installation INFINITI FX35 2008 Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 293 of 3924

AT-220

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

3. Connect TCM connectors.

4. Install O-ring in A/T assembly harness connector.CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

5. Install A/T fluid temperature sensor 2 to bracket.

6. Install A/T fluid temperature sensor 2 (with bracket) in control valve with TCM, and then tighten A/T fluid temperature sensor 2

mounting bolt to the specified torque. Refer to "COMPO-

NENTS".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

7. Install control valve with TCM in transmission case. CAUTION:

Make sure that turbine revolu tion sensor securely installs

turbine revolution sensor hole.

Hang down revolution senso r harness toward outside so

as not to disturb installation of control valve with TCM.

Adjust A/T assembly harness co nnector of control valve

with TCM to terminal hole of transmission case.

SCIA5447E

SCIA5155E

SCIA5264E

SCIA5301E

SCIA5034E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 296 of 3924

ON-VEHICLE SERVICEAT-223

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

c. Tighten oil pan mounting bolts to the specified torque in numeri- cal order shown in the figure after temporarily tightening them.

Refer to "COMPONENTS".

CAUTION:

Do not reuse oil pan mounting bolts.

16. Install drain plug to oil pan, and then tighten drain plug to the specified torque. Refer to "COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

17. Pull up A/T assembly harness connector. CAUTION:

Be careful not to damage connector.

18. Install snap ring to A/T assembly harness connector.

19. Connect A/T assembly harness connector.

20. Connect heated oxygen sensor 2 harness connector.

21. Install front cross bar. Refer to FSU-6, "

Removal and Installa-

tion".

22. Pour ATF into A/T assembly. Refer to AT- 11 , "

Changing A/T

Fluid".

23. Connect the battery cable to the negative terminal.

A/T FLUID TEMPERATURE SENSOR 2 REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery cabl e from the negative terminal.

2. Remove front cross bar. Refer to FSU-6, "

Removal and Installation".

3. Disconnect heated oxygen sensor 2 harness connector.

4. Drain ATF through drain plug.

5. Remove bracket (1) (VK45DE), clips (2), oil pan (3) and oil pan gasket.

: Vehicle front

: Bolt (22)

Drain plug (4)

SCIA4113E

SCIA5038E

SCIA5039E

SCIA8128E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 297 of 3924

AT-224

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

6. Check foreign materials in oil pan to help determine causes ofmalfunction. If the ATF is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indicates

varnish build up. Varnish can cause valves, servo, and clutches

to stick and can inhibit pump pressure.

If frictional material is de tected, perform A/T fluid cooler

cleaning. Refer to AT-13, "

A/T Fluid Cooler Cleaning".

7. Disconnect A/T fluid temperature sensor 2 connector (1). CAUTION:

Be careful not to damage connector.

8. Straighten terminal clip ( ) to free A/T fluid temperature sensor 2 harness.

9. Remove A/T fluid temperature sensor 2 with bracket from con- trol valve with TCM.

10. Remove bracket from A/T fluid temperature sensor 2.

Installation

CAUTION:

After completing installation, check A/T fluid leakage and A/F fluid level. Refer to AT- 11 , "

Checking A/T

Fluid".

SCIA5199E

SCIA8076E

SCIA5302E

SCIA5264E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 300 of 3924

ON-VEHICLE SERVICEAT-227

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

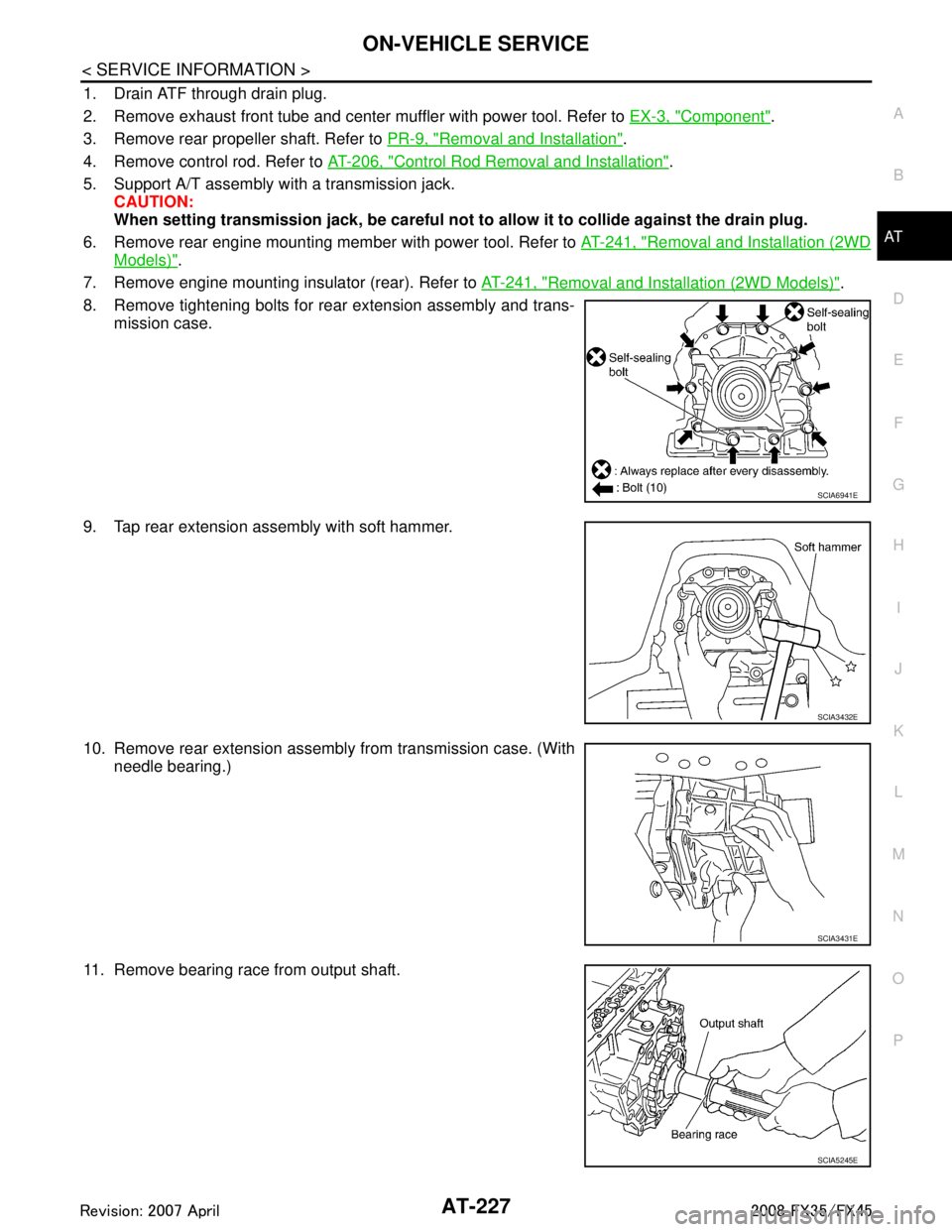

1. Drain ATF through drain plug.

2. Remove exhaust front tube and center muffler with power tool. Refer to EX-3, "

Component".

3. Remove rear propeller shaft. Refer to PR-9, "

Removal and Installation".

4. Remove control rod. Refer to AT-206, "

Control Rod Removal and Installation".

5. Support A/T assembly with a transmission jack. CAUTION:

When setting transmission jack, be careful not to allow it to collide against the drain plug.

6. Remove rear engine mounting member with power tool. Refer to AT-241, "

Removal and Installation (2WD

Models)".

7. Remove engine mounting insulator (rear). Refer to AT-241, "

Removal and Installation (2WD Models)".

8. Remove tightening bolts for rear extension assembly and trans- mission case.

9. Tap rear extension assembly with soft hammer.

10. Remove rear extension assembly from transmission case. (With needle bearing.)

11. Remove bearing race from output shaft.

SCIA6941E

SCIA3432E

SCIA3431E

SCIA5245E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 303 of 3924

AT-230

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

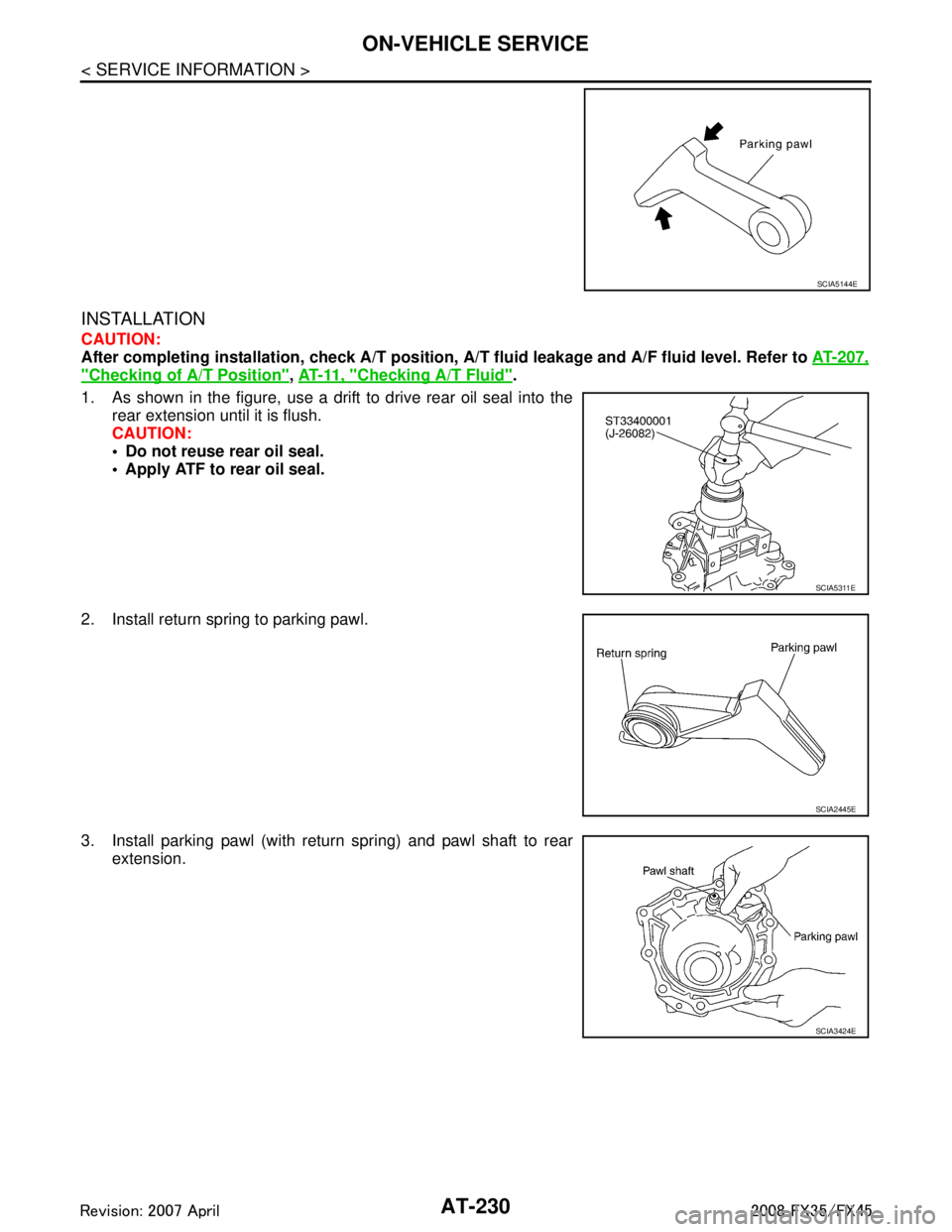

INSTALLATION

CAUTION:

After completing installation, check A/T position, A/T fluid leakage and A/F fluid level. Refer to AT-207,

"Checking of A/T Position", AT- 11 , "Checking A/T Fluid".

1. As shown in the figure, use a drift to drive rear oil seal into the rear extension until it is flush.

CAUTION:

Do not reuse rear oil seal.

Apply ATF to rear oil seal.

2. Install return spring to parking pawl.

3. Install parking pawl (with return spring) and pawl shaft to rear extension.

SCIA5144E

SCIA5311E

SCIA2445E

SCIA3424E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 305 of 3924

AT-232

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

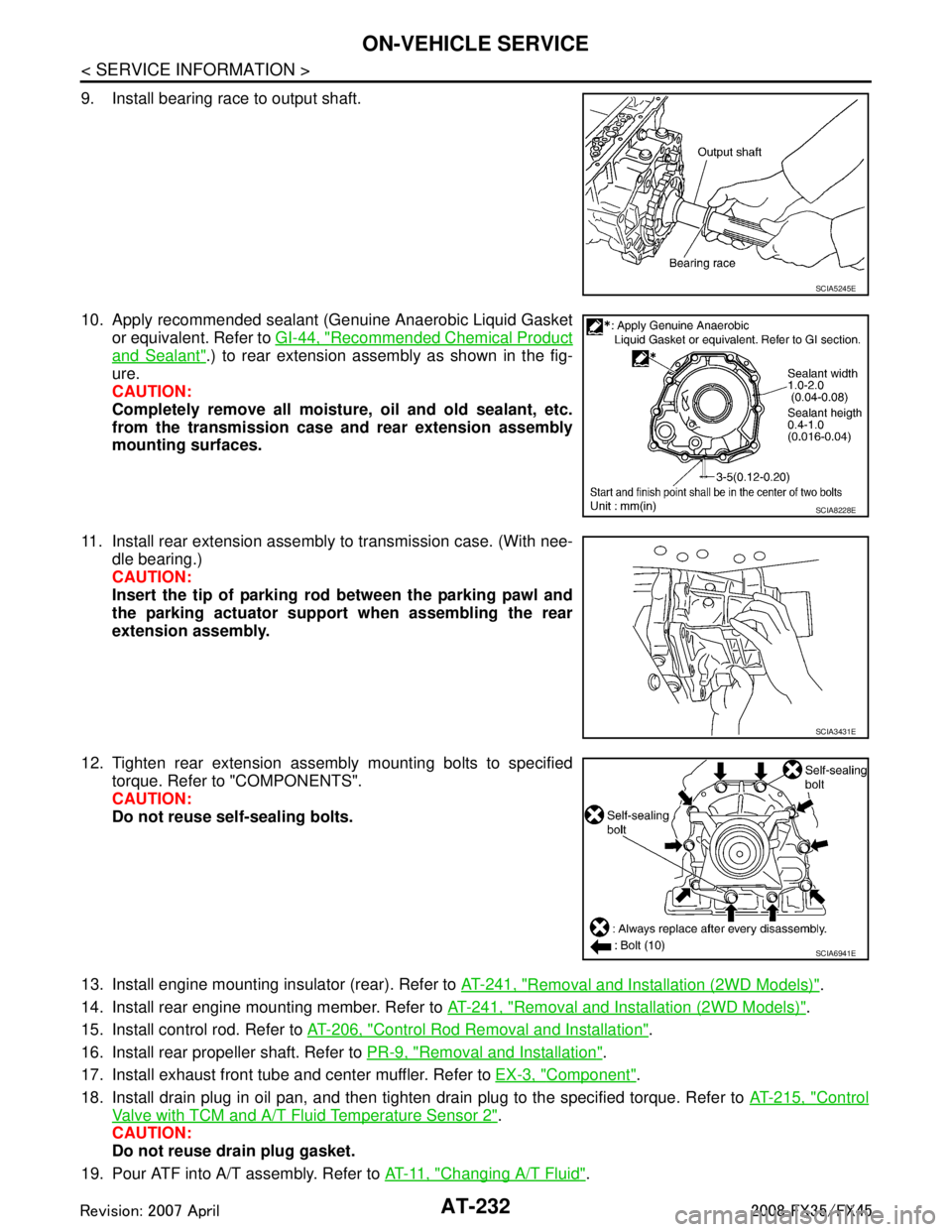

9. Install bearing race to output shaft.

10. Apply recommended sealant (Genuine Anaerobic Liquid Gasketor equivalent. Refer to GI-44, "

Recommended Chemical Product

and Sealant".) to rear extension assembly as shown in the fig-

ure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transmission case and rear extension assembly

mounting surfaces.

11. Install rear extension assembly to transmission case. (With nee- dle bearing.)

CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator support when assembling the rear

extension assembly.

12. Tighten rear extension assembly mounting bolts to specified torque. Refer to "COMPONENTS".

CAUTION:

Do not reuse self-sealing bolts.

13. Install engine mounting insulator (rear). Refer to AT-241, "

Removal and Installation (2WD Models)".

14. Install rear engine mounting member. Refer to AT-241, "

Removal and Installation (2WD Models)".

15. Install control rod. Refer to AT-206, "

Control Rod Removal and Installation".

16. Install rear propeller shaft. Refer to PR-9, "

Removal and Installation".

17. Install exhaust front tube and center muffler. Refer to EX-3, "

Component".

18. Install drain plug in oil pan, and then tighten drain plug to the specified torque. Refer to AT-215, "

Control

Valve with TCM and A/T Fluid Temperature Sensor 2".

CAUTION:

Do not reuse drain plug gasket.

19. Pour ATF into A/T assembly. Refer to AT- 11 , "

Changing A/T Fluid".

SCIA5245E

SCIA8228E

SCIA3431E

SCIA6941E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 306 of 3924

ON-VEHICLE SERVICEAT-233

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Rear Oil SealINFOID:0000000001327395

REMOVAL

1. Remove center muffler with power tool. Refer to EX-3, "Compo-

nent".

2. Remove rear propeller shaft. Refer to PR-9, "

Removal and

Installation".

3. Remove front propeller shaft (AWD models). Refer to PR-4,

"Removal and Installation".

4. Remove transfer assembly from A/T assembly (AWD models). Refer to TF-40, "

Removal and Installation".

5. Remove rear oil seal using a flat-bladed screwdriver. CAUTION:

Be careful not to scratch rear extension assembly (2WD

models) or adapter case assembly (AWD models).

INSTALLATION

CAUTION:

After completing installati on, check A/T fluid leakage and A/T fluid level. Refer to AT- 11 , "

Checking A/T

Fluid".

1. As shown in the figure, use the drift to drive rear oil seal into rear extension assembly (2WD models) or adapter case assembly

(AWD models) until it is flush.

CAUTION:

Do not reuse rear oil seal.

Apply ATF to rear oil seal.

2. Install transfer assembly to A/T assembly (AWD models). Refer to TF-40, "

Removal and Installation".

3. Install front propeller shaft (AWD models). Refer to PR-4,

"Removal and Installation".

4. Install rear propeller shaft. Refer to PR-9, "

Removal and Installa-

tion".

5. Install center muffler. Refer to EX-3, "

Component".

Revolution Sensor Component (2WD Models Only)INFOID:0000000001327396

COMPONENTS

SCIA5410E

SCIA5411E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 307 of 3924

AT-234

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

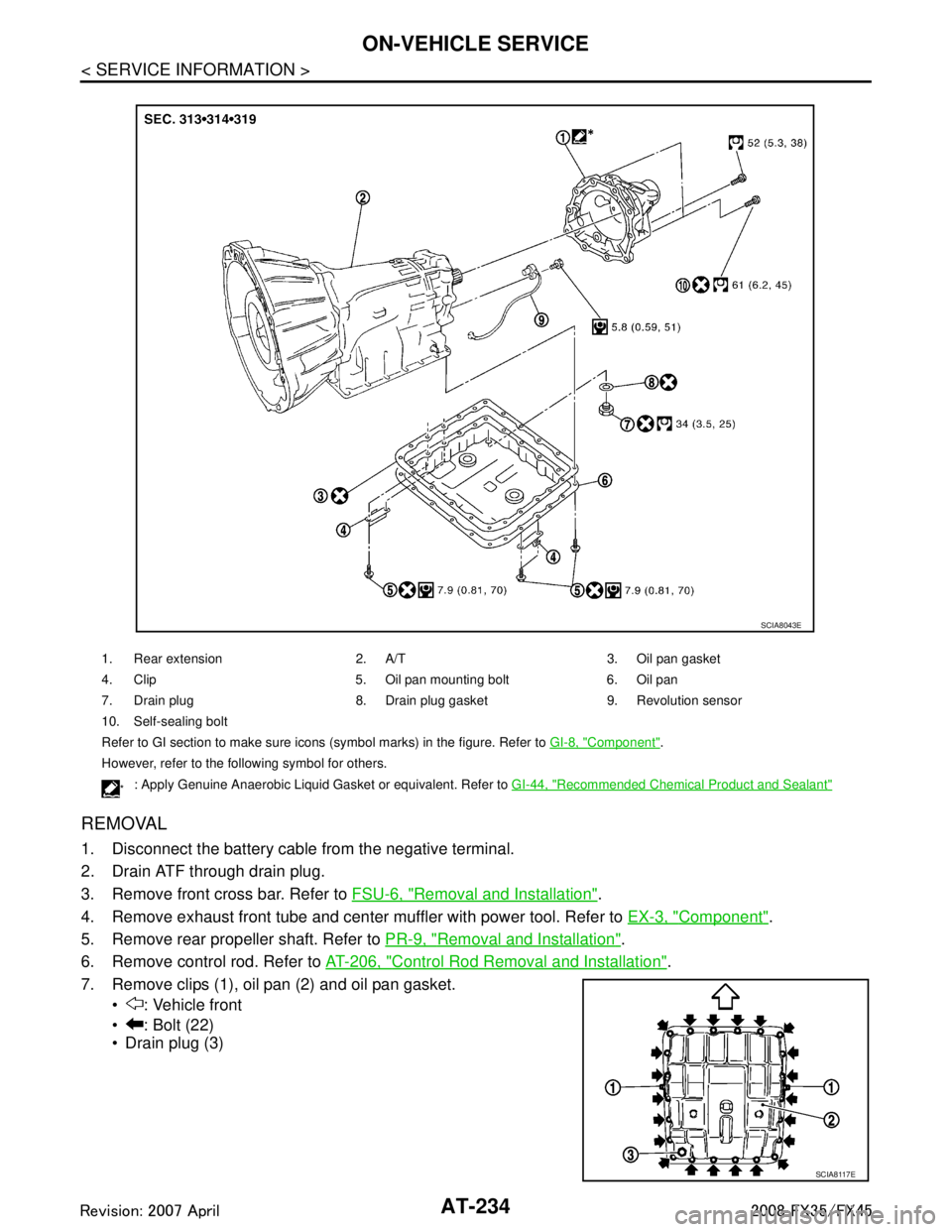

REMOVAL

1. Disconnect the battery cable from the negative terminal.

2. Drain ATF through drain plug.

3. Remove front cross bar. Refer to FSU-6, "

Removal and Installation".

4. Remove exhaust front tube and center muffler with power tool. Refer to EX-3, "

Component".

5. Remove rear propeller shaft. Refer to PR-9, "

Removal and Installation".

6. Remove control rod. Refer to AT-206, "

Control Rod Removal and Installation".

7. Remove clips (1), oil pan (2) and oil pan gasket. : Vehicle front

: Bolt (22)

Drain plug (3)

1. Rear extension 2. A/T 3. Oil pan gasket

4. Clip 5. Oil pan mounting bolt 6. Oil pan

7. Drain plug 8. Drain plug gasket 9. Revolution sensor

10. Self-sealing bolt

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

However, refer to the following symbol for others.

*: Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-44, "Recommended Chemical Product and Sealant"

SCIA8043E

SCIA8117E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 308 of 3924

ON-VEHICLE SERVICEAT-235

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

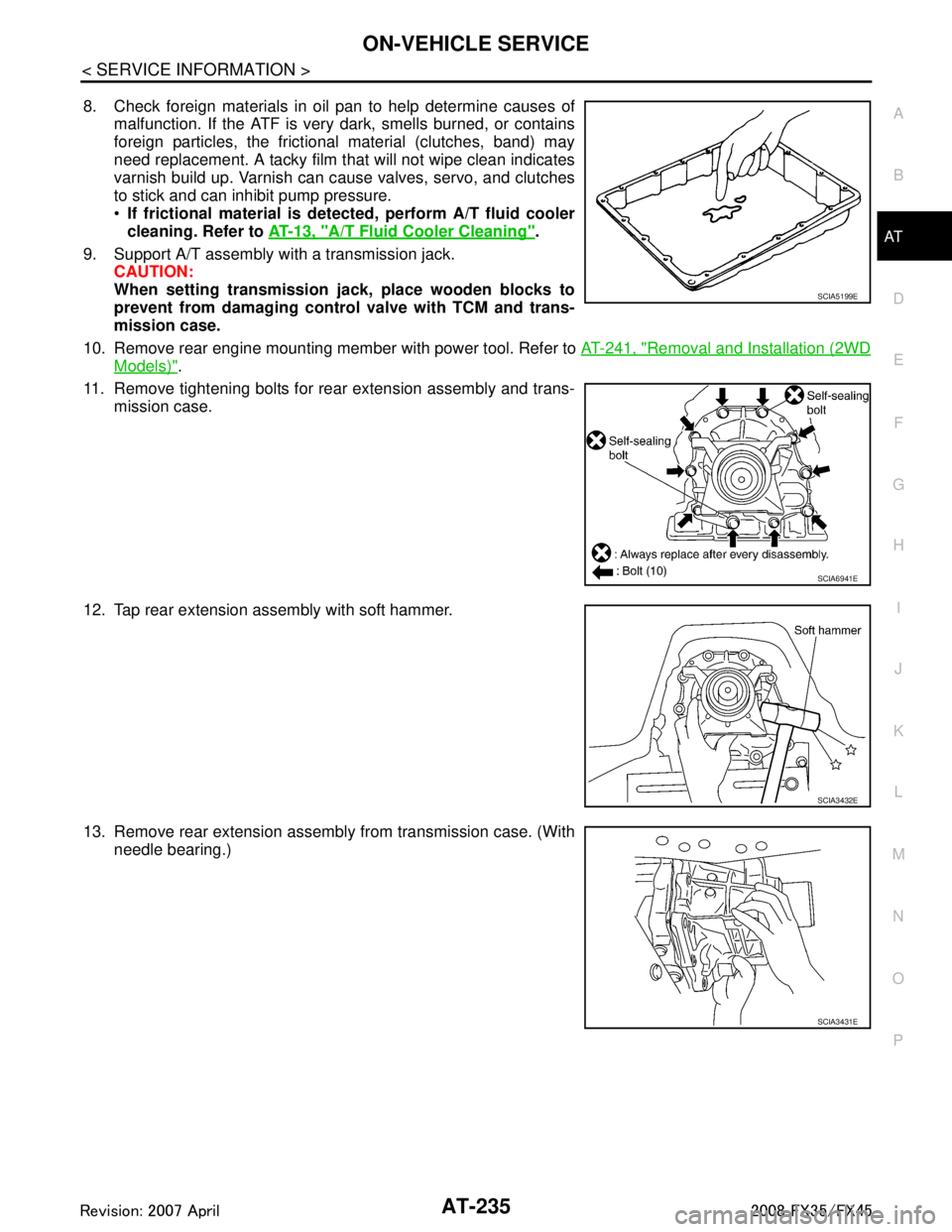

8. Check foreign materials in oil pan to help determine causes of malfunction. If the ATF is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indicates

varnish build up. Varnish can c ause valves, servo, and clutches

to stick and can inhibit pump pressure.

If frictional material is detected, perform A/T fluid cooler

cleaning. Refer to AT-13, "

A/T Fluid Cooler Cleaning".

9. Support A/T assembly with a transmission jack. CAUTION:

When setting transmission jack, place wooden blocks to

prevent from damaging control valve with TCM and trans-

mission case.

10. Remove rear engine mounting member with power tool. Refer to AT-241, "

Removal and Installation (2WD

Models)".

11. Remove tightening bolts for rear extension assembly and trans- mission case.

12. Tap rear extension assembly with soft hammer.

13. Remove rear extension assembly from transmission case. (With needle bearing.)

SCIA5199E

SCIA6941E

SCIA3432E

SCIA3431E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 309 of 3924

AT-236

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

14. Disconnect revolution sensor connector.CAUTION:

Be careful not to damage connector

15. Straighten terminal clip to free revolution sensor harness.

16. Remove revolution sensor from transmission case. CAUTION:

Do not subject it to impact by dropping or hitting it.

Do not disassemble.

Do not allow metal filings, etc. to get on the sensor's front

edge magnetic area.

Do not place in an area affected by magnetism.

INSTALLATION

CAUTION:

After completing installation, check A/T position , A/T fluid leakage and A/F fluid level. Refer to AT-207,

"Checking of A/T Position", AT- 11 , "Checking A/T Fluid".

1. Install revolution sensor in transmission case, and then tighten revolution sensor mounting bolt to the specified torque. Refer to

"COMPONENTS".

CAUTION:

Do not subject it to impact by dropping or hitting it.

Do not disassemble.

Do not allow metal filings, etc. to get on the sensor's front

edge magnetic area.

Do not place in an area affected by magnetism.

SCIA7524E

SCIA7525E

SCIA3997E

SCIA3997E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C