ignition INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2867 of 3924

PRECAUTIONSGI-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precaution for Fuel (Unlead ed Premium Gasoline Recommended)INFOID:0000000001325656

VQ35DE

INFINITI recommends the use of unleaded premium gasoli ne with an octane rating of at least 91 AKI (Anti-

Knock Index) number (Research octane number 96).

If unleaded premium gasoline is not available, you may use unleaded regular gasoline with an octane rating of

at least 87AKI number (Research octane number 91), but you may notice a decrease in performance.

CAUTION:

Do not use leaded gasoli ne. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unlead ed gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fu el other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

Precaution for Fuel (Unleaded Premium Gasoline Required)INFOID:0000000001325657

VK45DE

Use unleaded premium gasoline with an octane rating of at least 91 AKI (Anti-Knock Index) number (Research

octane number 96).

If unleaded premium gasoline is not available, unleaded r egular gasoline with an octane rating of at least 87

AKI number (Research octane number 91) can be us ed, but only under the following precautions:

have the fuel tank filled only partially with unl eaded regular gasoline, and fill up with unleaded premium gas-

oline as soon as possible.

avoid full throttle driving and abrupt acceleration.

However, for maximum vehicle performance, the u se of unleaded premium gasoline is recommended.

CAUTION:

Do not use leaded gasoli ne. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unlead ed gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fu el other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

Precaution for Multiport Fuel Inject ion System or Engine Control SystemINFOID:0000000001325658

Before connecting or disconnecti ng any harness connector for the

multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

Before disconnecting pressurized fuel line from fuel pump to injec- tors, be sure to release fuel pressure.

Be careful not to jar components such as ECM and mass air flow sensor.

Precaution for HosesINFOID:0000000001325659

HOSE REMOVAL AND INSTALLATION

SGI787

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2872 of 3924

GI-10

< SERVICE INFORMATION >

HOW TO USE THIS MANUAL

3.Refer to Component Parts and Harness Connector Location for the Systems described in each

section for identifi cation/location of componen ts and harness connectors.

4. Refer to the Circuit Diagra m for quick pinpoint check.

If you need to check circuit continuity between harness connectors in more detail, such as when a

sub-harness is used, refer to Wiring Diagram in each individual section and Harness Layout in PG

section for identificatio n of harness connectors.

5. When checking circuit continuity, ignition switch should be OFF.

6. Before checking voltage at co nnectors, check battery voltage.

7. After accomplishing the Diagnost ic Procedures and Electrical Components Inspection, make sure

that all harness connectors ar e reconnected as they were.

HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES

1.Work and diagnostic procedure

Start to diagnose a problem using procedures indicated in enclosed test groups.

2. Questions and required results

Questions and required results are indicated in bold type in test group.

The meaning of are as follows:

3. Symbol used in illustration

Symbols included in illustrations refer to measur ements or procedures. Before diagnosing a problem,

familiarize yourself with each symbol. Refer to "Connector Symbols" in GI Section and "KEY TO SYM-

BOLS SIGNIFYING MEASUREME NTS OR PROCEDURES" below.

4. Action items

Next action for each test group is indicated based on result of each question. Test group number is shown

in the left upper portion of each test group.

HARNESS WIRE COLOR AND CONNECTOR NUMBER INDICATION

There are two types of harness wire color and connector number indication.

TYPE 1: Harness Wire Color and Connec tor Number are Shown in Illustration

SAIA0256E

a. Battery voltage → 11 - 14V or approximately 12V

b. Voltage : Approximately 0V → Less than 1V

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2880 of 3924

GI-18

< SERVICE INFORMATION >

HOW TO USE THIS MANUAL

Letter designations next to test meter probe indicate harness (con-nector) wire color.

Connector numbers in a single circle M33 indicate harness con-

nectors.

Component Indication

Connector numbers in a double circle F211 indicate component connectors.

Switch Positions

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

ignition switch is “OFF”,

doors, hood and trunk lid/back door are closed,

pedals are not depressed, and

parking brake is released.

Detectable Lines and Non-Detectable Lines

In some wiring diagrams, two kinds of lines, r epresenting wires, with different weight are used.

AGI070

SGI860

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2891 of 3924

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-29

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Close the relay and probe at the solenoid. voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

Testing for “Shorts” in the Circuit

To simplify the discussion of shorts in the system, please refer to the following schematic.

RESISTANCE CHECK METHOD

Disconnect the battery negative cable and remove the blown fuse.

Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground.

Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

Close SW1 and jump the relay contacts with jumper wir e. Put probes at the load side of fuse terminal and a

known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

VOLTAGE CHECK METHOD

Remove the blown fuse and disconnect all loads (i .e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

Turn the ignition key to the ON or START position. Veri fy battery voltage at the battery + side of the fuse ter-

minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

With SW1 closed, relay and solenoid disconnected and t he DMM leads across both fuse terminals, check for

voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

With SW1 closed, relay contacts jumped with fused jumper wire check for voltage.

voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

Ground Inspection

Ground connections are very important to the proper oper ation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted re sistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can drasti-

cally affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit. Even

when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

Remove the ground bolt or screw.

Inspect all mating surfaces for tarnish, dirt, rust, etc.

SGI847-A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2902 of 3924

GI-40

< SERVICE INFORMATION >

TOW TRUCK TOWING

TOW TRUCK TOWING

Tow Truck TowingINFOID:0000000001325684

CAUTION:

All applicable state or Provincial (in Canada) laws and local laws regarding the towing operation

must be obeyed.

It is necessary to use proper towi ng equipment to avoid possible damage to the vehicle during tow-

ing operation. To wing is in accordance with Towing Procedure Manual at dealer.

Always attach safety chains before towing.

When towing, make sure that the transmission, steering system and powertrain are in good order. If

any unit is damaged, dollies must be used.

Never tow an automatic transmission model from the rear (that is backward) with four wheels on the

ground. This may cause serious and exp ensive damage to the transmission.

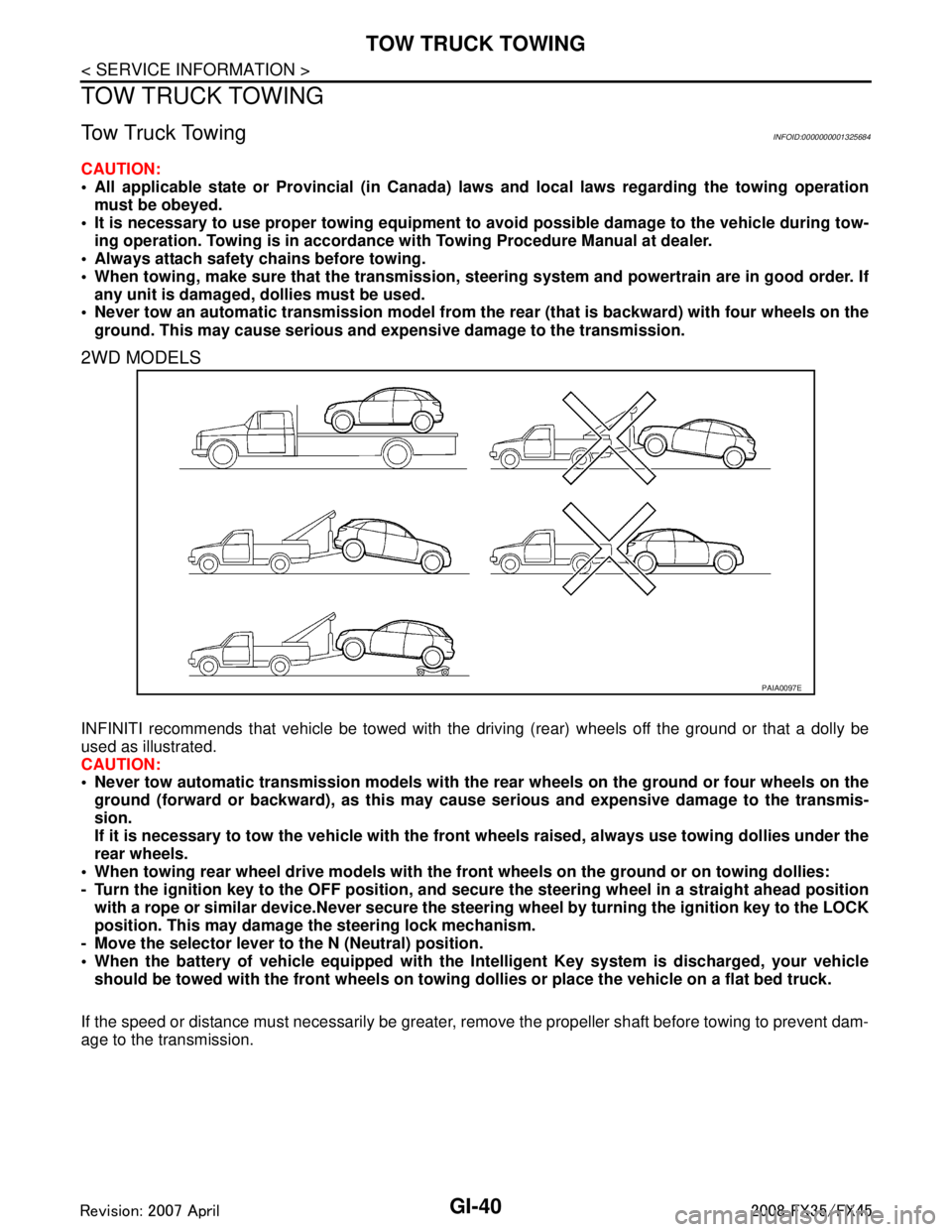

2WD MODELS

INFINITI recommends that vehicle be towed with the dr iving (rear) wheels off the ground or that a dolly be

used as illustrated.

CAUTION:

Never tow automatic transmission models with the r ear wheels on the ground or four wheels on the

ground (forward or backward), as this may cause serious and expensive damage to the transmis-

sion.

If it is necessary to tow the vehicle with the fron t wheels raised, always use towing dollies under the

rear wheels.

When towing rear wheel drive mo dels with the front wheels on the ground or on towing dollies:

- Turn the ignition key to the OFF position, and secure the steering wh eel in a straight ahead position

with a rope or similar device.Never secure the st eering wheel by turning the ignition key to the LOCK

position. This may damage the steering lock mechanism.

- Move the selector lever to the N (Neutral) position.

When the battery of vehicle equipped with the Intelligent Key system is discharged, your vehicle

should be towed with the front wh eels on towing dollies or place the vehicle on a flat bed truck.

If the speed or distance must necessarily be greater, re move the propeller shaft before towing to prevent dam-

age to the transmission.

PAIA0097E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2910 of 3924

GI-48

< SERVICE INFORMATION >

TERMINOLOGY

TERMINOLOGY

SAE J1930 Terminology ListINFOID:0000000001325691

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old te rms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATION OLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONS ULT-II DLC for CONSULT-II Diagno stic connector for CONSULT-II

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memory EEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2911 of 3924

TERMINOLOGYGI-49

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Exhaust gas recirculation control-BPT

valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valve EGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memory FEEPROM ***

Flash erasable programmable read only

memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulato r *** Pressure regulator

Fuel pressure regulator control solenoid

valve *** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulato r IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valve IACV-AAC valve Auxiliary

air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valve IACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold su rface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2929 of 3924

GW-16

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

to power window main switch terminal 19

to front power window switch (passenger side) terminal 10.

through 15A fuse [No. 22, located in the fuse block (J/B)]

to BCM terminal 42.

With ignition switch in ON or START position,

Power is supplied

through 15A fuse [No. 1, located in the fuse block (J/B)]

to BCM terminal 38, and

trough BCM terminal 53

to power window main switch terminal 10

to rear power window switch (LH and RH) terminal 1.

Ground supplied

to BCM terminal 49 and 52

through body grounds M35, M45 and M85.

to power window main switch terminal 17

through body grounds M35, M45 and M85.

to front power window switch (passenger side) terminal 11

through body grounds M35, M45 and M85.

MANUAL OPERATION

Front Driver Side Door

WINDOW UP

When the front LH switch in the power window main switch is pressed in the up position,

Power is supplied

through power window main switch terminal 8

to front power window motor (driver side) terminal 2.

Ground is supplied

to front power window motor (driver side) terminal 1

through power window main switch terminal 11.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the front LH switch in the power window main switch is pressed in the down position

Power is supplied

through power window main switch terminal 11

to front power window motor (driver side) terminal 1.

Ground is supplied

to front power window motor (driver side) terminal 2

through power window main switch terminal 8.

Then, the motor lowers the window until the switch is released.

Front Passenger Side Door

FRONT POWER WINDOW SWITCH (P ASSENGER SIDE) OPERATION

WINDOW UP

When the front power window switch (pass enger side) is pressed in the up position

Power is supplied

through front power window switch (passenger side) terminal 8

to front power window motor (passenger side) terminal 2.

Ground is supplied

to front power window motor (passenger side) terminal 1

through front power window switch (passenger side) terminal 9.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the front power window switch (passenger side) is pressed in the down position

Power is supplied

through front power window switch (passenger side) terminal 9

to front power window motor (passenger side) terminal 1.

Ground is supplied

to front power window motor (passenger side) terminal 2

through front power window switch (passenger side) terminal 8.

Then, the motor lowers the window until the switch is released.

POWER WINDOW MAIN SWITCH OPERATION

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2931 of 3924

GW-18

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

The one is applied only for front doors and the other is for all doors.

POWER WINDOW SERIAL LINK

Power window main switch, front power window switch (passenger side), and BCM transmit and receive the

signal by power window serial link.

The under mentioned signal is transmitted from BCM to power window main switch and front power window

switch (passenger side)

Keyless power window down signal.

The under mentioned signal is transmitted from power window main switch to front power window switch (pas-

senger side)

Front passenger side door window operation signal.

Power window control by key cylinder switch signal.

Power window lock signal.

Retained power operation signal.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for driver side door window.

When the lock position, ground of the rear power window switches in the power window main switch is discon-

nected. The power window lock signal is transmitted to front power window switch (passenger side) by power

window serial link. This prevents t he power window motors from operating.

RETAINED POWER OPERATION

When the ignition switch is turned to the OFF position from ON or START position.

Power is supplied for 45 seconds

through BCM terminal 53

to power window main switch terminal 10

to rear power window switch (LH and RH) terminals 1.

When power and ground are supplied, the BCM conti nues to be energized, and the power window can be

operated.

The retained power operation is canceled when the driver or passenger side door is opened.

RAP signal period can be changed by CONSULT-III. Refer to GW-26, "

CONSULT-III Function".

ANTI-PINCH SYSTEM

Power window main switch and front power window switch (passenger side) monitors the power window motor

operation and the power window position (full closed or other) for driver side and passenger side power win-

dow by the signals from encoder and limit switch in front power window motor (driver side and passenger

side).

When power window main switch detects inte rruption during the following close operation,

automatic close operation when igniti on switch is in the “ON” position

automatic close operation during retained power operation

manual close operation during retained power operation

power window main switch or front power window swit ch (passenger side) controls each power window motor

for open and the power window will be lowered about 150 mm (5.91 in).

POWER WINDOW CONTROL BY THE KEY CYLINDER SWITCH

When ignition key switch is OFF, front power window can be opened or closed by turning the key cylinder

switch UNLOCK / LOCK position more than 1.5 second over condition.

Power window can be opened as the door key cylinder is kept fully turning to the UNLOCK position.

Power window can be closed as the door key cylinder is kept fully turning to the LOCK position.

The power window DOWN stops when the following operations are carried out.

While performing open / close the window, power window is stopped at the position as the door key cylinder is placed on NEUTRAL.

When the ignition switch is turned ON while the power window DOWN is operated.

CAN Communication System DescriptionINFOID:0000000001327964

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2937 of 3924

GW-24

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

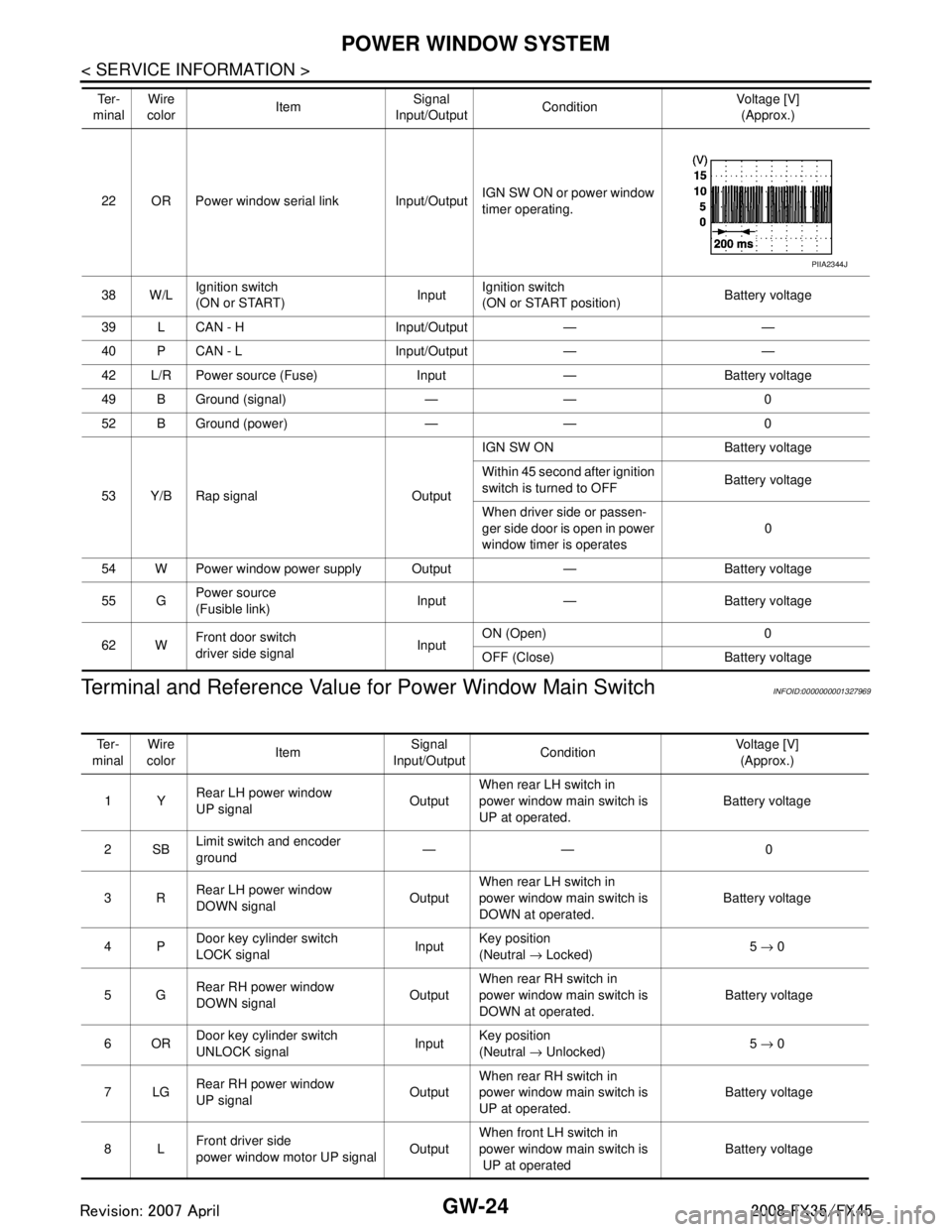

Terminal and Reference Value for Power Window Main Switch

INFOID:0000000001327969

22 OR Power window serial link Input/Output IGN SW ON or power window

timer operating.

38 W/L Ignition switch

(ON or START) InputIgnition switch

(ON or START position) Battery voltage

39 L CAN - H Input/Output — —

40 P CAN - L Input/Output — —

42 L/R Power source (Fuse) Input — Battery voltage

49 B Ground (signal) — — 0

52 B Ground (power) — — 0

53 Y/B Rap signal Output IGN SW ON Battery voltage

Within 45 second after ignition

switch is turned to OFF

Battery voltage

When driver side or passen-

ger side door is open in power

window timer is operates 0

54 W Power window power supply Output — Battery voltage

55 G Power source

(Fusible link)

Input — Battery voltage

62 W Front door switch

driver side signal InputON (Open) 0

OFF (Close) Battery voltage

Te r -

minal Wire

color Item Signal

Input/Output Condition Voltage [V]

(Approx.)

PIIA2344J

Te r -

minal Wire

color Item Signal

Input/Output Condition Voltage [V]

(Approx.)

1Y Rear LH power window

UP signal OutputWhen rear LH switch in

power window main switch is

UP at operated. Battery voltage

2SB Limit switch and encoder

ground —— 0

3R Rear LH power window

DOWN signal OutputWhen rear LH switch in

power window main switch is

DOWN at operated. Battery voltage

4P Door key cylinder switch

LOCK signal InputKey position

(Neutral

→ Locked) 5

→ 0

5G Rear RH power window

DOWN signal OutputWhen rear RH switch in

power window main switch is

DOWN at operated. Battery voltage

6OR Door key cylinder switch

UNLOCK signal Input

Key position

(Neutral

→ Unlocked) 5

→ 0

7LG Rear RH power window

UP signal OutputWhen rear RH switch in

power window main switch is

UP at operated. Battery voltage

8L Front driver side

power window motor UP signal

OutputWhen front LH switch in

power window main switch is

UP at operated

Battery voltage

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C