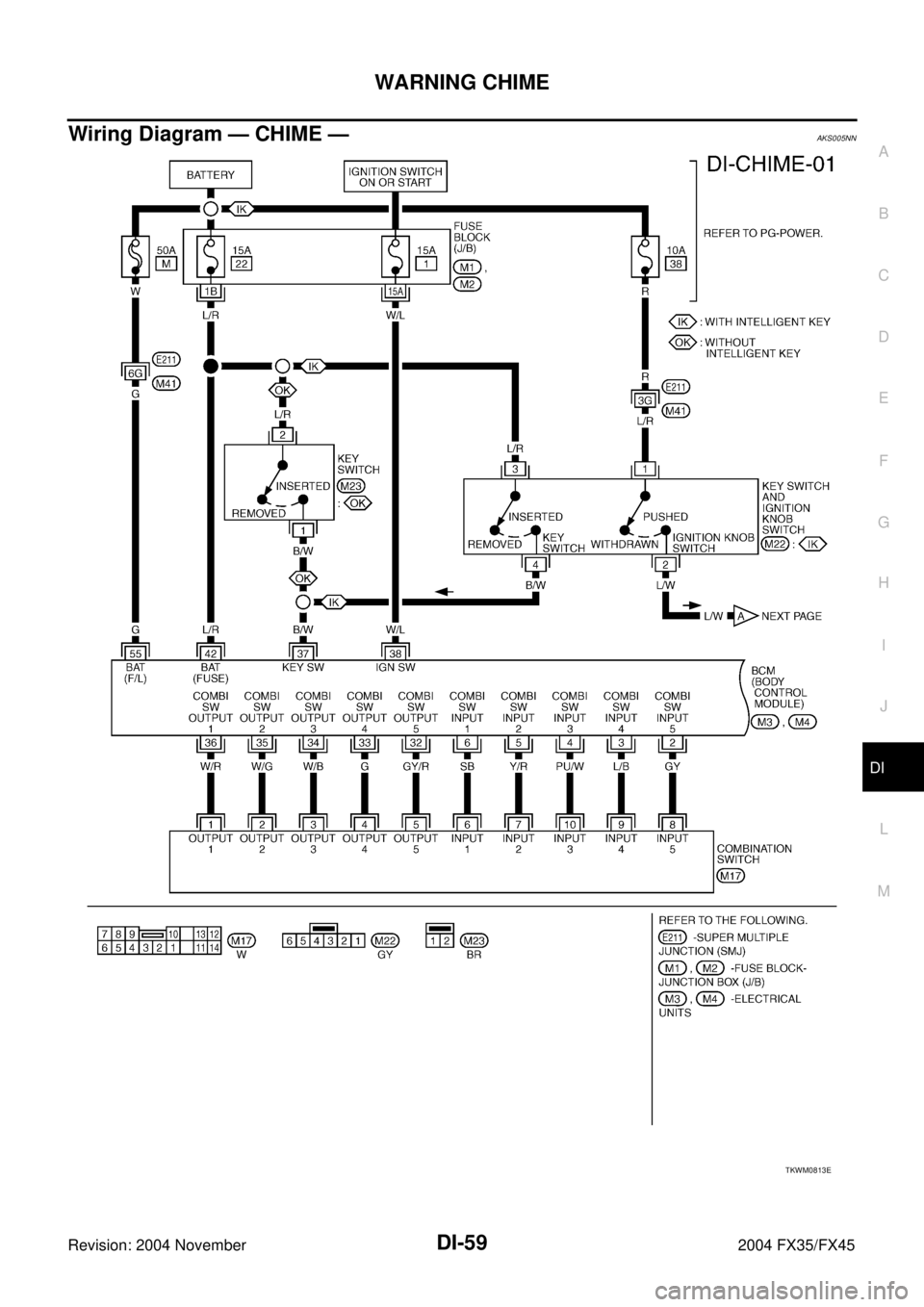

WARNING CHIME

DI-59

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2004 November 2004 FX35/FX45

Wiring Diagram — CHIME —AKS005NN

TKWM0813E

Page 1308 of 4449

WARNING CHIME

DI-65

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2004 November 2004 FX35/FX45

Preliminary CheckAKS005NS

CHECK POWER SUPPLY AND GROUND CIRCUIT

1. CHECK FUSE AND FUSIBLE LINK

Check BCM fuses and fusible link for blown-out.

Refer to DI-59, "Wiring Diagram — CHIME —" .

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer to PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK POWER SUPPLY CIRCUIT

1. Disconnect BCM connector.

2. Check voltage between BCM harness connector terminals and

ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness for open between BCM and fuse or fusible link.

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between BCM harness connector M4 terminals

49 (B), 52 (B) and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Unit Power source Fuse and fusible link No.

BCMBatteryM

22

Ignition switch ON or START 1

Terminals Ignition switch position

(+)

(–) OFF ACC ON

ConnectorTerminal

(Wire color)

M455 (G)

GroundBattery

voltageBattery

voltageBattery

voltage

42 (L/R)Battery

voltageBattery

voltageBattery

voltage

M3 38 (W/L) 0V 0VBattery

voltage

Continuity should exist.

SKIA5041E

Page 1315 of 4449

DI-72

WARNING CHIME

Revision: 2004 November 2004 FX35/FX45

5. CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector M3 terminal

37 (B/W) and key switch harness connector M23 terminal 1 (B/

W).

3. Check continuity between BCM harness connector M3 terminal

37 (B/W) and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6. CHECK KEY SWITCH POWER SUPPLY CIRCUIT

Check voltage between key switch harness connector M23 terminal

2 (L/R) and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-15, "Removal and Installa-

tion of BCM" .

NG >> Check harness for open or short between key switch

and fuse.

Key Warning Chime Does Not Operate (With Intelligent Key, When Mechanical

Key Is Used)

AKS0079U

1. CHECK FUSE

Check if the key switch and ignition knob switch 10A fuse (No. 38, located in the fuse and fusible link box) is

blown. Refer to DI-59, "

Wiring Diagram — CHIME —" .

Is the fuse blown?

YES >> Replace fuse. Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2.

2. CHECK WARNING CHIME OPERATION

Check the chime under conditions in exception of key warning chime (when mechanical key is used) opera-

tion.

Does warning chime sound?

YES >> GO TO 3.

NO >> Go to DI-68, "

All Warnings Are Not Operated" or DI-69, "Key Warning Chime and Light Warning

Chime Does Not Operate (Seat Belt Warning Chime Does Operate)" . Continuity should exist.

Continuity should not exist.

SKIA5050E

Battery voltage should exist.

SKIA5051E

Page 1322 of 4449

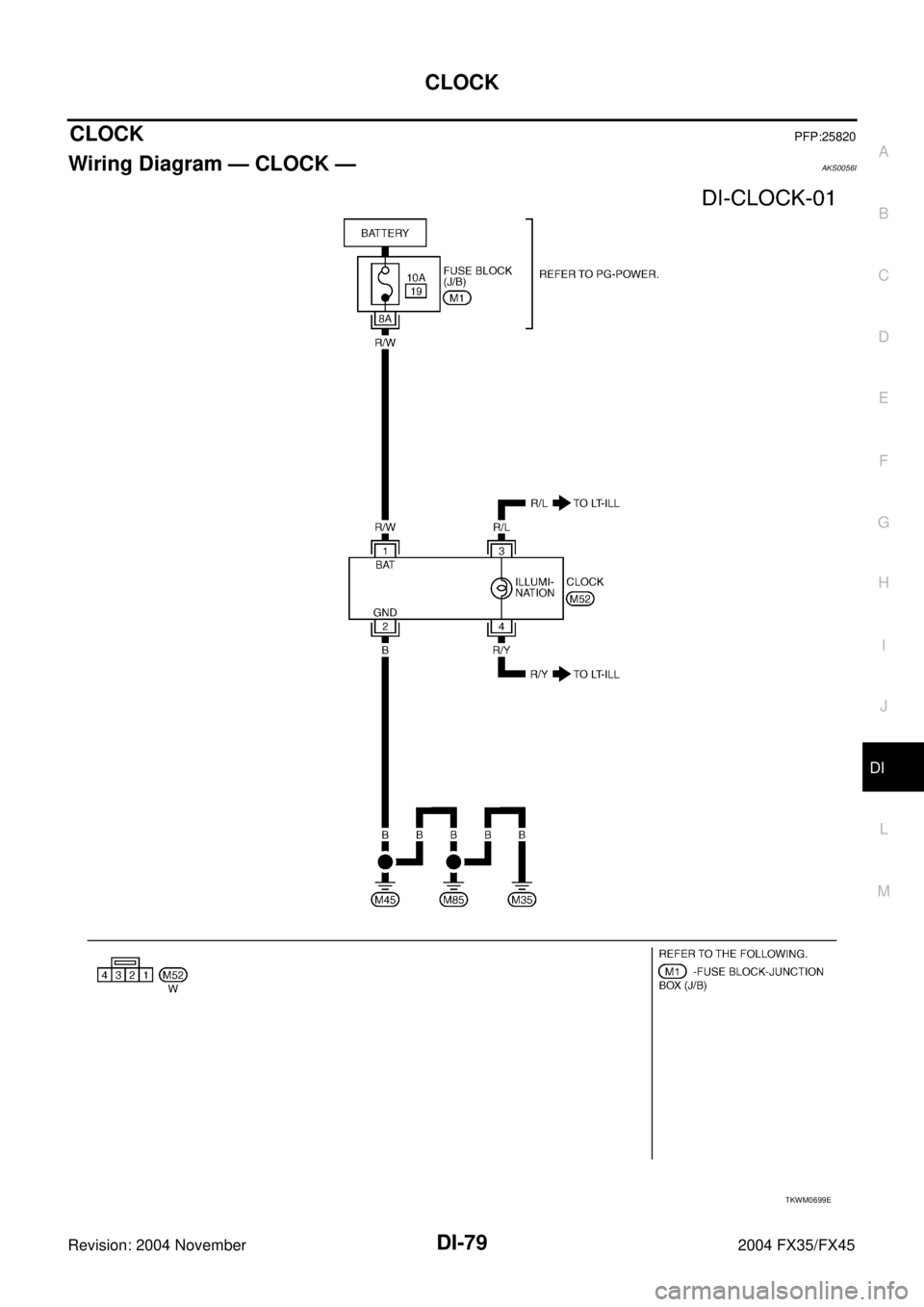

CLOCK

DI-79

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2004 November 2004 FX35/FX45

CLOCKPFP:25820

Wiring Diagram — CLOCK —AKS0056I

TKWM0699E

Page 1327 of 4449

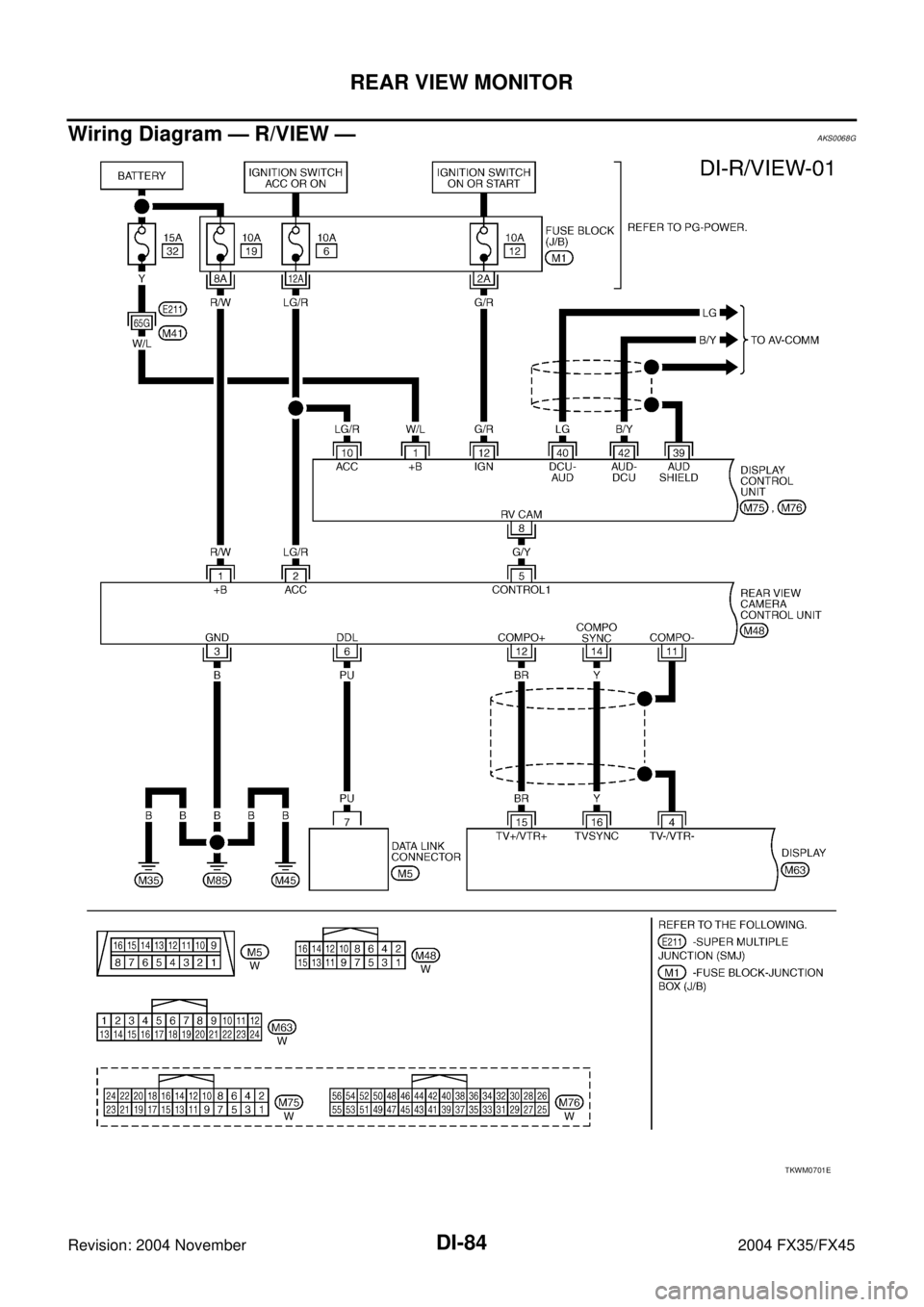

DI-84

REAR VIEW MONITOR

Revision: 2004 November 2004 FX35/FX45

Wiring Diagram — R/VIEW —AKS0068G

TKWM0701E

Page 1342 of 4449

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

Revision: 2004 November 2004 FX35/FX45

ENGINE CONTROL SYSTEM

VQ35DE

INDEX FOR DTC ...................................................... 15

Alphabetical Index .................................................. 15

DTC No. Index ....................................................... 19

PRECAUTIONS ........................................................ 23

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 23

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 23

Precaution .............................................................. 23

Wiring Diagrams and Trouble Diagnosis ................ 26

PREPARATION ......................................................... 27

Special Service Tools ............................................. 27

Commercial Service Tools ...................................... 28

ENGINE CONTROL SYSTEM .................................. 29

System Diagram ..................................................... 29

Vacuum Hose Drawing ........................................... 30

System Chart ......................................................... 31

Multiport Fuel Injection (MFI) System .................... 32

Electronic Ignition (EI) System ............................... 34

Air Conditioning Cut Control ................................... 35

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................... 35

CAN communication .............................................. 36

BASIC SERVICE PROCEDURE .............................. 37

Idle Speed and Ignition Timing Check .................... 37

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment ............................................................. 38

Accelerator Pedal Released Position Learning ...... 49

Throttle Valve Closed Position Learning ................ 49

Idle Air Volume Learning ........................................ 49

Fuel Pressure Check .............................................. 51

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 53

Introduction ............................................................ 53

Two Trip Detection Logic ........................................ 53

Emission-Related Diagnostic Information .............. 54

IVIS (Infiniti Vehicle Immobilizer System — NATS) ... 68

Malfunction Indicator Lamp (MIL) ........................... 68

OBD System Operation Chart ................................ 72TROUBLE DIAGNOSIS ............................................ 77

Trouble Diagnosis Introduction ............................... 77

DTC Inspection Priority Chart ................................. 80

Fail-Safe Chart ....................................................... 82

Basic Inspection ..................................................... 83

Symptom Matrix Chart ............................................ 88

Engine Control Component Parts Location ............ 92

Circuit Diagram ....................................................... 98

ECM Harness Connector Terminal Layout ...........100

ECM Terminals and Reference Value ...................100

CONSULT-II Function ...........................................109

Generic Scan Tool (GST) Function .......................122

CONSULT-II Reference Value in Data Monitor .....125

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................129

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .131

Description ............................................................131

Testing Condition ..................................................131

Inspection Procedure ............................................131

Diagnostic Procedure ...........................................132

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................135

Description ............................................................135

Diagnostic Procedure ...........................................135

POWER SUPPLY AND GROUND CIRCUIT ...........136

Wiring Diagram .....................................................136

Diagnostic Procedure ...........................................137

Ground Inspection ................................................141

DTC U1000, U1001 CAN COMMUNICATION LINE .142

Description ............................................................142

On Board Diagnosis Logic ....................................142

DTC Confirmation Procedure ...............................142

Wiring Diagram .....................................................143

Diagnostic Procedure ...........................................144

DTC P0011, P0021 IVT CONTROL ........................145

Description ............................................................145

CONSULT-II Reference Value in Data Monitor Mode

.145

On Board Diagnosis Logic ....................................146

Page 1343 of 4449

EC-2Revision: 2004 November 2004 FX35/FX45DTC Confirmation Procedure ...............................146

Diagnostic Procedure ...........................................148

DTC P0031, P0032, P0051, P0052 HO2S1 HEATER .149

Description ............................................................149

CONSULT-II Reference Value in Data Monitor Mode

.149

On Board Diagnosis Logic ....................................149

DTC Confirmation Procedure ...............................150

Wiring Diagram .....................................................151

Diagnostic Procedure ...........................................154

Component Inspection ..........................................156

Removal and Installation ......................................156

DTC P0037, P0038, P0057, P0058 HO2S2 HEATER .157

Description ............................................................157

CONSULT-II Reference Value in Data Monitor Mode

.157

On Board Diagnosis Logic ....................................157

DTC Confirmation Procedure ...............................158

Wiring Diagram .....................................................159

Diagnostic Procedure ...........................................162

Component Inspection ..........................................164

Removal and Installation ......................................164

DTC P0101 MAF SENSOR .....................................165

Component Description ........................................165

CONSULT-II Reference Value in Data Monitor Mode

.165

On Board Diagnosis Logic ....................................165

DTC Confirmation Procedure ...............................166

Overall Function Check ........................................167

Wiring Diagram .....................................................168

Diagnostic Procedure ...........................................169

Component Inspection ..........................................172

Removal and Installation ......................................172

DTC P0102, P0103 MAF SENSOR .........................173

Component Description ........................................173

CONSULT-II Reference Value in Data Monitor Mode

.173

On Board Diagnosis Logic ....................................173

DTC Confirmation Procedure ...............................174

Wiring Diagram .....................................................175

Diagnostic Procedure ...........................................176

Component Inspection ..........................................179

Removal and Installation ......................................179

DTC P0112, P0113 IAT SENSOR ...........................180

Component Description ........................................180

On Board Diagnosis Logic ....................................180

DTC Confirmation Procedure ...............................180

Wiring Diagram .....................................................182

Diagnostic Procedure ...........................................183

Component Inspection ..........................................184

Removal and Installation ......................................184

DTC P0117, P0118 ECT SENSOR ..........................185

Component Description ........................................185

On Board Diagnosis Logic ....................................185

DTC Confirmation Procedure ...............................186

Wiring Diagram .....................................................187

Diagnostic Procedure ...........................................188

Component Inspection ..........................................189

Removal and Installation ......................................189DTC P0122, P0123 TP SENSOR ............................190

Component Description ........................................190

CONSULT-II Reference Value in Data Monitor Mode

.190

On Board Diagnosis Logic ....................................190

DTC Confirmation Procedure ................................191

Wiring Diagram .....................................................192

Diagnostic Procedure ............................................193

Component Inspection ..........................................196

Removal and Installation .......................................196

DTC P0125 ECT SENSOR ......................................197

Component Description ........................................197

On Board Diagnosis Logic ....................................197

DTC Confirmation Procedure ................................198

Diagnostic Procedure ............................................198

Component Inspection ..........................................199

Removal and Installation .......................................199

DTC P0127 IAT SENSOR ........................................200

Component Description ........................................200

On Board Diagnosis Logic ....................................200

DTC Confirmation Procedure ................................200

Diagnostic Procedure ............................................201

Component Inspection ..........................................202

Removal and Installation .......................................202

DTC P0128 THERMOSTAT FUNCTION .................203

On Board Diagnosis Logic ....................................203

DTC Confirmation Procedure ................................203

Diagnostic Procedure ............................................203

Component Inspection ..........................................204

Removal and Installation .......................................204

DTC P0132, P0152 HO2S1 .....................................205

Component Description ........................................205

CONSULT-II Reference Value in Data Monitor Mode

.205

On Board Diagnosis Logic ....................................205

DTC Confirmation Procedure ................................206

Wiring Diagram .....................................................207

Diagnostic Procedure ............................................210

Component Inspection ..........................................212

Removal and Installation .......................................213

DTC P0133, P0153 HO2S1 .....................................214

Component Description ........................................214

CONSULT-II Reference Value in Data Monitor Mode

.214

On Board Diagnosis Logic ....................................214

DTC Confirmation Procedure ................................215

Overall Function Check .........................................216

Wiring Diagram .....................................................217

Diagnostic Procedure ............................................220

Component Inspection ..........................................224

Removal and Installation .......................................225

DTC P0134, P0154 HO2S1 .....................................226

Component Description ........................................226

CONSULT-II Reference Value in Data Monitor Mode

.226

On Board Diagnosis Logic ....................................226

DTC Confirmation Procedure ................................227

Overall Function Check .........................................228

Wiring Diagram .....................................................229