ignition INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3267 of 3924

INTERIOR ROOM LAMPLT-165

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

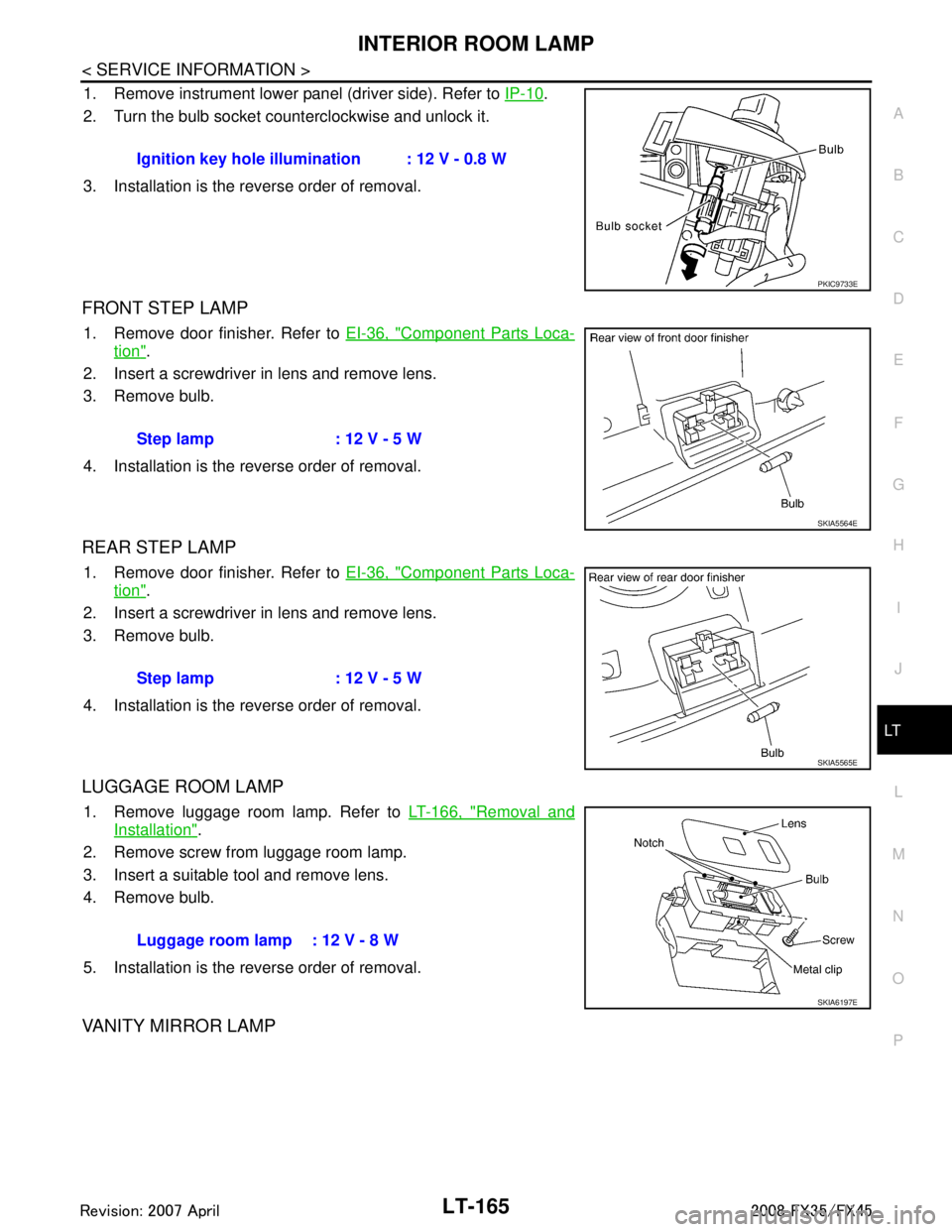

1. Remove instrument lower panel (driver side). Refer to IP-10.

2. Turn the bulb socket counterclockwise and unlock it.

3. Installation is the reverse order of removal.

FRONT STEP LAMP

1. Remove door finisher. Refer to EI-36, "Component Parts Loca-

tion".

2. Insert a screwdriver in lens and remove lens.

3. Remove bulb.

4. Installation is the reverse order of removal.

REAR STEP LAMP

1. Remove door finisher. Refer to EI-36, "Component Parts Loca-

tion".

2. Insert a screwdriver in lens and remove lens.

3. Remove bulb.

4. Installation is the reverse order of removal.

LUGGAGE ROOM LAMP

1. Remove luggage room lamp. Refer to LT-166, "Removal and

Installation".

2. Remove screw from luggage room lamp.

3. Insert a suitable tool and remove lens.

4. Remove bulb.

5. Installation is the reverse order of removal.

VANITY MIRROR LAMP

Ignition key hole illumination : 12 V - 0.8 W

PKIC9733E

Step lamp : 12 V - 5 W

SKIA5564E

Step lamp : 12 V - 5 W

SKIA5565E

Luggage room lamp : 12 V - 8 W

SKIA6197E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3271 of 3924

ILLUMINATIONLT-169

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

ILLUMINATION

System DescriptionINFOID:0000000001328422

Control of illumination lamps operation is dependent upon position of lighting switch (combination switch).

When lighting switch is placed in the 1ST or 2ND positi on (or if auto light system is activated), BCM (body con-

trol module) receives input signal requesting illuminati on lamps to illuminate. This input signal is communi-

cated to IPDM E/R (intelligent power distribution module engine room) through the CAN communication. The

CPU (central processing unit) located in the IPDM E/R co ntrols tail lamp relay coil. This relay, when energized,

directs power to illumination lamps, which then illuminate.

Power is supplied at all times

through 10A fuse (No. 71, located in IPDM E/R)

to tail lamp relay, located in IPDM E/R, and

to CPU located in IPDM E/R.

Power is also supplied at all times

through 50A fusible link (letter M, located in fuse, fusible link and relay box)

to BCM terminal 55,

through 15A fuse [No. 22 located in fuse block (J/B)]

to BCM terminal 42,

through 15A fuse (No. 78, located in IPDM E/R)

to CPU located in IPDM E/R,

through 10A fuse [No. 19 located in fuse block (J/B)]

to unified meter and A/C amp. terminal 21 and

to combination meter terminal 8.

With ignition switch in ON or START position, power is supplied

to ignition relay, located in IPDM E/R, from battery direct,

through 15A fuse [No. 1 located in fuse block (J/B)]

to BCM terminal 38,

through 10A fuse [No. 12, located in fuse block (J/B)]

to unified meter and A/C amp. terminal 22 and

to combination meter terminal 7.

With ignition switch in ACC or ON position, power is supplied

through 10A fuse [No. 6, located in fuse block (J/B)]

to combination meter terminal 4 and

to BCM terminal 11.

Ground is supplied

to BCM terminals 49 and 52

to unified meter and A/C amp. terminals 29 and 30, and

to combination meter terminals 5, 6, and 15

through grounds M35, M45, and M85,

to IPDM E/R terminals 38 and 60

through grounds E21, E50, and E51.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With lighting switch in the 1ST or 2ND position (or if auto light system is activated), BCM receives input signal

requesting illumination lamps to illuminate. This input signal is communicated to IPDM E/R through the CAN

communication. The CPU located in the IPDM E/R controls tail lamp relay coil, which, when energized, directs

power

through IPDM E/R terminal 22

to glove box lamp terminal 1

to A/T device (illumination) terminal 11

to snow mode switch (illumination) terminal 5

to VDC off switch (illumination) terminal 3

to clock (illumination) terminal 3

to hazard switch (illumination) terminal 3

to heated seat switch (driver side) (illumination) terminal 5

to heated seat switch (passenger side) (illumination) terminal 5

to door mirror remote control switch (illumination) terminal 16

to LDW switch (illumination) terminal 5

to combination switch (spiral cable) terminal 26

to microphone terminal 2 (with telephone system)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3272 of 3924

LT-170

< SERVICE INFORMATION >

ILLUMINATION

to A/C and AV switch (illumination) terminal 3

to DVD player (illumination) terminal 12

to coin box illumination terminal 2 and

to rear power window switch LH and RH (illumination) terminals 6,

through combination switch (spiral cable) terminal 18

to audio steering switch (illumination)

to icc steering switch (illumination) (with icc) and

to ascd steering switch (illumination) (without icc)

Illumination control

through combination meter terminal 19

to A/T device (illumination) terminal 12

to snow mode switch (illumination) terminal 6

to VDC off switch (illumination) terminal 4

to clock (illumination) terminal 4

to hazard switch (illumination) terminal 4

to heated seat switch (driver side) (illumination) terminal 6

to heated seat switch (passenger side) (illumination) terminal 6

to door mirror remote control switch terminal 15

to LDW switch (illumination) terminal 4,

to combination switch (spiral cable) terminal 27

to A/C and AV switch (illumination) terminal 4 and

to DVD player (illumination) terminal 10,

through combination switch (spiral cable) terminal 21

to audio steering switch (illumination)

to icc steering switch (illumination) (with icc) and

to ascd steering switch (illumination) (without icc)

Ground is supplied at all times

to glove box lamp terminal 2 and

to coin box illumination terminal 3

through grounds M35, M45 and M85,

to rear power window switch LH and RH (illumination) terminals 7

through grounds B15 and B45.

With power and ground supplied, illumination lamps illuminate.

EXTERIOR LAMP BATTERY SAVER CONTROL

When the lighting switch is in the 1ST or 2ND position (or if auto light system is activated), and ignition switch

is turned from ON or ACC to OFF, batte ry saver control function is activated.

Under this condition, illumination lamps remain illuminated for 5 minutes, then illumination lamps are turned

off.

When the lighting switch is turned from OFF to 1ST or 2 ND position (or if auto light system is activated) after

illumination lamps are turned off by battery save r control, and illumination lamps illuminate again.

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-III.

CAN Communication System DescriptionINFOID:0000000001328423

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitINFOID:0000000001328424

Refer to LAN-43, "CAN System Specification Chart".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3285 of 3924

BULB SPECIFICATIONSLT-183

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

BULB SPECIFICATIONS

HeadlampINFOID:0000000001328429

Exterior LampINFOID:0000000001328430

Interior Lamp/IlluminationINFOID:0000000001328431

Item Wattage (W)

High/Low (Xenon type) 35 (D2S)

Item Wattage (W)

Front combination lamp Front turn signal lamp 21 (amber)

Daytime/Parking lamp 21/5

Front side marker lamp 3.8

Rear combination lamp Stop/Tail lamp and Rear Turn signal lamp LED

Rear side marker lamp 3.8

Front fog lamp 35 (H8)

Back-up lamp 18

License plate lamp 5

High-mounted stop lamp (back door mount) LED

Item Wattage (W)

Map lamp 8

Interior room lamp 10

Personal lamp 8

Luggage room lamp 8

Step lamp 5

Glove box lamp 1.4

Vanity mirror lamp 1.32

Ignition key hole illumination 0.8

A/T device illumination lamp 1.4

Coin box illumination lamp 1.4

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3334 of 3924

ENGINE MAINTENANCE (VQ35DE ENGINE)MA-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

2. Apply engine oil to the oil seal contact surface of new oil filter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to the specification.

INSPECTION AFTER INSTALLATION

1. Start the engine, and check there is no leak of engine oil.

2. Stop the engine and wait for 10 minutes.

3. Check the engine oil level, and adjust the level. Refer to MA-15, "

Changing Engine Oil".

Changing Spark Plugs (Platinum-Tipped Type)INFOID:0000000001328907

REMOVAL

1. Remove engine cover with power tool. Refer to EM-19.

2. Remove ignition coil. Refer to EM-42

.

3. Remove spark plug with a spark plug wrench (commercial ser- vice tool).

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

The hot type spark plug is suitable when fouling occurs with the standard type spark plug under conditions

such as:

Frequent engine starts

Low ambient temperatures

The cold type spark plug is suitable when spark knock occurs with the standard type spark plug under condi-

tions such as:

Extended highway driving

Frequent high engine revolution

SMA010

Oil filter:

: 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

SEM294A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3341 of 3924

MA-24

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VK45DE ENGINE)

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to MA-22, "Changing Engine Oil".

2. Start engine, and check there is no leaks of engine oil.

3. Stop engine and wait for 15 minutes.

4. Check the engine oil level and add engine oil. Refer to MA-22, "

Changing Engine Oil".

Changing Spark Plugs (Platinum-Tipped Type)INFOID:0000000001328916

REMOVAL

1. Remove engine cover with power tool. Refer to EM-169.

2. Remove ignition coil. Refer to EM-187

.

3. Remove spark plug with spark plug wrench (commercial service tool).

CAUTION:

Do not drop or shock it.

INSPECTION AFTER REMOVAL

Use standard type spark plug for normal condition.

Hot type spark plug is suitable when fouling occurs with standard type spark plug under conditions such as: Frequent engine starts

Low ambient temperatures

Cold type spark plug is suitable when spark plug knock occurs with standard type spark plug under conditions such as: Extended highway driving

Frequent high engine revolution

CAUTION:

Do not drop or shock spark plug.Oil filter:

:17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

SEM294A

Make NGK

Standard type PLFR5A-11

Hot type PLFR4A-11

Cold type PLFR6A-11

Gap (Nominal) : 1.1 mm (0.043 in)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3365 of 3924

PG-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION PG

A

B

PG

N

O P

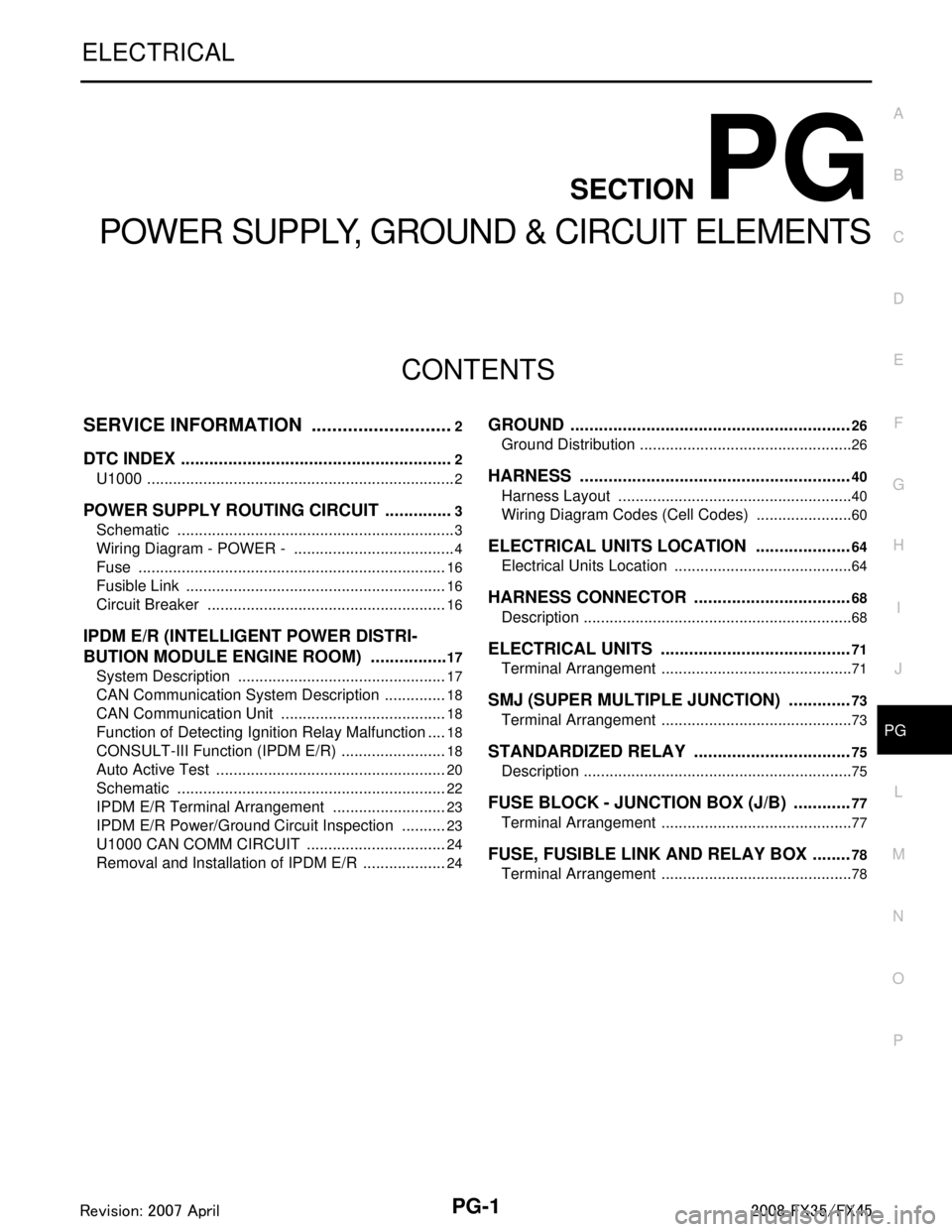

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

SERVICE INFORMATION .. ..........................2

DTC INDEX ..................................................... .....2

U1000 .................................................................. ......2

POWER SUPPLY ROUTING CIRCUIT ...............3

Schematic ........................................................... ......3

Wiring Diagram - POWER - ......................................4

Fuse ........................................................................16

Fusible Link .............................................................16

Circuit Breaker ........................................................16

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

17

System Description ............................................. ....17

CAN Communication System Description ...............18

CAN Communication Unit .......................................18

Function of Detecting Ignition Relay Malfunction ....18

CONSULT-III Function (IPDM E/R) ..................... ....18

Auto Active Test ......................................................20

Schematic ...............................................................22

IPDM E/R Terminal Arrangement ...........................23

IPDM E/R Power/Ground Circuit Inspection ...........23

U1000 CAN COMM CIRCUIT .................................24

Removal and Installation of IPDM E/R ....................24

GROUND ...........................................................26

Ground Distribution .............................................. ....26

HARNESS .........................................................40

Harness Layout ................................................... ....40

Wiring Diagram Codes (Cell Codes) .......................60

ELECTRICAL UNITS LOCATION ....................64

Electrical Units Location ..........................................64

HARNESS CONNECTOR .................................68

Description ...............................................................68

ELECTRICAL UNITS ........................................71

Terminal Arrangement .............................................71

SMJ (SUPER MULTIPLE JUNCTION) .............73

Terminal Arrangement .............................................73

STANDARDIZED RELAY .................................75

Description ...............................................................75

FUSE BLOCK - JUNCTION BOX (J/B) ............77

Terminal Arrangement .............................................77

FUSE, FUSIBLE LINK AND RELAY BOX ........78

Terminal Arrangement .............................................78

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3368 of 3924

PG-4

< SERVICE INFORMATION >

POWER SUPPLY ROUTING CIRCUIT

Wiring Diagram - POWER -

INFOID:0000000001328866

BATTERY POWER SUPPLY — IGNITION SW. IN ANY POSITION

TKWM4458E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3374 of 3924

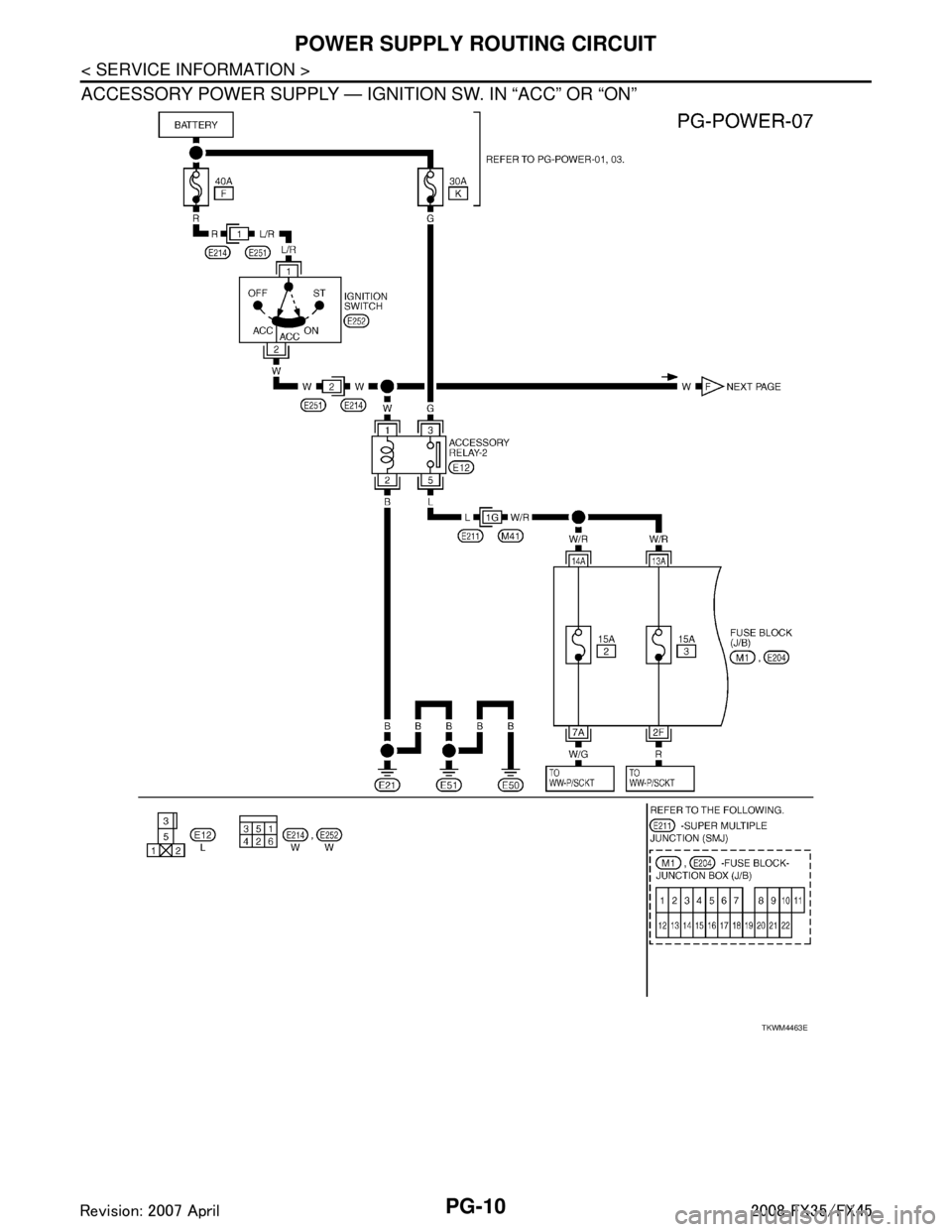

PG-10

< SERVICE INFORMATION >

POWER SUPPLY ROUTING CIRCUIT

ACCESSORY POWER SUPPLY — IGNITION SW. IN “ACC” OR “ON”

TKWM4463E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3376 of 3924

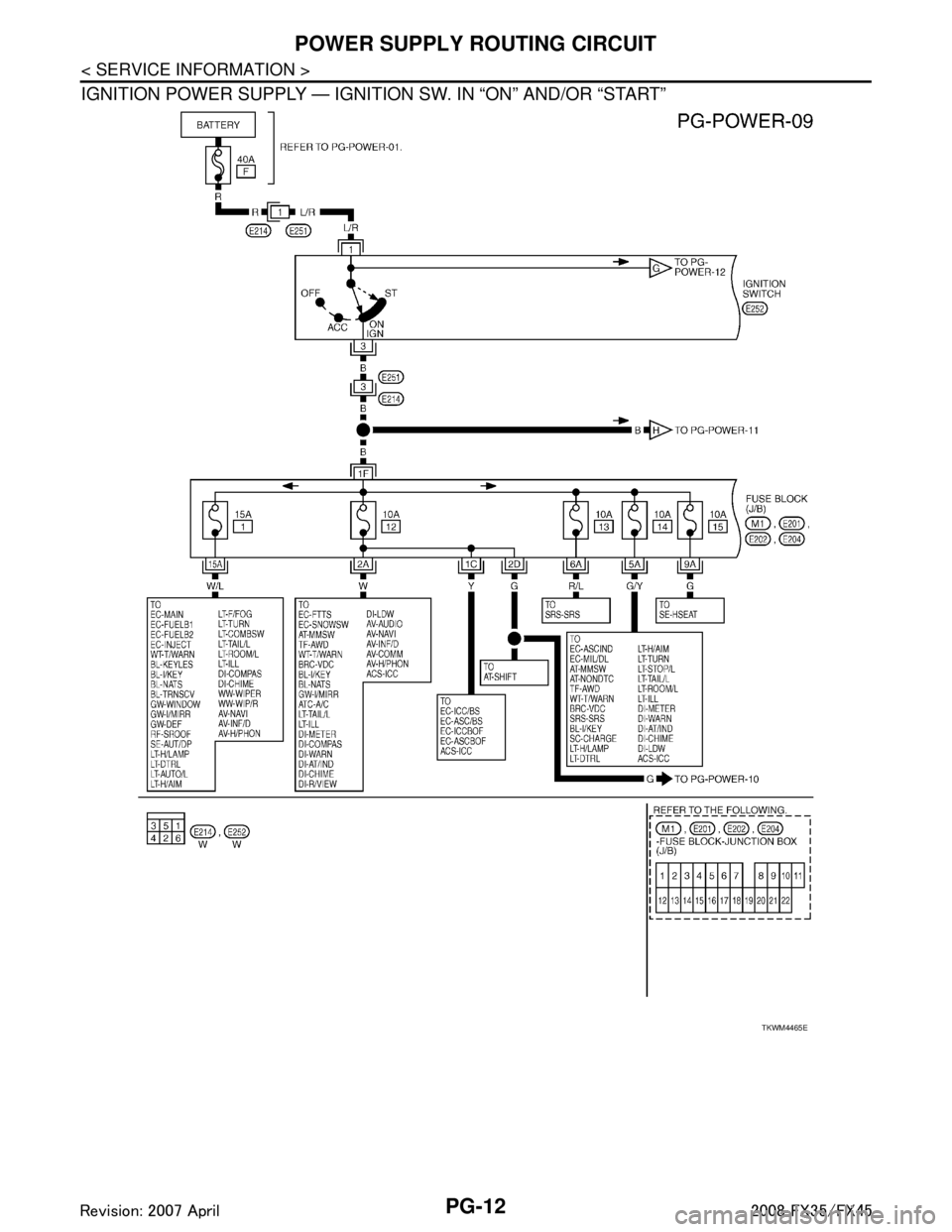

PG-12

< SERVICE INFORMATION >

POWER SUPPLY ROUTING CIRCUIT

IGNITION POWER SUPPLY — IGNITION SW. IN “ON” AND/OR “START”

TKWM4465E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C