mount INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 163 of 3924

AT-90

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

R POSI IND (ON/OFF) — —

N POSI IND (ON/OFF) — —

D POSI IND (ON/OFF) — —

4TH POSI IND (ON/OFF) — —

3RD POSI IND (ON/OFF) — —

2ND POSI IND (ON/OFF) — —

1ST POSI IND (ON/OFF) — —

MANU MODE IND (ON/OFF) — —

POWER M LAMP (ON/OFF) — —

F-SAFE IND/L (ON/OFF) — —

ATF WARN LAMP (ON/OFF) — — Not mounted but displayed

BACK-UP LAMP (ON/OFF) — —

STARTER RELAY (ON/OFF) — —

PNP SW3 MON (ON/OFF) — —

C/V CLB ID1 — —

C/V CLB ID2 — —

C/V CLB ID3 — —

UNIT CLB ID1 — —

UNIT CLB ID2 — —

UNIT CLB ID3 — —

TRGT GR RATIO — —

TRGT PRES TCC (kPa) — —

TRGT PRES L/P (kPa) — —

TRGT PRES I/C (kPa) — —

TRGT PRE FR/B (kPa) — —

TRGT PRES D/C (kPa) — —

TRG PRE HLR/C (kPa) — —

SHIFT PATTERN — —

DRV CST JUDGE — —

START RLY MON — —

NEXT GR POSI — —

SHIFT MODE — —

MANU GR POSI — —

VEHICLE SPEED (km/h) — X Vehicle sp eed recognized by the TCM.

Monitored item (Unit)

Select Monitor Item

Remarks

ECU IN-

PUT SIG- NALS MAIN SIG-

NALS SELEC-

TION

FROM

MENU

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 288 of 3924

ON-VEHICLE SERVICEAT-215

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

ON-VEHICLE SERVICE

Control Valve with TCM and A/T Fluid Temperature Sensor 2INFOID:0000000001327393

COMPONENTS

CONTROL VALVE WITH TCM ASSEMB LY REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery cable from the negative terminal.

2. Drain ATF through drain plug.

3. Remove front cross bar. Refer to FSU-6, "

Removal and Installation".

4. Disconnect heated oxygen sensor 2 harness connector.

5. Disconnect A/T assembly harness connector.

1. A/T 2. Snap ring 3. Sub-harness

4. Control valve with TCM 5. Bracket 6. A/T fluid temperature sensor 2

7. Oil pan gasket 8. Clip 9. Bracket (VK45DE)

10. Bracket (VK45DE) 11. Oil pan mounting bolt 12. Oil pan

13. Magnet 14. Drain plug 15. Drain plug gasket

16. Terminal cord assembly 17. O-ring

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SCIA8045E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 293 of 3924

AT-220

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

3. Connect TCM connectors.

4. Install O-ring in A/T assembly harness connector.CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

5. Install A/T fluid temperature sensor 2 to bracket.

6. Install A/T fluid temperature sensor 2 (with bracket) in control valve with TCM, and then tighten A/T fluid temperature sensor 2

mounting bolt to the specified torque. Refer to "COMPO-

NENTS".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

7. Install control valve with TCM in transmission case. CAUTION:

Make sure that turbine revolu tion sensor securely installs

turbine revolution sensor hole.

Hang down revolution senso r harness toward outside so

as not to disturb installation of control valve with TCM.

Adjust A/T assembly harness co nnector of control valve

with TCM to terminal hole of transmission case.

SCIA5447E

SCIA5155E

SCIA5264E

SCIA5301E

SCIA5034E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 295 of 3924

AT-222

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

12. Connect revolution sensor connector.

13. Securely fasten revolution sensor harness with terminal clip.

14. Install magnets in oil pan.

15. Install oil pan to transmission case.

a. Install oil pan gasket to oil pan.CAUTION:

Do not reuse oil pan gasket.

Install it in the direction to align hole positions.

Completely remove all moisture , oil and old gasket, etc. from oil pan gasket mounting surface.

b. Install oil pan (3) (with oil pan gasket), clips (2) and brackets (1) (VK45DE) to transmission case.

: Vehicle front

: Bolt (22)

CAUTION:

Install it so that drain plug (4) comes to the position as

shown in the figure.

Be careful not to pinch harnesses.

Completely remove all moisture, oil and old gasket, etc. from oil pan mounting surface.

SCIA7524E

SCIA7525E

SCIA5200E

SCIA8128E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 296 of 3924

ON-VEHICLE SERVICEAT-223

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

c. Tighten oil pan mounting bolts to the specified torque in numeri- cal order shown in the figure after temporarily tightening them.

Refer to "COMPONENTS".

CAUTION:

Do not reuse oil pan mounting bolts.

16. Install drain plug to oil pan, and then tighten drain plug to the specified torque. Refer to "COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

17. Pull up A/T assembly harness connector. CAUTION:

Be careful not to damage connector.

18. Install snap ring to A/T assembly harness connector.

19. Connect A/T assembly harness connector.

20. Connect heated oxygen sensor 2 harness connector.

21. Install front cross bar. Refer to FSU-6, "

Removal and Installa-

tion".

22. Pour ATF into A/T assembly. Refer to AT- 11 , "

Changing A/T

Fluid".

23. Connect the battery cable to the negative terminal.

A/T FLUID TEMPERATURE SENSOR 2 REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery cabl e from the negative terminal.

2. Remove front cross bar. Refer to FSU-6, "

Removal and Installation".

3. Disconnect heated oxygen sensor 2 harness connector.

4. Drain ATF through drain plug.

5. Remove bracket (1) (VK45DE), clips (2), oil pan (3) and oil pan gasket.

: Vehicle front

: Bolt (22)

Drain plug (4)

SCIA4113E

SCIA5038E

SCIA5039E

SCIA8128E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 298 of 3924

ON-VEHICLE SERVICEAT-225

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

1. Install A/T fluid temperature sensor 2 to bracket.

2. Install A/T fluid temperature sens or 2 (with bracket) in control

valve with TCM, and then tighten A/T fluid temperature sensor 2

mounting bolt to the specified torque. Refer to "COMPO-

NENTS".

3. Connect A/T fluid temperature sensor 2 connector (1).

4. Securely fasten A/T fluid temperature sensor 2 harness with ter- minal clip ( ).

5. Install oil pan to transmission case.

a. Install oil pan gasket to oil pan. CAUTION:

Do not reuse oil pan gasket.

Install it in the direction to align hole positions.

Completely remove all moisture , oil and old gasket, etc. from oil pan mounting surface.

b. Install oil pan (3) (with oil pan gasket), clips (2) and brackets (1) (VK45DE) to transmission case.

: Vehicle front

: Bolt (22)

CAUTION:

Install it so that drain plug (4) comes to the position as

shown in the figure.

Be careful not to pinch harnesses.

Completely remove all moistu re, oil and old gasket, etc.

from oil pan mounting surface.

SCIA5264E

SCIA5302E

SCIA8076E

SCIA8128E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 299 of 3924

AT-226

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

c. Tighten oil pan mounting bolts to the specified torque in numeri-cal order shown in the figure after temporarily tightening them.

Refer to "COMPONENTS".

CAUTION:

Do not reuse oil pan mounting bolts.

6. Install drain plug to oil pan, and then tighten drain plug to the specified torque. Refer to "COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

7. Connect heated oxygen sensor 2 harness connector.

8. Install front cross bar. Refer to FSU-6, "

Removal and Installa-

tion".

9. Pour ATF into A/T assembly. Refer to AT- 11 , "

Changing A/T Fluid".

10. Connect the battery cable to the negative terminal.

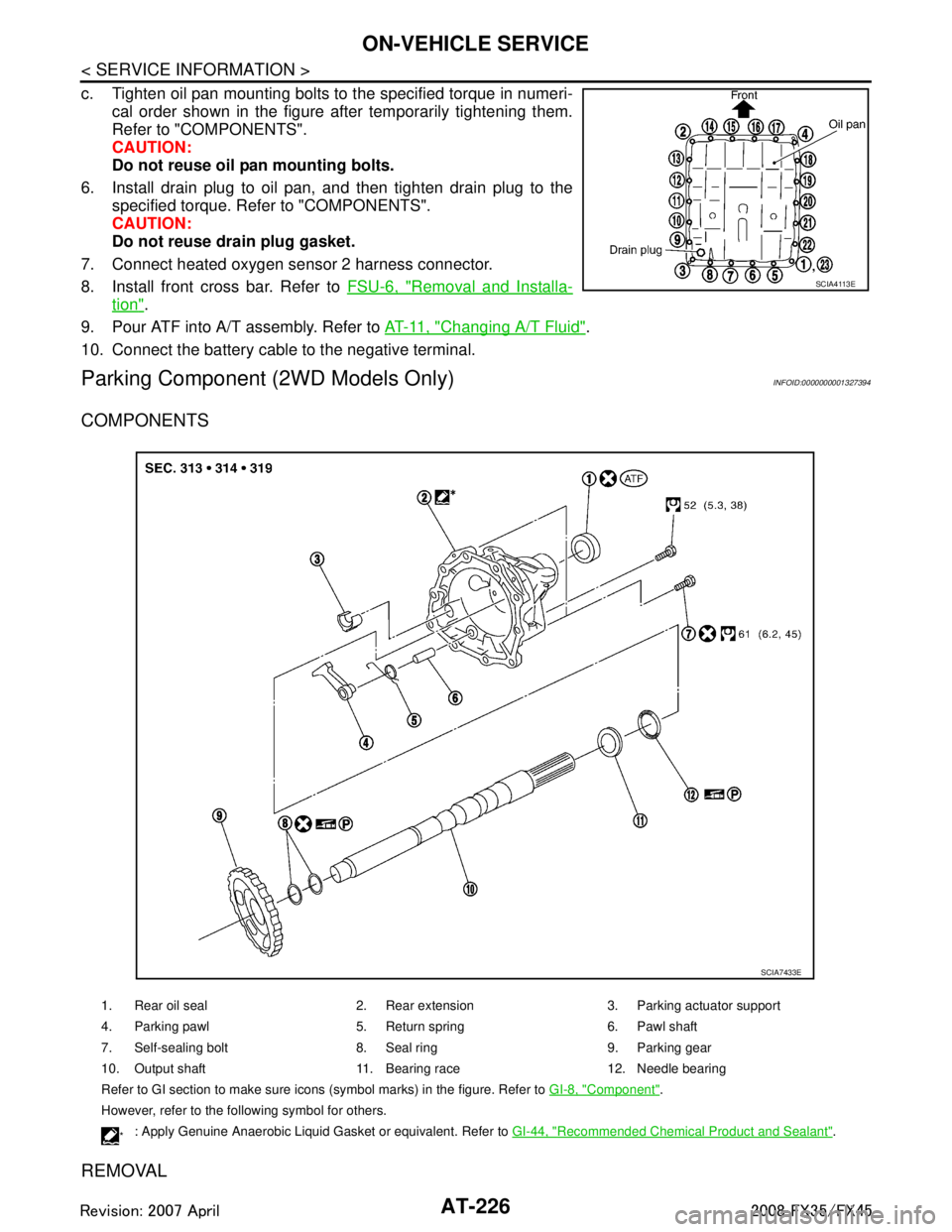

Parking Component (2WD Models Only)INFOID:0000000001327394

COMPONENTS

REMOVAL

SCIA4113E

1. Rear oil seal 2. Rear extension 3. Parking actuator support

4. Parking pawl 5. Return spring 6. Pawl shaft

7. Self-sealing bolt 8. Seal ring 9. Parking gear

10. Output shaft 11. Bearing race 12. Needle bearing

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

However, refer to the following symbol for others.

*: Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-44, "Recommended Chemical Product and Sealant".

SCIA7433E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 300 of 3924

ON-VEHICLE SERVICEAT-227

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

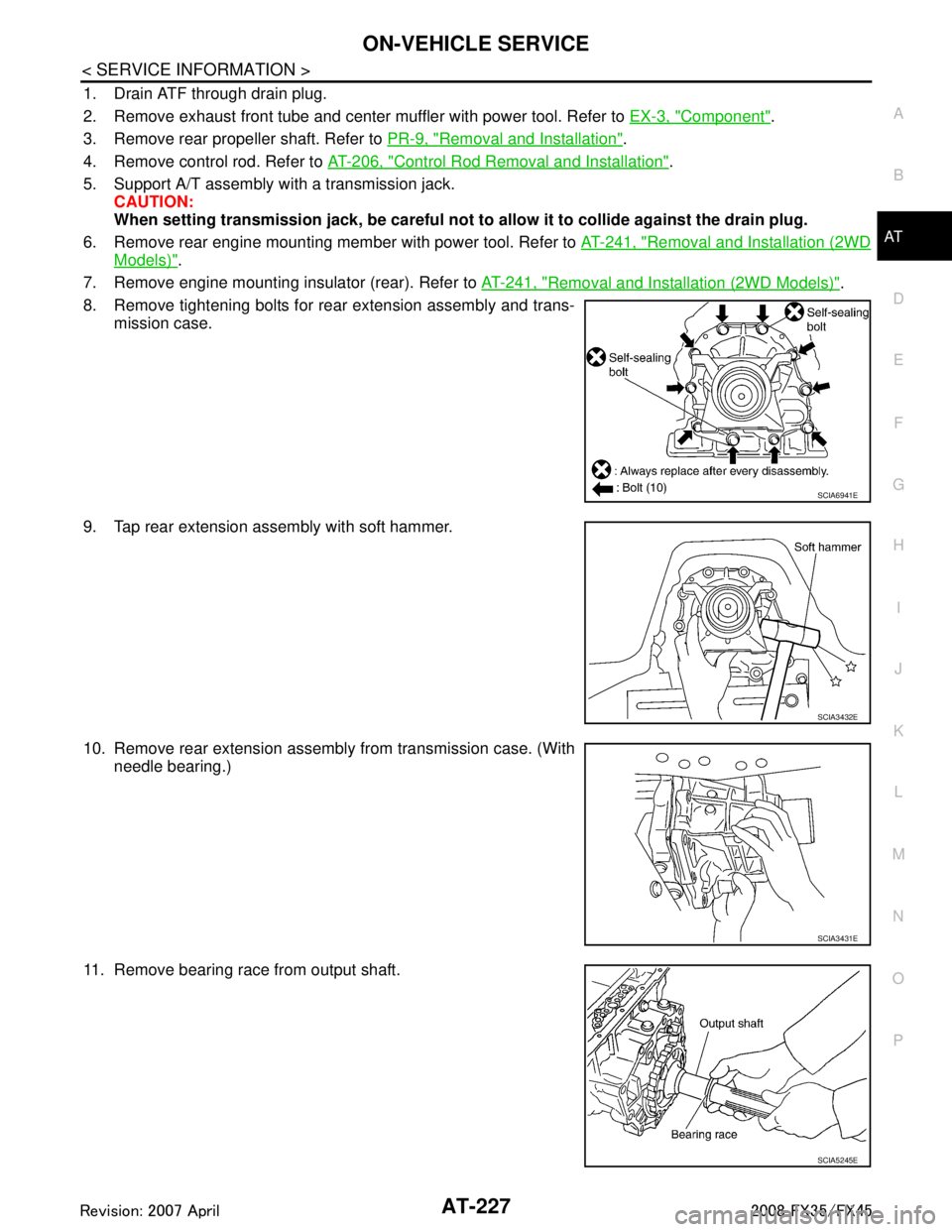

1. Drain ATF through drain plug.

2. Remove exhaust front tube and center muffler with power tool. Refer to EX-3, "

Component".

3. Remove rear propeller shaft. Refer to PR-9, "

Removal and Installation".

4. Remove control rod. Refer to AT-206, "

Control Rod Removal and Installation".

5. Support A/T assembly with a transmission jack. CAUTION:

When setting transmission jack, be careful not to allow it to collide against the drain plug.

6. Remove rear engine mounting member with power tool. Refer to AT-241, "

Removal and Installation (2WD

Models)".

7. Remove engine mounting insulator (rear). Refer to AT-241, "

Removal and Installation (2WD Models)".

8. Remove tightening bolts for rear extension assembly and trans- mission case.

9. Tap rear extension assembly with soft hammer.

10. Remove rear extension assembly from transmission case. (With needle bearing.)

11. Remove bearing race from output shaft.

SCIA6941E

SCIA3432E

SCIA3431E

SCIA5245E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 305 of 3924

AT-232

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

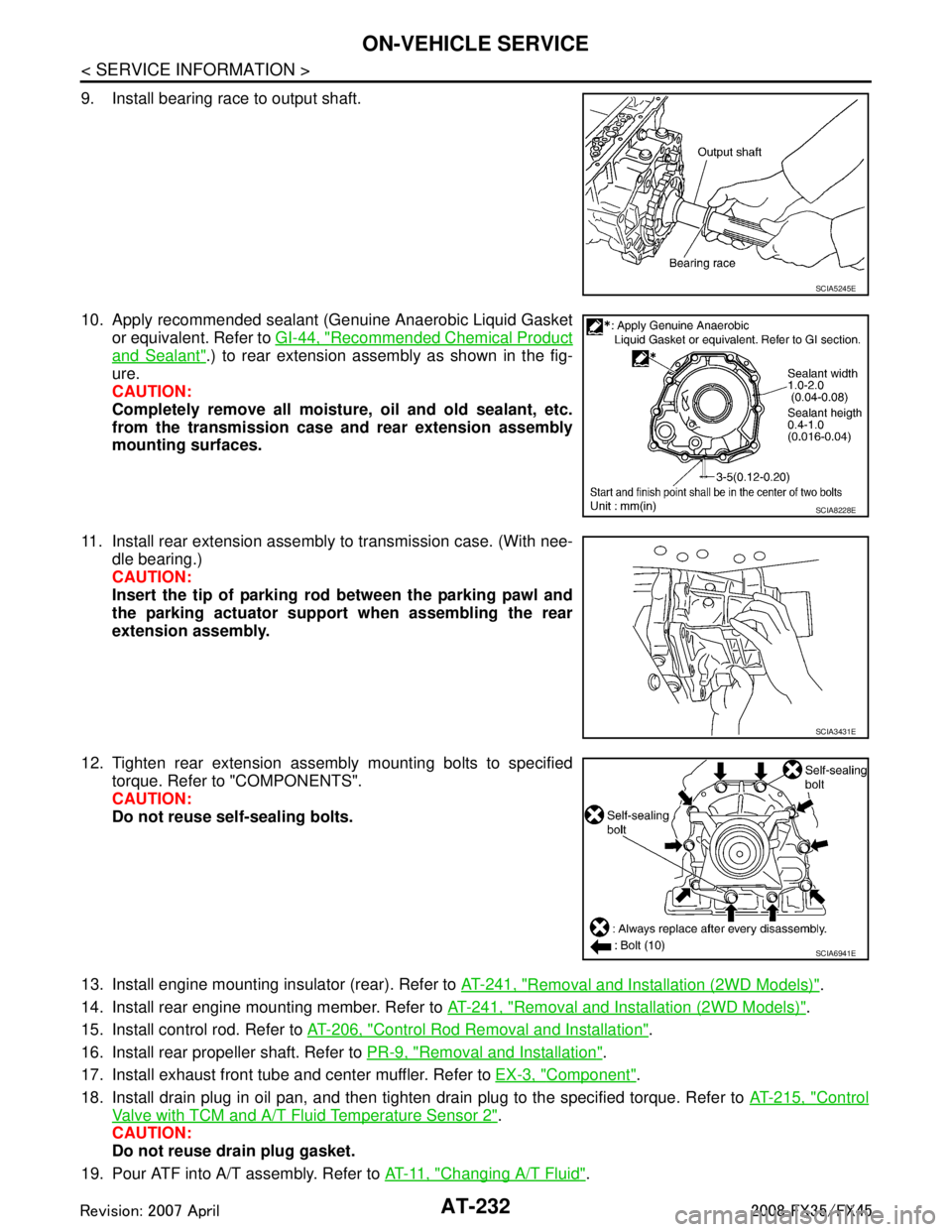

9. Install bearing race to output shaft.

10. Apply recommended sealant (Genuine Anaerobic Liquid Gasketor equivalent. Refer to GI-44, "

Recommended Chemical Product

and Sealant".) to rear extension assembly as shown in the fig-

ure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transmission case and rear extension assembly

mounting surfaces.

11. Install rear extension assembly to transmission case. (With nee- dle bearing.)

CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator support when assembling the rear

extension assembly.

12. Tighten rear extension assembly mounting bolts to specified torque. Refer to "COMPONENTS".

CAUTION:

Do not reuse self-sealing bolts.

13. Install engine mounting insulator (rear). Refer to AT-241, "

Removal and Installation (2WD Models)".

14. Install rear engine mounting member. Refer to AT-241, "

Removal and Installation (2WD Models)".

15. Install control rod. Refer to AT-206, "

Control Rod Removal and Installation".

16. Install rear propeller shaft. Refer to PR-9, "

Removal and Installation".

17. Install exhaust front tube and center muffler. Refer to EX-3, "

Component".

18. Install drain plug in oil pan, and then tighten drain plug to the specified torque. Refer to AT-215, "

Control

Valve with TCM and A/T Fluid Temperature Sensor 2".

CAUTION:

Do not reuse drain plug gasket.

19. Pour ATF into A/T assembly. Refer to AT- 11 , "

Changing A/T Fluid".

SCIA5245E

SCIA8228E

SCIA3431E

SCIA6941E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 307 of 3924

AT-234

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

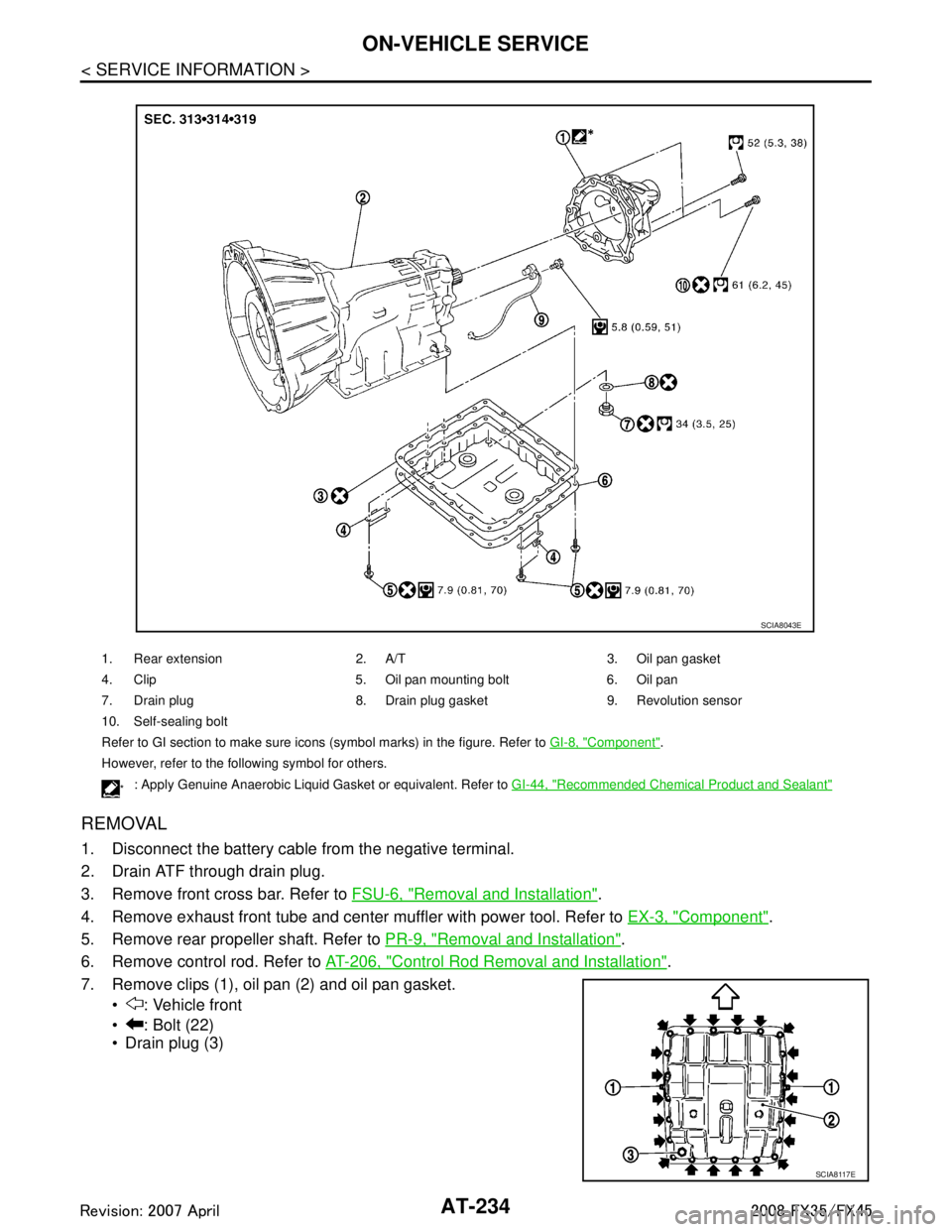

REMOVAL

1. Disconnect the battery cable from the negative terminal.

2. Drain ATF through drain plug.

3. Remove front cross bar. Refer to FSU-6, "

Removal and Installation".

4. Remove exhaust front tube and center muffler with power tool. Refer to EX-3, "

Component".

5. Remove rear propeller shaft. Refer to PR-9, "

Removal and Installation".

6. Remove control rod. Refer to AT-206, "

Control Rod Removal and Installation".

7. Remove clips (1), oil pan (2) and oil pan gasket. : Vehicle front

: Bolt (22)

Drain plug (3)

1. Rear extension 2. A/T 3. Oil pan gasket

4. Clip 5. Oil pan mounting bolt 6. Oil pan

7. Drain plug 8. Drain plug gasket 9. Revolution sensor

10. Self-sealing bolt

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

However, refer to the following symbol for others.

*: Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-44, "Recommended Chemical Product and Sealant"

SCIA8043E

SCIA8117E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C