sensor INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 405 of 3924

AT-332

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

A/T Fluid Temperature Sensor

INFOID:0000000001327418

Turbine Revolution SensorINFOID:0000000001327419

Vehicle Speed Sensor A/T (Revolution Sensor)INFOID:0000000001327420

Reverse BrakeINFOID:0000000001327421

Total End PlayINFOID:0000000001327422

Name Condition CONSULT- III “DATA MONITOR” (Approx.) Resistance (Approx.)

A/T fluid temperature sensor 1 0

°C (32 °F) 3.3 V 15 k Ω

20 °C (68 °F) 2.7 V 6.5 k Ω

80 °C (176 °F) 0.9 V 0.9 k Ω

A/T fluid temperature sensor 2 0

°C (32 °F) 3.3 V 10 k Ω

20 °C (68 °F) 2.5 V 4 k Ω

80 °C (176 °F) 0.7 V 0.5 k Ω

Name Condition Data (Approx.)

Turbine revoluti on sensor 1 When running at 50 km/h (31 MPH) in 4th speed with the closed throttle po-

sition signal OFF.

1.3 kHz

Turbine revoluti on sensor 2 When moving at 20 km/h (12 MPH) in 1st speed with the closed throttle po-

sition signal OFF.

Name Condition Data (Approx.)

Revolution sensor When moving at 20 km/h (12 MPH). 185 Hz

Model code number 91X3A, 91X3B 96X1C

Number of drive plates 6

Number of driven plates 6

Clearance mm (in) Standard 0.7 - 1.1 (0.028 - 0.043)

Total end play mm (in) 0.25 - 0.55 (0.0098 - 0.0217)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 406 of 3924

ATC-1

AIR CONDITIONER

C

DE

F

G H

I

K L

M

SECTION AT C

A

B

AT C

N

O P

CONTENTS

AUTOMATIC AIR CONDITIONER

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Working with HFC-134a (R-134a) ......4

General Refrigerant Precaution ................................4

Precaution for Refrigerant Connection ......................5

Precaution for Service of Compressor ......................9

Precaution for Service Equipment .............................9

Precaution for Leak Detection Dye .........................11

PREPARATION ..................................................13

Special Service Tool ........................................... ....13

HFC-134a (R-134a) Service Tool and Equipment ....13

Commercial Service Tool ........................................16

REFRIGERATION SYSTEM ..............................17

Refrigerant Cycle ................................................ ....17

Refrigerant System Protection ................................17

V-6 Variable Displacement Compressor .................17

Component Part Location .......................................21

LUBRICANT ................................................... ....22

Maintenance of Lubricant Quantity in Compressor ....22

AIR CONDITIONER CONTROL .........................24

Description of Air Conditioner LAN Control Sys-

tem ...................................................................... ....

24

System Construction ...............................................24

Description of Control System .................................27

Control Operation ....................................................27

Fail-Safe Function ...................................................28

Discharge Air Flow ..................................................29

System Description .................................................30

CAN Communication System Description ...............30

TROUBLE DIAGNOSIS .....................................32

CONSULT-III Function ........................................ ....32

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

32

Component Parts and Harness Connector Loca-

tion ...........................................................................

34

Schematic ................................................................36

Wiring Diagram - A/C - ............................................37

Auto Amp. Terminal and Reference Value ..............42

Self-Diagnosis Function ...........................................43

Operational Check ...................................................50

Power Supply and Ground Circuit for Auto Amp .....52

LAN System Circuit .................................................54

Mode Door Motor Circuit .........................................57

Air Mix Door Motor Circuit .......................................59

Air Mix Door Motor PBR Circuit ...............................62

Intake Door Motor Circuit .........................................62

Blower Motor Circuit ................................................64

Magnet Clutch Circuit ..............................................69

Insufficient Cooling ..................................................75

Insufficient Heating ..................................................82

Noise .......................................................................83

Self-Diagnosis .........................................................84

Memory Function .....................................................85

Ambient Sensor Circuit ............................................86

In-vehicle Sensor Circuit ..........................................88

Sunload Sensor Circuit ............................................91

Intake Sensor Circuit ...............................................94

CONTROLLER ..................................................97

Removal and Installation of A/C and AV Switch ......97

AUTO AMP ........................................................98

Removal and Installation of Unified Meter and A/C

Amp .........................................................................

98

AMBIENT SENSOR ..........................................99

Removal and Installation .........................................99

IN-VEHICLE SENSOR ....................................100

Removal and Installation .......................................100

SUNLOAD SENSOR .......................................101

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 407 of 3924

ATC-2

Removal and Installation .......................................101

INTAKE SENSOR ............................................102

Removal and Installation ..................................... ..102

BLOWER UNIT ................................................103

Removal and Installation ..................................... ..103

Disassembly and Assembly ...................................104

BLOWER MOTOR ...........................................105

Removal and Installation ..................................... ..105

INTAKE DOOR MOTOR ..................................106

Removal and Installation ..................................... ..106

IN-CABIN MICROFILTER ................................107

Removal and Installation ..................................... ..107

HEATER & COOLING UNIT ASSEMBLY .......108

Removal and Installation ..................................... ..108

Disassembly and Assembly ...................................111

MODE DOOR MOTOR ....................................113

Removal and Installation ..................................... ..113

AIR MIX DOOR MOTOR ..................................114

Removal and Installation ..................................... ..114

HEATER CORE ...............................................115

Removal and Installation ..................................... ..115

DUCTS AND GRILLES ....................................116

Removal and Installation ..................................... ..116

REFRIGERANT LINES ....................................120

HFC-134a (R-134a) Service Procedure .............. ..120

Component .......................................................... .121

Removal and Installation of Compressor ..............123

Removal and Installation of Compressor Clutch ...125

Removal and Installation of Low-Pressure Flexi-

ble Hose ............................................................... .

128

Removal and Installation of High-pressure Flexi-

ble Hose ................................................................

129

Removal and Installation of Low-Pressure Pipe 1

(Engine Compartment) ..........................................

131

Removal and Installation of High-pressure Pipe 1

and 2 (Engine Compartment) ................................

132

Removal and Installation of Low-Pressure Pipe 2

and High-pressure Pipe 3 .....................................

133

Removal and Installation of Liquid Tank ...............134

Removal and Installation of Condenser ................135

Removal and Installation of Refrigerant Pressure

Sensor .................................................................. .

137

Removal and Installation of Evaporator ................137

Removal and Installation of Expansion Valve .......138

Checking of Refrigerant Leaks ............................. .138

Checking System for Leaks Using the Fluorescent

Leak Detector ........................................................

138

Dye Injection .........................................................139

Electrical Leak Detector ........................................139

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

142

Compressor ......................................................... .142

Lubricant ...............................................................142

Refrigerant ............................................................142

Engine Idling Speed ..............................................142

Belt Tension ..........................................................142

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 410 of 3924

PRECAUTIONSATC-5

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Never release refrigerant into the air. Use appr oved recovery/recycling equipment to capture the

refrigerant every time an air co nditioning system is discharged.

Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

Never store or heat refrigerant containers above 52 °C (126 °F).

Never heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

Never intentionally drop, puncture, or incinerate refrigerant containers.

Keep refrigerant away from open flames: poison ous gas will be produced if refrigerant burns.

Refrigerant will displace oxygen, therefore be certa in to work in well ventilated areas to prevent suf-

focation.

Never pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air conditioning

systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have been

shown to be combustible at elevat ed pressures. These mixtures, if ig nited, may cause injury or prop-

erty damage. Additional health a nd safety information may be obtain ed from refrigerant manufactur-

ers.

Precaution for Refrigerant ConnectionINFOID:0000000001328155

A new type refrigerant connection has been introduced to a ll refrigerant lines except the following location.

Expansion valve to evaporator

Refrigerant pressure sensor to condenser

ABOUT ONE-TOUCH JOINT

Description

One-touch joints are pipe joints which do not require tools during piping connection.

Unlike conventional connection methods using union nuts and flanges, controlling tightening torque at con-

nection point is not necessary.

When removing a pipe joint, use a disconnector.

COMPONENT PARTS

FUNCTIONS OF COMPONENT PARTS

NOTE:

1 Pipe (Male-side) Retains O-rings.

Retains garter spring in cage (A).

2 Garter spring Anchors female-side piping.

3 Indicator ring When connection is made properly, this is ejected from male-side piping. (This part is no longer nec-

essary after connection.)

4 O-ring Seals connection point. (Not reusable)

5 Pipe (Female-side) Seals connection by compressing O-rings.

Anchors piping connection using flare (B) and garter spring.

RJIA4383J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 413 of 3924

ATC-8

< SERVICE INFORMATION >

PRECAUTIONS

VK45DE

CAUTION:

The new and former refrigerant connections use different O-ring configurations. Never confuse O-

rings since they are not interchangeable. If a wrong O- ring is installed, refrigerant may leak at the con-

nection.

O-Ring Part Numbers and Specifications

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loo sen the discharge side hose fitting and remove it.

SJIA1774E

Connection type Piping connection point Part number QTY O-ring size

New Low-pressure pipe 1 to low-pressure pipe 2 (One-touch joint) 92473 N8221 2 16

Low-pressure pipe 2 to expansion valve 92473 N8210 1 16

High-pressure pipe 1 to high-pressure pipe 2 (One-touch joint) 92471 N8221 2 8

High-pressure pipe 3 to expansion valve 92471 N8210 1 8

High-pressure pipe 2 to high-pressure pipe 3 (One-touch joint) 92471 N8221 2 8

Condenser to high-pressure flexible hose (One-touch joint) 92472 N8221 2 12

Condenser to high-pressure pipe 1 (One-touch joint) 92471 N8221 2 8

Low-pressure flexible hose to low-pressure pipe 1 (One-touch joint) 92473 N8221 2 16

Low-pressure pipe to low-pressure flexible hose (VK45DE) 92474 N8210 1 19

Compressor to low-pressure flexible hose (VQ35DE) 92474 N8210 1 19

Compressor to low-pressure pipe (VK45DE) 92474 N8210 1 19

Compressor to high-pressure flexible hose 92472 N8210 1 12

Liquid tank to condenser pipe

Inlet

92471 N8210 1

8

Outlet 1

Former Refrigerant pressure sensor to condenser J2476 89956 1 10

Expansion valve to evaporator

Inlet 92475 71L00 1 12

Outlet 92475 72L00 1 16

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 422 of 3924

REFRIGERATION SYSTEMATC-17

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000001328162

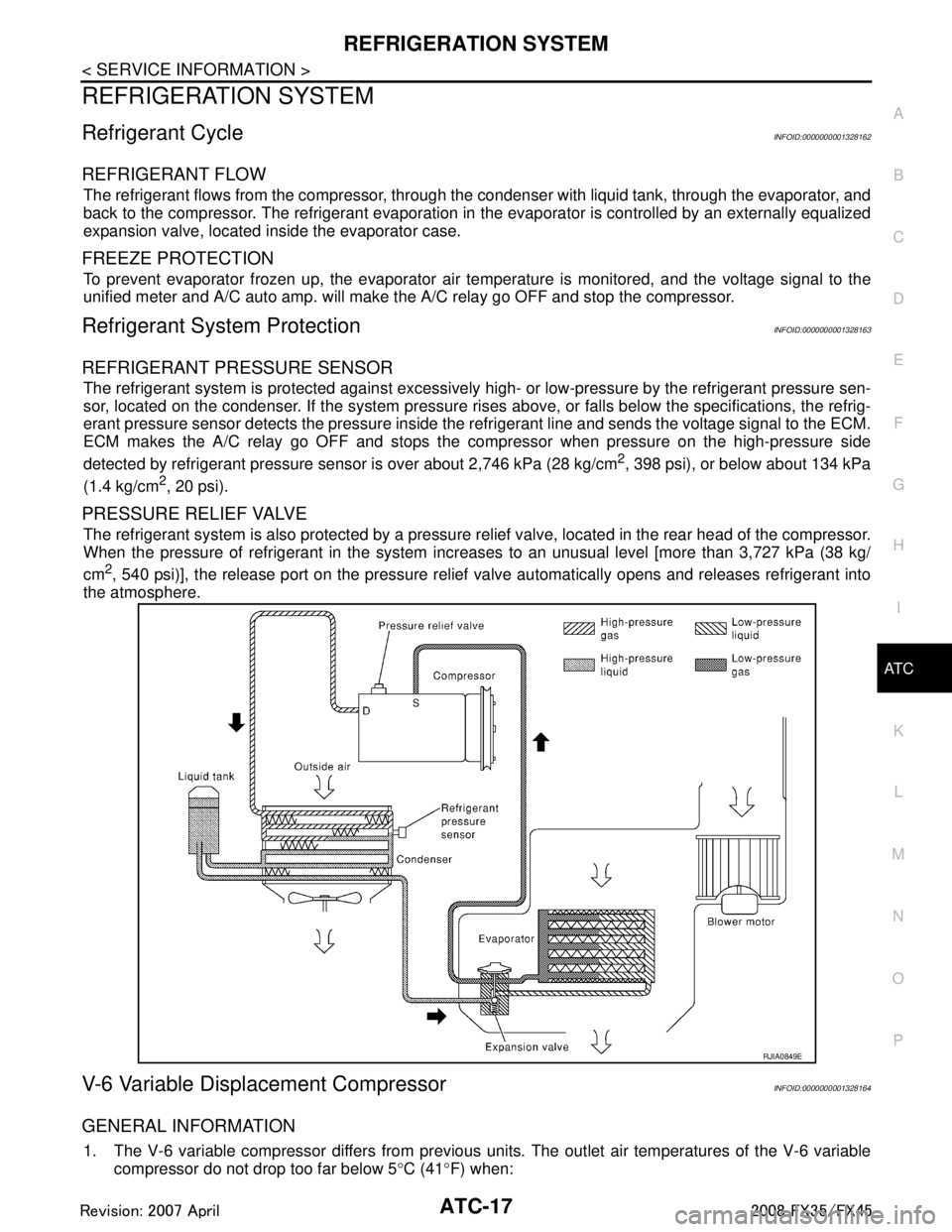

REFRIGERANT FLOW

The refrigerant flows from the compressor, through the condenser with liquid tank, through the evaporator, and

back to the compressor. The refrigerant evaporation in the evaporator is controlled by an externally equalized

expansion valve, located inside the evaporator case.

FREEZE PROTECTION

To prevent evaporator frozen up, the evaporator air te mperature is monitored, and the voltage signal to the

unified meter and A/C auto amp. will make t he A/C relay go OFF and stop the compressor.

Refrigerant System ProtectionINFOID:0000000001328163

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively high- or low-pressure by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rise s above, or falls below the specifications, the refrig-

erant pressure sensor detects the pressure inside t he refrigerant line and sends the voltage signal to the ECM.

ECM makes the A/C relay go OFF and stops the compressor when pressure on the high-pressure side

detected by refrigerant pressure sens or is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below about 134 kPa

(1.4 kg/cm

2, 20 psi).

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system in creases to an unusual level [more than 3,727 kPa (38 kg/

cm

2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into

the atmosphere.

V-6 Variable Displacement CompressorINFOID:0000000001328164

GENERAL INFORMATION

1. The V-6 variable compressor differs from previous units. The outlet air temperatures of the V-6 variable

compressor do not drop too far below 5 °C (41 °F) when:

RJIA0849E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 429 of 3924

ATC-24

< SERVICE INFORMATION >

AIR CONDITIONER CONTROL

AIR CONDITIONER CONTROL

Description of Air Conditioner LAN Control SystemINFOID:0000000001328167

The LAN (Local Area Network) syst em consists of unified meter and A/C amp., mode door motor, air mix door

motors and intake door motor.

A configuration of these component s is shown in the figure below.

System ConstructionINFOID:0000000001328168

A small network is constructed between the unifi ed meter and A/C amp., air mix door motors, mode door

motor and intake door motor. The unified meter and A/C amp. and motors are connected by data transmission

lines and motor power supply lines. The LAN network is built through the ground circuits of each door motor.

Addresses, motor opening angle signals, motor stop si gnals and error checking messages are all transmitted

through the data transmission lines connecting the unified meter and A/C amp. and each door motor.

The following functions are contained in LCUs built into the air mix door motors, the mode door motor and the

intake door motor.

Address

Motor opening angle signals

Data transmission

Motor stop and drive decision

Opening angle sensor (PBR function)

Comparison

Decision (Unified meter and A/C amp. indicated value and motor opening angle comparison)

OPERATION

The unified meter and A/C amp. receives data from each of the sensors. The unified meter and A/C amp.

sends mode door, air mix door and intake door opening angle data to the mode door motor LCU, air mix door

motor LCU and intake door motor LCU.

The mode door motor, air mix door motors and intake door motor read their respective signals according to the

address signal. Opening angle indication signals received from the unified meter and A/C amp. and each of

the motor position sensors is compared by the LCUs in each door motor with the existing decision and open-

ing angles. Subsequently, HOT/COLD, DEF/VENT and FRE/ REC operation is selected. The new selection

data is returned to the unified meter and A/C amp.

SJIA1609E

RJIA1747E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 431 of 3924

ATC-26

< SERVICE INFORMATION >

AIR CONDITIONER CONTROL

The air mix doors are automatically controlled so that in-vehicle temperature is maintained at a predetermined

value by the temperature setting, ambient temper ature, in-vehicle temperature and amount of sunload.

FAN SPEED CONTROL

Blower speed is automatically controlled by the temperature setting, ambient temperature, in-vehicle tempera-

ture, intake temperature, amount of sunload and air mix door position.

With pressing AUTO switch, the blower motor starts to gradually increase air flow volume.

When engine coolant temperature is low, the blower moto r operation is delayed to prevent cool air from flow-

ing.

INTAKE DOOR CONTROL

The intake doors are automatically controlled by the tem perature setting, ambient temperature, in-vehicle tem-

perature, intake temperature, amount of s unload and ON/OFF operation of the compressor.

MODE DOOR CONTROL

The mode door is automatically controlled by the temperat ure setting, ambient temperature, in-vehicle temper-

ature, intake temperature and amount of sunload.

MAGNET CLUTCH CONTROL

When A/C switch, AUTO switch or DEF switch is pr essed, unified meter and A/C amp. transmits compressor

ON signal to BCM.

BCM sends compressor ON signal to ECM, via CAN communication.

ECM judges whether compressor can be turned ON, based on each sensor status (refrigerant-pressure sen-

sor signal, throttle angle, etc.). If it judges compre ssor can be turned ON, it sends compressor ON signal to

IPDM E/R, via CAN communication.

Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate com-

pressor.

When sending compressor ON signal to IPDM E/R via CAN communication, ECM simultaneously sends com-

pressor feedback signal to unified meter and A/C amp. via CAN communication.

Unified meter and A/C amp., then, uses input compressor feedback signal to control air inlet.

SELF-DIAGNOSIS SYSTEM

The self-diagnosis system is built into the unified mete r and A/C amp. to quickly locate the cause of malfunc-

tions.

RJIA1957E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 432 of 3924

AIR CONDITIONER CONTROLATC-27

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Description of Control SystemINFOID:0000000001328169

The control system consists of input sensors, swit ches, the unified meter and A/C amp. (microcomputer) and

outputs. The relationship of these co mponents is shown in the figure below:

Control OperationINFOID:0000000001328170

DISPLAY SCREEN

The operation status of the system is displayed on the screen.

AUTO SWITCH

The compressor, intake doors, air mix doors, mode doors and blower speed are automatically controlled so

that the in-vehicle temperature will reach, and be mainta ined at the set temperature selected by the operator.

SJIA1658E

SJIA1567E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 447 of 3924

ATC-42

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Auto Amp. Terminal and Reference Value

INFOID:0000000001328180

Measure voltage between each terminal and ground by referring ter-

minals and reference value for unified meter and A/C amp.

PIN CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUE FOR UNIFIED METER AND A/C AMP.

SJIA1566E

RJIA1966E

Te r m i n a l

No. Wire

color ItemIgnition

switch Condition Vo l ta g e

(V)

1LCAN-H — — —

11 P C A N - L — — —

21 R/W Power supply from BAT OFF — Battery voltage

22 W Power supply from IGN ON — Battery voltage

29 B Ground (Power) ON — Approx. 0

30 B Ground ON — Approx. 0

35 LG Power supply from ACC ACC — Battery voltage

39 Y Ambient sensor — — —

40 BR/W In-vehicle sensor — — —

41 P Intake sensor — — —

42 R/Y Compressor ON signal ON A/C switch: ON

(Blower motor operates.)

Approx. 0

OFF switch: ON

(A/C system: OFF)

SJIA1423J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C