no start INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 41 of 3924

![INFINITI FX35 2008 User Guide

ACS-34

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS —

GENERAL DESCRIPTION

8. DTC 55 will be shown.

9. Turn ignition switch OFF to exit the diagnosis.

10. Perform ICC system running test (drive v INFINITI FX35 2008 User Guide

ACS-34

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS —

GENERAL DESCRIPTION

8. DTC 55 will be shown.

9. Turn ignition switch OFF to exit the diagnosis.

10. Perform ICC system running test (drive v](/img/42/57017/w960_57017-40.png)

ACS-34

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS —

GENERAL DESCRIPTION

8. DTC 55 will be shown.

9. Turn ignition switch OFF to exit the diagnosis.

10. Perform ICC system running test (drive vehicle wit h ICC system ON), and make sure that ICC warning

lamp (Orange) does not illuminate.

Self-Diagnostic Erasing Method

1. Stop the vehicle and turn the ignition switch OFF.

2. Turn ignition switch ON and start self-diagnosis.

3. During self-diagnosis mode, press CANCEL switch 5 times, and DISTANCE switch 5 times in this order. NOTE:

Press them within 10 seconds after pressing CANCEL switch at first.

When operation is not completed within 10 seconds, start again from step 2 above.

4. DTC 55 will be shown. NOTE:

DTC of an existing malfunction will not be erased.

5. Turn ignition switch OFF to exit the diagnosis.

6. Perform ICC system running test (drive vehicle wit h ICC system ON), and make sure that ICC system

warning lamp (Orange) does not illuminate.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 59 of 3924

![INFINITI FX35 2008 User Guide

ACS-52

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

NG >> 1. Repair harness between ICC unit and A/T assembly.

2. Erase DTC and perform ICC system running test. Then per INFINITI FX35 2008 User Guide

ACS-52

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

NG >> 1. Repair harness between ICC unit and A/T assembly.

2. Erase DTC and perform ICC system running test. Then per](/img/42/57017/w960_57017-58.png)

ACS-52

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

NG >> 1. Repair harness between ICC unit and A/T assembly.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

4.CHECK TCM START SIGNAL CIRCUIT

Check TCM start signal. Refer to AT-99, "

Diagnosis Procedure".

OK or NG

OK >> 1. Replace ICC unit. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Repair or replace damaged parts. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

5.CHECK SHIFT POSITION SIGNAL

With TCM diagnosis, check that shift operates normally. Refer to AT-103, "

Diagnosis Procedure".

OK or NG

OK >> 1. Replace ICC unit. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Perform TCM self-diagnosis. 2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

DTC 97 AT CIRCUITINFOID:0000000001328841

1.CHECK AT CIRCUIT

With TCM diagnosis, check that shift operates normally. Refer to AT-103, "

Diagnosis Procedure".

OK or NG

OK >> 1. Replace ICC unit. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Perform TCM self-diagnosis. 2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

DTC 98 GEAR POSITIONINFOID:0000000001328842

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Perform self-diagnosis of ICC system.

2. Check if “DTC 43 ABS/TCS/VDC CIRC” or “DTC 41 VHCL SPEED SE CIRC” other than “DTC 98 GEAR

POSITION” is indicated in self-diagnosis item in the display.

Is any indicated?

YES >> 1. Repair or replace applicable item. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 2.

2.CHECK VEHICLE SPEED SIGNAL

With “Data Monitor” of “ICC”, check that “VHCL SPEED SE” is normal.

OK or NG

OK >> GO TO 3.

NG >> 1. Replace ICC unit. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

3.CHECK SHIFT GEAR POSITION

Check that gear positions are correct in A/T.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 66 of 3924

![INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS FOR SYMPTOMSACS-59

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

After adjusting ICC sensor beam aiming, perform ICC system running test. Check that preceding veh INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS FOR SYMPTOMSACS-59

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

After adjusting ICC sensor beam aiming, perform ICC system running test. Check that preceding veh](/img/42/57017/w960_57017-65.png)

TROUBLE DIAGNOSIS FOR SYMPTOMSACS-59

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

After adjusting ICC sensor beam aiming, perform ICC system running test. Check that preceding vehicle

detection performance has been improved.

OK or NG

OK >> INSPECTION END

NG >> 1. Replace ICC sensor, and perform laser beam aiming adjustment. 2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

Symptom 8 the System Does Not De tect the Vehicle Ahead at AllINFOID:0000000001328856

1.VISUAL CHECK 1

With ignition switch turned ON (engine not started), che ck that all indicator lamps in ICC system display are

continuously lit. (Check for a missing segm ent in preceding vehicle detection display.)

OK or NG

OK >> GO TO 2.

NG >> Check for combination meter. Refer to DI-15, "

Trouble Diagnosis".

2. VISUAL CHECK 2

Check ICC sensor body window for c ontamination and foreign materials.

OK or NG

OK >> If any contamination or foreign materials are found, remove them. Perform ICC system running

test.

NG >> GO TO 3.

3.VISUAL CHECK 3

Check ICC sensor body window for cracks and scratches.

OK or NG

OK >> GO TO 4.

NG >> 1. Replace ICC sensor, and perform laser beam aiming adjustment. 2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

4.ADJUST ICC SENSOR

After adjusting ICC sensor beam aiming, perform ICC system running test. Check that preceding vehicle

detection performance has been improved.

OK or NG

OK >> INSPECTION END

NG >> 1. Replace ICC sensor, and perform laser beam aiming adjustment.

2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

SELF-DIAGNOSIS BY ICC SYST EM DISPLAY WILL NOT RUNINFOID:0000000001544638

PKIB4144E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 74 of 3924

AT-1

TRANSMISSION/TRANSAXLE

DE

F

G H

I

J

K L

M

SECTION AT

A

B

AT

N

O P

CONTENTS

AUTOMATIC TRANSMISSION

SERVICE INFORMATION .. ..........................5

INDEX FOR DTC ............................................ .....5

Alphabetical Index ............................................... ......5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

7

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine .....................................................

7

Precaution .................................................................7

Service Notice or Precaution .....................................8

PREPARATION ...................................................9

Special Service Tool ........................................... ......9

Commercial Service Tool ..........................................9

A/T FLUID ...........................................................11

Changing A/T Fluid ............................................. ....11

Checking A/T Fluid ..................................................11

A/T Fluid Cooler Cleaning .......................................13

A/T CONTROL SYSTEM ....................................16

Cross-Sectional View (2WD Models) .................. ....16

Cross-Sectional View (VQ35DE Models for AWD) ....17

Cross-Sectional View (VK45DE Models for AWD) ....18

Shift Mechanism .................................................. ....18

TCM Function ..........................................................29

CAN Communication ...............................................30

Input/Output Signal of TCM .....................................31

Line Pressure Control .............................................31

Shift Control ............................................................33

Lock-up Control .......................................................34

Engine Brake Control ..............................................35

Control Valve ...........................................................36

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......38

Introduction ......................................................... ....38

OBD-II Function for A/T System ..............................38

One or Two Trip Detection Logic of OBD-II ............38

OBD-II Diagnostic Trouble Code (DTC) .............. ....38

Malfunction Indicator Lamp (MIL) ............................40

TROUBLE DIAGNOSIS ....................................41

DTC Inspection Priority Chart ..................................41

Fail-Safe ..................................................................41

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

42

A/T Electrical Parts Location ...................................48

Circuit Diagram ........................................................49

Inspections Before Trouble Diagnosis .....................49

Road Test ................................................................53

Vehicle Speed at Which Gear Shifting Occurs ........58

Vehicle Speed at Which Lock-up Occurs/Releas-

es .............................................................................

58

Symptom Chart ........................................................59

TCM Input/Output Signal Reference Value .............83

CONSULT-III Function (TRANSMISSION) ..............84

Diagnosis Procedure without CONSULT-III ............91

DTC U1000 CAN COMMUNICATION LINE .....94

Description ........................................................... ....94

On Board Diagnosis Logic .......................................94

Possible Cause ........................................................94

DTC Confirmation Procedure ..................................94

Wiring Diagram - AT - CAN .....................................95

Diagnosis Procedure ...............................................96

DTC P0615 START SIGNAL CIRCUIT .............97

Description ...............................................................97

CONSULT-III Reference Value in Data Monitor

Mode ........................................................................

97

On Board Diagnosis Logic .......................................97

Possible Cause ........................................................97

DTC Confirmation Procedure ..................................97

Wiring Diagram - AT - STSIG ..................................98

Diagnosis Procedure ...............................................99

DTC P0700 TCM .............................................101

Description .............................................................101

On Board Diagnosis Logic .....................................101

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 77 of 3924

AT-4

BRAKE SIGNAL CIRCUIT ..............................165

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

165

Diagnosis Procedure .............................................165

A/T INDICATOR CIRCUIT ...............................166

Description ........................................................... ..166

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

166

Diagnosis Procedure .............................................166

TROUBLE DIAGNOSIS FOR SYMPTOMS .....167

Wiring Diagram - AT - NONDTC .......................... ..167

A/T Check Indicator Lamp Does Not Come On .....170

Engine Cannot Be Started in "P" or "N" Position ...170

In "P" Position, Vehicle Moves When Pushed .......171

In "N" Position, Vehicle Moves ..............................172

Large Shock ("N" to "D" Position) ..........................173

Vehicle Does Not Creep Backward in "R" Position ..175

Vehicle Does Not Creep Forward in "D" Position ..178

Vehicle Cannot Be Started from D1 .......................180

A/T Does Not Shift: D1→ D2 ................................ ..182

A/T Does Not Shift: D2→ D3 ................................ ..184

A/T Does Not Shift: D3→ D4 ................................ ..186

A/T Does Not Shift: D4→ D5 ................................ ..188

A/T Does Not Lock-up ......................................... ..190

A/T Does Not Hold Lock-up Condition ...................192

Lock-up Is Not Released .......................................194

Engine Speed Does Not Return to Idle .................194

Cannot Be Changed to Manual Mode ...................195

A/T Does Not Shift: 5th Gear → 4th Gear ........... ..196

A/T Does Not Shift: 4th Gear → 3rd Gear ........... ..197

A/T Does Not Shift: 3rd Gear → 2nd Gear .......... ..199

A/T Does Not Shift: 2nd Gear → 1st Gear ........... ..201

Vehicle Does Not Decelerate by Engine Brake ... ..202

SHIFT CONTROL SYSTEM ............................205

Control Device Removal and Installation ............. ..205

Control Rod Removal and Installation ...................206

Adjustment of A/T Position ....................................207

Checking of A/T Position .......................................207

A/T SHIFT LOCK SYSTEM .............................208

Description ........................................................... ..208

Shift Lock System Electrical Parts Location ..........208

Wiring Diagram - AT - SHIFT .................................209

Diagnosis Procedure .............................................209

KEY INTERLOCK CABLE ...............................212

Component .......................................................... ..212

Removal and Installation .......................................212

ON-VEHICLE SERVICE ...................................215

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ....................................................... .

215

Parking Component (2WD Models Only) ..............226

Rear Oil Seal .........................................................233

Revolution Sensor Component (2WD Models

Only) .....................................................................

233

AIR BREATHER HOSE ....................................239

Removal and Installation ...................................... .239

TRANSMISSION ASSEMBLY ..........................241

Removal and Installation (2WD Models) .............. .241

Removal and Installation (AWD Models) ..............243

OVERHAUL ......................................................249

Component .......................................................... .249

Oil Channel ...........................................................261

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ......................... .

264

DISASSEMBLY .............................................. ..267

Disassembly ......................................................... .267

REPAIR FOR COMPONENT PARTS ..............285

Oil Pump .............................................................. .285

Front Sun Gear, 3rd One-Way Clutch ...................287

Front Carrier, Input Clutch, Rear Internal Gear .....289

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ..................................................

295

High and Low Reverse Clutch ..............................301

Direct Clutch .........................................................303

ASSEMBLY .................................................... ..306

Assembly (1) ........................................................ .306

Adjustment ............................................................320

Assembly (2) .........................................................323

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

330

General Specification ........................................... .330

Vehicle Speed at Which Gear Shifting Occurs .....330

Vehicle Speed at Which Lock-up Occurs/Releas-

es ..........................................................................

331

Stall Speed ............................................................331

Line Pressure ........................................................331

A/T Fluid Temperature Sensor ..............................332

Turbine Revolution Sensor ...................................332

Vehicle Speed Sensor A/T (Revolution Sensor) ...332

Reverse Brake ......................................................332

Total End Play .......................................................332

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 78 of 3924

INDEX FOR DTCAT-5

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

SERVICE INFORMATION

INDEX FOR DTC

Alphabetical IndexINFOID:0000000001327120

NOTE:

If “DTC U1000” is displayed with other DTCs, fi rst perform the trouble diagnosis for “DTC U1000 CAN

COMMUNICATION”. Refer to AT- 9 4

.

*1: These numbers are prescribed by SAE J2012.

*2: These malfunctions cannot be displayed MIL if another malfunction is assigned to MIL.

DTC No. IndexINFOID:0000000001327121

NOTE:

If “DTC U1000” is displayed with other DTCs, fi rst perform the trouble diagnosis for “DTC U1000 CAN

COMMUNICATION”. Refer to AT- 9 4

.

Items

(CONSULT-III screen terms) DTC

Reference page

OBD-II Except OBD-II

CONSULT-III GST

(*1) CONSULT-III only “TRANS- MISSION”

A/T 1ST E/BRAKING — P1731 AT- 1 4 1

ATF 1ST GR FNCTN P0731 P0731 AT- 11 4

ATF 2ND GR FNCTN P0732 P0732AT- 11 6

ATF 3RD GR FNCTN P0733 P0733AT- 11 8

ATF 4TH GR FNCTN P0734 P0734AT- 1 2 0

ATF 5TH GR FNCTN P0735 P0735AT- 1 2 2

A/T INTERLOCK P1730 P1730AT- 1 3 9

A/T TCC S/V FNCTN

P0744(*2)P0744AT- 1 2 6

ATF TEMP SEN/CIRC P0710 P1710 AT- 1 3 2

CAN COMM CIRCUIT U1000 U1000 AT- 9 4

D/C SOLENOID/CIRC P1762 P1762AT- 1 4 7

ENGINE SPEED SIG P0725 P0725 AT- 11 2

FR/B SOLENOID/CIRC P1757 P1757AT- 1 4 5

HLR/C SOL/CIRC P1767 P1767AT- 1 4 9

I/C SOLENOID/CIRC P1752 P1752AT- 1 4 3

L/PRESS SOL/CIRC P0745 P0745AT- 1 2 8

LC/B SOLENOID/CIRC P1772 P1772AT- 1 5 1

LC/B SOLENOID FNCT

P1774(*2)P1774AT- 1 5 3

MANU MODE SW/CIRC — P1815 AT- 1 5 5

PNP SW/CIRC P0705 P0705AT- 1 0 2

STARTER RELAY/CIRC — P0615 AT- 9 7

TCC SOLENOID/CIRC P0740 P0740AT- 1 2 4

TCM P0700 P0700AT- 1 0 1

TP SEN/CIRC A/T P1705 P1705AT- 1 3 0

TURBINE REV S/CIRC P0717 P0717AT- 1 0 6

VEH SPD SE/CIR-MTR — P1721AT- 1 3 7

VEH SPD SEN/CIR AT P0720 P0720AT- 1 0 8

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 79 of 3924

AT-6

< SERVICE INFORMATION >

INDEX FOR DTC

*1: These numbers are prescribed by SAE J2012.

*2: These malfunctions cannot be displayed MIL if another malfunction is assigned to MIL.DTC

Items

(CONSULT-III screen terms) Reference page

OBD-II Except OBD-II

CONSULT-III GST

(*1)

C O N S U LT- I I I

only “TRANSMIS- SION”

— P0615 STARTER RELAY/CIRC AT- 9 7

P0700 P0700 TCM AT- 1 0 1

P0705 P0705 PNP SW/CIRCAT- 1 0 2

P0710 P1710 ATF TEMP SEN/CIRCAT- 1 3 2

P0717 P0717 TURBINE REV S/CIRCAT- 1 0 6

P0720 P0720 VEH SPD SEN/CIR ATAT- 1 0 8

P0725 P0725 ENGINE SPEED SIG AT- 11 2

P0731 P0731 A/T 1ST GR FNCTNAT- 11 4

P0732 P0732 A/T 2ND GR FNCTNAT- 11 6

P0733 P0733 A/T 3RD GR FNCTNAT- 11 8

P0734 P0734 A/T 4TH GR FNCTNAT- 1 2 0

P0735 P0735 A/T 5TH GR FNCTNAT- 1 2 2

P0740 P0740 TCC SOLENOID/CIRCAT- 1 2 4

P0744(*2)P0744 A/T TCC S/V FNCTNAT- 1 2 6

P0745 P0745 L/PRESS SOL/CIRC AT- 1 2 8

P1705 P1705 TP SEN/CIRC A/TAT- 1 3 0

— P1721 VEH SPD SE/CIR-MTRAT- 1 3 7

P1730 P1730 A/T INTERLOCK AT- 1 3 9

— P1731 A/T 1ST E/BRAKINGAT- 1 4 1

P1752 P1752 I/C SOLENOID/CIRC AT- 1 4 3

P1757 P1757 FR/B SOLENOID/CIRCAT- 1 4 5

P1762 P1762 D/C SOLENOID/CIRCAT- 1 4 7

P1767 P1767 HLR/C SOL/CIRCAT- 1 4 9

P1772 P1772 LC/B SOLENOID/CIRCAT- 1 5 1

P1774(*2)P1774 LC/B SOLENOID FNCTAT- 1 5 3

— P1815 MANU MODE SW/CIRC AT- 1 5 5

U1000 U1000 CAN COMM CIRCUIT AT- 9 4

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 84 of 3924

A/T FLUIDAT-11

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

A/T FLUID

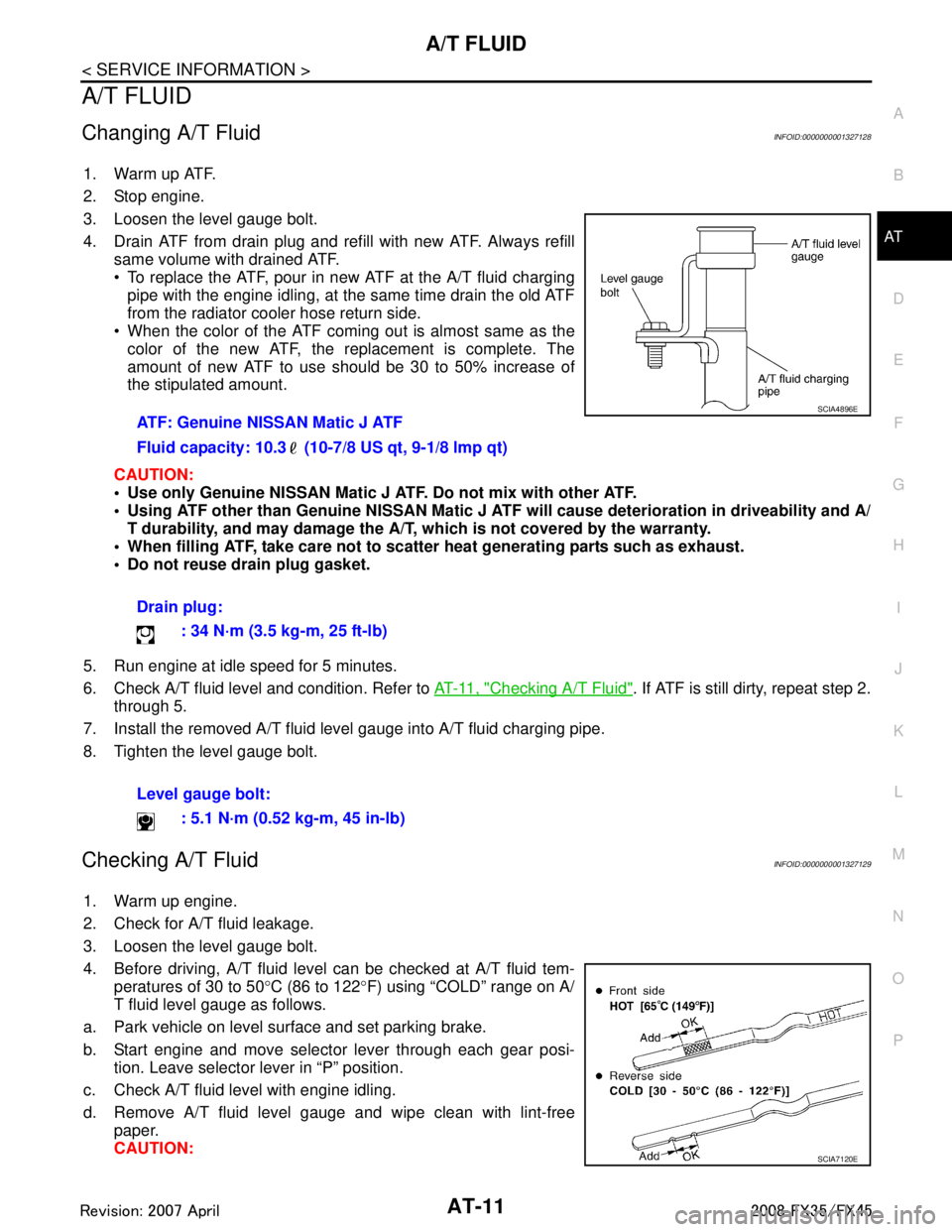

Changing A/T FluidINFOID:0000000001327128

1. Warm up ATF.

2. Stop engine.

3. Loosen the level gauge bolt.

4. Drain ATF from drain plug and refill with new ATF. Always refill same volume with drained ATF.

To replace the ATF, pour in new ATF at the A/T fluid chargingpipe with the engine idling, at the same time drain the old ATF

from the radiator cooler hose return side.

When the color of the ATF coming out is almost same as the

color of the new ATF, the replacement is complete. The

amount of new ATF to use should be 30 to 50% increase of

the stipulated amount.

CAUTION:

Use only Genuine NISSAN Matic J ATF. Do not mix with other ATF.

Using ATF other than Genuine NISSAN Matic J AT F will cause deterioration in driveability and A/

T durability, and may damage the A/T, which is not covered by the warranty.

When filling ATF, take care not to scatter heat generating parts such as exhaust.

Do not reuse drain plug gasket.

5. Run engine at idle speed for 5 minutes.

6. Check A/T fluid level and condition. Refer to AT- 11 , "

Checking A/T Fluid". If ATF is still dirty, repeat step 2.

through 5.

7. Install the removed A/T fluid level gauge into A/T fluid charging pipe.

8. Tighten the level gauge bolt.

Checking A/T FluidINFOID:0000000001327129

1. Warm up engine.

2. Check for A/T fluid leakage.

3. Loosen the level gauge bolt.

4. Before driving, A/T fluid level can be checked at A/T fluid tem- peratures of 30 to 50 °C (86 to 122 °F) using “COLD” range on A/

T fluid level gauge as follows.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi- tion. Leave selector lever in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free paper.

CAUTION:ATF: Genuine NISSAN Matic J ATF

Fluid capacity: 10.3 (10-7/8 US qt, 9-1/8 lmp qt)

Drain plug:

: 34 N·m (3.5 kg-m, 25 ft-lb)

Level gauge bolt: : 5.1 N·m (0.52 kg-m, 45 in-lb)

SCIA4896E

SCIA7120E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 91 of 3924

AT-18

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

Cross-Sectional View (V K45DE Models for AWD)

INFOID:0000000001327133

Shift MechanismINFOID:0000000001327134

The A/T uses compact triple planetary gear systems to improve power transmission efficiency, simplify con-

struction and reduce weight.

It also employs an optimum shift control and super wide gear ratios. They improve starting performance and

acceleration during medium and high-speed operation.

CONSTRUCTION

1. Front planetary gear 2. Mid planetary gear 3. Rear planetary gear

4. Direct clutch 5. High and low reverse clutch 6. Reverse brake

7. Drum support 8. Forward brake 9. Low coast brake

10. Input shaft 11. Torque converter 12. Oil pump

13. Front brake 14. 3rd one-way clutch 15. Input clutch

16. 1st one-way clutch 17. Control valve with TCM 18. Forward one-way clutch

19. Adapter case 20. Output shaft

SCIA5268E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 102 of 3924

A/T CONTROL SYSTEMAT-29

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

TCM FunctionINFOID:0000000001327135

The function of the TCM is to:

Receive input signals sent from various switches and sensors.

Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

Send required output signals to the respective solenoids.

CONTROL SYSTEM OUTLINE

The automatic transmission senses vehicle operating condi tions through various sensors or signals. It always

controls the optimum shift position and reduces shifting and lock-up shocks.

1. Front brake 2. Input clutch 3. Direct clutch

4. High and low reverse clutch 5. Reverse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. Front carrier

19. Mid carrier 20. Rear internal gear 21. Output shaft

22. Parking gear 23. Parking pawl

SCIA1519E

SENSORS (or SIGNALS)

⇒TCM

⇒ACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed signal

Manual mode switch signal

Stop lamp switch signal

Turbine revolution sensor

ATF pressure switch Shift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-III co

mmunication

line

Duet-EA control

CAN system Input clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch sole-

noid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Starter relay

Back-up lamp relay

: