ignition INFINITI FX35 2008 Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 449 of 3924

ATC-44

< SERVICE INFORMATION >

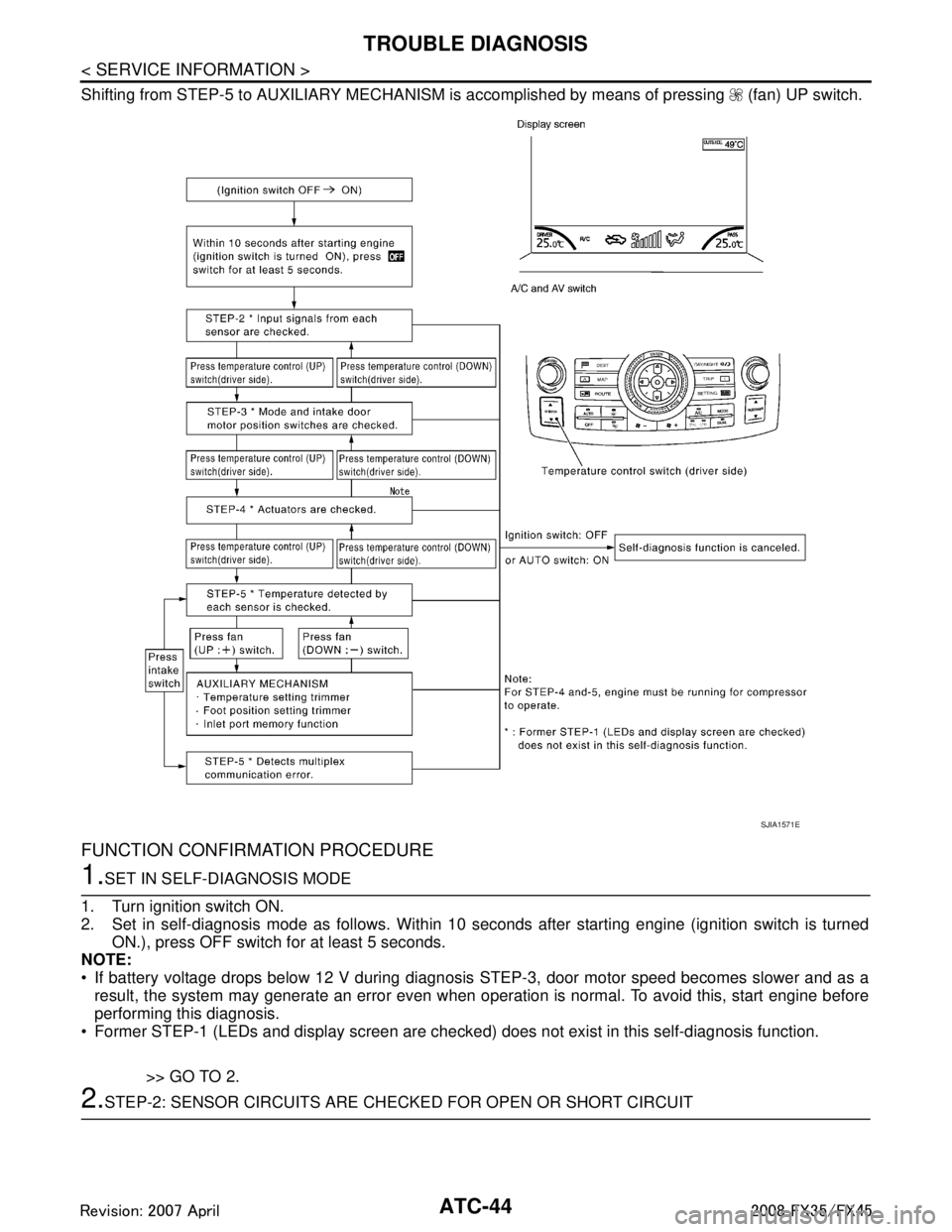

TROUBLE DIAGNOSIS

Shifting from STEP-5 to AUXILIARY MECHANISM is accomplished by means of pressing (fan) UP switch.

FUNCTION CONFIRMATION PROCEDURE

1.SET IN SELF-DIAGNOSIS MODE

1. Turn ignition switch ON.

2. Set in self-diagnosis mode as follows. Within 10 seconds after starting engine (ignition switch is turned ON.), press OFF switch for at least 5 seconds.

NOTE:

If battery voltage drops below 12 V during diagnosis STEP-3, door motor speed becomes slower and as a

result, the system may generate an error even when operation is normal. To avoid this, start engine before

performing this diagnosis.

Former STEP-1 (LEDs and display screen are checked) does not exist in this self-diagnosis function.

>> GO TO 2.

2.STEP-2: SENSOR CIRCUITS ARE CHECK ED FOR OPEN OR SHORT CIRCUIT

SJIA1571E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 452 of 3924

TROUBLE DIAGNOSISATC-47

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

10.CHECK IN-VEHICLE SENSOR

Press (DEF) switch for the second time. Temperature detected

by in-vehicle sensor is indicated on the display.

NOTE:

If the temperature indicated on the display greatly differs from the

actual temperature, check sensor circuit first, and then check sensor.

OK or NG

OK >> GO TO 11.

NG >> Go to In-vehicle Sensor Circuit. Refer to ATC-88, "

In-

vehicle Sensor Circuit".

11 .CHECK INTAKE SENSOR

Press (DEF) switch for the third time. Temperature detected by

intake sensor is indicated on the display.

NOTE:

If the temperature indicated on the display greatly differs from the

actual temperature, check sensor circuit first, and then check sensor.

OK or NG

OK >> GO TO 12.

NG >> Go to Intake Sensor Circuit. Refer to ATC-94, "

Intake

Sensor Circuit".

12.CHECK CAN COMMUNICATION ERROR

1. Press intake switch.

2. CAN communication error between the unified meter and A/C amp. and the display control unit can be detected as self-diag-

nosis results. (If plural errors occur, the display of each error will

blink twice for 0.5 second intervals.)

OK or NG

OK >> 1. Turn ignition switch OFF or AUTO switch ON. 2. INSPECTION END

NG >> Go to CAN communication. Refer to BCS-11, "

CON-

SULT-III Function (BCM)".

Unified meter and A/C amp. - Display control unit

13.CHECK MALFUNCTIONING SENSOR AND DOOR MOTOR

Refer to the following chart for malfunctioning code No.

(If two or more sensors and door motors malfuncti on, corresponding code Nos. indicates 1 second each.)

*1: Perform self-diagnosis STEP-2 under sunshine.

PJIA0152E

PJIA0153E

SJIA1611E

Code No. Malfunctioning sensor and door motor (Including circuits) Reference page 21 / −21 Ambient sensor ATC-86, "

Ambient Sensor Circuit"

22 / −22 In-vehicle sensor AT C - 8 8 , "In-vehicle Sensor Circuit"

24 / −24 Intake sensor AT C - 9 4 , "Intake Sensor Circuit"

25 / −25

Sunload sensor*1AT C - 9 1 , "Sunload Sensor Circuit"

26 / −26 Air mix door motor PBR (Driver side)

AT C - 6 2 , "Air Mix Door Motor PBR Circuit"27 / −27 Air mix door motor PBR (Passenger side)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 455 of 3924

ATC-50

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

4. Press the mode switch as desired.

When battery cable is disconnected or battery voltage is below 10 V, trimmer operation is canceled. Wind dis-

tribution ratio set becomes that of initial condition.

AUXILIARY MECHANISM: INLET PORT MEMORY FUNCTION

When ignition switch is turned from OFF to ON, inlet port memory function at manual mode can be set.

Operating procedures for this trimmer are as follows:1. Begin self-diagnosis STEP-5 mode. Refer to "Self-diagnosis Function".

2. Press (fan) UP switch to set system in auxiliary mode.

3. Press the intake switch as desired.

When battery cable is disconnected or battery voltage is below 10 V, memory function is canceled. Memory

function set becomes that of initial condition.

Operational CheckINFOID:0000000001328182

The purpose of the operational check is to c heck if the individual system operates properly.

CHECKING MEMORY FUNCTION

1. Press the temperature control (UP) switch (driver side) until 32°C (90 °F) is displayed.

2. Press OFF switch.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous temperature.

7. Press OFF switch.

If NG, go to trouble diagnosis procedure for ATC-85, "

Memory Function".

If OK, continue the check.

CHECKING BLOWER

SJIA1581E

LED status of

FRE position LED status of

REC position Setting status

Setting changeover

method

FRE REC

OFF OFF AUTO control AUTO control

Intake SW: ON

OFF ON AUTO control (Initial setting)

Manual REC status is memorized.

(Initial setting)

ON OFF Manual FRE status is memorized. AUTO control

ON ON Manual FRE status is memorized. Manual REC status is memorized.

Conditions : Engine running at normal operating temperature

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 458 of 3924

TROUBLE DIAGNOSISATC-53

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

The PTC is built into the A/C and AV switch. It can be set at an inter-

val of 0.5 °C (1.0 °F) in the 18 °C (60 °F) to 32 °C (90 °F) temperature

range by pressing temperature cont rol switch. The set temperature

is displayed.

DIAGNOSIS PROCEDURE FOR A/C SYSTEM

SYMPTOM: A/C system does not activate.

1.CHECK POWER SUPPLY CIRCUIT FO R UNIFIED METER AND A/C AMP.

1. Disconnect unified meter and A/C amp. connector.

2. Check voltage between unified meter and A/C amp. harness connector M56 terminals 21, 22 and 35, unified meter and A/C

amp. harness connector M57 terminal 46 and ground.

OK or NG

OK >> GO TO 2.

NG >> Check 10A and 15A fuses [Nos. 6, 10, 11, 12 and 19, located in the fuse block (J/B)]. Refer to

PG-77

.

If fuses are OK, check harness for open circuit. Repair or replace if necessary.

If fuses are NG, check harness fo r short circuit and replace fuse.

2.CHECK GROUND CIRCUIT FOR UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

SJIA1583E

RJIA1983E

Terminals Ignition switch position

(+)

(− )OFFACC ON

Unified

meter and A/C amp.

connector Te r m i n a l N o .

M56 21

GroundBattery volt-

age Battery

voltage Battery

voltage

M56 22 Approx. 0 V Approx. 0 V Battery

voltage

M56 35 Approx. 0 V Battery

voltage Battery

voltage

M57 46 Approx. 0 V Battery

voltage Battery

voltage

RJIA1984E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 459 of 3924

ATC-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

2. Check continuity between unified meter and A/C amp. harnessconnector M56 terminal 29, 30 and ground.

OK or NG

OK >> Replace unified meter and A/C amp.

NG >> Repair harness or connector.

LAN System CircuitINFOID:0000000001328184

SYMPTOM: Mode door motor, intake door motor and/or air mix door motor(s) does not operate normally.

DIAGNOSIS PROCEDURE FOR LAN CIRCUIT

1.CHECK POWER SUPPLY FOR UNI FIED METER AND A/C AMP.

1. Turn ignition switch ON.

2. Check voltage between unified meter and A/C amp. harness connector M57 terminal 54 and ground.

OK or NG

OK >> GO TO 2.

NG >> Replace unified meter and A/C amp.

2.CHECK SIGNAL FOR UNIFIED METER AND A/C AMP. 29, 30 – Ground : Continuity should exist.

RJIA1985E

RJIA1775E

54 – Ground : Battery voltage

RJIA1986E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 460 of 3924

TROUBLE DIAGNOSISATC-55

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Confirm A/C LAN signal between unified meter and A/C amp. har-

ness connector M57 terminal 43 and ground using an oscilloscope.

OK or NG

OK >> GO TO 3.

NG >> Replace unified meter and A/C amp.

3.CHECK POWER SUPPLY FOR EACH DOOR MOTOR

Check voltage between each door motor harness connector terminal

1 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK SIGNAL FOR EACH DOOR MOTOR

Confirm A/C LAN signal between each door motor harness connec-

tor terminal 3 and ground using an oscilloscope.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5.CHECK MOTOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect each door motor connector.

Te r m i n a l s

Vo l ta g e

(+)

(− )

Unified meter and A/

C amp. connector Te r m i n a l N o .

M57 43 Ground

RJIA1987E

SJIA1453J

1 – Ground : Battery voltage

RJIA1988E

Door motor Te r m i n a l s

Vol tag e

(+)

(− )

Con-

nector Te r m i n a l

No.

Mode M258 3

Ground

Air mix

(Driver

side)

M252 3

Air mix

(Passen-

ger side) M257 3

Intake M253 3

RJIA1989E

SJIA1453J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 461 of 3924

ATC-56

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

3. Check continuity between each door motor harness connectorterminal 2 and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6.CHECK MOTOR OPERATION

1. Reconnect each door motor connector.

2. Turn ignition switch ON.

3. Confirm operation of each door motor.

OK or NG

OK >> (Return to operate normally.) Poor contact in motor connector.

NG >> (Does not operate normally.) GO TO 7.

7.CHECK AIR MIX DOOR MOTOR AND INTAKE DOOR MOTOR OPERATION

1. Turn ignition switch OFF.

2. Disconnect mode, air mix (driver side, pass enger side), and intake door motor connectors.

3. Reconnect air mix (driver side, passenger side) and intake door motor connectors.

4. Turn ignition switch ON.

5. Confirm operation of air mix door motor (driver side, passenger side) and intake door motor.

OK or NG

OK >> [Air mix (driver side, passenger side) and intake door motors operate normally.]

Replace mode door motor.

NG >> [Air mix (driver side, passenger side) and intake door motors does not operate normally.]

GO TO 8.

8.CHECK MODE DOOR MOTOR AND INTAKE DOOR MOTOR OPERATION

1. Turn ignition switch OFF.

2. Disconnect air mix door motor (driver side, passenger side) connectors.

3. Reconnect mode door motor connector.

4. Turn ignition switch ON.

5. Confirm operation of mode door motor and intake door motor.

OK or NG

OK >> (Mode and intake door motors operate normally.) GO TO 10.

NG >> (Mode and intake door motors does not operate normally.) GO TO 9.

9.CHECK MODE DOOR MOTOR AND AIR MIX DOOR MOTOR OPERATION

1. Turn ignition switch OFF.

2. Disconnect intake door motor connector.

3. Reconnect air mix door motor (driver side, passenger side) connectors.

4. Turn ignition switch ON.

5. Confirm operation of mode door motor and air mix door motor (driver side, passenger side).

OK or NG

OK >> [Mode and air mix door motor (driver side, passenger side) operate normally.] Replace intake door motor.

NG >> [Mode and air mix door motor (driver side, passenger side) does not operate normally.]

Replace display and A/C auto amp.

10.CHECK AIR MIX DOOR MOTOR OPERATION 2 – Ground : Continuity should exist.

RJIA1990E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 462 of 3924

TROUBLE DIAGNOSISATC-57

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

1. Turn ignition switch OFF.

2. Disconnect air mix door motor (driver side) connector.

3. Turn ignition switch ON.

4. Confirm operation of air mix door motor (passenger side).

OK or NG

OK >> [Air mix door motor (passenger side) operates normally.] Replace air mix door motor (driver side).

NG >> [Air mix door motor (passenger side) does not operate normally.] Replace air mix door motor (passenger side).

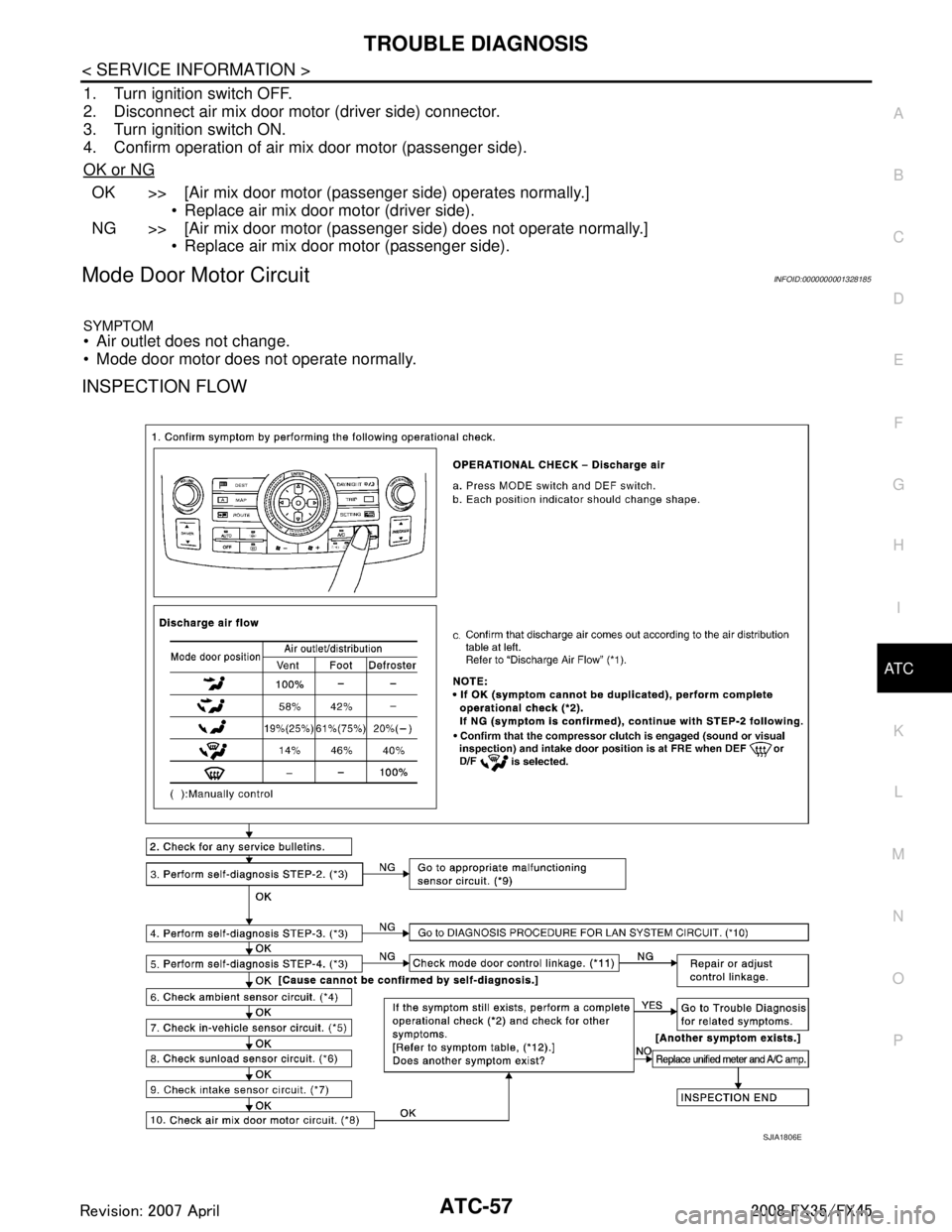

Mode Door Motor CircuitINFOID:0000000001328185

SYMPTOM

Air outlet does not change.

Mode door motor does not operate normally.

INSPECTION FLOW

SJIA1806E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 472 of 3924

TROUBLE DIAGNOSISATC-67

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

COMPONENT DESCRIPTION

Brush-Less Motor

The blower motor utilizes a brush-less motor with a rotating magnet.

Quietness is improved over previous motors where the brush was

the point of contact and the coil rotated.

DIAGNOSIS PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning.

1.CHECK POWER SUPPLY FOR BLOWER MOTOR

1. Disconnect blower motor connector.

2. Turn ignition switch ON.

3. Check voltage between blower motor harness connector M78 terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> Check power supply circuit and 15A fuses [Nos. 10 and 11, located in the fuse block (J/B)]. Refer to PG-

77.

If fuses are OK, check harness for open circuit. Repair or replace if necessary.

If fuses are NG, check harness fo r short circuit and replace fuse.

2.CHECK BLOWER MOTOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between blower motor harness connector M78 terminal 3 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK CIRCUIT CONTINUITY BETWEEN BLOWER MOTOR AND UNIFIED METER AND A/C AMP.

1. Disconnect unified meter and A/C amp. connector.

ZHA152H

SJIA0266E

1 – Ground : Battery voltage

RJIA1997E

3 – Ground : Continuity should exist.

RJIA1998E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 473 of 3924

ATC-68

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

2. Check continuity between blower motor harness connector M78terminal 2 and unified meter and A/C amp. harness connector

M57 terminal 53.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK UNIFIED METER AND A/C AMP. OUTPUT SIGNAL

1. Reconnect blower motor connector and unified meter and A/C amp. connector.

2. Turn ignition switch ON.

3. Change the fan speed from Lo to Hi, and check the duty ratios between blower motor harness connector M78 terminal 2 and

ground using an oscilloscope. Normal terminal 2 drive signal

duty ratios are shown in the table below.

OK or NG

OK >> Replace blower motor after conf irming the fan air flow does not change.

NG >> Replace unified meter and A/C amp.

COMPONENT INSPECTION

Blower Motor

2 – 53 : Continuity should exist.

RJIA1999E

RJIA2000E

SJIA1802E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C