window INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2956 of 3924

POWER WINDOW SYSTEMGW-43

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

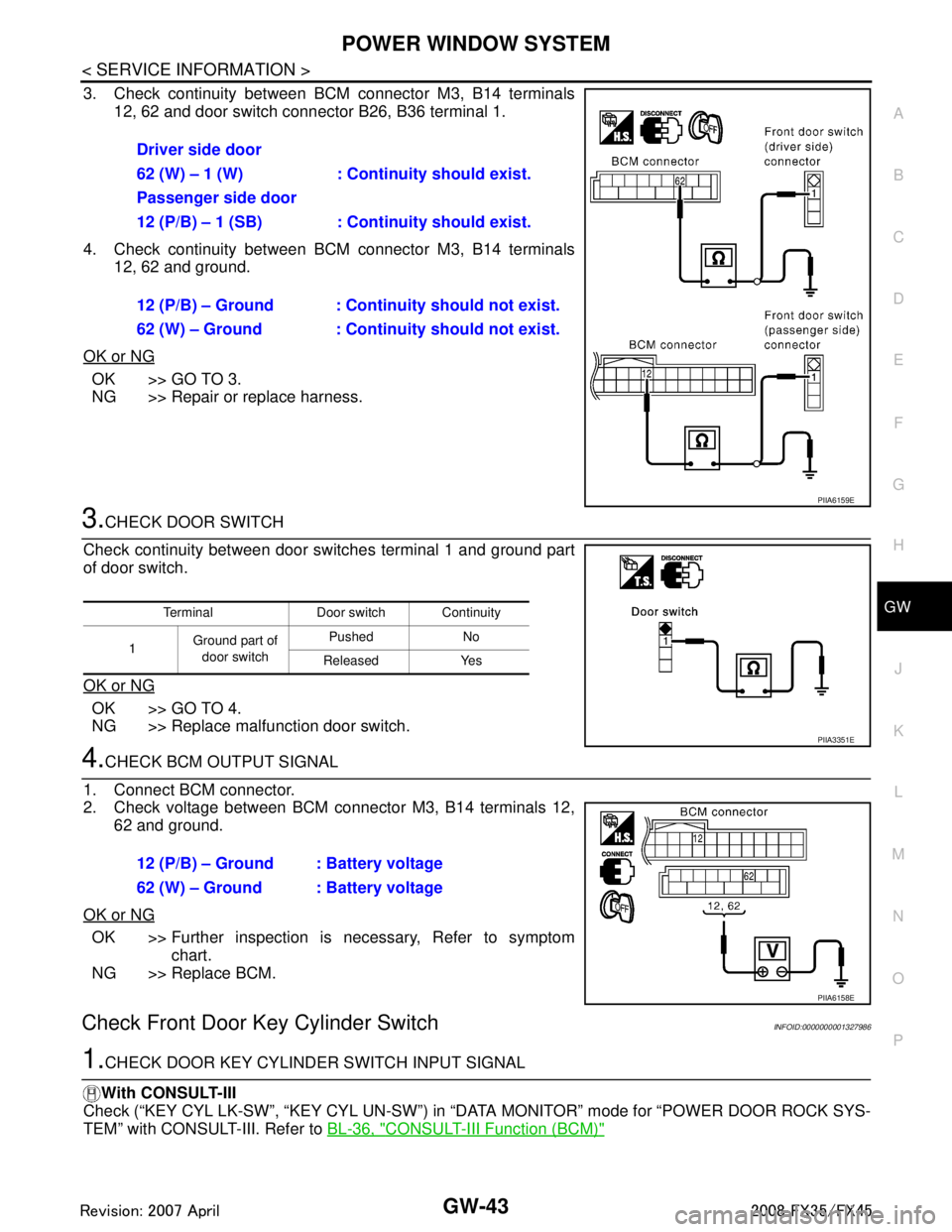

3. Check continuity between BCM connector M3, B14 terminals 12, 62 and door switch connector B26, B36 terminal 1.

4. Check continuity between BCM connector M3, B14 terminals 12, 62 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

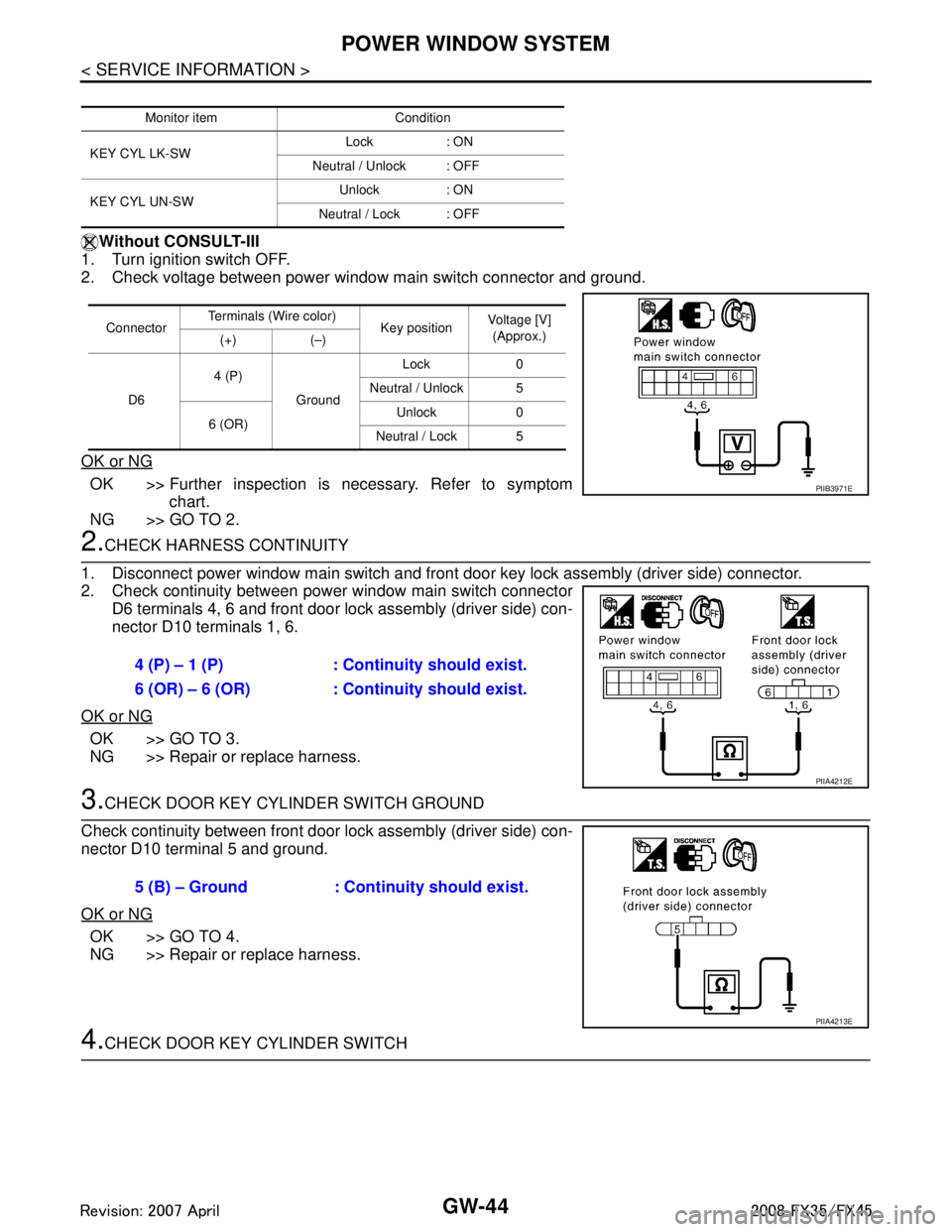

3.CHECK DOOR SWITCH

Check continuity between door switches terminal 1 and ground part

of door switch.

OK or NG

OK >> GO TO 4.

NG >> Replace malfunction door switch.

4.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Check voltage between BCM connector M3, B14 terminals 12, 62 and ground.

OK or NG

OK >> Further inspection is necessary, Refer to symptom chart.

NG >> Replace BCM.

Check Front Door Key Cylinder SwitchINFOID:0000000001327986

1.CHECK DOOR KEY CYLINDER SWITCH INPUT SIGNAL

With CONSULT-III

Check (“KEY CYL LK-SW”, “KEY CYL UN-SW”) in “D ATA MONITOR” mode for “POWER DOOR ROCK SYS-

TEM” with CONSULT-III. Refer to BL-36, "

CONSULT-III Function (BCM)"

Driver side door

62 (W) – 1 (W) : Continuity should exist.

Passenger side door

12 (P/B) – 1 (SB) : Continuity should exist.

12 (P/B) – Ground : Contin uity should not exist.

62 (W) – Ground : Contin uity should not exist.

PIIA6159E

Terminal Door switch Continuity

1 Ground part of

door switch Pushed No

Released Yes

PIIA3351E

12 (P/B) – Ground : Battery voltage

62 (W) – Ground : Battery voltage

PIIA6158E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2957 of 3924

GW-44

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

Without CONSULT-III

1. Turn ignition switch OFF.

2. Check voltage between power window main switch connector and ground.

OK or NG

OK >> Further inspection is necessary. Refer to symptom chart.

NG >> GO TO 2.

2.CHECK HARNESS CONTINUITY

1. Disconnect power window main switch and front door key lock assembly (driver side) connector.

2. Check continuity between power window main switch connector D6 terminals 4, 6 and front door lock assembly (driver side) con-

nector D10 terminals 1, 6.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK DOOR KEY CYLINDER SWITCH GROUND

Check continuity between front door lock assembly (driver side) con-

nector D10 terminal 5 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK DOOR KEY CYLINDER SWITCH

Monitor item Condition

KEY CYL LK-SW Lock : ON

Neutral / Unlock : OFF

KEY CYL UN-SW Unlock : ON

Neutral / Lock : OFF

Connector Terminals (Wire color)

Key position Voltage [V]

(Approx.)

(+) (–)

D6 4 (P)

Ground Lock 0

Neutral / Unlock 5

6 (OR) Unlock 0

Neutral / Lock 5

PIIB3971E

4 (P) – 1 (P) : Conti nuity should exist.

6 (OR) – 6 (OR) : Cont inuity should exist.

PIIA4212E

5 (B) – Ground : Continuity should exist.

PIIA4213E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2958 of 3924

POWER WINDOW SYSTEMGW-45

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

Check continuity between door lock assembly terminals 1, 6 and 5.

OK or NG

OK >> Further inspection is necessary. Refer to symptom chart.

NG >> Replace front door key cylinder (driver side) switch.

Check Power Window Serial Link (Passenger Side)INFOID:0000000001327987

1.CHECK POWER WINDOW SWITCH OUTPUT SIGNAL

With CONSULT-III

Check (“CDL LOCK SW ”, “CDL UNLOCK SW”) in DATA MONITOR mode for “REMOTE KEYLESS ENTRY

SYSTEM” with CONSULT-III. Refer to BL-36, "

CONSULT-III Function (BCM)".

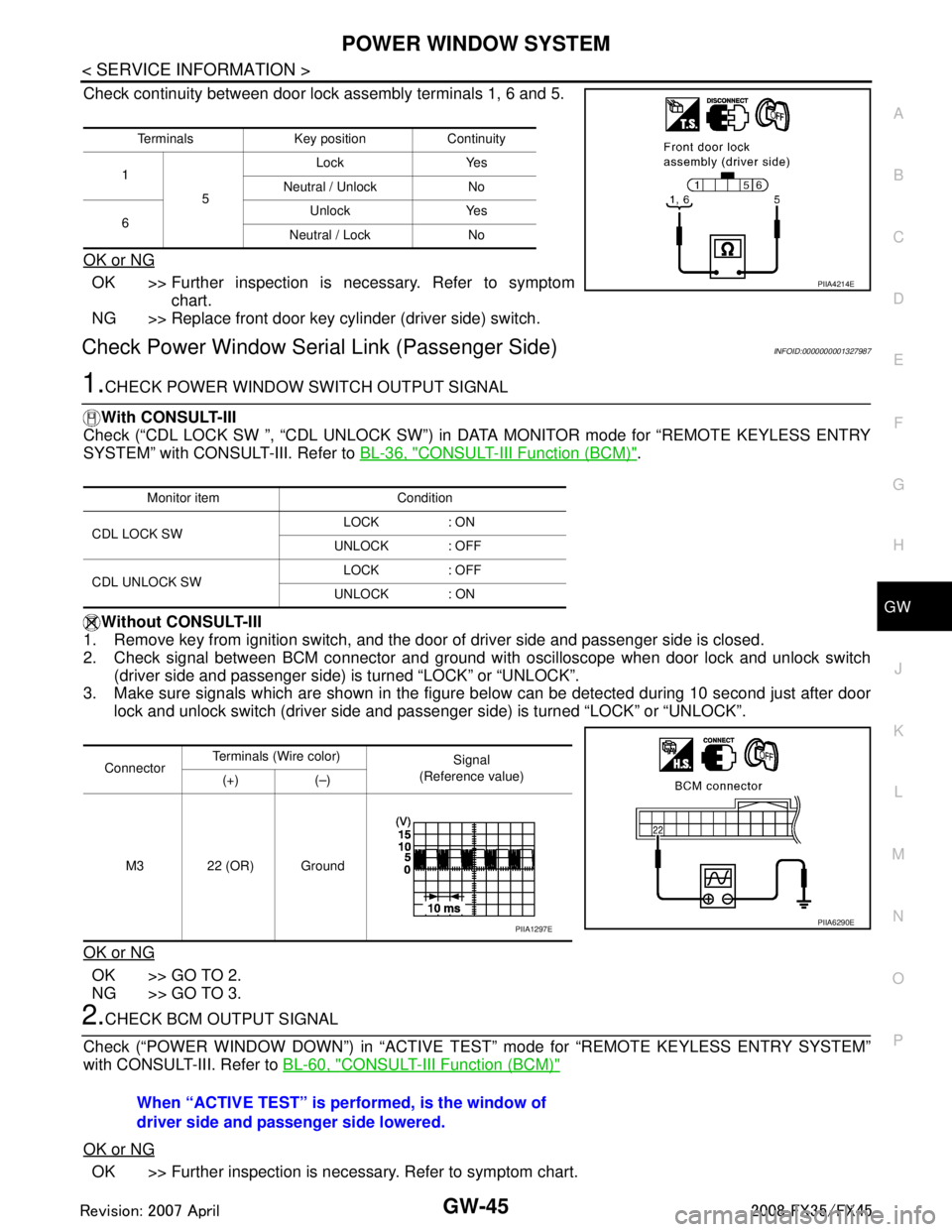

Without CONSULT-III

1. Remove key from ignition switch, and the door of driver side and passenger side is closed.

2. Check signal between BCM connector and ground wit h oscilloscope when door lock and unlock switch

(driver side and passenger side) is turned “LOCK” or “UNLOCK”.

3. Make sure signals which are shown in the figure below can be detected during 10 second just after door

lock and unlock switch (driver side and passenger side) is turned “LOCK” or “UNLOCK”.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK BCM OUTPUT SIGNAL

Check (“POWER WINDOW DOWN”) in “ACTIVE T EST” mode for “REMOTE KEYLESS ENTRY SYSTEM”

with CONSULT-III. Refer to BL-60, "

CONSULT-III Function (BCM)"

OK or NG

OK >> Further inspection is necessary. Refer to symptom chart.

Terminals Key position Continuity

1 5 Lock Yes

Neutral / Unlock No

6 Unlock Yes

Neutral / Lock No

PIIA4214E

Monitor item Condition

CDL LOCK SW LOCK : ON

UNLOCK : OFF

CDL UNLOCK SW LOCK : OFF

UNLOCK : ON

Connector Terminals (W

ire color)

Signal

(Reference value)

(+) (–)

M3 22 (OR) Ground

PIIA6290EPIIA1297E

When “ACTIVE TEST” is performed, is the window of

driver side and passenger side lowered.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2959 of 3924

GW-46

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

NG >> Replace BCM.

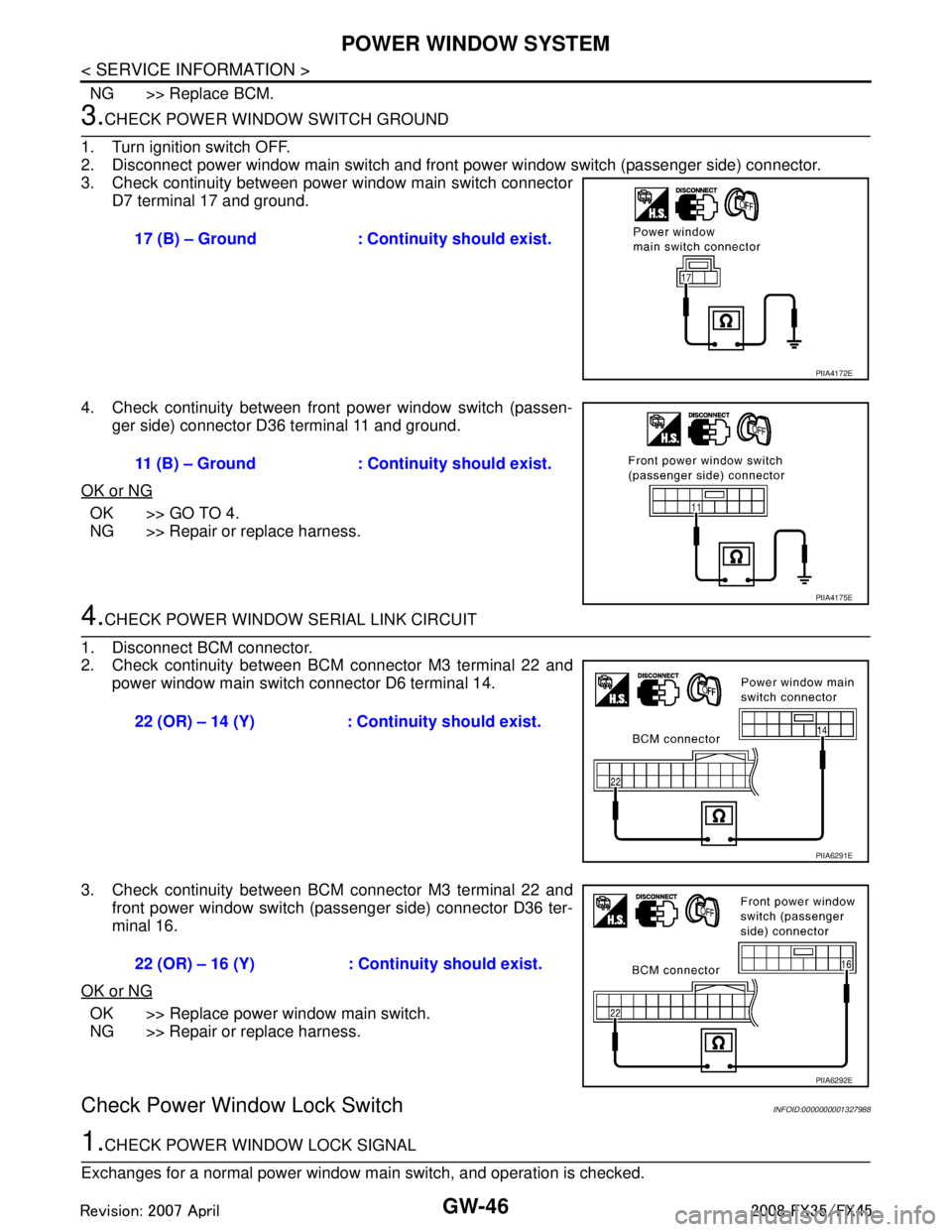

3.CHECK POWER WINDOW SWITCH GROUND

1. Turn ignition switch OFF.

2. Disconnect power window main switch and front power window switch (passenger side) connector.

3. Check continuity between power window main switch connector D7 terminal 17 and ground.

4. Check continuity between front power window switch (passen- ger side) connector D36 terminal 11 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK POWER WINDOW SERIAL LINK CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM connector M3 terminal 22 and power window main switch connector D6 terminal 14.

3. Check continuity between BCM connector M3 terminal 22 and front power window switch (passenger side) connector D36 ter-

minal 16.

OK or NG

OK >> Replace power window main switch.

NG >> Repair or replace harness.

Check Power Window Lock SwitchINFOID:0000000001327988

1.CHECK POWER WINDOW LOCK SIGNAL

Exchanges for a normal power window main switch, and operation is checked. 17 (B) – Ground : Continuity should exist.

PIIA4172E

11 (B) – Ground : Continuity should exist.

PIIA4175E

22 (OR) – 14 (Y) : Cont

inuity should exist.

PIIA6291E

22 (OR) – 16 (Y) : Cont inuity should exist.

PIIA6292E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2960 of 3924

POWER WINDOW SYSTEMGW-47

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

Does power window lock operate?

YES >> Replace power window main switch.

NO >> Check condition of harness and connector.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2961 of 3924

GW-48

< SERVICE INFORMATION >

SIDE WINDOW GLASS

SIDE WINDOW GLASS

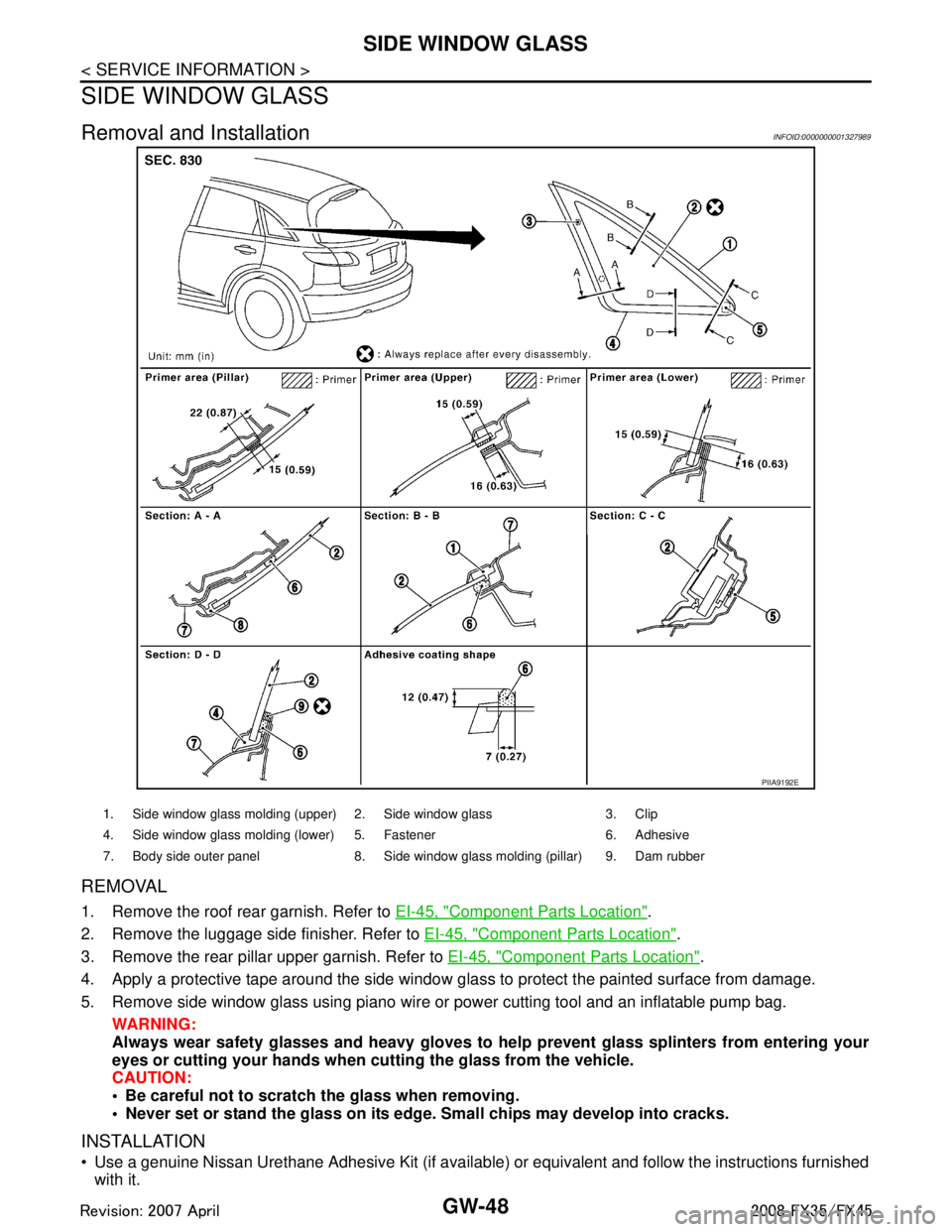

Removal and InstallationINFOID:0000000001327989

REMOVAL

1. Remove the roof rear garnish. Refer to EI-45, "Component Parts Location".

2. Remove the luggage side finisher. Refer to EI-45, "

Component Parts Location".

3. Remove the rear pillar upper garnish. Refer to EI-45, "

Component Parts Location".

4. Apply a protective tape around the side window gl ass to protect the painted surface from damage.

5. Remove side window glass using piano wire or power cutting tool and an inflatable pump bag. WARNING:

Always wear safety glasses and heavy gloves to help prevent glass splinters from entering your

eyes or cutting your hands when cu tting the glass from the vehicle.

CAUTION:

Be careful not to scratch the glass when removing.

Never set or stand the glass on its edge. Small chips may develop into cracks.

INSTALLATION

Use a genuine Nissan Urethane Adhesive Kit (if available) or equivalent and follow the instructions furnished

with it.

PIIA9192E

1. Side window glass molding (upper) 2. Side window glass 3. Clip

4. Side window glass molding (lower) 5. Fastener 6. Adhesive

7. Body side outer panel 8. Side window glass molding (pillar) 9. Dam rubber

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2962 of 3924

SIDE WINDOW GLASSGW-49

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

While the urethane adhesive is curing, open all door window s. This will prevent the glass from being forced

out by passenger room air pressure when all doors are closed.

The molding must be installed securely so that it is in position and leaves no clearance.

Inform the customer that the v ehicle should remain stationary until the urethane adhesive has completely

cured (approximately 24 hours). Curing time varies with temperature and humidity.

WARNING:

Keep heat and open flames away as primers and adhesive are flammable.

The materials contained in the ki t are harmful if swallowed, and may irritate skin and eyes. Never let

them in contact with the skin and eyes.

Use in an open, well ventilated location. Never breathe the vapors. They may be harmful if inhaled.

Move immediately to an area with fresh air if affected by vapor inhalation.

Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the side window in case of an accident.

CAUTION:

Never use an adhesive which is past its usable term. Shelf life of this product is limited to six months

after the date of manufacture. Adhere carefully to the expiration or manufacture date printed on the

box.

Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

Never leave primers or adhesive cartridge un attended with their caps open or off.

The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depend ing on temperature and humidities. The curing time will increase

under lower temperature and lower humidity.

Repairing Water Leakage for side window glass

Leakage can be repaired without removing glass.

Determine the extent of leakage if water is leaki ng between the urethane adhesive material and body or glass.

This can be done by applying water to the side window area while pushing glass outward.

Apply primer (if necessary) and then urethane adhes ive to the leakage point to stop the leakage.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2963 of 3924

GW-50

< SERVICE INFORMATION >

FRONT DOOR GLASS AND REGULATOR

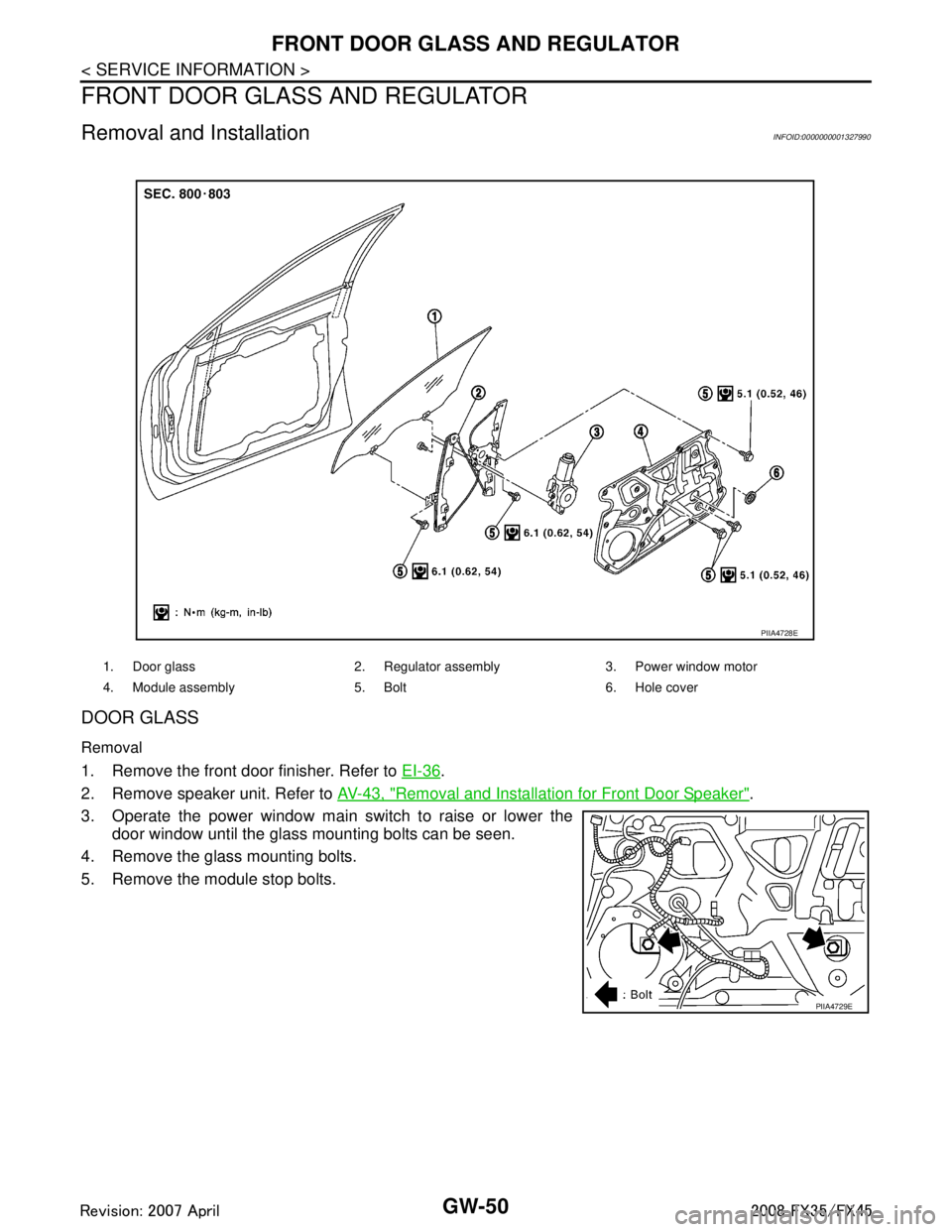

FRONT DOOR GLASS AND REGULATOR

Removal and InstallationINFOID:0000000001327990

DOOR GLASS

Removal

1. Remove the front door finisher. Refer to EI-36.

2. Remove speaker unit. Refer to AV-43, "

Removal and Installation for Front Door Speaker".

3. Operate the power window main switch to raise or lower the door window until the glass mounting bolts can be seen.

4. Remove the glass mounting bolts.

5. Remove the module stop bolts.

1. Door glass 2. Regulator assembly 3. Power window motor

4. Module assembly 5. Bolt 6. Hole cover

PIIA4728E

PIIA4729E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2964 of 3924

FRONT DOOR GLASS AND REGULATORGW-51

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

6. While holding the door glass, raise it at the rear end to pull the glass out of the sash toward the outside of the door.

Installation

Install in the reverse order of removal.

REGULATOR ASSEMBLY

Removal

1. Remove the front door finisher. Refer to EI-36.

2. Remove speaker unit. Refer to AV-43, "

Removal and Installation for Front Door Speaker".

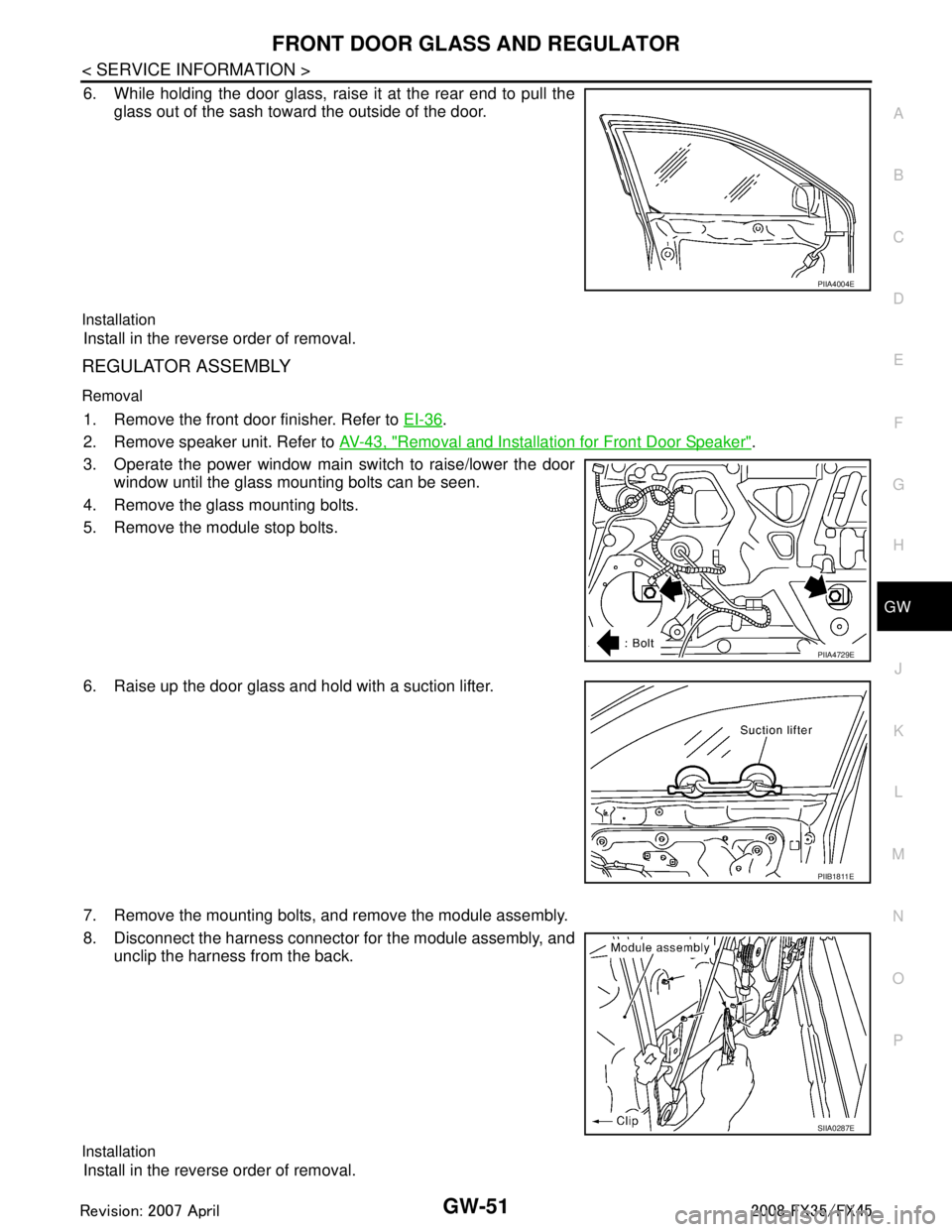

3. Operate the power window main switch to raise/lower the door window until the glass mounting bolts can be seen.

4. Remove the glass mounting bolts.

5. Remove the module stop bolts.

6. Raise up the door glass and hold with a suction lifter.

7. Remove the mounting bolts, and remove the module assembly.

8. Disconnect the harness connector for the module assembly, and

unclip the harness from the back.

Installation

Install in the reverse order of removal.

PIIA4004E

PIIA4729E

PIIB1811E

SIIA0287E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2965 of 3924

GW-52

< SERVICE INFORMATION >

FRONT DOOR GLASS AND REGULATOR

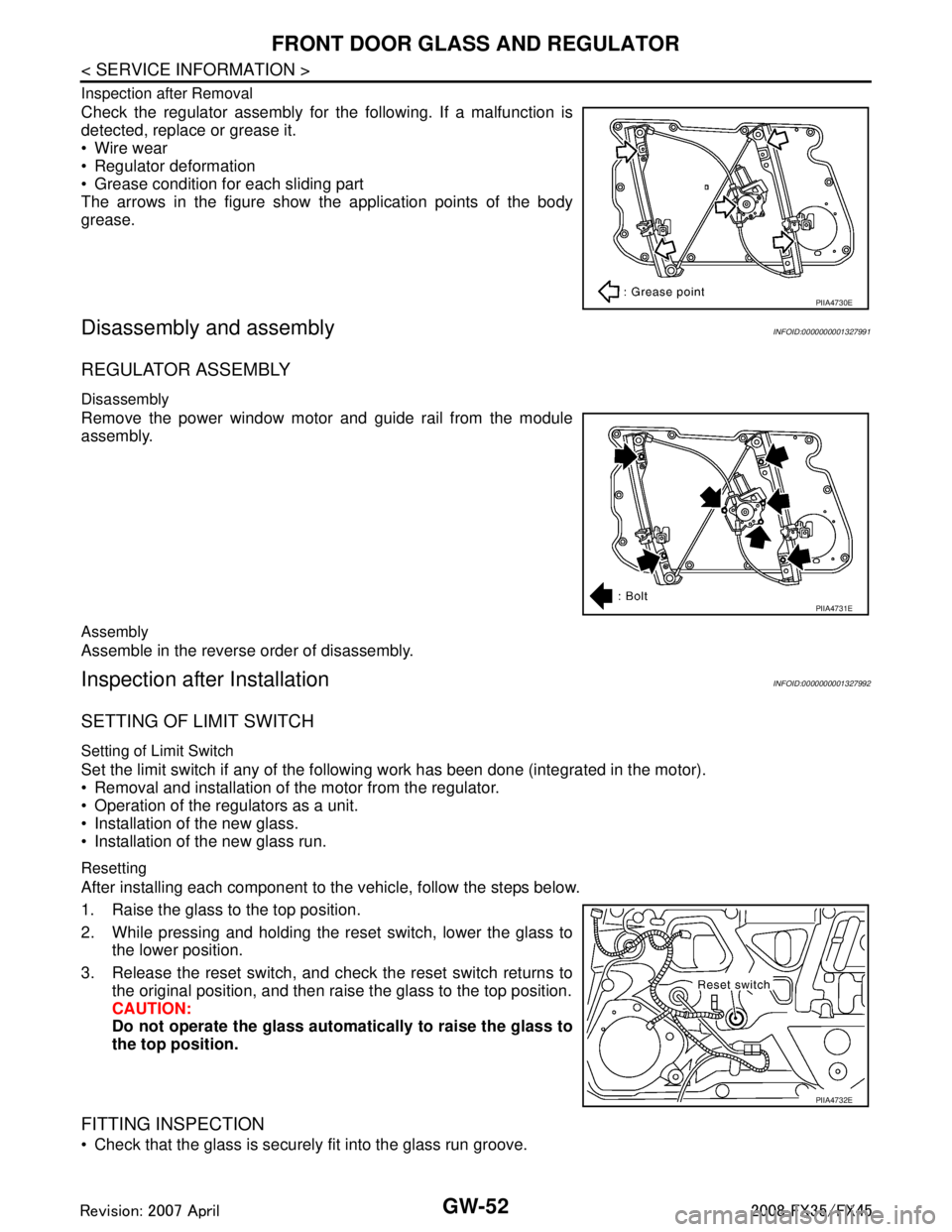

Inspection after Removal

Check the regulator assembly for the following. If a malfunction is

detected, replace or grease it.

Wire wear

Regulator deformation

Grease condition for each sliding part

The arrows in the figure show the application points of the body

grease.

Disassembly and assemblyINFOID:0000000001327991

REGULATOR ASSEMBLY

Disassembly

Remove the power window motor and guide rail from the module

assembly.

Assembly

Assemble in the reverse order of disassembly.

Inspection after InstallationINFOID:0000000001327992

SETTING OF LIMIT SWITCH

Setting of Limit Switch

Set the limit switch if any of the following work has been done (integrated in the motor).

Removal and installation of the motor from the regulator.

Operation of the regulators as a unit.

Installation of the new glass.

Installation of the new glass run.

Resetting

After installing each component to the vehicle, follow the steps below.

1. Raise the glass to the top position.

2. While pressing and holding the reset switch, lower the glass to the lower position.

3. Release the reset switch, and check the reset switch returns to the original position, and then rais e the glass to the top position.

CAUTION:

Do not operate the glass automa tically to raise the glass to

the top position.

FITTING INSPECTION

Check that the glass is securely fit into the glass run groove.

PIIA4730E

PIIA4731E

PIIA4732E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C