bulb INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3105 of 3924

LT-3

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Component Parts and Harness Connector Loca-

tion ......................................................................

..

138

System Description ...............................................138

Schematic .............................................................143

Wiring Diagram - ROOM/L - ..................................145

Terminal and Reference Value for BCM ...............153

How to Proceed with Trouble Diagnosis ...............154

Preliminary Check .................................................154

CONSULT-III Functions (BCM) .............................155

Interior Room Lamp Control Does Not Operate ....157

Map Lamp Control Does Not Operate ...................158

Personal Lamp Control Does Not Operate ...........160

Ignition Keyhole Illumination Control Does Not

Operate .................................................................

161

All Step Lamps Do Not Operate ............................162

All Interior Room Lamps Do Not Operate .............164

Bulb Replacement ............................................... ..164

Removal and Installation .......................................166

ILLUMINATION ...............................................169

System Description ................................................169

CAN Communication System Description .............170

CAN Communication Unit ......................................170

Schematic ..............................................................171

Wiring Diagram - ILL - ...........................................173

Bulb Replacement .................................................181

Removal and Installation .......................................182

BULB SPECIFICATIONS ................................183

Headlamp ..............................................................183

Exterior Lamp ........................................................183

Interior Lamp/Illumination ......................................183

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3106 of 3924

LT-4

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612924

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

General Precaution for Service OperationINFOID:0000000001328264

Never work with wet hands.

Xenon headlamp includes high voltage generating part. Be sure to disconnect battery negative cable (negative terminal) or power

fuse before removing, installing, or touching the xenon headlamp

(including lamp bulb).

Turn the lighting switch OFF before disconnecting and connecting the connector.

When turning the xenon headlamp on and while it is illuminated, never touch the harness, bulb, and socket of the headlamp.

When checking the headlamp on/off operation, check it on vehicle

and with the power connected to the vehicle-side connector.

Do not touch the headlamp bulb glass surface with bare hands or allow oil or grease to get on it. Do not touch the headl amp bulb just after the headlamp is turned off, because

it is very hot.

Install the xenon headlamp bulb socket co rrectly. If it is installed improperly, high-voltage leak or corona dis-

charge may occur that can melt the bulb, connecto r, and housing. Do not illuminate the xenon headlamp

bulb out of the headlamp housing. Doing so can cause fire and harm your eyes.

When the bulb has burned out, wrap it in a thick vinyl bag and discard. Do not break the bulb.

Leaving the bulb removed from the headlamp housing for a long period of time can deteriorate the perfor- mance of the lens and reflector (dirt, clouding). Al ways prepare a new bulb and have it on hand when replac-

ing the bulb.

When adjusting the headlamp aiming, turn the aiming adjus tment screw only in the tightening direction. (If it

is necessary to loosen the screw, first fully loosen the screw, and then turn it in the tightening direction.)

Do not use organic solvent (paint thinner or gasoline) to clean lamps and to remove old sealant.

PKID0793E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3107 of 3924

HEADLAMP - XENON TYPE -LT-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

HEADLAMP - XENON TYPE -

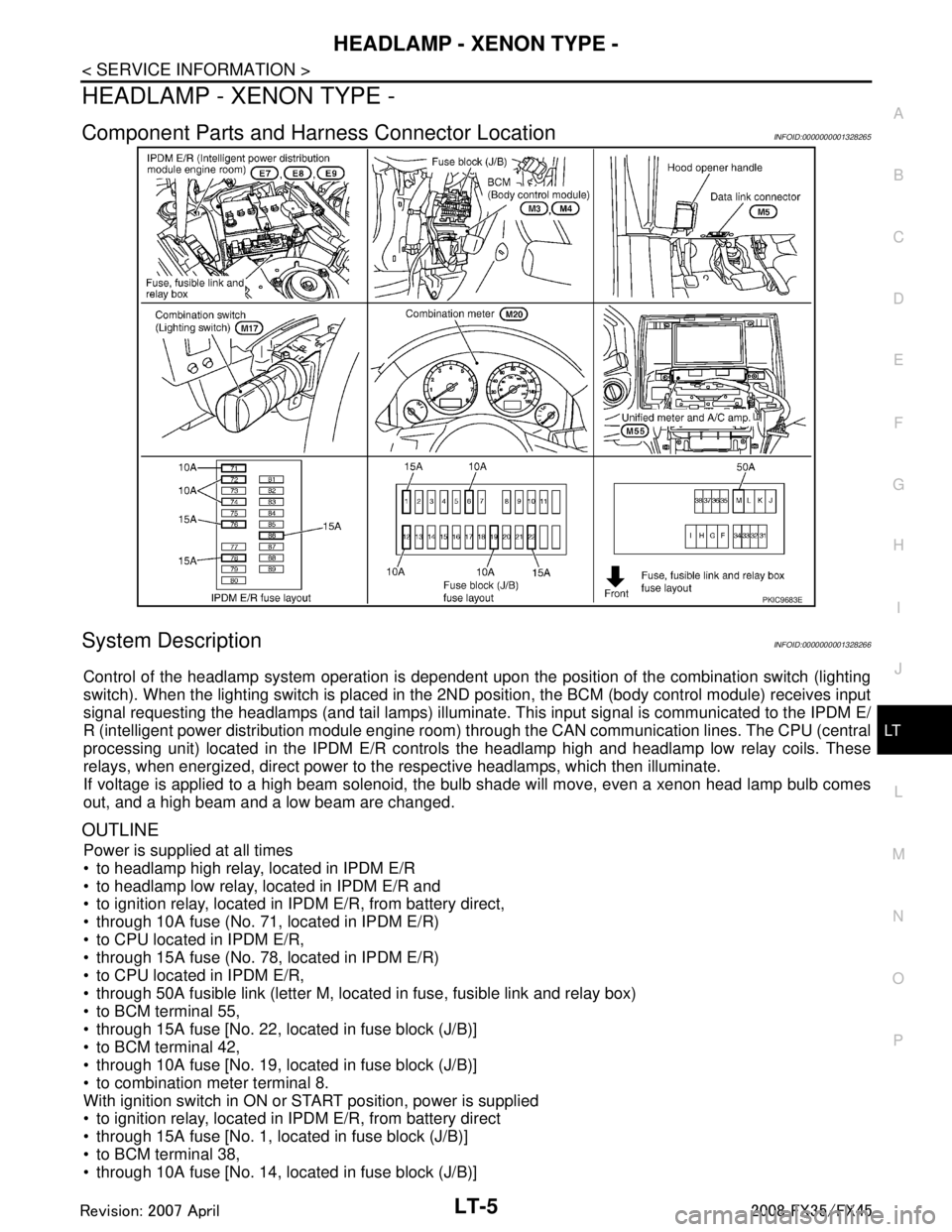

Component Parts and Har ness Connector LocationINFOID:0000000001328265

System DescriptionINFOID:0000000001328266

Control of the headlamp system operation is dependent upon t he position of the combination switch (lighting

switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives input

signal requesting the headlamps (and tail lamps) illuminate. This input signal is communicated to the IPDM E/

R (intelligent power distribution module engine room) through the CAN communication lines. The CPU (central

processing unit) located in the IPDM E/R contro ls the headlamp high and headlamp low relay coils. These

relays, when energized, direct power to the respective headlamps, which then illuminate.

If voltage is applied to a high beam solenoid, the bulb shade will move, even a xenon head lamp bulb comes

out, and a high beam and a low beam are changed.

OUTLINE

Power is supplied at all times

to headlamp high relay, located in IPDM E/R

to headlamp low relay, located in IPDM E/R and

to ignition relay, located in IPDM E/R, from battery direct,

through 10A fuse (No. 71, located in IPDM E/R)

to CPU located in IPDM E/R,

through 15A fuse (No. 78, located in IPDM E/R)

to CPU located in IPDM E/R,

through 50A fusible link (letter M, located in fuse, fusible link and relay box)

to BCM terminal 55,

through 15A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42,

through 10A fuse [No. 19, located in fuse block (J/B)]

to combination meter terminal 8.

With ignition switch in ON or START position, power is supplied

to ignition relay, located in IPDM E/R, from battery direct

through 15A fuse [No. 1, located in fuse block (J/B)]

to BCM terminal 38,

through 10A fuse [No. 14, located in fuse block (J/B)]

PKIC9683E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3108 of 3924

LT-6

< SERVICE INFORMATION >

HEADLAMP - XENON TYPE -

to combination meter terminal 7.

With ignition switch in ACC or ON position, power is supplied

through 10A fuse [No. 6, located in fuse block (J/B)]

to BCM terminal 11.

Ground is supplied

to BCM terminals 49 and 52

through grounds M35, M45 and M85,

to IPDM E/R terminals 38 and 60

through grounds E21, E50 and E51,

to combination meter terminals 5, 6 and 15

through grounds M35, M45 and M85.

HEADLAMP OPERATION

Low Beam Operation

With the lighting switch in the 2ND position, the BCM receives input signal requesting the headlamps to illumi-

nate. This input signal is communicated to the IP DM E/R through the CAN communication lines. The CPU

located in the IPDM E/R controls the headlamp lo w relay coil, which when energized, directs power

through 15A fuse (No. 76, located in IPDM E/R)

through IPDM E/R terminal 20

to front combination lamp RH terminal 6,

through 15A fuse (No. 86, located in IPDM E/R)

through IPDM E/R terminal 30

to front combination lamp LH terminal 6.

Ground is supplied

to front combination lamp RH and LH terminals 7

through grounds E21, E50 and E51,

With power and ground supplied, low beam headlamps illuminate.

High Beam Operation/Flash-to-Pass Operation

With the lighting switch in the 2ND position and placed in the HIGH or PASS position, the BCM receives input

signal requesting the headlamp high beams to illuminate. Th is input signal is communicated to the IPDM E/R

through the CAN communication lines. The CPU located in the IPDM E/R controls the headlamp high relay

coil and low relay coil, which when energized, directs power

through 15A fuse (No. 76, located in IPDM E/R)

through IPDM E/R terminal 20

to front combination lamp RH terminal 6,

through 15A fuse (No. 86, located in IPDM E/R)

through IPDM E/R terminal 30

to front combination lamp LH terminal 6,

through 10A fuse (No. 72, located in IPDM E/R)

through IPDM E/R terminal 27

to front combination lamp RH terminal 5,

through 10A fuse (No. 74, located in IPDM E/R)

through IPDM E/R terminal 28

to front combination lamp LH terminal 5.

Ground is supplied

to front combination lamp RH and LH terminals 7

through grounds E21, E50 and E51,

With power and ground supplied, the high beam headlamps illuminate.

If voltage is applied to a high beam solenoid, the bulb shade will move, even a xenon head lamp bulb comes

out, and a high beam and a low beam are changed.

The unified meter and A/C amp. that received the hi gh beam request signal by BCM through the CAN commu-

nication makes a high beam indicator lamp turn on in combination meter.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description".

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the 2ND position (ON), and the ignition switch is turned

from ON or ACC to OFF, the battery saver control function is activated.

Under this condition, the headlamps remain illumi nated for 5 minutes, then the headlamps are turned OFF.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3109 of 3924

HEADLAMP - XENON TYPE -LT-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-III.

AUTO LIGHT OPERATION (IF EQUIPPED)

Refer to LT-47, "System Description".

VEHICLE SECURITY SYSTEM

The vehicle security system will flash the high beams if the system is triggered. Refer to BL-163.

XENON HEADLAMP

Xenon type lamps are used for to the low beam headlamps . Xenon bulbs do not use a filament. Instead, they

produce light when a high voltage current is passed between two tungsten electrodes through a mixture of

xenon (an inert gas) and certain other metal halides. In addition to strong lighting power, electronic control of

the power supply gives the headlamps stable quality and tone color.

Followings are some advantages of the xenon type headlamp.

The light produced by the headlamps is white color si milar to sunlight that is easy to the eyes.

Light output is nearly double that of halogen headl amps, affording increased area of illumination.

Counter-reflected luminance increases and the contrast enhances on the wet road in the rain. That makes

visibility go up more than the increase of the light volume.

Power consumption is approximately 25 percent less than halogen headlamps, reducing battery load.

CAN Communication System DescriptionINFOID:0000000001328267

CAN (Controller Area Network) is a serial communication li ne for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitINFOID:0000000001328268

Refer to LAN-43, "CAN System Specification Chart".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3122 of 3924

LT-20

< SERVICE INFORMATION >

HEADLAMP - XENON TYPE -

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector andfront combination lamp (RH and LH) harness connectors.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-24, "Removal and Installation of IPDM E/R".

NG >> Repair harness or connector.

6.CHECK HEADLAMP GROUND

Check continuity between front combination lamp (RH and LH) har-

ness connectors and ground.

OK or NG

OK >> Check headlamp harness, connector and bulb.

NG >> Repair harness or connector.

Headlamp Does Not Change To High Beam (One Side)INFOID:0000000001381743

1.CHECK HEADLAMP INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH or LH connector.

3. Turn ignition switch ON.

4. Lighting switch is turned HIGH BEAM position.

5. Check voltage between front combination lamp RH or LH har- ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK HEADLAMP CIRCUIT

Te r m i n a l s Continuity

IPDM E/R Front combination lamp

Connector Terminal Connector Terminal

RH E7 27 E24 5

Ye s

LH 28 E44 5

PKIA5206E

Front combination lamp

connector Te r m i n a l

Ground Continuity

RH E24 7 Ye s

LH E44 7

PKIA5207E

Te r m i n a l s

Vo l ta g e

(Approx.)

(+)

(-)

Front combination lamp

connector Te r m i n a l

RH E24 5 Ground Battery voltage

LH E44 5

PKIA5205E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3125 of 3924

HEADLAMP - XENON TYPE -LT-23

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front combination lamp (RH and LH) harness connectors.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-24, "Removal and Installation of IPDM E/R".

NG >> Repair harness or connector.

6.CHECK HEADLAMP GROUND

1. Turn ignition switch OFF.

2. Check continuity between front combination lamp (RH and LH) harness connectors and ground.

OK or NG

OK >> Check headlamp harness and connectors, ballasts (HID control unit), and xenon bulbs. Refer to LT-27, "

Xenon

Headlamp Trouble Diagnosis".

NG >> Repair harness or connector.

Headlamp Low Beam Does Not Illuminate (One Side)INFOID:0000000001381745

1.CHECK BULB

Check ballast (HID control unit) and xenon bulb of lamp which does not illuminate. Refer to LT-27, "

Xenon

Headlamp Trouble Diagnosis".

OK or NG

OK >> GO TO 2.

NG >> Replace malfunctioning part.

2.CHECK HEADLAMP INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH or LH connector.

3. Turn ignition switch ON.

4. Lighting switch is turned 2ND position.

5. Check voltage between front combination lamp RH or LH har- ness connector and ground.

OK or NG

OK >> GO TO 4.

Te r m i n a l s Continuity

IPDM E/R Front combination lamp

Connector Terminal Connector Terminal

RH E7 20 E24 6

Ye s

LH 30 E44 6

PKIA5209E

Front combination lamp

connector Terminal

Ground Continuity

RH E24 7 Ye s

LH E44 7

PKIA5207E

Te r m i n a l s

Vol tag e

(Approx.)

(+)

(-)

Front combination lamp

connector Terminal

RH E24 6 Ground Battery voltage

LH E44 6

PKIA5208E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3126 of 3924

LT-24

< SERVICE INFORMATION >

HEADLAMP - XENON TYPE -

NG >> GO TO 3.

3.CHECK HEADLAMP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front combination lamp RH or LH harness connector.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-24, "Removal and Installation of IPDM E/R".

NG >> Repair harness or connector.

4.CHECK HEADLAMP GROUND

Check continuity between front comb ination lamp RH or LH harness

connector and ground.

OK or NG

OK >> Check headlamp harness and connector.

NG >> Repair harness or connector.

Headlamp RH Low Beam and Hi gh Beam Does Not IlluminateINFOID:0000000001381746

1.CHECK BULB

Inspect ballast (HID control unit) and xenon bulb of lamp which does not illuminate. Refer to LT-27, "

Xenon

Headlamp Trouble Diagnosis".

OK or NG

OK >> GO TO 2.

NG >> Replace malfunctioning part.

2. CHECK HEADLAMP GROUND

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH connector.

3. Check continuity between front combination lamp RH harness connector E24 terminal 7 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK HEADLAMP CIRCUIT

Te r m i n a l s Continuity

IPDM E/R Front combination lamp

Connector Terminal Connector Terminal

RH E7 20 E24 6

Ye s

LH 30 E44 6

PKIA5209E

Front combination lamp

connector Te r m i n a l

Ground Continuity

RH E24 7 Ye s

LH E44 7

PKIA5207E

7 – Ground : Continuity should exist.

PKIA5207E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3127 of 3924

HEADLAMP - XENON TYPE -LT-25

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector E7 ter- minal 27 and front combination lamp RH harness connector E24

terminal 5.

3. Check continuity between IPDM E/R harness connector E7 ter- minal 20 and front combination lamp RH harness connector E24

terminal 6.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-24, "Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

Headlamp LH Low Beam and High Beam Does Not IlluminateINFOID:0000000001381747

1.CHECK BULB

Inspect ballast (HID control unit) and xenon bulb of lamp which does not illuminate. Refer to LT-27, "

Xenon

Headlamp Trouble Diagnosis".

OK or NG

OK >> GO TO 2.

NG >> Replace malfunctioning part.

2.CHECK HEADLAMP GROUND

1. Turn ignition switch OFF.

2. Disconnect front combination lamp LH connector.

3. Check continuity between front combination lamp LH harness connector E44 terminal 7 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK HEADLAMP CIRCUIT

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector E7 ter- minal 28 and front combination lamp LH harness connector E44

terminal 5.27 – 5 : Continui

ty should exist.

PKIA7587E

20 – 6 : Continuity should exist.

PKIA5211E

7 – Ground : Continuity should exist.

PKIA5207E

28 – 5 : Continuity should exist.

PKIA5212E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3128 of 3924

LT-26

< SERVICE INFORMATION >

HEADLAMP - XENON TYPE -

3. Check continuity between IPDM E/R harness connector E7 ter-minal 30 and front combination lamp LH harness connector E44

terminal 6.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-24, "Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

Headlamps Does Not Turn OFFINFOID:0000000001381748

1.CHECK HEADLAMP TURN OFF

Make sure that lighting switch is OFF. And check if headlamp turns off when ignition switch is turned OFF.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK COMBINATION SWITCH INPUT SIGNAL

CONSULT-III DATA MONITOR

1. Select “HEAD LAMP1” and “HEAD LAMP2” of BCM data monitor item.

2. With operating the lighting switch, check the monitor status.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-24, "Removal and Installation of IPDM E/R".

NG >> Check combination switch (lighting switch). Refer to LT-104, "

Combination Switch Inspection".

3.CHECKING CAN COMMUNICATIONS BETWEEN BCM AND IPDM E/R

Perform self-diagnosis for “BCM” with CONSULT-III.

Display of self-diagnosis results

NO DTC>> Replace IPDM E/R. Refer to PG-24, "Removal and Installation of IPDM E/R".

CAN COMM CIRCUIT>> Refer to LAN-43, "

CAN System Specification Chart".

General Information for Xenon Headlamp Trouble DiagnosisINFOID:0000000001328284

In most cases, malfunction of xenon headlamp - “does not ill uminate”, “flickers” or “dark” - is caused by a mal-

functioning xenon bulb. A malfunctioning HID control unit or lamp housing, however, may be a cause. Be sure

to perform trouble diagnosis following the steps described below.

Caution:INFOID:0000000001328285

Installation or removal of connector must be done with lighting switch OFF.

Disconnect the battery cable from the negative terminal or remove power fuse.

When the lamp is illuminated (when lighting switch is ON), never touch harness, HID control unit, inside of

lamp, or lamp metal parts.

To check illumination, temporarily install lamp in vehicle. Be sure to connect power at vehicle side connector.

If error can be traced directly to electrical system, fi rst check for items such as blown fuses and fusible links,

broken wires or loose connectors, dislocated terminals, and improper connections.

Never work with wet hands.

Using a tester for HID control unit circuit trouble diagnosis is prohibited.

Disassembling HID control unit or harnesses ( bulb socket harness, ECM harness) is prohibited.

Immediately after illumination, light intensity and color will fluctuate, but there is nothing wrong.

When bulb has come to end of its life, brightness will dr op significantly, it will flash repeatedly, or light color

will turn reddish. 30 – 6 : Continuity should exist.

PKIA5213E

When lighting switch is OFF : HEAD LAMP SW1 OFF

: HEAD LAMP SW2 OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C