Brake INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1014 of 3924

BR-30

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

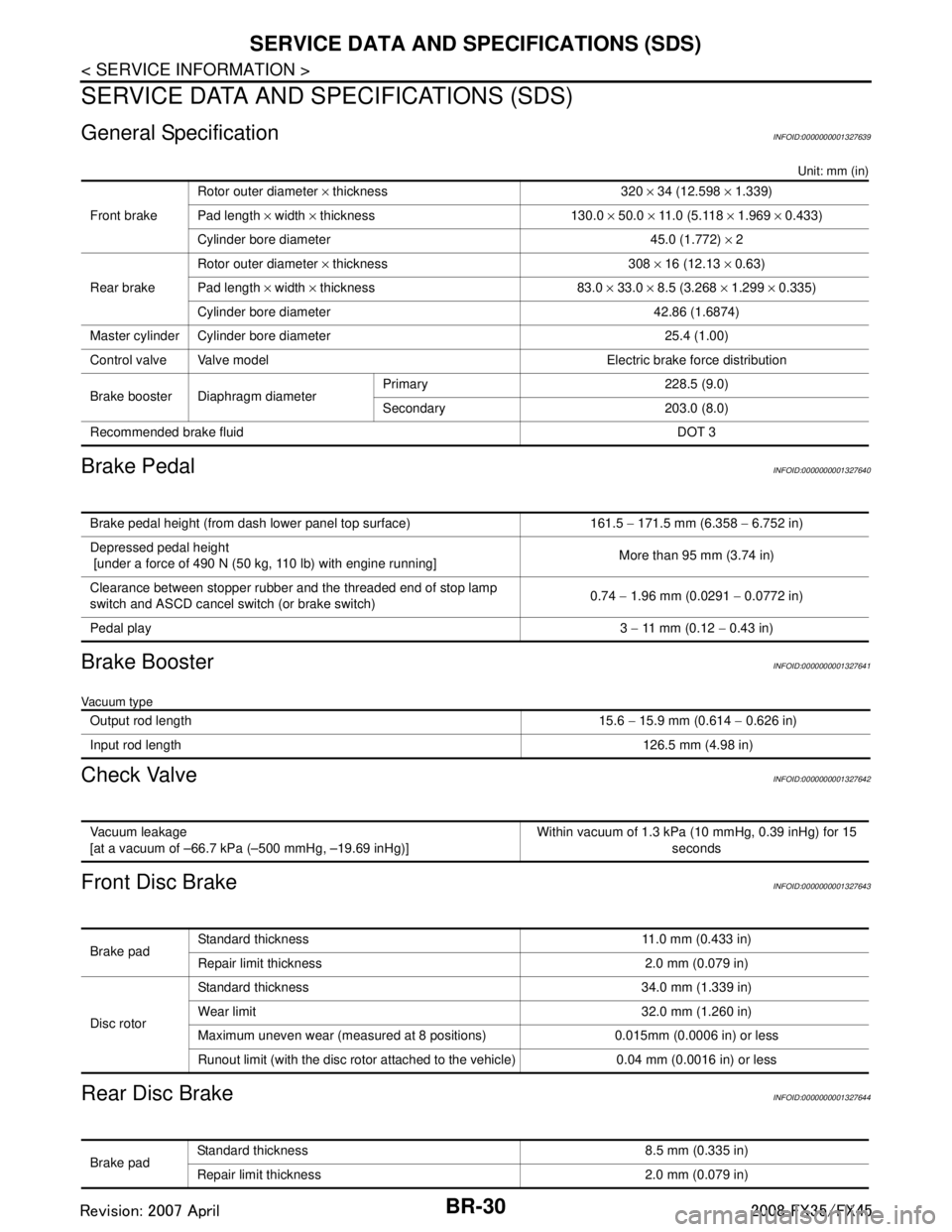

General SpecificationINFOID:0000000001327639

Unit: mm (in)

Brake PedalINFOID:0000000001327640

Brake BoosterINFOID:0000000001327641

Vacuum type

Check ValveINFOID:0000000001327642

Front Disc BrakeINFOID:0000000001327643

Rear Disc BrakeINFOID:0000000001327644

Front brakeRotor outer diameter

× thickness 320 × 34 (12.598 × 1.339)

Pad length × width × thickness 130.0 × 50.0 × 11.0 (5.118 × 1.969 × 0.433)

Cylinder bore diameter 45.0 (1.772) × 2

Rear brake Rotor outer diameter

× thickness 308 × 16 (12.13 × 0.63)

Pad length × width × thickness 83.0 × 33.0 × 8.5 (3.268 × 1.299 × 0.335)

Cylinder bore diameter 42.86 (1.6874)

Master cylinder Cylinder bore diameter 25.4 (1.00)

Control valve Valve model Electric brake force distribution

Brake booster Diaphragm diameter Primary 228.5 (9.0)

Secondary 203.0 (8.0)

Recommended brake fluid DOT 3

Brake pedal height (from dash lower panel top surface) 161.5 − 171.5 mm (6.358 − 6.752 in)

Depressed pedal height

[under a force of 490 N (50 kg, 110 lb) with engine running] More than 95 mm (3.74 in)

Clearance between stopper rubber and the threaded end of stop lamp

switch and ASCD cancel switch (or brake switch) 0.74

− 1.96 mm (0.0291 − 0.0772 in)

Pedal play 3 − 11 mm (0.12 − 0.43 in)

Output rod length 15.6 − 15.9 mm (0.614 − 0.626 in)

Input rod length 126.5 mm (4.98 in)

Vacuum leakage

[at a vacuum of –66.7 kPa (–500 mmHg, –19.69 inHg)]Within vacuum of 1.3 kPa (10 mmHg, 0.39 inHg) for 15

seconds

Brake padStandard thickness 11.0 mm (0.433 in)

Repair limit thickness 2.0 mm (0.079 in)

Disc rotor Standard thickness 34.0 mm (1.339 in)

Wear limit 32.0 mm (1.260 in)

Maximum uneven wear (measured at 8 positions) 0.015mm (0.0006 in) or less

Runout limit (with the disc rotor attached to the vehicle) 0.04 mm (0.0016 in) or less

Brake pad

Standard thickness 8.5 mm (0.335 in)

Repair limit thickness 2.0 mm (0.079 in)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1016 of 3924

BRC-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

SERVICE INFORMATION .. ..........................

3

DTC INDEX ..................................................... .....3

C1101-C1116 ...................................................... ......3

C1120-C1136 ............................................................3

C1140-C1170 ............................................................3

U1000 ........................................................................4

PRECAUTIONS ...................................................5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

Precaution for Brake System ....................................5

Precaution for Brake Control .....................................5

PREPARATION ...................................................7

Special Service Tool ........................................... ......7

Commercial Service Tool ..........................................7

ON-VEHICLE SERVICE ......................................8

Adjustment of Steering Angle Sensor Neutral Po-

sition .................................................................... ......

8

Calibration of Decel G Sensor (AWD Models) ..........8

SYSTEM DESCRIPTION ................................ ....10

Schematic ........................................................... ....10

Functions .................................................................10

Fail-Safe Function ...................................................11

Hydraulic Circuit Diagram .......................................12

CAN Communication ...............................................12

TROUBLE DIAGNOSIS .....................................13

Fail-Safe Function ............................................... ....13

How to Proceed with Diagnosis ..............................13

Component Part Location .......................................16

Schematic ...............................................................17

Wiring Diagram - VDC - ..........................................18

Control Unit Input/Output Signal Standard ..............23

CONSULT-III Functions (ABS) ................................26

Self-Diagnosis ..................................................... ....26

Data Monitor ........................................................ ....28

Active Test ...............................................................30

For Fast and Accurate Diagnosis ............................31

Basic Inspection ......................................................32

TROUBLE DIAGNOSIS FOR SYSTEM ............34

DTC C1101 RR RH SENSOR-1 ..............................34

DTC C1102 RR LH SENSOR-1 ..............................35

DTC C1103 FR RH SENSOR-1 ..............................35

DTC C1104 FR LH SENSOR-1 ...............................35

DTC C1105 RR RH SENSOR-2 ..............................36

DTC C1106 RR LH SENSOR-2 ..............................36

DTC C1107 FR RH SENSOR-2 ..............................36

DTC C1108 FR LH SENSOR-2 ...............................36

DTC C1109 BATTERY VOLTAGE [ABNORMAL] ....36

DTC C1110 CONTROLLER FAILURE ....................37

DTC C1111 PUMP MOTOR ....................................37

DTC C1113 G-SENSOR .........................................38

DTC C1115 ABS SENSOR [ABNORMAL SIG-

NAL] .........................................................................

39

DTC C1116 STOP LAMP SW .................................39

DTC C1120 FR LH IN ABS SOL .............................40

DTC C1121 FR LH OUT ABS SOL .........................41

DTC C1122 FR RH IN ABS SOL ......................... ....41

DTC C1123 FR RH OUT ABS SOL .........................42

DTC C1124 RR LH IN ABS SOL .............................42

DTC C1125 RR LH OUT ABS SOL ..................... ....42

DTC C1126 RR RH IN ABS SOL ............................42

DTC C1127 RR RH OUT ABS SOL ........................42

DTC C1130 ENGINE SIGNAL 1 .......................... ....42

DTC C1131 ENGINE SIGNAL 2 ..............................42

DTC C1132 ENGINE SIGNAL 3 ..............................42

DTC C1133 ENGINE SIGNAL 4 ..............................42

DTC C1136 ENGINE SIGNAL 6 ..............................42

DTC C1140 ACTUATOR RLY .................................43

DTC C1142 PRESS SEN CIRCUIT ........................43

DTC C1143 ST ANG SEN CIRCUIT ................... ....44

DTC C1144 ST ANG SEN SIGNAL .........................45

DTC C1145 YAW RATE SENSOR ..........................46

DTC C1146 SIDE G-SEN CIRCUIT ........................46

DTC C1155 BR FLUID LEVEL LOW .......................46

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1020 of 3924

![INFINITI FX35 2008 Service Manual

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI INFINITI FX35 2008 Service Manual

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI](/img/42/57017/w960_57017-1019.png)

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612923

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000001327654

Recommended fluid is brake fluid “DOT 3”. Refer to MA-9.

Do not reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas such as body. If brake fluid is splashed, wipe it off and flush area with water immediately.

Do not use mineral oils such as gasoline or kerosene to clean. They will ruin rubber parts and cause improper operation.

Using a flare nut crowfoot and torque wrench, securely tighten brake tube flare nuts.

Brake system is an important safe ty part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Before working, turn ignition switch OFF and disconnect electrical

connectors of ABS actuator and elec tric unit (control unit) or bat-

tery negative terminal.

When installing brake piping, be sure to check torque.

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with

a dust collector.

Precaution for Brake ControlINFOID:0000000001327655

During VDC/TCS/ABS operation, brake pedal lightly vi brates and a mechanical noise may be heard. This is

normal.

Just after starting vehicle after turning ignition switch ON, brake pedal may vibrate or motor operating noise

may be heard from engine room. This is a normal status of operation check.

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnostic

servicing. Besides electrical system inspection, c heck booster operation, brake fluid level, and fluid leaks.

If tire size and type are used in an improper combinat ion, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

If there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, VDC/TCS/ABS

function may have a malfunction or error.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR686C

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1021 of 3924

![INFINITI FX35 2008 Service Manual

BRC-6

< SERVICE INFORMATION >[VDC/TCS/ABS]

PRECAUTIONS

If the following components are replaced with non-genui

ne components or converted, VDC OFF indicator

lamp and SLIP indicator lamp may turn on INFINITI FX35 2008 Service Manual

BRC-6

< SERVICE INFORMATION >[VDC/TCS/ABS]

PRECAUTIONS

If the following components are replaced with non-genui

ne components or converted, VDC OFF indicator

lamp and SLIP indicator lamp may turn on](/img/42/57017/w960_57017-1020.png)

BRC-6

< SERVICE INFORMATION >[VDC/TCS/ABS]

PRECAUTIONS

If the following components are replaced with non-genui

ne components or converted, VDC OFF indicator

lamp and SLIP indicator lamp may turn on or the VDC system may not operate properly. Components

related to suspension (shock absorber, strut, spring, bushing, etc.), Tires, wheels (exclude specified size),

components related to brake (pad, rotor, caliper, etc. ), components related to engine (muffler, ECM, etc.),

components related to body reinforcement (roll bar, tower bar, etc.).

Driving in the condition of breakage or excessive wear of suspension, tires or components related to the

brakes may cause VDC OFF indicator lamp and SLIP indicator lamp turn on, and the VDC system may not

operate properly.

When the TCS or VDC is activated by sudden accele ration or sudden turn, some noise may occur. The

noise is a result of the normal operation of the TCS and VDC.

When driving on roads which have extreme slopes (s uch as mountainous roads) or high banks (such as

sharp carves on a freeway), the VDC may not operate nor mally, or VDC OFF indicator lamp and SLIP indi-

cator lamp may turn on. However, this is not a malfunction, if normal operation can be resumed after restart-

ing engine.

Sudden turns (such as spin turns, acceleration turns) , drifting, etc. When VDC function is OFF (VDC OFF

SW ON) may cause the G sensor system indicate a malf unction. However, this is not a malfunction, if nor-

mal operation can be resumed after restarting engine.

Change 4 tires at a time. Be sure to use specified- size tires that have the same brand name and pattern.

Wheel sensor errors can be detected be self-diagnosis when tires have wide abrasion variations or the size

is different from the genuine tires.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1022 of 3924

![INFINITI FX35 2008 Service Manual

PREPARATIONBRC-7

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

Special Service ToolINFOID:0000000001327656

The actual shapes of Kent-Moore tools may differ fr om INFINITI FX35 2008 Service Manual

PREPARATIONBRC-7

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

Special Service ToolINFOID:0000000001327656

The actual shapes of Kent-Moore tools may differ fr om](/img/42/57017/w960_57017-1021.png)

PREPARATIONBRC-7

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

Special Service ToolINFOID:0000000001327656

The actual shapes of Kent-Moore tools may differ fr om those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000001327657

Tool number

(Kent-Moore No.)

Tool name Description

ST30720000

(J-25405)

Drift

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

Installing rear sensor rotor

ST27863000

(—)

Drift

a: 74.5 mm (2.933 in) dia.

b: 62.5 mm (2.461 in) dia.

KV40104710

(—)

Drift

a: 76.3 mm (3.004 in) dia.

b: 67.9 mm (2.673 in) dia.

ZZA0701D

ZZA0832D

ZZA0832D

Tool name

Description

1: Flare nut crowfoot

a: 10 mm (0.39 in)/ 12 mm (0.47 in)

2: Torque wrench Installing brake tube

S-NT360

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1025 of 3924

![INFINITI FX35 2008 Service Manual

BRC-10

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

SYSTEM DESCRIPTION

SchematicINFOID:0000000001327660

FunctionsINFOID:0000000001327661

VDC

In addition to the TCS/ABS function, the driv INFINITI FX35 2008 Service Manual

BRC-10

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

SYSTEM DESCRIPTION

SchematicINFOID:0000000001327660

FunctionsINFOID:0000000001327661

VDC

In addition to the TCS/ABS function, the driv](/img/42/57017/w960_57017-1024.png)

BRC-10

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

SYSTEM DESCRIPTION

SchematicINFOID:0000000001327660

FunctionsINFOID:0000000001327661

VDC

In addition to the TCS/ABS function, the driver

steering amount and brake operation amount are detected

from steering angle sensor and pressure sensor, and the vehicle's driving status (amount of under steering /

over steering) is determined from information from G s ensor, wheel sensor, etc., and this information is used

to improve vehicle stability by controlling the braking and engine power to all four wheels.

SLIP indicator lamp flashes to inform the driver of VDC operation.

During VDC operation, body and brake pedal lightly vibrate and mechanical noises may be heard. This is

normal.

ABS warning lamp, VDC OFF indicator lamp, and SLIP indicator lamp might turn on when vehicle is subject

to strong shaking or large vibration, such as when vehi cle is on a turn table, a ship or a steep slope such as

bank while engine is running. In this case, restart engine on a normal road, and if ABS warning lamp, VDC

OFF indicator lamp, and SLIP indicator lamp turn off, there is no malfunction.

TCS

The wheel spin of the drive wheels is detected by ABS actuator and electric unit (control unit) from the wheel

speed signals from four wheels, so if wheel spin occurs , drive wheel right and left brake fluid pressure con-

trol and engine fuel cut are performed while throttle value is restricted to reduce the engi\

ne torque and

decrease the amount of wheel spin. In addition, the degree throttle is opened is controlled to achieve the

optimum engine torque.

Depending on road circumstances, the driver may have a sluggish feel. This is normal, because the opti-

mum traction has the highest priority under TCS operation.

TCS may be activated any time vehicle suddenly accelerates, suddenly down/upshifts, or is driven on a road with a varying surface friction coefficient.

During TCS operation, it informs a driver of sy stem operation by flashing SLIP indicator lamp.

ABS

The Anti-Lock Braking System is a function that detec ts wheel revolution while braking, and it improves han-

dling stability during sudden braking by electrically prev enting 4 wheel lock. Maneuverability is also improved

for avoiding obstacles.

If the electrical system malfunc tions, then the fail-safe function star ts, the ABS becomes inoperative, and

ABS warning lamp turns on.

Electrical system diagnosis by CONSULT-III is available.

During ABS operation, brake pedal lightly vibrates and a mechanical noise may be heard. This is normal.

When starting engine, or just after starting vehicle, brake pedal may vibrate or motor operating noises may be heard from engine compartment. This is a normal status of operation check.

SFIA1160E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1026 of 3924

![INFINITI FX35 2008 Service Manual

SYSTEM DESCRIPTIONBRC-11

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gra INFINITI FX35 2008 Service Manual

SYSTEM DESCRIPTIONBRC-11

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gra](/img/42/57017/w960_57017-1025.png)

SYSTEM DESCRIPTIONBRC-11

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

EBD

The Electronic Brake Distribution is a function that detects subtle slippages between front and rear wheels

during braking, and it improves handling stability by elec tronically controlling the brake fluid pressure which

results in reduced rear wheel slippage.

In case of electrical system malfunction, the fail- safe function is activated, EBD and ABS becomes inopera-

tive, and ABS warning lamp and brake warning lamp are turned on.

Electrical system diagnosis by CONSULT-III is available.

During EBD operation, brake pedal lightly vibrates and a mechanical noise may be heard. This is normal.

When starting engine, or just after starting vehicle, brake pedal may vibrate or motor operating noises may

be heard from engine compartment. This is a normal status of operation check.

Stopping distance may be longer than that of vehicles without EBD when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

Fail-Safe FunctionINFOID:0000000001327662

VDC / TCS SYSTEM

In case of malfunction in the VDC/TCS system, VDC O FF indicator lamp and SLIP indicator lamp are turned

on, and the condition of vehicle is the same as the c ondition of vehicles without VDC/TCS system. In case of

malfunction in the VDC/TCS system, the ABS control c ontinues to operate normally without VDC/TCS control.

CAUTION:

If the fail-safe function is acti vated, then perform the self-diagnos is for VDC/TCS/ABS control system.

ABS, EBD SYSTEM

In case of electrical malfunctions with the ABS, ABS warning lamp, VDC OFF indicator lamp and SLIP indica-

tor lamp will turn on. In case of electrical malfunc tions with the EBD, brake warning lamp, ABS warning lamp,

VDC OFF indicator lamp and SLIP indicator lamp wil l turn on. Simultaneously, the VDC/TCS/ABS become one

of the following conditions of the fail-safe function.

For malfunction of ABS, only the EBD is activated and t he condition of vehicle is the same condition of vehi-

cles without TCS/ABS system.

NOTE:

ABS self-diagnosis sound may be heard. That is a no rmal condition because a self-diagnosis for “Ignition

switch ON” and “The first starting” are being performed.

For malfunction of EBD, EBD and ABS become inoperative, and the condition of vehicle is the same as the

condition of vehicles wit hout TCS/ABS, EBD system.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1028 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISBRC-13

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS

Fail-Safe FunctionINFOID:0000000001327665

VDC/TCS SYSTEM

In case of malfunction in th INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISBRC-13

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS

Fail-Safe FunctionINFOID:0000000001327665

VDC/TCS SYSTEM

In case of malfunction in th](/img/42/57017/w960_57017-1027.png)

TROUBLE DIAGNOSISBRC-13

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS

Fail-Safe FunctionINFOID:0000000001327665

VDC/TCS SYSTEM

In case of malfunction in the VDC/TCS system, VDC O FF indicator lamp and SLIP indicator lamp are turned

on, and the condition of vehicle is the same as the c ondition of vehicles without VDC/TCS system. In case of

malfunction in the VDC/TCS system, the ABS control c ontinues to operate normally without VDC/TCS control.

CAUTION:

If the fail-safe function is acti vated, then perform the self-diagnos is for VDC/TCS/ABS control system.

ABS, EBD SYSTEM

In case of electrical malfunctions with the ABS, ABS warning lamp, VDC OFF indicator lamp, SLIP indicator

lamp will turn on. In case of electrical malfuncti ons with the EBD, brake warning lamp, ABS warning lamp,

VDC OFF indicator lamp and SLIP indicator lamp wil l turn on. Simultaneously, the VDC/TCS/ABS become one

of the following conditions of the fail-safe function.

For malfunction of ABS, only the EBD is activated and t he condition of vehicle is the same condition of vehi-

cles without TCS/ABS system.

NOTE:

ABS self-diagnosis sound may be heard. That is a no rmal condition because a self-diagnosis for “Ignition

switch ON” and “The first starting” are being performed.

For malfunction of EBD, EBD and ABS become inoperative, and the condition of vehicle is the same as the

condition of vehicles wit hout TCS/ABS, EBD system.

How to Proceed with DiagnosisINFOID:0000000001327666

BASIC CONCEPT

Most important point to perform diagnosis is to unders tand systems (control and mechanism) in vehicle thor-

oughly.

It is also important to clarify customer complaints before inspec- tion.

First of all, reproduce symptom, and understand it fully.

Ask customer about his/her complaints carefully. In some cases, it

will be necessary to check symptom by driving vehicle with cus-

tomer.

NOTE:

Customers are not professionals. Do not assume “maybe cus-

tomer means...” or “maybe customer mentioned this symptom”.

It is essential to check symptoms right from beginning in order to repair a malfunction completely.

For an intermittent malfunction, it is important to reproduce symp-

tom based on interview with customer and past examples. Do not

perform inspection on ad hoc basis. Most intermittent malfunctions

are caused by poor contacts. In this case, it will be effective to

shake suspected harness or connector by hand. When repairs are

performed without any symptom check, no one can judge if mal-

function has actually been eliminated.

After diagnosis, make sure to perform “erase memory”. Refer to BRC-26, "

Self-Diagnosis".

For an intermittent malfunction, move harness or harness connec- tor by hand to check poor contact or false open circuit.

Always read “GI General Information” to confirm general precautions. Refer to GI-3, "

General Precaution".

SEF234G

SEF233G

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1039 of 3924

![INFINITI FX35 2008 Service Manual

BRC-24

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Monitor item Display content Data monitor

Condition Reference value in

normal operation

SLCT LVR POSI A/T shift position P: P position

R INFINITI FX35 2008 Service Manual

BRC-24

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Monitor item Display content Data monitor

Condition Reference value in

normal operation

SLCT LVR POSI A/T shift position P: P position

R](/img/42/57017/w960_57017-1038.png)

BRC-24

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Monitor item Display content Data monitor

Condition Reference value in

normal operation

SLCT LVR POSI A/T shift position P: P position

R: R position

N: N position

D: D position

GEAR A/T gear position 1: 1st gear

2: 2nd gear

3: 3rd gear

4: 4th gear

5: 5th gear

FR RH SENSOR

FR LH SENSOR

RR RH SENSOR

RR LH SENSOR Wheel speed Vehicle stopped 0 [km/h (MPH)]

Vehicle running (Note 1)

Almost in accordance

with speedometer

display

(within

± 10 %)

ACCEL POS SIG Open/close condition of throttle valve

(linked with a

ccelerator pedal) Accelerator pedal not depressed

(Engine stopped)

0 %

Depress accelerator pedal

(Engine stopped) 0 to 100 %

ENGINE SPEED With engine running With engine stopped 0 rpm

Engine running

Almost in accordance

with tachometer dis-

play

STR ANGLE SIG Steering angle detected by steering angle

sensor Straight-ahead Approx. 0 deg

Steering wheel turned –756 to 756 deg

YAW RATE SEN Yaw rate detected by yaw rate sensor Vehicle stopped Approx. 0 d/s

Vehicle running –100 to 100 d/s

SIDE G-SENSOR Transverse G detected by side G sensor Vehicle stopped

Approx. 0 m/s

2

Vehicle running–16.7 to 16.7 m/s2

PRESS SENSORBrake fluid pressure detected by pressure

sensor With ignition switch turned ON and brake

pedal released

Approx. 0 bar

With ignition switch turned ON and brake

pedal depressed 0 to 170 bar

BATTERY VOLT Battery voltage supplied to ABS actuator

and electric unit (control unit) Ignition switch ON 10 to 16 V

STOP LAMP SW Brake pedal operation Brake pedal depressed ON

Brake pedal not depressed OFF

OFF SW VDC OFF switch ON/OFF status VDC OFF switch ON

(When VDC OFF indicator lamp is ON)

ON

VDC OFF switch OFF

(When VDC OFF indicator lamp is OFF) OFF

ABS WARN LAMP ABS warning lamp ON condition (Note 2) ABS warning lamp ON ON

ABS warning lamp OFF OFF

MOTOR RELAY Operation status of motor and motor relay Ignition switch ON or engine running

(ABS not operated)

OFF

Ignition switch ON or engine running (ABS

operated) ON

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1040 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISBRC-25

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ACTUATOR RLY Actuator relay operation status Actuator (solenoid) is active

(“ACTIVE TEST” with CONS INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISBRC-25

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ACTUATOR RLY Actuator relay operation status Actuator (solenoid) is active

(“ACTIVE TEST” with CONS](/img/42/57017/w960_57017-1039.png)

TROUBLE DIAGNOSISBRC-25

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ACTUATOR RLY Actuator relay operation status Actuator (solenoid) is active

(“ACTIVE TEST” with CONSULT-III)

ON

When actuator relay is inactive

(in fail-safe mode) OFF

OFF LAMP VDC OFF indicator lamp status

(Note 3) When VDC OFF indicator lamp is ON ON

When VDC OFF indicator lamp is OFF OFF

SLIP LAMP SLIP indicator lamp status

(Note 4) When SLIP indicator lamp is ON ON

When SLIP indicator lamp is OFF OFF

FR LH IN SOL

FR LH OUT SOL

FR RH IN SOL

FR RH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOL Solenoid valve operation Actuator (solenoid) is active (“ACTIVE

TEST” with CONSULT-III) and actuator re-

lay is active (ignition switch ON)

ON

When actuator (solenoid) is not active or

actuator relay is inactive (in fail-safe

mode) OFF

CV1

CV2

SV1

SV2 VDC/TCS switch-over valve status When actuator (switch-over valve) is ac-

tive (“ACTIVE TEST” with CONSULT-III)

and actuator relay is active (ignition switch

ON)

ON

When actuator (switch-over valve) is not

active or actuator relay is inactive (in fail-

safe mode) OFF

DECEL G-SEN Longitudinal acceleration detected by decel

G sensor (Note 5) Vehicle stopped Approx. 0 G

Vehicle running -1.7 to +1.7 G

FLUID LEV SW ON/OFF status of brake fluid level switch When brake fluid level switch ON ON

When brake fluid level switch OFF OFF

VDC FAIL SIG

TCS FAIL SIG

ABS FAIL SIG

EBD FAIL SIG Fail signal status VDC fail

TCS fail

ABS fail

EBD fail

ON

VDC normal

TCS normal

ABS normal

EBD normal OFF

EBD WARN LAMP Brake warning lamp on condition

(Note 6) Brake warning lamp ON ON

Brake warning lamp OFF OFF

EBD SIGNAL EBD operation EBD active ON

EBD not active OFF

ABS SIGNAL ABS operation ABS active ON

ABS not active OFF

TCS SIGNAL TCS operation TCS active ON

TCS not active OFF

VDC SIGNAL VDC operation VDC active ON

VDC not active OFF

CRANKING SIG CRANKING status Cranking ON

Not cranking OFF

4WD FAIL REQ ETS fail status (Note 5) ETS fail ON

ETS normal OFF

Monitor item Display content

Data monitor

Condition Reference value in

normal operation

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C