fog light INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1903 of 3924

![INFINITI FX35 2008 User Guide

BASIC SERVICE PROCEDUREEC-663

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 se INFINITI FX35 2008 User Guide

BASIC SERVICE PROCEDUREEC-663

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 se](/img/42/57017/w960_57017-1902.png)

BASIC SERVICE PROCEDUREEC-663

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

Throttle Valve Closed Position LearningINFOID:0000000001326520

DESCRIPTION

Throttle Valve Closed Position Learning is an operation to l

earn the fully closed position of the throttle valve by

monitoring the throttle position sensor output signal . It must be performed each time harness connector of

electric throttle control ac tuator or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

Idle Air Volume LearningINFOID:0000000001326521

DESCRIPTION

Idle Air Volume Learning is an operation to learn the idle air volume that keeps each engine within the specific

range. It must be performed under any of the following conditions:

Each time electric throttle control actuator or ECM is replaced.

Idle speed or ignition timing is out of specification.

PREPARATION

Before performing Idle Air Volume Learning, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

Battery voltage: More than 12.9V (At idle)

Engine coolant temperature: 70 - 99 °C (158 - 210 °F)

PNP switch: ON

Electric load switch: OFF (Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illuminated.

Steering wheel: Neutral (Straight-ahead position)

Vehicle speed: Stopped

Transmission: Warmed-up

- With CONSULT-III: drive vehicle unt il “ATF TEMP SE 1” in “DATA MONITOR” mode of “A/T” system indi-

cates less than 0.9V.

- Without CONSULT-III: driv e vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-III

1. Perform EC-662, "Accelerator Pedal Released Position Learning".

2. Perform EC-663, "

Throttle Valve Closed Position Learning".

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREP ARATION (previously mentioned) are in good order.

5. Select “IDLE AIR VOL LEA RN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

7. Make sure that “CMPLT” is displayed on CONSULT-III screen. If “CMPLT” is not displayed, Idle Air Vol-

ume Learning will not be carried out successfully. In this case, find the cause of the incident by referring to

the DIAGNOSTIC PROCEDURE below.

8. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifications.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1940 of 3924

![INFINITI FX35 2008 User Guide

EC-700

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS

FUEL T/TMP SE

°C or °F The fuel temperature (determined by the signal

voltage of the fuel tank temperature sensor) is

displayed.

INT/A INFINITI FX35 2008 User Guide

EC-700

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS

FUEL T/TMP SE

°C or °F The fuel temperature (determined by the signal

voltage of the fuel tank temperature sensor) is

displayed.

INT/A](/img/42/57017/w960_57017-1939.png)

EC-700

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS

FUEL T/TMP SE

°C or °F The fuel temperature (determined by the signal

voltage of the fuel tank temperature sensor) is

displayed.

INT/A TEMP SE °C or °F The intake air temperature (determined by the

signal voltage of the intake air temperature sen-

sor) is indicated.

EVAP SYS PRES V The signal voltage of EVAP control system pres-

sure sensor is displayed.

FUEL LEVEL SE V The signal voltage of the fuel level sensor is dis-

played.

START SIGNAL ON/OFF Indicates start signal status [ON/OFF] computed

by the ECM according to the signals of engine

speed and battery voltage. After starting the engine, [OFF] is dis-

played regardless of the starter signal.

CLSD THL POS ON/OFF Indicates idle position [ON/OFF] computed by

ECM according to the accelerator pedal position

sensor signal.

AIR COND SIG ON/OFF Indicates [ON/OFF] condition of the air condi-

tioner switch as determined by the air condition-

er signal.

P/N POSI SW ON/OFF Indicates [ON/OFF] condition from the park/neu-

tral position (PNP) switch signal.

PW/ST SIGNAL ON/OFF [ON/OFF] condition of the power steering sys-

tem (determined by the signal voltage of the

power steering pressure sensor signal) is indi-

cated.

LOAD SIGNAL ON/OFF Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger switch is ON and/or

lighting switch is in 2nd position.

OFF: Both rear window defogger switch and

lighting switch are OFF.

IGNITION SW ON/OFF Indicates [ON/OFF] condition from ignition

switch signal.

HEATER FAN SW ON/OFF Indicates [ON/OFF] condition from the heater

fan switch signal.

BRAKE SW ON/OFF Indicates [ON/OFF] condition from the stop

lamp switch signal.

INJ PULSE-B1 msec Indicates the actual fuel injection pulse width compensated by ECM according to the input

signals. When the engine is stopped, a certain

computed value is indicated.

INJ PULSE-B2 msec

IGN TIMING BTDC Indicates the ignition timing computed by ECM

according to the input signals. When the engine is stopped, a certain

value is indicated.

CAL/LD VALUE [%] % “Calculated load value” indicates the value of

the current air flow divided by peak air flow.

MASS AIRFLOW g·m/s Indicates the mass air flow computed by ECM

according to the signal voltage of the mass air

flow sensor.

PURG VOL C/V % Indicates the EVAP canister purge volume con-

trol solenoid valve control value computed by

the ECM according to the input signals.

The opening becomes larger as the value in- creases.

INT/V TIM (B1) °CA

Indicates [ °CA] of intake camshaft advanced an-

gle.

INT/V TIM (B2) °CA

Monitored item Unit Description Remarks

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1946 of 3924

![INFINITI FX35 2008 User Guide

EC-706

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS

●

Specification data ar e reference values.

● Specification data are output/input values which are detected or supplied by the ECM at t INFINITI FX35 2008 User Guide

EC-706

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS

●

Specification data ar e reference values.

● Specification data are output/input values which are detected or supplied by the ECM at t](/img/42/57017/w960_57017-1945.png)

EC-706

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS

●

Specification data ar e reference values.

● Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly relate d to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data in spite of the

ignition timing not being adjusted to the specification data. This IGN TIMING moni tors the data calculated by the ECM according to the signals

input from the camshaft position sensor and other ignition timing related sensors.

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED Run engine an d compare CONSULT-III value with the tachometer indication.Almost the same speed as

the tachometer indication.

MAS A/F SE-B1 See EC-709

.

B/FUEL SCHDL See EC-709

.

A/F ALPHA-B1

A/F ALPHA-B2 See

EC-709

.

COOLAN TEMP/S Engine: After warming up More than 70 °C (158 °F)

A/F SEN1 (B1)

A/F SEN1 (B2) Engine: After warming up Maintaining engine speed at 2,000 rpm Fluctuates around 1.5 V

HO2S2 (B1)

HO2S2 (B2) Revving engine from idle to 3,000 rpm quickly after the following conditions

are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at idle for 1 minute under no load 0 - 0.3V

←→ Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2) Revving engine from idle to 3,000 rpm quickly after the following conditions

are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at idle for 1 minute under no load LEAN

←→ RICH

VHCL SPEED SE Turn drive wheels and compare CONSULT-III value with the speedometer in-

dication. Almost the same speed as

speedometer indication

BATTERY VOLT Ignition switch: ON (Engine stopped) 11 - 14V

ACCEL SEN 1 Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released 0.5 - 1.0V

Accelerator pedal: Fully depressed 4.0 - 4.8V

ACCEL SEN 2* Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released 0.3 - 1.2V

Accelerator pedal: Fully depressed 3.9 - 4.8V

TP SEN 1-B1

TP SEN 2-B1* Ignition switch: ON

(Engine stopped)

Selector lever: D Accelerator pedal: Fully released More than 0.36V

Accelerator pedal: Fully depressed Less than 4.75V

EVAP SYS PRES Ignition switch: ON Approx. 1.8 - 4.8V

START SIGNAL Ignition switch: ON → START → ON OFF → ON → OFF

CLSD THL POS Ignition switch: ON

(Engine stopped) Accelerator pedal:

Fully released ON

Accelerator pedal: Slightly depressed OFF

AIR COND SIG Engine: After warming up, idle the

engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)

ON

P/N POSI SW Ignition switch: ON Selector lever: P or N ON

Selector lever: Except above OFF

PW/ST SIGNAL Engine: After warming up, idle the

engine Steering wheel: Not being turned OFF

Steering wheel: Being turned ON

LOAD SIGNAL Ignition switch: ON Rear window defogger switch: ON

and/or lighting switch: 2nd position

ON

Rear window defogger switch and lighting

switch: OFF OFF

IGNITION SW Ignition switch: ON → OFF → ON ON → OFF → ON

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1949 of 3924

![INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-709

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000001326536

The specifica INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-709

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000001326536

The specifica](/img/42/57017/w960_57017-1948.png)

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-709

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000001326536

The specification (SP) value indicates the tolerance of

the value that is displayed in “SPEC” of “DATA MONI-

TOR” mode with CONSULT-III during normal operation of the Engine Control System. When the value in

“SPEC” of “DATA MONITOR” mode is within the SP val ue, the Engine Control System is confirmed OK. When

the value in “SPEC” of “DATA MONITOR” mode is NOT within the SP value, the Engine Control System may

have one or more malfunctions.

The SP value is used to detect malfunctions that may af fect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board correc- tion)

A/F ALPHA-B1/B2 (The mean value of air-fuel ratio feedback correction factor per cycle)

MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionINFOID:0000000001326537

Vehicle driven distance: More than 5,000 km (3,107 miles)

Barometric pressure: 98.3 - 104.3 kPa (1.003 - 1.064 kg/cm

2, 14.25 - 15.12 psi)

Atmospheric temperature: 20 - 30 °C (68 - 86 °F)

Engine coolant temperature: 75 - 95 °C (167 - 203 °F)

Transmission: Warmed-up

- After the engine is warmed up to normal operating temper ature, drive vehicle until “ATF TEMP SE 1” (A/T

fluid temperature sensor signal) indicates more than 60 °C (140 °F).

Electrical load: Not applied

- Rear window defogger switch, air conditioner switch, li ghting switch are OFF. Steering wheel is straight

ahead.

Engine speed: Idle

Inspection ProcedureINFOID:0000000001326538

NOTE:

Perform “SPEC” in “DATA MONITOR” mode in maximum scale display.

1. Perform EC-658, "

Basic Inspection".

2. Confirm that the testing conditions indicated above are met.

3. Select “B/FUEL SCHDL”, “A/F ALPHA-B1”, “A/F ALPHA-B2” and “MAS A/F SE-B1” in “SPEC” of “DATA

MONITOR” mode with CONSULT-III.

4. Make sure that monitor items are within the SP value.

5. If NG, go to EC-710, "

Diagnosis Procedure".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2387 of 3924

![INFINITI FX35 2008 User Guide

ELECTRICAL LOAD SIGNALEC-1147

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000001327048

The electrical load signal (Headlamp switch si INFINITI FX35 2008 User Guide

ELECTRICAL LOAD SIGNALEC-1147

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000001327048

The electrical load signal (Headlamp switch si](/img/42/57017/w960_57017-2386.png)

ELECTRICAL LOAD SIGNALEC-1147

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000001327048

The electrical load signal (Headlamp switch signal, r

ear window defogger switch signal, etc.) is transferred

through the CAN communication line from BCM to ECM via IPDM E/R.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000001327049

Specification data are reference values.

Diagnosis ProcedureINFOID:0000000001327050

1.CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-I

1. Turn ignition switch ON.

2. Connect CONSULT-III and select “DATA MONITOR” mode.

3. Select “LOAD SIGNAL” and check indication under the following conditions.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

Check “LOAD SIGNAL” indication under the following conditions.

OK or NG

OK >> GO TO 3.

NG >> GO TO 5.

3.CHECK HEATER FAN SIGNAL CIRCUIT OVERALL FUNCTION

Select “HEATER FAN SW” and check indication under the following conditions.

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

4.CHECK REAR WINDOW DEFOGGER SYSTEM

MONITOR ITEM CONDITION SPECIFICATION

LOAD SIGNAL Ignition switch: ON Rear window defogger switch: ON

and/or lighting switch: 2nd position

ON

Rear window defogger switch and lighting

switch: OFF OFF

HEATER FAN SW Engine: After warming up, idle the

engine Heater fan switch: ON ON

Heater fan switch: OFF OFF

Condition Indication

Rear window defogger switch: ON ON

Rear window defogger switch: OFF OFF

Condition Indication

Lighting switch: ON at 2nd position ON

Lighting switch: OFF OFF

Condition Indication

Heater fan control switch: ON ON

Heater fan control switch: OFF OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2436 of 3924

![INFINITI FX35 2008 User Guide

EC-1196

< SERVICE INFORMATION >[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel PressureINFOID:0000000001327089

Idle Speed and Ignition TimingINFOID:000000000 INFINITI FX35 2008 User Guide

EC-1196

< SERVICE INFORMATION >[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel PressureINFOID:0000000001327089

Idle Speed and Ignition TimingINFOID:000000000](/img/42/57017/w960_57017-2435.png)

EC-1196

< SERVICE INFORMATION >[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel PressureINFOID:0000000001327089

Idle Speed and Ignition TimingINFOID:0000000001327090

*: Under the following conditions:

Air conditioner switch: OFF

Electric load: OFF (Lights, heater fan & rear window defogger)

Steering wheel: Kept in straight-ahead position

Calculated Load ValueINFOID:0000000001327091

Mass Air Flow SensorINFOID:0000000001327092

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorINFOID:0000000001327093

Engine Coolant Te

mperature SensorINFOID:0000000001327094

Fuel Tank Temperature SensorINFOID:0000000001327095

Fuel pressure at idling kPa (kg/cm2, psi) Approximately 350 (3.57, 51)

Target idle speed No load* (in P or N position) 650

±50 rpm

Air conditioner: ON In P or N position 700 rpm or more

Ignition timing In P or N position 12 ° ± 5 ° BTDC

Condition Calculated load value% (Using CONSULT-III or GST)

At idle 14.0 - 33.0

At 2,500 rpm 12.0 - 25.0

Supply voltageBattery voltage (11 - 14V)

Output voltage at idle 1.0 - 1.3V*

Mass air flow (Using CONSULT-III or GST) 2.0 - 6.0 g·m/sec at idle*

7.0 - 20.0 g·m/sec at 2,500 rpm*

Temperature °C ( °F) Resistance k Ω

25 (77) 1.800 - 2.200

Temperature °C ( °F) Resistance k Ω

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Temperature °C ( °F) Resistance k Ω

20 (68) 2.3 - 2.7

50 (122) 0.79 - 0.90

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2981 of 3924

GW-68

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

CONSULT-III Function (IPDM E/R)

INFOID:0000000001328007

DATA MONITOR

ACTIVE TEST

Work FlowINFOID:0000000001328008

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to GW-60, "

System Description".

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to GW-68,

"Trouble Diagnosis Symptom Chart".

4. Does rear window defogger operate no rmally? YES: GO TO 5, NO: GO TO 3.

5. INSPECTION END.

Trouble Diagnosis Symptom ChartINFOID:0000000001328009

Make sure other systems us ing the signal of the following systems operate normally.

Test item Content

REAR DEFOGGER Gives a drive sign al to the rear window defogger rela y to activate it.

IPDM E/R diagnostic test

item Check item diagnostic

test mode Content

REAR DEFOGGER Data monitor Displays the input data of BCM in real time.

Active test Gives a drive signal to a load to check the operation.

Monitored Item Description

RR DEF REQ Indicates [ON/OFF] condition of rear window defogger function by IPDM E/R.

Test Item Description

REAR DEFOGGER This test is able to check rear window defogger operation. Rear window defogger operates when “ON”

on CONSULT-III screen is touched.

Symptom Diagnoses / Service procedure Refer to page

Rear window defogger and door mirror defogger do not op-

erate. 1. Check BCM power supply and ground circuit

GW-69

2. Check IPDM E/R auto active test PG-20

3. Check rear window defogger switch circuit GW-69

4. Check rear window defogger power supply circuit GW-70

5. Replace IPDM E/ R PG-24

Rear window defogger does not operate but both of door

mirror defogger operate. 1. Check rear window defogger circuit

GW-72

2. Check filament GW-77

Door mirror defogger does not operated but both of rear

window defogger operate. Check door mirror defogger power supply circuit

GW-73

Driver side door mirror defogger does not operate. Check driver side door mirror defogger circuit GW-75

Passenger side door mirror defogger does not operate. Check passenger side door mirror defogger circuit GW-75

Rear window defogger switch does not light, and rear win-

dow defogger is not displayed on the display.

But rear window defogger operates. Check rear window defogger signal

GW-76

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2989 of 3924

GW-76

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

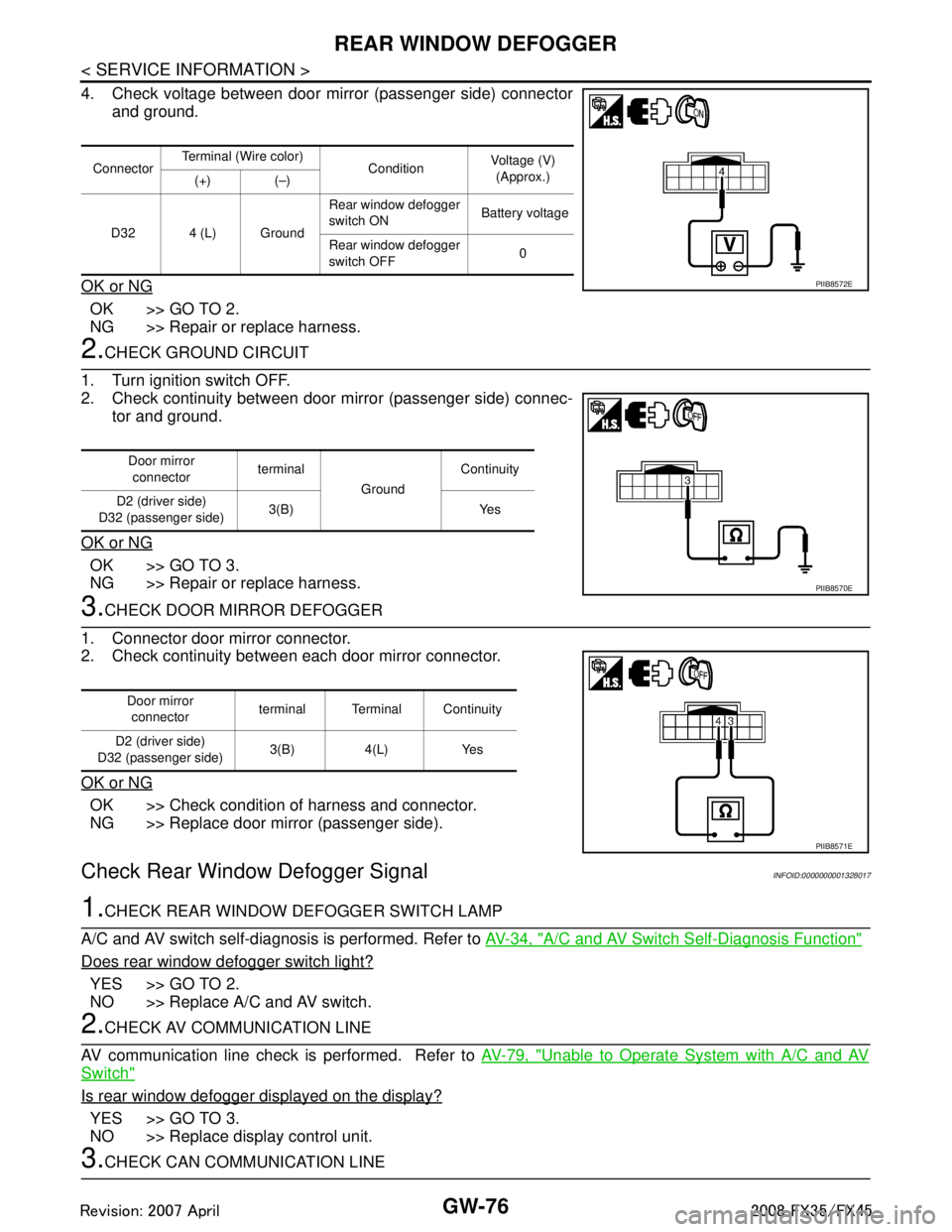

4. Check voltage between door mirror (passenger side) connectorand ground.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace harness.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between door mirror (passenger side) connec- tor and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK DOOR MIRROR DEFOGGER

1. Connector door mirror connector.

2. Check continuity between each door mirror connector.

OK or NG

OK >> Check condition of harness and connector.

NG >> Replace door mirror (passenger side).

Check Rear Windo w Defogger SignalINFOID:0000000001328017

1.CHECK REAR WINDOW DEFOGGER SWITCH LAMP

A/C and AV switch self-diagnosis is performed. Refer to AV-34, "

A/C and AV Switch Self-Diagnosis Function"

Does rear window defogger switch light?

YES >> GO TO 2.

NO >> Replace A/C and AV switch.

2.CHECK AV COMMUNICATION LINE

AV communication line check is performed. Refer to AV-79, "

Unable to Operate System with A/C and AV

Switch"

Is rear window defogger displayed on the display?

YES >> GO TO 3.

NO >> Replace display control unit.

3.CHECK CAN COMMUNICATION LINE

ConnectorTerminal (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

D32 4 (L) Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

PIIB8572E

Door mirror

connector terminal

GroundContinuity

D2 (driver side)

D32 (passenger side) 3(B) Yes

PIIB8570E

Door mirror

connector terminal Terminal Continuity

D2 (driver side)

D32 (passenger side) 3(B) 4(L) Yes

PIIB8571E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2991 of 3924

GW-78

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

Conductive silver composition (Dupont No. 4817 or equivalent)

Ruler 30 cm (11.8 in) long

Drawing pen

Heat gun

Alcohol

Cloth

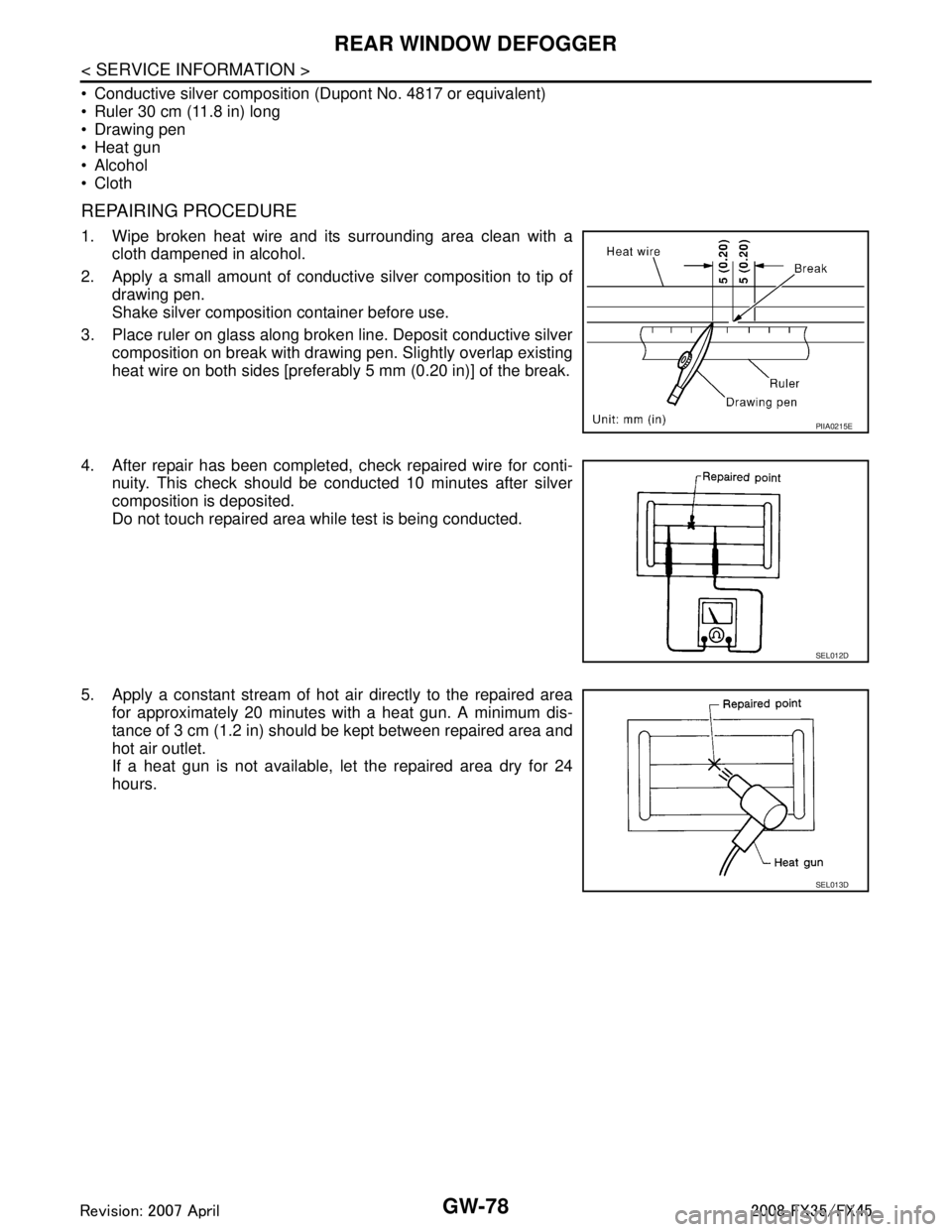

REPAIRING PROCEDURE

1. Wipe broken heat wire and its surrounding area clean with acloth dampened in alcohol.

2. Apply a small amount of conductive silver composition to tip of

drawing pen.

Shake silver composition container before use.

3. Place ruler on glass along broken line. Deposit conductive silver composition on break with drawing pen. Slightly overlap existing

heat wire on both sides [preferably 5 mm (0.20 in)] of the break.

4. After repair has been completed, check repaired wire for conti- nuity. This check should be conducted 10 minutes after silver

composition is deposited.

Do not touch repaired area while test is being conducted.

5. Apply a constant stream of hot air directly to the repaired area for approximately 20 minutes with a heat gun. A minimum dis-

tance of 3 cm (1.2 in) should be kept between repaired area and

hot air outlet.

If a heat gun is not available, let the repaired area dry for 24

hours.

PIIA0215E

SEL012D

SEL013D

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3065 of 3924

![INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSISLAN-45

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Current gear position signal T R

Manual mode indicator signal T R

Output shaft revolution signal R T

P range si INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSISLAN-45

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Current gear position signal T R

Manual mode indicator signal T R

Output shaft revolution signal R T

P range si](/img/42/57017/w960_57017-3064.png)

TROUBLE DIAGNOSISLAN-45

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Current gear position signal T R

Manual mode indicator signal T R

Output shaft revolution signal R T

P range signal T R R

Shift position indicator signal T R

Turbine revolution signal R T

A/C switch signal R T

Buzzer output signal TR

TR

Blower fan motor switch signal R T

Day time running light request signal T R

Door lock/unlock status signal T R

Door switch signal R T R R R R

Front fog light request signal T R

Front wiper request signal T R

High beam request signal T R R

Horn chirp signal T R

Ignition switch signal T R R

Key fob door unlock signal T R

Key fob ID signal T R

Key switch signal T R

Low beam request signal T R

Oil pressure switch signal RT

TR

Position light request signal T R R

Rear window defogger switch signal T R

Run flat tire warning lamp signal T R

Sleep wake up signal TRRR

RT

Theft warning horn request signal T R

Tire pressure warn ing lamp signal T R

Turn indicator signal T R

Alarm request signal R T

Back door open request signal R T

Door lock/unlock request signal R T

Ignition knob switch signal R T

Key warning signal T R

Power window open request signal R T

Steering angle sensor signal T R

Distance to empty signal R T

Fuel level low warning signal R T

Fuel level sensor signal R T

Manual mode shift down signal R T Signal name/Connecting unit

ECM

DISP TCM

BCM

I-KEY

STRG

M&AABS

ADP

IPDM-E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C