u1000 INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 479 of 3924

ATC-74

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

OK or NG

OK >> GO TO 12.

NG-1 >> If the voltage is approx. 5 V when blower motor is ON: Replace unified meter and A/C amp.

NG-2 >> If the voltage is approx. 0 V when blower motor is OFF: Replace BCM.

12.CHECK CAN COMMUNICATION

Check CAN communication. Refer to BCS-13, "

U1000 CAN Communication Circuit".

BCM – ECM

ECM – IPDM E/R

ECM – Unified meter and A/C amp.

OK or NG

OK >> Replace ECM

NG >> Repair or replace malfunctioning part(s).

COMPONENT INSPECTION

Refrigerant Pressure Sensor

The refrigerant pressure sensor is attached to the condenser.

Make sure that the A/C refrigerant pressure and the sensor output

voltage are within the specified r ange as shown in the A/C operating

condition figure. Refer to EC-581

(VQ35DE) or EC-1177 (VK45DE).

Te r m i n a l s

Condition Voltage

(+)

(− )

Unified meter

and A/C amp.

connector Te r m i n a l N o .

M57 57 Ground A/C switch: ON

(Blower motor operates.)

Approx. 0 V

OFF switch: ON

(A/C system: OFF)

SJIA1474J

RJIA2011E

RJIA2954E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 721 of 3924

BCS-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION BCS

A

B

BCS

N

O P

CONTENTS

BODY CONTROL SYSTEM

SERVICE INFORMATION .. ..........................2

DTC INDEX ..................................................... .....2

U1000 .................................................................. ......2

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

BCM (BODY CONTROL MODULE) ..................4

System Description .............................................. .....4

CAN Communication Unit .........................................9

Schematic ................................................................10

CONSULT-III Function (BCM) .................................11

U1000 CAN Communication Circuit ........................13

Removal and Installation of BCM ............................13

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 722 of 3924

BCS-2

< SERVICE INFORMATION >

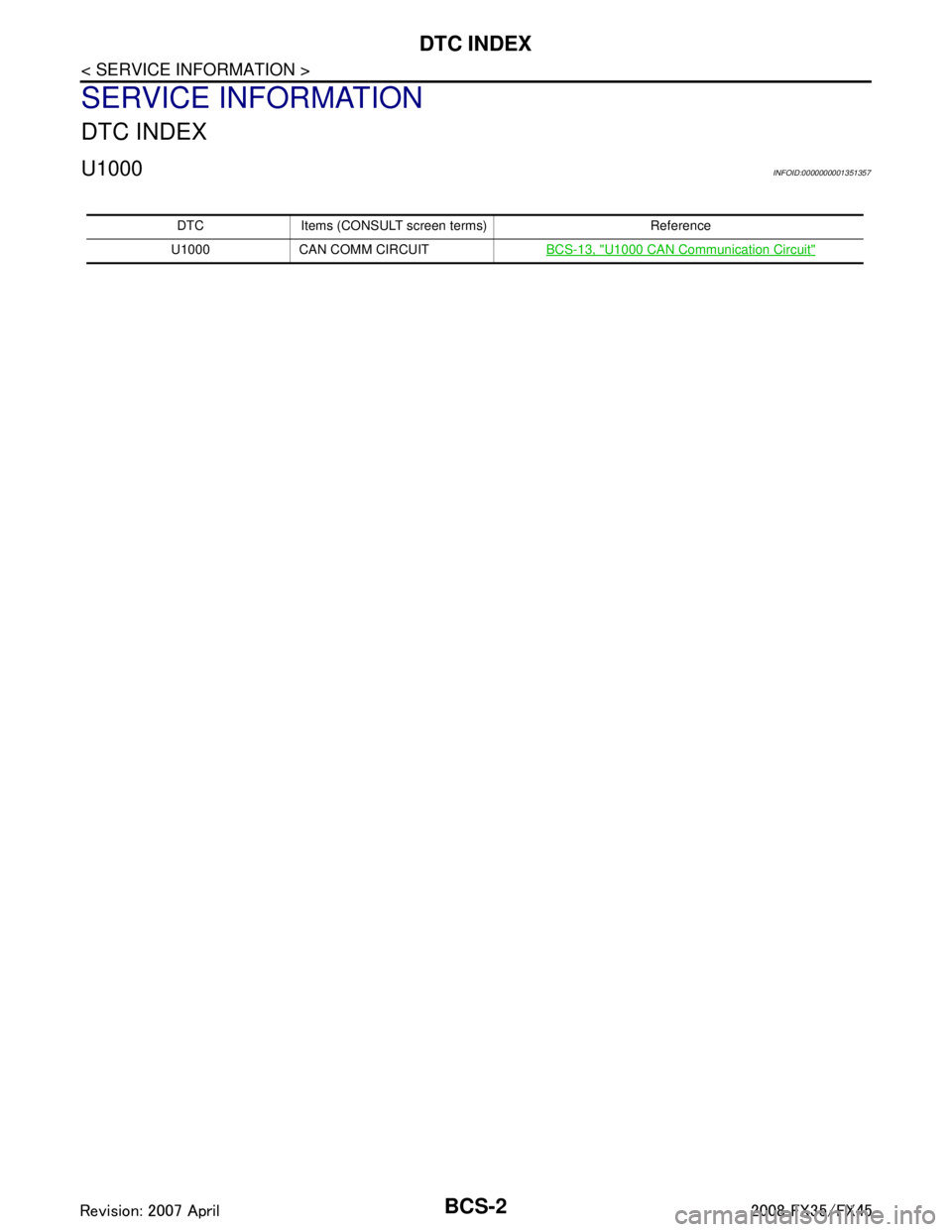

DTC INDEX

SERVICE INFORMATION

DTC INDEX

U1000INFOID:0000000001351357

DTC Items (CONSULT screen terms) Reference

U1000 CAN COMM CIRCUIT BCS-13, "

U1000 CAN Communication Circuit"

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 733 of 3924

BCM (BODY CONTROL MODULE)BCS-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

SELF-DIAG RESULTS

U1000 CAN Communication CircuitINFOID:0000000001606767

1.PERFORM SELF DIAGNOSTIC

1. Turn ignition switch ON and wait for 2 seconds or more.

2. Check “Self Diagnostic Result” of BCM.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Refer to LAN-14, "Trouble Diagnosis Flow Chart".

NO >> Refer to GI-25, "

How to Perform Efficient Diagnosis for an Electrical Incident".

Removal and Installation of BCMINFOID:0000000001328613

REMOVAL

1. Remove the dash side finisher (LH). Refer to EI-38.

2. Disconnect BCM connector.

3. Remove bracket mounting screws (3) to remove BCM and fuse block with bracket.

Item Description

RESET SETTING VALUE Return a value set with WORK SUPPORT of each system to a default value in factory shipment.

DTC DTC Detection Condition Possible cause

U1000: CAN COMM CIRCUIT When BCM cannot communicate CAN com-

munication signal continuously for 2 sec-

onds or more. Any item (or items) of the following listed below is

malfunctioning in CAN communication system.

Transmission

Receiving (ECM)

Receiving (IPDM E/R)

Receiving (METER/M&A)

Receiving (I-KEY)

SKIA4964E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 735 of 3924

BL-1

BODY

C

DE

F

G H

J

K L

M

SECTION BL

A

B

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

DTC INDEX ..................................................... .....4

INTELLGENT KEY UNIT U1000 ...............................4

INTELLGENT KEY UNIT B2013-B2014 ............. ......4

ECM P1610-P1615 ...................................................4

PRECAUTIONS ...................................................5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

5

Precaution for Work ..................................................5

PREPARATION ...................................................6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................6

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS .......................................................................

7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ............9

Diagnostic Worksheet .............................................11

HOOD .................................................................13

Fitting Adjustment ............................................... ....13

Removal and Installation of Hood Assembly ...........14

Removal and Installation of Hood Lock Control ......15

Hood Lock Control Inspection ............................. ....16

RADIATOR CORE SUPPORT ...........................18

Removal and Installation ..................................... ....18

FRONT FENDER ................................................20

Removal and Installation ..................................... ....20

POWER DOOR LOCK SYSTEM ........................21

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

21

System Description .................................................22

CAN Communication System Description ...............23

CAN Communication Unit .................................... ....23

Schematic/With Intelligent Key ................................24

Wiring Diagram - D/LOCK -/With Intelligent Key .....25

Schematic/Without Intellig ent Key ...........................30

Wiring Diagram - D/LOCK -/Without Intelligent

Key ...................................................................... ....

31

Terminal and Reference Value for BCM ..................35

Terminal and Reference Value for Intelligent Key

Unit (With Intelligent Key System) ...........................

35

Work Flow ................................................................36

CONSULT-III Function (BCM) .................................36

Trouble Diagnosis Chart by Symptom .....................37

Check BCM Power Supply and Ground Circuit .......37

Check Door Switch ..................................................38

Check Key Switch ....................................................42

Check Door Lock and Unlock Switch ......................43

Check Door Lock Actuator (Driver Side) .................45

Check Door Lock Actuator (Passenger Side and

Rear LH/RH) ............................................................

45

Check Fuel Lid Lock Actuator ..................................46

Check Front Door Key Cylinder Switch (Lock) ........47

Check Front Door Key Cylinder Switch (Unlock) .....47

Check Select Unlock Relay Circuit ..........................48

REMOTE KEYLESS ENTRY SYSTEM .............50

Component Parts and Harness Connector Loca-

tion ...........................................................................

50

System Description ..................................................50

CAN Communication System Description ...............53

CAN Communication Unit ........................................53

Schematic ................................................................54

Wiring Diagram - KEYLES - ....................................55

Terminal and Reference Value for BCM ..................58

Terminal and Reference Value for IPDM E/R ..........59

CONSULT-III Function (BCM) .................................60

Work Flow ................................................................62

Trouble Diagnosis Chart by Symptom .....................62

Check Key Fob Battery and Function ......................63

Check ACC Switch ..................................................64

Check Door Switch ..................................................65

Check Key Switch ....................................................68

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 738 of 3924

BL-4

< SERVICE INFORMATION >

DTC INDEX

SERVICE INFORMATION

DTC INDEX

INTELLGENT KEY UNIT U1000INFOID:0000000001529387

INTELLGENT KEY UNIT B2013-B2014INFOID:0000000001529388

ECM P1610-P1615INFOID:0000000001529389

CONSULT display Descr iption Reference page

U1000: CAN COMM CIRCUIT M alfunction is detected in CA N communication.

BCS-13, "

U1000 CAN

Communication Circuit"

CONSULT display Descr iption Reference page

B2013: STRG COMM 1 .Malfunction is detected in communication of Intelligent

Key unit and steering lock unit BL-124, "

Check Steering

Lock Unit"

B2014: STRG COMM 2

Malfunction is detected in communication of Intelligent Key

unit and steering lock unit. BL-124, "Check Steering

Lock Unit"

CONSULT display Descr

iption Reference page

P1610: LOCK MODE When the starting operation is carried out 5 or more times

consecutively under the following conditions, IVIS(NATS)

will shift the mode to prevent the engine start.

• unregistered ignition key is used (without intelligent key

system)

BCM or ECM malfunctioning BL-198, "

Diagnosis Proce-

dure 5"

P1611: ID DISCORD, IMM-ECM

The result of ID verification between BCM and ECM is NG.

System initialization is required. BL-197, "Diagnosis Proce-

dure 4"

P1612: CHAIN OF ECM-IMMU Communication impossible between ECM and BCM.

BL-197, "Diagnosis Proce-

dure 2"

P1613: ECM INT CIRC-IMMUThe malfunction of ECM internal circuit to BCM communi-

cation line is detected. BL-195, "Diagnosis Proce-

dure 1"

P1614: CHAIN OF IMMU-KEY BCM cannot receive the key ID signal.

BL-200, "Diagnosis Proce-

dure 6"

P1615: DIFFERENCE OF KEY

BCM can receive the key ID signal but the result of ID ver-

ification between key ID and BCM is NG. BL-197, "Diagnosis Proce-

dure 3"

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 806 of 3924

BL-72

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

3. Check continuity between IPDM E/R connector E9 terminal 51and horn relay connector E10 terminal 1.

OK or NG

OK >> Check harness connection.

NG >> Repair or replace harness.

Check Hazard Warn ing Lamp FunctionINFOID:0000000001327829

1.CHECK HAZARD WARNING LAMP

Do hazard warning lamp flash with hazard switch?

YES or NO

YES >> Hazard warning lamp circuit is OK.

NO >> Check hazard circuit. Refer to LT- 7 8

.

Check Horn FunctionINFOID:0000000001327830

First perform the “SELF-DIAG RESULTS” in “BCM” wi th CONSULT-III, then perform the trouble diagnosis of

malfunction system indicated “SELF-DIAG RESULTS” of “BCM”. Refer to BCS-13, "

U1000 CAN Communica-

tion Circuit".

1.CHECK HORN FUNCTION

Does horn sound with horn switch?

YES or NO

YES >> Horn circuit is OK.

NO >> Check horn circuit. Refer to WW-48, "

Wiring Diagram - HORN -".

Check Headlamp FunctionINFOID:0000000001327831

First perform the “SELF-DIAG RESULTS” in “BCM” wi th CONSULT-III, then perform the trouble diagnosis of

malfunction system indicated “SELF-DIAG RESULTS” of “BCM”. Refer to BCS-13, "

U1000 CAN Communica-

tion Circuit".

1.CHECK HEADLAMP FUNCTION

Does headlamp come on when turning lighting switch “ON”?

YES or NO

YES >> Headlamp operation circuit is OK.

NO >> Check headlamp system. Refer to LT- 5 , "

System Description".

Check Map Lamp and Ignition Keyhole Illumination FunctionINFOID:0000000001327832

1.CHECK MAP LAMP AND IGNITION KEYHOLE ILLUMINATION FUNCTION

When map lamp switch is in “DOOR” position, open the front door (LH or RH).

OK or NG

51 (SB) – 1 (SB) : Continuity should exist.

PIIA6404E

Map lamp and ignition keyhole illumination should illuminate.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 838 of 3924

BL-104

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

CONSULT-III Application Item

INFOID:0000000001327849

WORK SUPPORT

SELF-DIAGNOSTIC RESULTS

DATA MONITOR

MAIN SIGNALS Display Item

Part to be diagnosed Inspection Item, Diagnosis Mode Description

Intelligent Key WORK SUPPORT

Performs Intelligent Key-ID registration, check, and deletion.

Performs steering lock unit ID registration.

Changes settings for each function (ON/OFF).

SELF-DIAG RESULTS Intelligent Key unit performs CAN communication diagnosis.

DATA MONITOR Displays Intelligent Key unit input data in real time.

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can

be read.

ACTIVE TEST Sends drive signals door lock actuator, buzzer or combination meter to

perform operation check.

ECU PART NUMBER Displays Intelligent Key unit part No.

Monitor item Description

CONFIRM KEY FOB ID The Intelligent Key ID can be confirmed.

TAKE OUT FROM WINDOW WARN The condition of Intelligent Key warning function can be changed.

LOW BATT OF KEY FOB WARN The condition of low battery warning function can be changed.

I-KEY FUNCTION The condition of Intellig ent Key's function can be changed.

ANSWER BACK FUNCTION The co ndition of answer back function can be changed.

HORN WITH KEYLESS LOCK The condition of key reminder function can be set.

SELECTIVE UNLOCK FUNCTION The co ndition of selective unlock function can be changed.

HAZARD ANSWER BACK The condition of key reminder function can be set.

ANSWER BACK WITH I-KEY LOCK The condition of ke y reminder function (LOCK) can be changed.

ANSWER BACK WITH I-KEY UNLOCK The condition of ke y reminder function (UNLOCK) can be changed.

AUTO RELOCK TIMER This mode is able confirm and changed auto door lock function operation time set-

ting.

PANIC ALARM DELAY This mode is able to confirm and change panic alarm function operation delay time

setting.

P/W DOWN DELAY This mode is able to confirm and change remote window open function.

ENGINE START BY I-KEY This mode is able to confirm and change start function ON - OFF setting.

LOCK/UNLOCK BY I-KEY The condition of lock/unlock function can be set.

LUG ROOM ENGINE START This mode is able to confirm and change operation range.

Self-diag results Description Diagnosis procedure Reference page

CAN COMM

[U1000] Malfunction is detected in CAN communication. Check CAN communication system.

BCS-13

STRG COMM1

[B2013]Malfunction is detected in communication of Intel-

ligent Key unit and steering lock unit.

Check steering lock unit.

BL-124

STRG COMM2

[B2014]Malfunction is detected in communication of Intel-

ligent Key unit and steering lock unit.

Check steering lock unit.

BL-124

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 845 of 3924

INTELLIGENT KEY SYSTEMBL-111

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Check CAN Comm unication System InspectionINFOID:0000000001534751

1.PERFORM SELF DIAGNOSTIC

1. Turn ignition switch ON and wait for 2 seconds or more.

2. Check “Self Diagnostic Result” of BCM.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Refer to BCS-13, "U1000 CAN Communication Circuit".

NO >> INSPECTION END.

Check Intelligent Key Unit Power Supply and Ground CircuitINFOID:0000000001327853

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition knob OFF position.

2. Disconnect Intelligent Key unit connector.

3. Check voltage between Intelligent Key unit connector and ground.

OK or NG

Door lock non-operation warning does not

sound. Intelligent Key warning chime does not sound

1. Intelligent Key battery inspection BL-130

2. Check door request switch BL-119

3. Check inside key antennaBL-123

4. Check Intelligent Key warning buzzerBL-120

5. Replace Intelligent Key unitBL-130

Ignition knob OFF position warning chime does not sound

1. Intelligent Key battery inspection BL-130

2. Check door request switch BL-119

3. Check outside key antennaBL-121

4. Check Intelligent Key warning buzzerBL-120

5. Check ignition knob switch BL-114

6. Replace Intelligent Key unitBL-130

Door ajar alarm

1. Check CAN communications BCS-13

2. Check door request switch BL-119

3. Check outside key antennaBL-121

4. Check Intelligent Key warning buzzerBL-120

5. Check door switch BL-115

6. Intelligent Key battery inspectionBL-130

7. Replace Intelligent Key unitBL-130

Symptom Diagnoses service procedure Refer to page

ConnectorTe r m i n a l

(Wire color) Ignition knob position

M34 (+) (–) OFF ACC ON

6

(W)

Ground 0V 0V Battery voltage

10

(LG) 0V Battery voltage Battery voltage

11

(L/R) Battery voltage Battery voltage Battery voltage

MIIB0360E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 863 of 3924

INTELLIGENT KEY SYSTEMBL-129

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Check Horn FunctionINFOID:0000000001327868

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-III, then perform the trouble diagnosis of

malfunction system indicated “SELF-DI AG RESULTS” of “BCM”. Refer to BCS-13, "

U1000 CAN Communica-

tion Circuit".

1.CHECK HORN FUNCTION

Does horn sound with horn switch?

YES or NO

YES >> Horn circuit is OK.

NO >> Check horn circuit. Refer to WW-48, "

Wiring Diagram - HORN -".

Check Headlamp FunctionINFOID:0000000001327869

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-III, then perform the trouble diagnosis of

malfunction system indicated “SELF-DI AG RESULTS” of “BCM”. Refer to BCS-13, "

U1000 CAN Communica-

tion Circuit".

1.CHECK HEADLAMP OPERATION

Does headlamp come on when turning lighting switch “ON”?

YES or NO

YES >> Headlamp operation circuit is OK.

NO >> Check headlamp system. Refer to LT- 5 , "

System Description".

Check IPDM E/R OperationINFOID:0000000001327870

1.CHECK IPDM E/R INPUT VOLTAGE

Check voltage between IPDM E/R connector E9 terminal 51 (SB) and ground.

OK or NG

OK >> Replace IPDM E/R.

NG >> GO TO 2.

2.CHECK IPDM E/R HARNESS

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R and horn relay connector.

3. Check continuity between IPDM E/R connector E9 terminal 51 (SB) and horn relay connector E10 termi-

nal 1 (SB).

OK or NG

OK >> Check harness connection.

NG >> Repair or replace harness. 51 (SB) – Ground : Battery voltage

PIIA6403E

51 (SB) – 1 (SB) : Continuity should exist.

PIIA6404E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C