installation INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1127 of 3924

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................3

DTC INDEX ..................................................... .....3

U1000 - U1010 .................................................... ......3

B2202 - B2205 ..........................................................3

C1B00 - C1B03 .........................................................3

PRECAUTION .....................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

COMBINATION METERS ...................................5

System Description ............................................. ......5

Component Parts and Harness Connector Loca-

tion ............................................................................

8

Arrangement of Combination Meter ..........................9

Circuit Diagram .......................................................10

Wiring Diagram - METER - .....................................11

Terminal and Reference Value for Combination

Meter .......................................................................

13

Terminal and Reference Value for Unified Meter

and A/C Amp ...........................................................

14

Self-Diagnosis Mode of Combination Meter ............14

CONSULT-III Function (METER/M&A) ...................15

Trouble Diagnosis ...................................................15

Symptom Chart .......................................................16

Power Supply and Ground Circuit Inspection .........16

Vehicle Speed Signal Inspection .............................17

Engine Speed Signal Inspection .............................18

Engine Coolant Temperature Signal Inspection ......19

Fuel Level Sensor Signal Inspection .......................19

Fuel Gauge Pointer Fluctuates, Indicator Wrong

Value or Varies ........................................................

21

Fuel Gauge Does Not Move to FULL Position ........21

Odo/Trip Meter and Illumination Control Switch In-

spection ............................................................... ....

21

Electrical Component Inspection .............................21

Removal and Installation of Combination Meter .....22

Disassembly and Assembly of Combination Meter

....

23

Removal and Installation of Odo/Trip Meter and Il-

lumination Control Switch .................................... ....

24

UNIFIED METER AND A/C AMP ......................26

System Description ..................................................26

Schematic ................................................................27

CONSULT-III Function (METER/M&A) ....................27

Power Supply and Ground Circuit Inspection ..........29

DTC [U1000] CAN Communication Circuit ..............30

DTC [B2202] Meter Commun ication Circuit ............30

DTC [B2205] Vehicle Speed Circuit .................... ....32

Removal and Installation of Unified Meter and A/C

Amp .........................................................................

32

WARNING LAMPS ............................................34

System Description .............................................. ....34

Schematic ................................................................35

Wiring Diagram - WARN - .......................................36

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

43

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

45

Component Inspection .............................................46

A/T INDICATOR ................................................47

System Description ..................................................47

Wiring Diagram - AT/IND - .......................................48

A/T Indicator Is Malfunction .....................................49

WARNING CHIME .............................................51

System Description .............................................. ....51

Component Parts and Harness Connector Loca-

tion ...........................................................................

53

Schematic ................................................................54

Wiring Diagram - CHIME - .......................................55

Terminal and Reference Value for BCM ..................57

Terminal and Reference Value for Unified Meter

and A/C Amp. ...................................................... ....

59

Terminal and Reference Value for Combination

Meter .......................................................................

59

CONSULT-III Function (METER/M&A) ....................60

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1128 of 3924

DI-2

CONSULT-III Function (BCM) ................................60

Trouble Diagnosis ...................................................61

Symptom Chart .......................................................61

Power Supply and Ground Circuit Inspection .........61

Combination Meter Buzzer Circuit Inspection .........62

Front Door Switch (Driver Side) Signal Inspection ...63

Key Switch Signal Inspection (Without Intelligent

Key) ..................................................................... ...

64

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ...

65

Lighting Switch Signal Inspection ...........................66

Seat Belt Buckle Switch (Driver Side) Signal In-

spection ............................................................... ...

66

Component Inspection ............................................67

LANE DEPARTURE WARNING SYSTEM ........69

Precaution for Lane Departure Warning (LDW)

system ................................................................. ...

69

System Description .................................................69

Action Test ..............................................................71

Camera Aiming Adjustment ....................................71

Component Parts and Harness Connector Loca-

tion ..........................................................................

76

Schematic ...............................................................77

Wiring Diagram - LDW - .........................................78

Terminal and Reference Value for LDW Camera

Unit .........................................................................

81

CONSULT-III Function (LDW) ................................81

Trouble Diagnosis ...................................................83

Preliminary Check ..................................................84

Power Supply and Ground Circuit Inspection .........84

DTC [C1B00] CAMERA UNIT MALF ......................85

DTC [C1B01] CAM AIMING INCMP .......................85

DTC [C1B02] VHCL SPD DATA MALF ..................85

DTC [C1B03] ABNRML TEMP DETECT ................86

DTC [U1000] CAN COMM CIRCUIT ......................86

DTC [U1010] CONTROL UNIT (CAN) ....................86

LDW Chime Circuit Inspection ................................86

LDW Switch Circuit Inspection ...............................88

LDW Indicator Lamp Circuit Inspection ..................90

Turn Signal Input Inspection ................................ ...91

Electrical Component Inspection ............................91

Removal and Installation for LDW Camera Unit .....91

Removal and Installation for LDW Chime ............ ...91

Removal and Installation for LDW Switch ...............92

CAN COMMUNICATION ...................................93

System Description .............................................. ...93

CAN Communication Unit .......................................93

COMPASS .........................................................94

Precaution for Compass ...................................... ...94

System Description .................................................94

Troubleshooting ......................................................94

Zone Variation Setting Procedure ...........................95

Calibration Procedure .............................................95

Wiring Diagram - COMPAS - ..................................97

Removal and Installation of Compass ....................97

CLOCK ..............................................................98

Wiring Diagram - CLOCK - .................................. ...98

Removal and Installation of Clock ...........................98

REAR VIEW MONITOR ....................................100

System Description .............................................. .100

Component Parts and Harness Connector Loca-

tion ........................................................................

101

Schematic .............................................................102

Wiring Diagram - R/VIEW - ...................................103

Terminal and Reference Value for Rear View

Camera Control Unit .............................................

106

CONSULT-III Function (REARVIEW CAMERA) ...106

Side Distance Guideline Correction ......................107

Power Supply and Ground Circuit Inspection .......108

Rear View Is Not Displayed with the A/T Selector

Lever in R-Position ................................................

108

The Rear View Image Is Distorted ........................112

Removal and Installation of Rear View Camera

Control Unit .......................................................... .

113

Removal and Installation of Rear View Camera ...113

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1130 of 3924

DI-4

< SERVICE INFORMATION >

PRECAUTION

PRECAUTION

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612921

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1144 of 3924

DI-18

< SERVICE INFORMATION >

COMBINATION METERS

2. Check voltage signal between unified meter and A/C amp. har-ness connector M56 terminal 26 and ground.

OK or NG

OK >> GO TO 3.

NG-1 >> If monitor indicates “0 V” constantly, perform the following. 1. Check each unit inputting vehicle speed signal (8 pulse), harness and connector betweeneach unit and unified meter and A/C amp.

2. Repair or replace malfunctioning part.

NG-2 >> If monitor indicates “5 V” or “12 V” constantly, replace unified meter and A/C amp. Refer to DI-32,

"Removal and Installation of Unified Meter and A/C Amp".

3.CHECK CONTINUITY BETWEEN COMBINATION METER AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and unified meter and A/C amp. connector.

3. Check continuity between combination meter harness connector

M20 terminal 1 and unified meter and A/C amp. harness con-

nector M56 terminal 26.

OK or NG

OK >> Replace combination meter.

NG >> Repair harness or connector.

Engine Speed Signal InspectionINFOID:0000000001328446

Symptom: Tachometer indication is malfunction.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Connect CONSULT-III, and start engine.

2. Select “METER/M&A” on CONSULT-III.

3. Using “TACHO METER” on “Data Monitor”, compare the value of “Data Monitor” with tachometer pointer

of combination meter.

OK or NG

OK >> GO TO 2.

NG >> Replace combination meter.

2.CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

Select “Data Monitor” of CONSULT-III to compare values between “ ENG SPEED” of “ENGINE” and “TACHO

METER” of “METER/M&A”.

OK or NG

OK >> Perform self-diagnosis of ECM. Refer to EC-117, "CONSULT-III Function (ENGINE)" (VQ35DE)

or EC-695, "

CONSULT-III Function (ENGINE)" (VK45DE).

NG >> Replace unified meter and A/C amp. Refer to DI-32, "

Removal and Installation of Unified Meter

and A/C Amp".

26 – Ground:

NOTE:

Maximum voltage may be 5 V due to

specifications (connected units).

SKIB0338E

PKIA1935E

1 – 26 : Continuity should exist.

SKIB0343E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1145 of 3924

COMBINATION METERSDI-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Engine Coolant Temperature Signal InspectionINFOID:0000000001328447

Symptom: Water temperature gauge indication is malfunction.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Connect CONSULT-III, and start engine.

2. Select “METER/M&A” on CONSULT-III.

3. Using “W TEMP METER” on “Data Monitor”, compare the value of “Data Monitor” with water temperature

gauge pointer of combination meter.

OK or NG

OK >> GO TO 2.

NG >> Replace combination meter.

2.CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

Select “Data Monitor” of CONSULT-“COOLAN TEMP/S ” of “ENGINE” and “W TEMP METER” of “METER/

M&A”.

OK or NG

OK >> Perform self-diagnosis of ECM. Refer to EC-117, "CONSULT-III Function (ENGINE)" (VQ35DE)

or EC-695, "

CONSULT-III Function (ENGINE)" (VK45DE).

NG >> Replace unified meter and A/C amp. Refer to DI-32, "

Removal and Installation of Unified Meter

and A/C Amp".

Fuel Level Sensor Signal InspectionINFOID:0000000001328448

Symptom:

Fuel gauge indication is malfunctioning.

Low-fuel warning lamp indication is irregular.

NOTE:

The following symptoms are not malfunctions.

Fuel gauge Depending on vehicle posture or driving circumstance, the fuel level in the tank varies, and the pointer may

fluctuate.

If the vehicle is fueled with the ignition switch ON, the pointer will move slowly.

Low-fuel warning lamp

Depending on vehicle posture or driving circumstance, t he fuel in the tank flows and the warning lamp ON

timing may change.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Select “METER A/C AMP” on CONSULT-III.

2. Using “FUEL METER” on “Data Monitor”, compare t he value of “Data Monitor” with fuel gauge pointer of

combination meter.

OK or NG

Water temperature gauge pointer Reference value of data monitor [ °C ( °F)]

Hot Approx. 130 (266)

Middle Approx. 70 - 105 (158 - 221) Cold Approx. 50 (122)

Fuel gauge pointer Reference value of data monitor [lit.] Full Approx. 86

Three quarters Approx. 70 Half Approx. 48

A quarter Approx. 25 Empty Approx. 9

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1146 of 3924

DI-20

< SERVICE INFORMATION >

COMBINATION METERS

OK >> GO TO 2.

NG >> Replace combination meter.

2.CHECK FUEL LEVEL SENSOR (SUB) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector and fuel level sensor unit (sub) connector.

3. Check continuity between unified meter and A/C amp. harness

connector (A) M56 terminal 28 and fuel level sensor unit (sub)

harness connector (B) B40 terminal 1.

4. Check continuity between unified meter and A/C amp. harness connector (A) M56 terminal 28 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK FUEL LEVEL SENSOR (MAIN·SUB) CIRCUIT

1. Disconnect fuel level sensor unit and fuel pump (main) connector.

2. Check continuity between fuel level sensor unit (sub) harness

connector (A) B40 terminal 2 and fuel level sensor unit and fuel

pump (main) harness connector (B) B39 terminal 2.

3. Check continuity between fuel level sensor unit (sub) harness

connector (A) B40 terminal 2 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK FUEL LEVEL SENSOR (MAIN) CIRCUIT

1. Check continuity between fuel level sensor unit and fuel pump (main) harness connector (A) B39 terminal 5 and unified meter

and A/C amp. harness connector (B) M56 terminal 36.

2. Check continuity between fuel level sensor unit and fuel pump (main) harness connector (A) B39 terminal 5 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5.CHECK FUEL LEVEL SENSOR

Check components. Refer to DI-21, "

Electrical Component Inspection".

OK or NG

OK >> Check fuel level sensor unit installation, and c heck whether the float arm interferes or binds with

any of the internal components in the fuel tank. Repair or replace malfunctioning part, if neces-

sary.

NG >> Replace fuel level sensor unit. 28 – 1 : Continuity should exist.

28 – Ground : Continuity should not exist.

SKIB8527E

2 – 2 : Continuity should exist.

2 – Ground : Continuity should not exist.

SKIB8697E

5 – 36 : Continuity should exist.

5 – Ground : Continuity should not exist.

SKIB8528E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1147 of 3924

COMBINATION METERSDI-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Fuel Gauge Pointer Fluctuates, Indicator Wrong Value or VariesINFOID:0000000001328449

1.CHECK FUEL GAUGE FLUCTUATION

Test drive vehicle to see if gauge fluctuates onl y during driving or at the instant of stopping.

Does the indication value vary only during driving or at the instant of stopping?

YES >> The pointer fluctuation may be caused by fuel level change in the fuel tank. Condition is normal.

NO >> Ask the customer about the situation when the symptom occurs in detail, and perform the trouble

diagnosis.

Fuel Gauge Does Not Move to FULL PositionINFOID:0000000001328450

1.QUESTION 1

Does it take a long time for the pointer to move to FULL position?

YES >> GO TO 2.

NO >> GO TO 3.

2.QUESTION 2

Was the vehicle fueled with the ignition switch ON?

YES >> Be sure to fuel the vehicle with the ignition swit ch OFF. Otherwise, it will take a long time to move

to FULL position because of the c haracteristic of the fuel gauge.

NO >> GO TO 3.

3.QUESTION 3

Is the vehicle parked on an incline?

YES >> Check the fuel level indication with vehicle on a level surface.

NO >> GO TO 4.

4.QUESTION 4

During driving, does the fuel gauge pointer move gradually toward EMPTY position?

YES >> Check the fuel level sensor unit. Refer to DI-21, "Electrical Component Inspection".

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

Odo/Trip Meter and Illuminati on Control Switch InspectionINFOID:0000000001328451

Symptom: Illumination control does not operate.

1.CHECK ODO/TRIP METER AND I LLUMINATION CONTROL SWITCH

1. Remove odo/trip meter and illumination control switch. Refer to DI-24, "

Removal and Installation of Odo/

Trip Meter and Illumination Control Switch".

2. Check continuity odo/trip meter and illumination control switch. Refer to DI-21, "

Electrical Component

Inspection".

OK or NG

OK >> Replace combination meter.

NG >> Replace odo/trip meter and illumination control switch.

Electrical Component InspectionINFOID:0000000001328452

ODO/TRIP METER AND ILLUMINATION CONTROL SWITCH

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1148 of 3924

DI-22

< SERVICE INFORMATION >

COMBINATION METERS

Check continuity between terminals 25, 26, 35 or 36 and 27.

FUEL LEVEL SENSOR UNIT

For removal, refer to FL-4, "Component".

Fuel Level Sensor Unit and Fuel Pump (Main)

Check the resistance between terminals 2 and 5.

*1 and *2: When float rod is in contact with stopper.

If the results of check are NG, check the fuel level sensor unit and

fuel pump (main) harness. Refer to "Fuel Level Sensor Unit and

Pump (Main) Harness".

Fuel Level Sensor Unit and Pump (Main) Harness

Check continuity at following terminals.

If the results of check are NG, replace fuel pump assembly. If the results of check are OK, replace fuel level sensor unit.

Fuel Level Sensor Unit (Sub)

Check resistance between terminals 1 and 2.

*1 and *2: When float rod is in contact with stopper.

Removal and Installation of Combination MeterINFOID:0000000001328453

Refer to IP-10, "Component Parts Location".

Terminal Condition Continuity

25

27Illumination control swit

ch (–) is pressed. Yes

Illumination control swit ch (–) is released. No

26 Illumination control swit

ch (+) is pressed. Yes

Illumination control swit ch (+) is released. No

35 Trip transfer switch is pressed. Yes

Trip transfer switch is released. No

36 Trip reset switch is pressed. Yes

Trip reset switch is released. No

SKIB8529E

Terminal Float position [mm (in)]

Resistance val-

ue [Ω]

25 *1 Full 236 (9.29) Approx. 3

*2 Empty 29 (1.14) Approx. 80

SKIB3550J

Terminal Continuity

2 - Signal terminal (A) Ye s

5 - Ground terminal (B)

SKIB3551J

Terminal Float position [mm (in)] Resistance val-

ue [Ω]

12 *1 Full 6 (0.24) Approx. 3

*2 Empty 203 (7.99) Approx. 48

SKIB8530E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1150 of 3924

DI-24

< SERVICE INFORMATION >

COMBINATION METERS

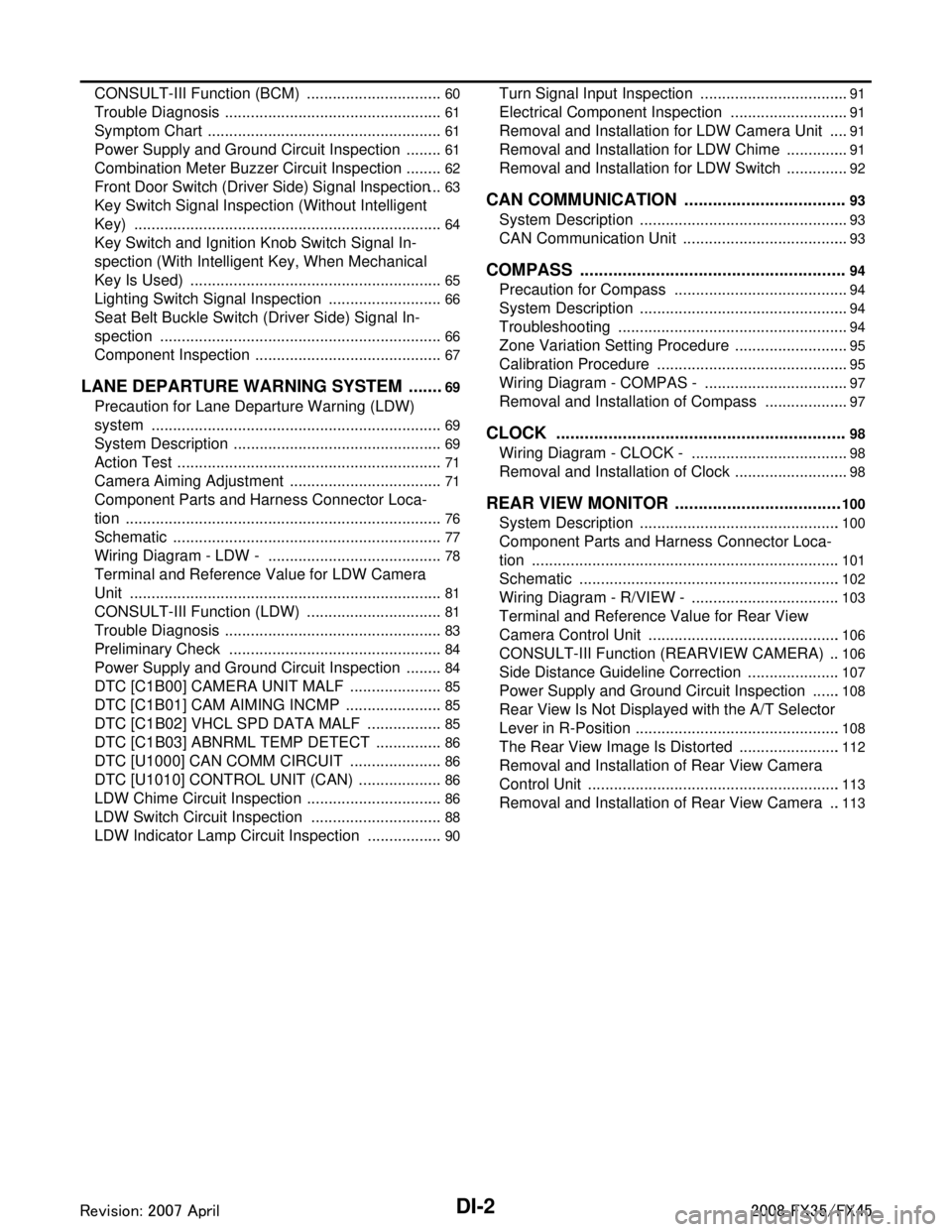

4. Remove tabs (A) and remove switch and meter housing (1).

5. Remove screws (A) and remove reinforcing metal (1).

6. Remove screws (A) and remove plate (1).

7. Disengage tabs (A) to separate front cover (1).

ASSEMBLY

Assembly is the reverse order of disassembly.

Removal and Installation of Odo/Trip Meter and Illumination Control SwitchINFOID:0000000001328455

REMOVAL

1. Remove combination meter. Refer to IP-10, "Component Parts Location".

SKIB8479E

SKIB8480E

SKIB8481E

SKIB8482E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1151 of 3924

COMBINATION METERSDI-25

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

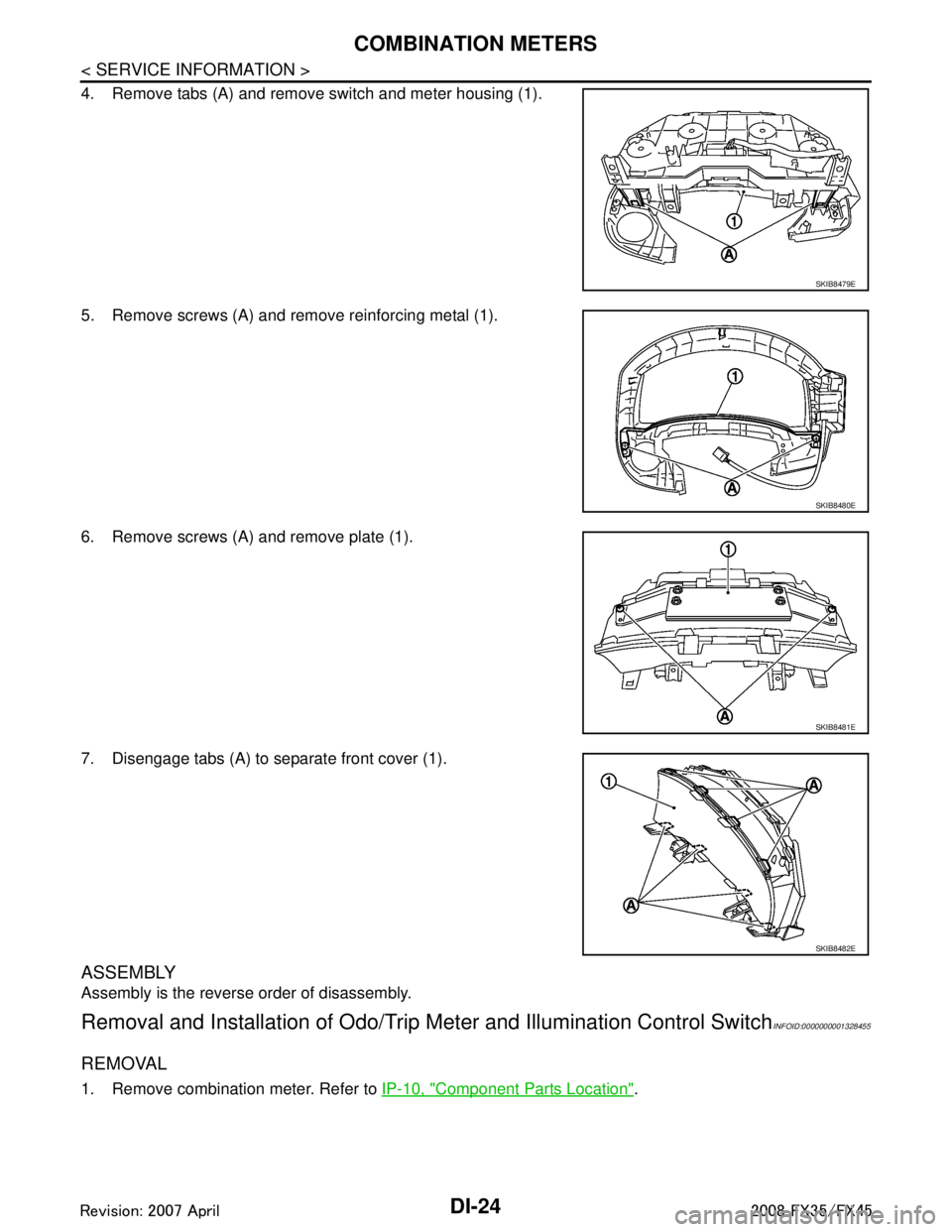

2. Remove switch and meter housing. Refer to DI-23, "Disassem-

bly and Assembly of Combination Meter".

3. Remove screws (2), and remove switch assembly.

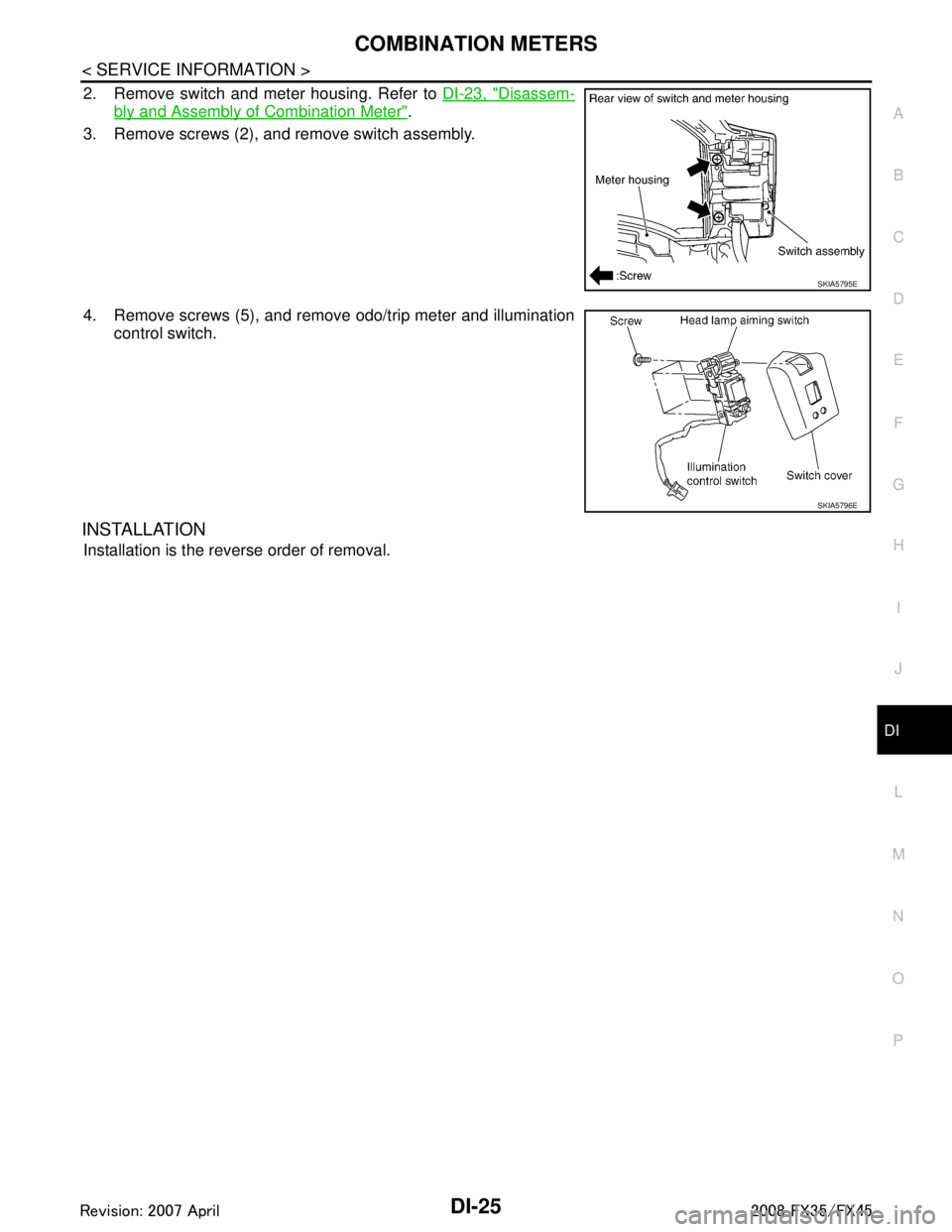

4. Remove screws (5), and remove odo/trip meter and illumination control switch.

INSTALLATION

Installation is the reverse order of removal.

SKIA5795E

SKIA5796E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C