trunk INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3521 of 3924

RF-6

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000001328031

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas).Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the Nissan Squeak and Rattle Kit (J43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3647 of 3924

SE-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000001328095

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the Nissan Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3735 of 3924

SE-96

< SERVICE INFORMATION >

REAR SEAT

REMOVAL

1. Pull the lock at the front bottom of the seat cushion forward (1

for each side), and pull the seat cushion upward to release the

wire from the plastic hook, then pull the seat cushion forward to

remove.

2. Remove the seatback mounting nuts.

3. Remove the seatback mounting bolt and nut. Remove the remote control wire.

INSTALLATION

Install in the reverse order of removal.

NOTE:

After rear wheel house finisher assembly is remove the seatback is installed. Refer to EI-45, "

Component

Parts Location".

REMOVAL OF SEAT CUSHION TRIM AND PAD

13. Bolt 14. Seatback garnish (RH) 15. Trunk net hook

16. Clip (C101) 17. Headrest (center) 18. Seatback trim (LH)

19. Seatback pad (LH) 20. Seatback frame (LH) 21. Seatback garnish (LH)

22. Armrest bracket cover 23. Armrest bracket 24. Armrest

25. Reclining device inner cover (LH) 26. Reclining device outer cover (LH) 27. Reclining lever (LH)

28. Seat hinge cover (LH) 29. Seat cushion trim 30. Seat cushion pad

31. Cup holder bracket 32. Cup holder

PIIA6034E

PIIA6035E

PIIA6036E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3736 of 3924

REAR SEATSE-97

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

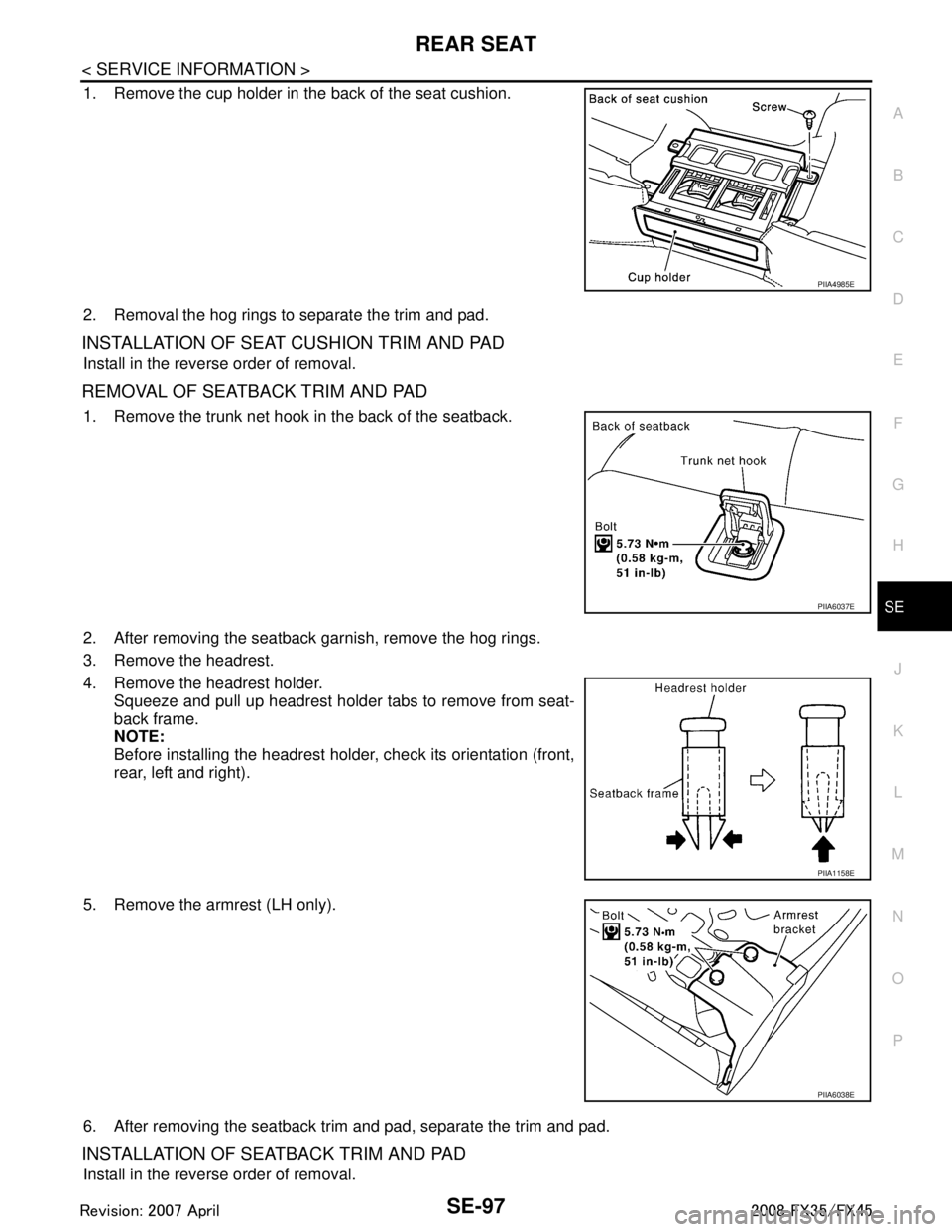

1. Remove the cup holder in the back of the seat cushion.

2. Removal the hog rings to separate the trim and pad.

INSTALLATION OF SEAT CUSHION TRIM AND PAD

Install in the reverse order of removal.

R E M O VA L O F S E AT B A C K T R I M A N D PA D

1. Remove the trunk net hook in the back of the seatback.

2. After removing the seatback garnish, remove the hog rings.

3. Remove the headrest.

4. Remove the headrest holder. Squeeze and pull up headrest holder tabs to remove from seat-

back frame.

NOTE:

Before installing the headrest holder, check its orientation (front,

rear, left and right).

5. Remove the armrest (LH only).

6. After removing the seatback trim and pad, separate the trim and pad.

INSTALLATION OF SEATBACK TRIM AND PAD

Install in the reverse order of removal.

PIIA4985E

PIIA6037E

PIIA1158E

PIIA6038E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C