flat tire INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3070 of 3924

![INFINITI FX35 2008 User Guide

LAN-50

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

High beam request signal T R R

Horn chirp signal T R

Ignition switch signal T R R

Key fob door unlock signal T R

Key fob ID signal T R

Key switch INFINITI FX35 2008 User Guide

LAN-50

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

High beam request signal T R R

Horn chirp signal T R

Ignition switch signal T R R

Key fob door unlock signal T R

Key fob ID signal T R

Key switch](/img/42/57017/w960_57017-3069.png)

LAN-50

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

High beam request signal T R R

Horn chirp signal T R

Ignition switch signal T R R

Key fob door unlock signal T R

Key fob ID signal T R

Key switch signal T R

Low beam request signal T R

Oil pressure switch signalRT

TR

Position light request signal R T R R

Rear window defogger switch signal T R

Run flat tire warning lamp signal T R

Sleep wake up signal TRRR

RT

Theft warning horn request signal T R

Tire pressure warning lamp signal T R

Turn indicator signal T R

Alarm request signal R T

Back door open request signal R T

Door lock/unlock request signal R T

Ignition knob switch signal R T

Key warning signal T R

Power window open request signal R T

Steering angle sensor signal T R

Snow mode switch signal R T

Turn LED burnout status signal R T

Distance to empty signal R T

Fuel level low warning signal R T

Fuel level sensor signal R T

Manual mode shift down signal R T

Manual mode shift up signal R T

Manual mode signal R T

Not manual mode signal R T

Parking brake switch signal R R T

Stop lamp switch signal R R T

Vehicle speed signal RRT

R RRRR T R

A/T shift schedule change demand signal R T

ABS operation signal T

ABS warning lamp signal RT

Brake warning lamp signal RT

SLIP indicator lamp signal RT

TCS operation signal T

Signal name/Connecting unit

ECM

4WD

DISP TCM

BCM

I-KEY

STRG M&AABS

ADP

IPDM-E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3072 of 3924

![INFINITI FX35 2008 User Guide

LAN-52

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

ICC operation signal R T

ICC system display signal T R

ICC warning lamp signal T R

A/T CHECK indicator lamp signal T R

A/T self-diagnosis signal INFINITI FX35 2008 User Guide

LAN-52

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

ICC operation signal R T

ICC system display signal T R

ICC warning lamp signal T R

A/T CHECK indicator lamp signal T R

A/T self-diagnosis signal](/img/42/57017/w960_57017-3071.png)

LAN-52

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

ICC operation signal R T

ICC system display signal T R

ICC warning lamp signal T R

A/T CHECK indicator lamp signal T R

A/T self-diagnosis signal R T

Current gear position signal R T R

Manual mode indicator signal R T R

Output shaft revolution signal R R T R

P range signal R T R R

Shift position indicator signal R T R

Turbine revolution signal R R T

A/C switch signal R T

Blower fan motor switch signal R T

Day time running light request signal T R

Door lock/unlock status signal T R

Door switch signal R T R R R R

Front fog light request signal T R

Front wiper request signal R T R

High beam request signal T R R

Horn chirp signal T R

Ignition switch signal T R R

Key fob door unlock signal T R

Key fob ID signal T R

Key switch signal T R

Low beam request signal T R

Oil pressure switch signalRT

TR

Position light request signal R T R R

Rear window defogger switch signal T R

Run flat tire warning lamp signal T R

Sleep wake up signal TRRR

RT

Theft warning horn request signal T R

Tire pressure warning lamp signal T R

Turn indicator signal T R R

Alarm request signal R T

Back door open request signal R T

Door lock/unlock request signal R T

Ignition knob switch signal R T

Key warning signal T R

Power window open request signal R T

Steering angle sensor signal T R

Distance to empty signal R T Signal name/Connecting unit

ECM

4WD

DISP ICC

TCM

BCM

I-KEY

LANE

STRG M&A

ABS

LASER ADP

IPDM-E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3129 of 3924

HEADLAMP - XENON TYPE -LT-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Xenon Headlamp Trouble DiagnosisINFOID:0000000001328286

1.CHECK 1: XENON HEADLAMP LIGHTING

Install normal xenon bulb to corresponding xenon bulb headlamp, and check if lamp lights up.

OK or NG

OK >> Replace xenon bulb.

NG >> GO TO 2.

2.CHECK 2: XENON HEADLAMP LIGHTING

Install normal HID control unit to corresponding xenon headlamp, and check if lamp lights up.

OK or NG

OK >> Replace HID control unit.

NG >> GO TO 3.

3.CHECK 3: XENON HEADLAMP LIGHTING

Install normal xenon lamp housing assembly to corresponding xenon headlamp, and check if lamp lights up.

OK or NG

OK >> Replace xenon headlamp housing assembly. [Malfunction in starter (boosting circuit) in xenon headlamp housing]

NG >> INSPECTION END

Aiming AdjustmentINFOID:0000000001328287

PREPARATION BEFORE ADJUSTING

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on level ground.

3. Set that there is no-load in vehicle other than the driv er (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank.

LOW BEAM AND HIGH BEAM

PKIC9684E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3177 of 3924

FRONT FOG LAMPLT-75

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

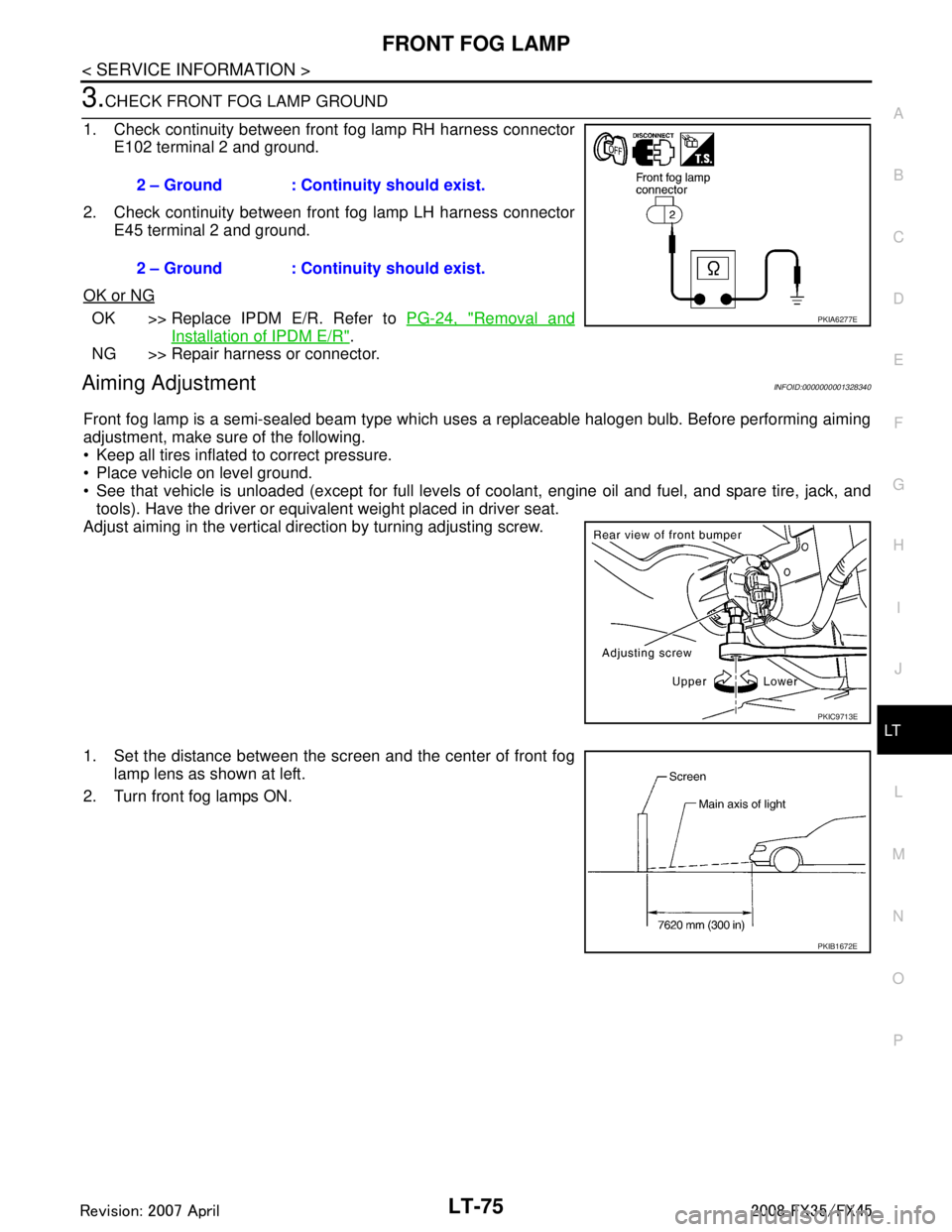

3.CHECK FRONT FOG LAMP GROUND

1. Check continuity between front fog lamp RH harness connector E102 terminal 2 and ground.

2. Check continuity between front fog lamp LH harness connector E45 terminal 2 and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-24, "Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

Aiming AdjustmentINFOID:0000000001328340

Front fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing aiming

adjustment, make sure of the following.

Keep all tires inflated to correct pressure.

Place vehicle on level ground.

See that vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and spare tire, jack, and tools). Have the driver or equivalent weight placed in driver seat.

Adjust aiming in the vertical direction by turning adjusting screw.

1. Set the distance between the scr een and the center of front fog

lamp lens as shown at left.

2. Turn front fog lamps ON. 2 – Ground : Continuity should exist.

2 – Ground : Continuity should exist.

PKIA6277E

PKIC9713E

PKIB1672E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3348 of 3924

CHASSIS AND BODY MAINTENANCEMA-31

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

a. Install balance weight in the position shown in the figure at right.

b. When installing balance weight to road wheels, set it into the grooved area on the inner wall of the road wheel as shown in the

figure so that the balance weight center is aligned with the tire

balance machine indication position (angle).

CAUTION:

Always use genuine NISSAN adhesion balance weights.

Balance weights are unreusable; always replace with newones.

Do not install more than three sheets of balance weight.

c. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other (as shown in

the figure).

CAUTION:

Do not install one balance weig ht sheet on top of another.

3. Start tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the tire balance machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start tire balance machine. Make sure that inner and outer resid- ual unbalance values are 5.0 g (0.18 oz) each or below.

If either residual unbalance value exceeds 5.0 g (0.18 oz), repeat installation procedures.

Tire RotationINFOID:0000000001328927

After rotation the tires, adjust the tire pressure.

Retighten the wheel nuts when the vehicle has been driven for

1,000 km (600 miles) (also in cases of a flat tire, etc.).

CAUTION:

Do not include the T-type spare tire when rotating the tires.

When installing wheels, tighte n them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Be careful not to tighten wh eel nut at torque exceeding the

criteria for preventing strain of disc rotor.

Use NISSAN genuine wheel nu ts for aluminum wheels.

SEIA0271E

Maximum allowable un-

balanceDynamic (At rim flange) Less than 5.0 g (0.18 oz) (one side)

Static (At rim flange) Less than 20 g (0.71 oz)

SMA056D

Tightening torque of wheel nut

: 108 N·m (11 kg, 83 ft-lb)SMA829C

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3358 of 3924

PARKING BRAKE SYSTEMPB-3

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

PB

N

O P

PARKING BRAKE SYSTEM

On-Vehicle InspectionINFOID:0000000001327646

PEDAL STROKE

• When parking brake pedal is operated with a force of 200 N (20.4 kg, 44.9 lb), make sure the parking brake

pedal stroke is within the specified number of notches . (Check it by listening and counting the ratchet clicks.)

Make sure that brake warning lamp comes on when parking brake pedal is depressed with in one notch.

INSPECT COMPONENTS

Make sure the components are installed properly (check for looseness, backlash, etc.).

Check parking brake pedal assembly for bend, damage and cracks, and replace if necessary.

Check cable for wear and damage, and replace if necessary.

Check parking brake switch for malfunction, and replace if necessary.

ADJUSTMENT

1. Insert a deep socket wrench to rotate adjusting nut and loosen cable sufficiently. Then, return pedal.

2. Remove tires from vehicle with power tool.

3. Using wheel nuts, fix disc rotor to hub and prevent it from tilting.

4. Remove adjusting hole plug installed on disc rotor. Using a flat- bladed screwdriver, turn adjuster to clockwise in the figure until

disc rotor is locked. After locking, turn adjuster to opposite direc-

tion by 5 or 6 notches.

5. Rotate disc rotor to make sure that there is no drag. Then install adjusting hole plug.

6. After adjusting the clearance of rear shoes, with no drag on rear brake, adjuster cable as follows:

a. Operate pedal 10 or more times with a force of 490 N (50 kg, 110 lb).

b. Depress pedal until a deep socket wrench can be inserted. Insert deep socket, and rotate adjusting nut to adjust pedal stroke.

CAUTION:

Do not reuse adjusting nut after removing it.

c. When parking brake pedal is operated with a force of 200 N (20.4 kg, 44.9 lb), make sure the stroke is

within the specified number of notches. (Check it by listening and counting the ratchet clicks.)

d. With parking brake pedal completely returned, make sure there is no drag on rear brake. Pedal stroke : 4

− 5 notches

SFIA1139E

Pedal stroke : 4 − 5 notches

PFIA0295E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3464 of 3924

STEERING WHEELPS-9

< SERVICE INFORMATION >

C

DE

F

H I

J

K L

M A

B

PS

N

O P

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000001327712

CHECKING CONDITION OF INSTALLATION

Check installation condition of steering gear assemb ly, front suspension, axle and steering column.

Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

Check if the mounting bolts for steering gear assembly are loose or not. Refer to PS-17

.

CHECKING STEERING WHEEL PLAY

1. Set tires to the straight ahead, start engine, then turn steering wheel to the left and right lightly, and mea-

sure steering wheel movement on the outer circumfe rence when steering wheel is turned up to the point

where tires start moving.

CHECKING NEUTRAL POSITION ON STEERING WHEEL

Check neutral position on steering wheel after confirming that front wheel alignment is correct. Refer to FSU-5,

"Wheel Alignment Inspection".

1. Set vehicle to the straight direction, chec k if steering wheel is in the neutral position.

2. If it is not in the neutral position, remo ve steering wheel and reinstall it correctly.

3. If the neutral position cannot adjust in the two teeth of steering gear assembly, loosen outer socket lock

nuts of steering outer sockets, then adjust outer so cket by the same amount in the opposite direction.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating te mperature. [Make sure temperature of fluid is

approximately 50 to 80 °C (122 to 176 °F).]

NOTE:

Tires need to be inflated normal pressure.

4. Check steering wheel turning force when steering wheel has been turned 360 ° from neutral position.

NOTE:

Multiply the distance L from the hook of spring balance to the

center of steering wheel by the measurement value with a spring

balance.

5. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer to PS-27, "

On-Vehicle Inspection and Service".

End play of the axle direction for steering wheel : 0 mm (0 in)

SGIA0546E

Steering wheel play on the

outer circumference : 0 − 35 mm (0 − 1.38 in)

Steering wheel turning force : Less than 7.45 N·m (0.76 kg-m, 66 in-lb)

SGIA1136E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3744 of 3924

PRECAUTIONSSRS-7

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612877

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for SRS "AIR BAG" and "SEAT BELT PRE-TENSIONER" Service

INFOID:0000000001327741

Do not use electrical test equipment to check SRS ci rcuits unless instructed to in this Service Manual.

Before servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are remov ed, it is still possible for the air bag and seat belt pre-

tensioner to deploy. Therefore, do not work on any SR S connectors or wires until at least 3 minutes have

passed.

Diagnosis sensor unit must always be installed with their arrow marks “ ⇐” pointing towards the front of the

vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

The spiral cable must be aligned with the neutral position since its rotations are limited. Do not turn steering

wheel and column after removal of steering gear.

Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Always replace instrument panel pad following front passenger air bag deployment.

Disposal, recycling, and transportation of air bag m odules and seat belt pre-tensioners should be performed

in compliance with applicable federal, state and local laws and regulations.

Occupant Classification System PrecautionINFOID:0000000001327742

Replace occupant classification system control uni t and passenger front seat cushion as an assembly.

Refer to Refer to Service Manual .

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3784 of 3924

COLLISION DIAGNOSISSRS-47

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

COLLISION DIAGNOSIS

For Frontal CollisionINFOID:0000000001327773

To repair the SRS, perform the following steps.

When SRS (except the front side air bag and sidecurt ain air bag modules) is activated in a collision:

1. Replace the diagnosis sensor unit.

2. Remove the air bag modules (except the front side air bag modulesand side curtain air bag modules),

crash zone sensor assembly, bracket andseat belt pre-tensioner assemblies.

3. Check the SRS components using the table below:

- Replace any SRS components showing visible signs of damage (dents,cracks and deformation).

4. Install new air bag modules (except the front side air bag modules and side curtain air bag modules) crash

zone sensor assembly, bracket and seat belt pre-tensioner assemblies.

5. Conduct self-diagnosis using CONSULT-III or “AIR BAG”warning lamp. Refer to SRS-23, "

SRS Operation

Check" for details. Ensure entire SRS operates properly.

When SRS is not acti vated in a collision:

1. Check the SRS components using the table below:

- Replace any SRS components showing visible signs of damage (dents, cracks and deformation).

2. Conduct self-diagnosis using CONSULT-III or “AIR BAG” warning lamp. Refer to SRS-23, "

SRS Operation

Check" for details. Ensure entire SRS operates properly.

When only one front air bag modu le is activated in a collision:

1. Replace the following components:

- Diagnosis sensor unit

- Crash zone sensor

- Activated front air bag and seat belt pre-tensioner.

2. Check the other SRS components using the table below. (Refer to “SRS is NOT activated”.)

- Replace any SRS components showing visible signs of damage (dents, cracks and deformation).

3. Conduct self-diagnosis using CONSULT-III or “AIR BAG” warning lamp. Refer to SRS-23, "

SRS Operation

Check" for details. Ensure entire SRS operates properly.

Only one front air bag may inflate a crash, depending on t he crash severity and whether the front occupants

are belted or unbelted. This does not indicate improper performance of the system. Perform self-diagnosis to

make sure the entire SRS operates properly.

SRS INSPECTION (FOR FRONTAL COLLISION)

Part SRS is activated SRS is NOT activated

Driver airbag

module If the Driver airbag has deployed:

REPLACE.

Install with new fasteners. If the Driver air bag has NOT been activated:

[same text as in current manual]

Passenger front

airbag module If the Passenger front airbag has deployed:

REPLACE.

Install with new fasteners. If the Passenger front air bag has NOT been activated:

[same text as in current manual]

Crash zone

sensor If any of the front airbags or seat belt pre-

tensionsers have been activated:

REPLACE the crash zone sensor and bracket

with new fasteners. If the front airbags or seat belt pre-tensionsers have NOT

been activated:

[same text as in current manual]

Seat belt pre-ten-

sioner assemblies If the driver or passenger Seat belt pre-tension-

er has been activated:

REPLACE the seat belt pre-tensioner

assemblies with new fasteners. If the pre-tensioners have NOT been activated:

[same text as in current manual]

Diagnosis sensor

unit If any of the SRS components have been

activated:

REPLACE the Diagnosis sensor unit.

Install with new fasteners. If none of the SRS components have been activated:

[same text as in current manual]

Steering wheel [same text as in current manual]

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3841 of 3924

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

ROAD WHEELS & TIRES

SERVICE INFORMATION .. ..........................2

INDEX FOR DTC ............................................ .....2

DTC No. Index .................................................... ......2

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution .................................................................3

Service Notice or Precaution .....................................4

PREPARATION ...................................................5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

6

NVH Troubleshooting Chart ................................ ......6

ROAD WHEEL ....................................................7

Inspection ............................................................ ......7

ROAD WHEEL TIRE ASSEMBLY ......................8

Balancing Wheels (Bonding Weight Type) .......... ......8

Tire Rotation ..............................................................9

TIRE PRESSURE MONITORING SYSTEM .......10

System Component ............................................. ....10

System Description .................................................10

CAN COMMUNICATION ....................................13

System Description ............................................. ....13

TROUBLE DIAGNOSES ....................................14

Schematic ........................................................... ....14

Wiring Diagram- T/WARN - .....................................15

Control Unit Input/Output Signal Standard ..............17

ID Registration Procedure ................................... ....19

Transmitter Wake Up Operation ..............................20

Self-Diagnosis .........................................................20

CONSULT-III Function (BCM) .................................22

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

24

Preliminary Check ...................................................25

Malfunction Code/Symptom Chart ...........................26

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

28

Transmitter or Control Unit (BCM) ...........................28

Transmitter - 1 .........................................................28

Transmitter - 2 .........................................................29

Vehicle Speed Signal ..............................................29

TROUBLE DIAGNOSIS FOR SYMPTOMS ......30

Low Tire Pressure Warning Lamp Does Not Come

On When Ignition Switch Is Turned On ...................

30

Low Tire Pressure Warning Lamp Stays On When

Ignition Switch Is Turned On ............................... ....

30

Low Tire Pressure Warning Lamp Blinks When Ig-

nition Switch Is Turned On ......................................

31

Run-Flat Tire Warning Lamp Stays On When Igni-

tion Switch Is Turned On .........................................

32

Turn Signal Lamp Blinks When Ignition Switch Is

Turned On ...............................................................

32

ID Registration Cannot Be Completed ....................32

REMOVAL AND INSTALLATION .....................33

Transmitter ..............................................................33

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

35

Road Wheel .............................................................35

Tire ..........................................................................35

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C