seats INFINITI FX35 2008 Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3606 of 3924

SEAT BELTSSB-7

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

7. Repeat steps above as necessary to check the other seat belts.

SEAT BELT RETRACTOR ON-VEHICLE INSPECTION

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are of the Emergency Locki ng Retractors (ELR) type. In an emergency (sudden stop)

the retractor will lock and prevent the webbing from extending any further. All 3-point type seat belt retractors

except the driver's seat belt also have an Automati c Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted part ially, the ALR mode automatically locks the seat belt

in a specific position so the webbi ng cannot be extended any further. To c ancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors using the following test(s ) to determine if a retractor assembly is operating prop-

erly.

Stationary Inspection for ELR Function

Grasp the shoulder webbing and pull forward quickly. The retractor should lock and prevent the belt from

extending further.

Stationary Inspection for ALR Function

1. Pull out entire length of seat belt from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts indicating that the

retractor is in the Automatic Locking Retractor (ALR) mode.

3. Grasp the seat belt and try to pull out the retracto r. The webbing must lock and not extend any further. If

necessary replace the retractor assembly.

4. Allow the entire length of the webbing to retract to cancel the automatic locking mode.

Moving Inspection for ELR Function

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be p aved and dry. DO NOT perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event the

retractor does not lock.

1. Fasten driver's seat belt. Buckle a passenger in to the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h ( 10 MPH). Notify any passengers of a pending sudden stop.

The driver and passenger must be prepared to brace t hemselves in the event the retractor does not lock.

Apply brakes firmly and make a very hard stop.

During stop, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock, per-

form the retractor off-vehicle inspection.

SEAT BELT RETRACTOR OFF-VEHICLE INSPECTION

1. Remove the seat belt retractor assembly.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3648 of 3924

SQUEAK AND RATTLE TROUBLE DIAGNOSESSE-9

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun-visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted under-hood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs c an usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3654 of 3924

AUTOMATIC DRIVE POSITIONERSE-15

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

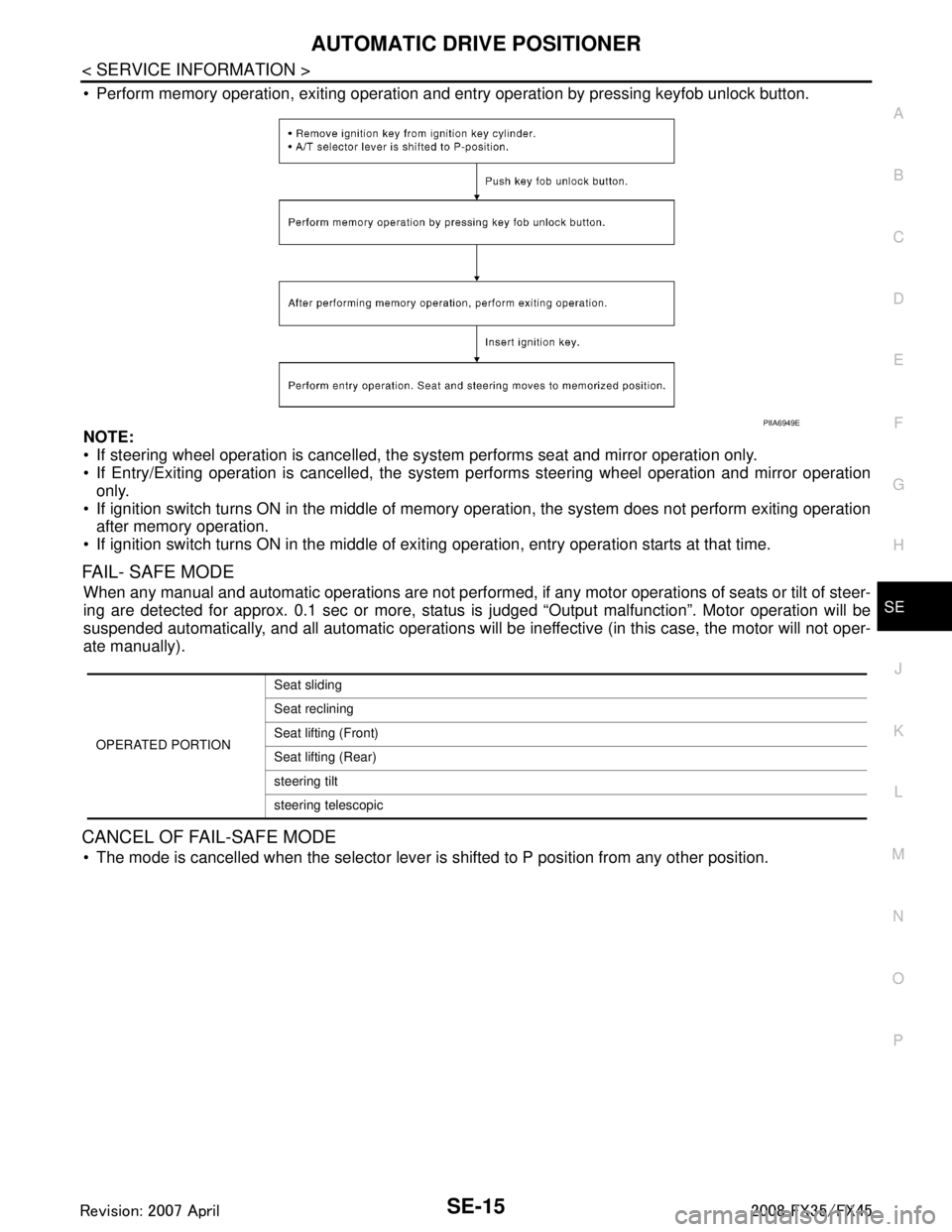

Perform memory operation, exiting operation and entry operation by pressing keyfob unlock button.

NOTE:

If steering wheel operation is cancelled, t he system performs seat and mirror operation only.

If Entry/Exiting operation is canc elled, the system performs steering wheel operation and mirror operation

only.

If ignition switch turns ON in the middle of memory operation, the system does not perform exiting operation

after memory operation.

If ignition switch turns ON in the middle of exit ing operation, entry operation starts at that time.

FAIL- SAFE MODE

When any manual and automatic operations are not performed, if any motor operations of seats or tilt of steer-

ing are detected for approx. 0.1 sec or more, status is judged “Output malfunction”. Motor operation will be

suspended automatically, and all automatic operations will be ineffective (in this case, the motor will not oper-

ate manually).

CANCEL OF FAIL-SAFE MODE

The mode is cancelled when the selector lever is shifted to P position from any other position.

PIIA6949E

OPERATED PORTIONSeat sliding

Seat reclining

Seat lifting (Front)

Seat lifting (Rear)

steering tilt

steering telescopic

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3724 of 3924

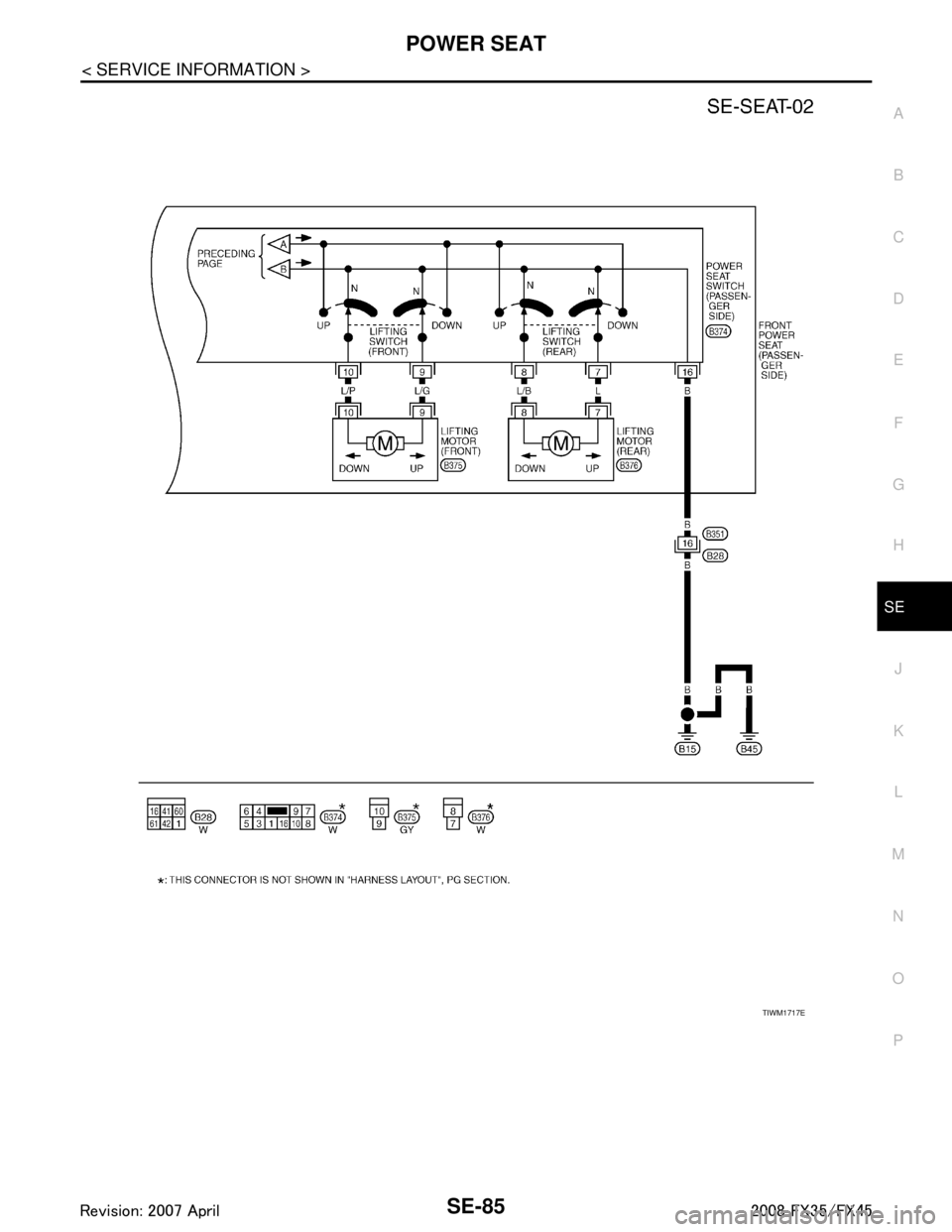

POWER SEATSE-85

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

TIWM1717E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3726 of 3924

HEATED SEATSE-87

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

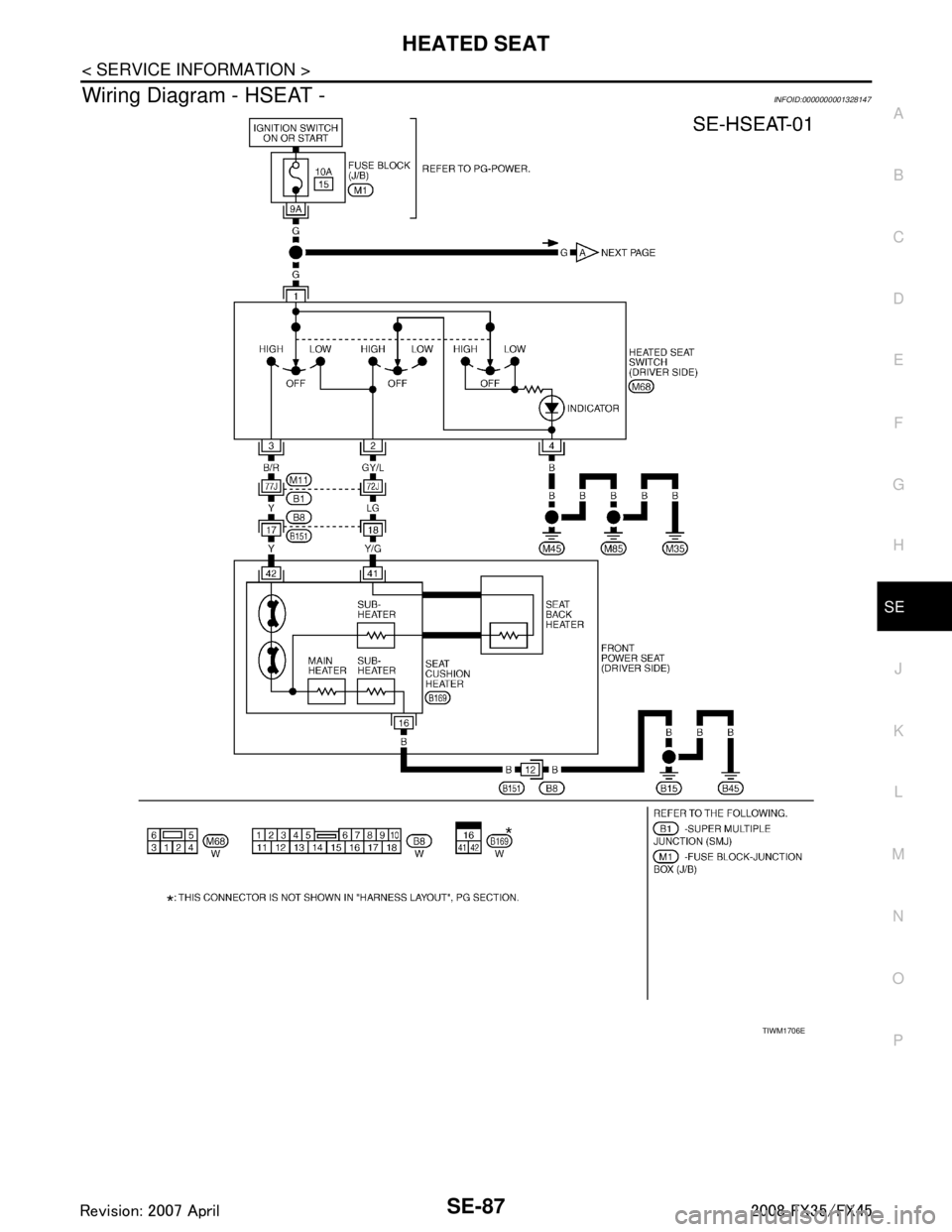

Wiring Diagram - HSEAT -INFOID:0000000001328147

TIWM1706E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3728 of 3924

FRONT SEATSE-89

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

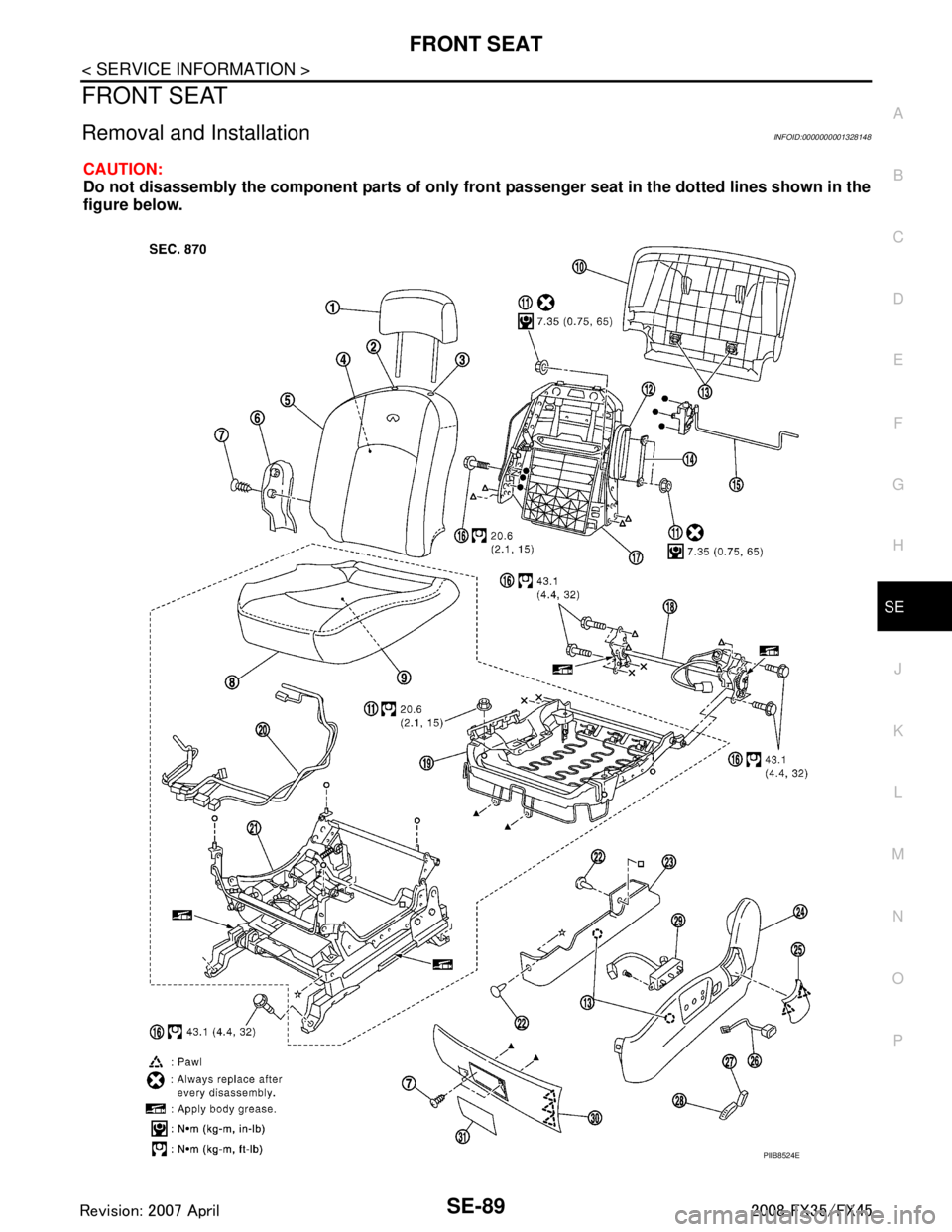

FRONT SEAT

Removal and InstallationINFOID:0000000001328148

CAUTION:

Do not disassembly the component parts of only fron t passenger seat in the dotted lines shown in the

figure below.

PIIB8524E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3730 of 3924

FRONT SEATSE-91

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

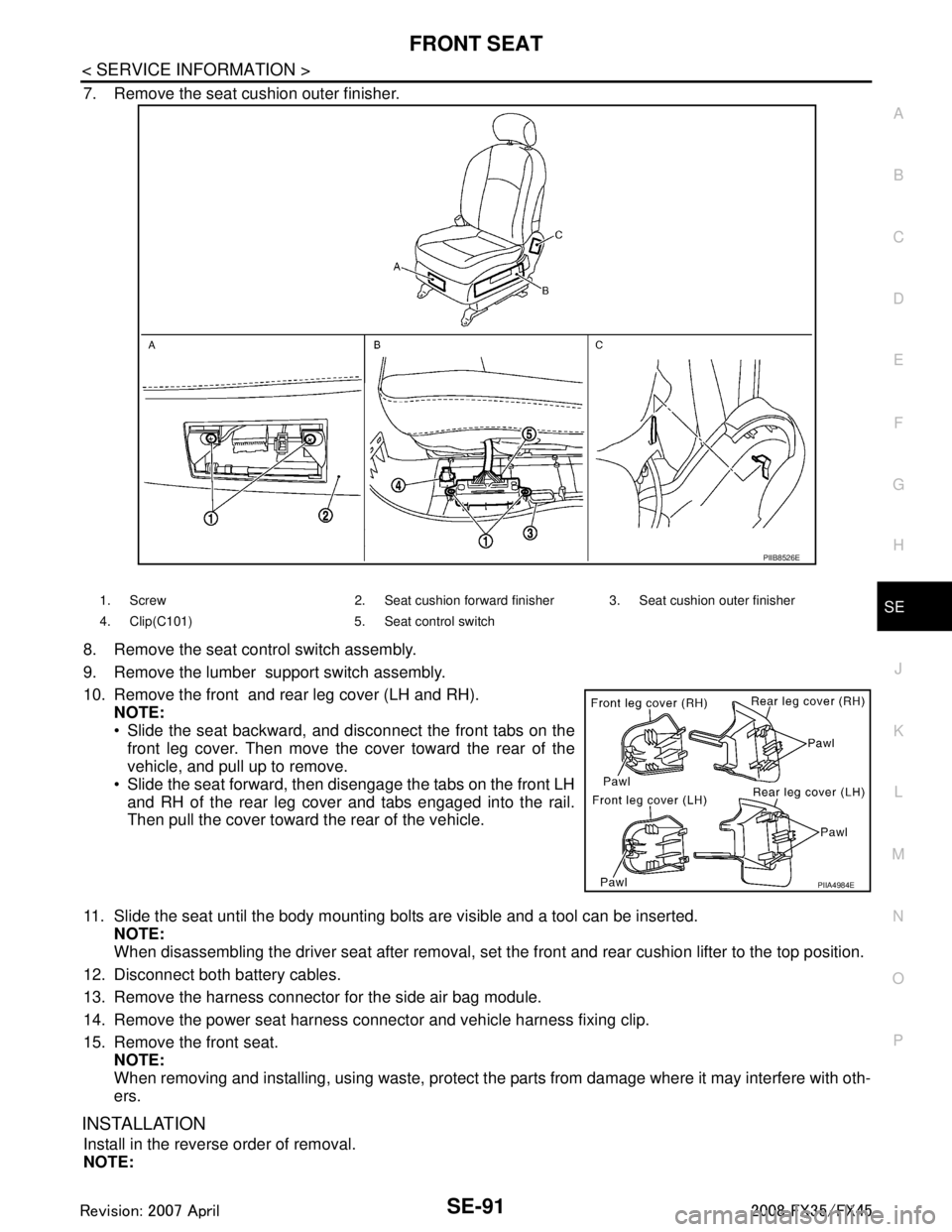

7. Remove the seat cushion outer finisher.

8. Remove the seat control switch assembly.

9. Remove the lumber support switch assembly.

10. Remove the front and rear leg cover (LH and RH). NOTE:

Slide the seat backward, and disconnect the front tabs on the

front leg cover. Then move the cover toward the rear of the

vehicle, and pull up to remove.

Slide the seat forward, then disengage the tabs on the front LH and RH of the rear leg cover and tabs engaged into the rail.

Then pull the cover toward the rear of the vehicle.

11. Slide the seat until the body mounting bolts are visible and a tool can be inserted. NOTE:

When disassembling the driver seat after removal, set the front and rear cushion lifter to the top position.

12. Disconnect both battery cables.

13. Remove the harness connector for the side air bag module.

14. Remove the power seat harness connector and vehicle harness fixing clip.

15. Remove the front seat. NOTE:

When removing and installing, using waste, protect t he parts from damage where it may interfere with oth-

ers.

INSTALLATION

Install in the reverse order of removal.

NOTE:

PIIB8526E

1. Screw 2. Seat cushion forward finisher 3. Seat cushion outer finisher

4. Clip(C101) 5. Seat control switch

PIIA4984E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3732 of 3924

FRONT SEATSE-93

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

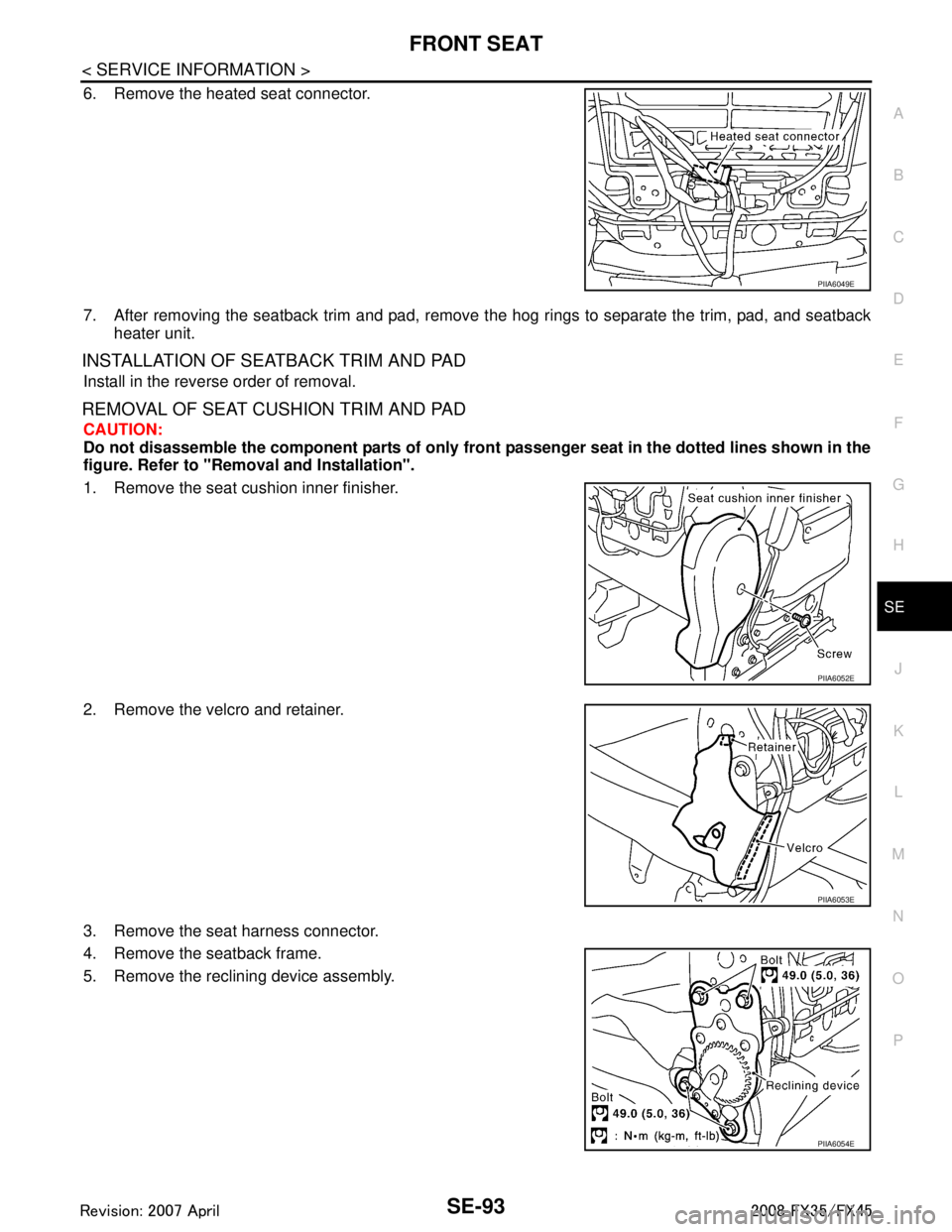

6. Remove the heated seat connector.

7. After removing the seatback trim and pad, remove t he hog rings to separate the trim, pad, and seatback

heater unit.

INSTALLATION OF SEATBACK TRIM AND PAD

Install in the reverse order of removal.

REMOVAL OF SEAT CUSHION TRIM AND PAD

CAUTION:

Do not disassemble the component parts of only fron t passenger seat in the dotted lines shown in the

figure. Refer to "Removal and Installation".

1. Remove the seat cushion inner finisher.

2. Remove the velcro and retainer.

3. Remove the seat harness connector.

4. Remove the seatback frame.

5. Remove the reclining device assembly.

PIIA6049E

PIIA6052E

PIIA6053E

PIIA6054E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3734 of 3924

REAR SEATSE-95

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

REAR SEAT

Removal and InstallationINFOID:0000000001328149

PIIB8527E

1. Headrest (side) 2. Headrest holder (free) 3. Headrest holder (locked)

4. Seatback trim (RH) 5. Seatback pad (RH) 6. Seatback frame (RH)

7. Nut 8. Seat hinge cover (RH) 9. Screw

10. Reclining lever (RH) 11. Reclining device outer cover (RH) 12. Reclining device inner cover (RH)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3736 of 3924

REAR SEATSE-97

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

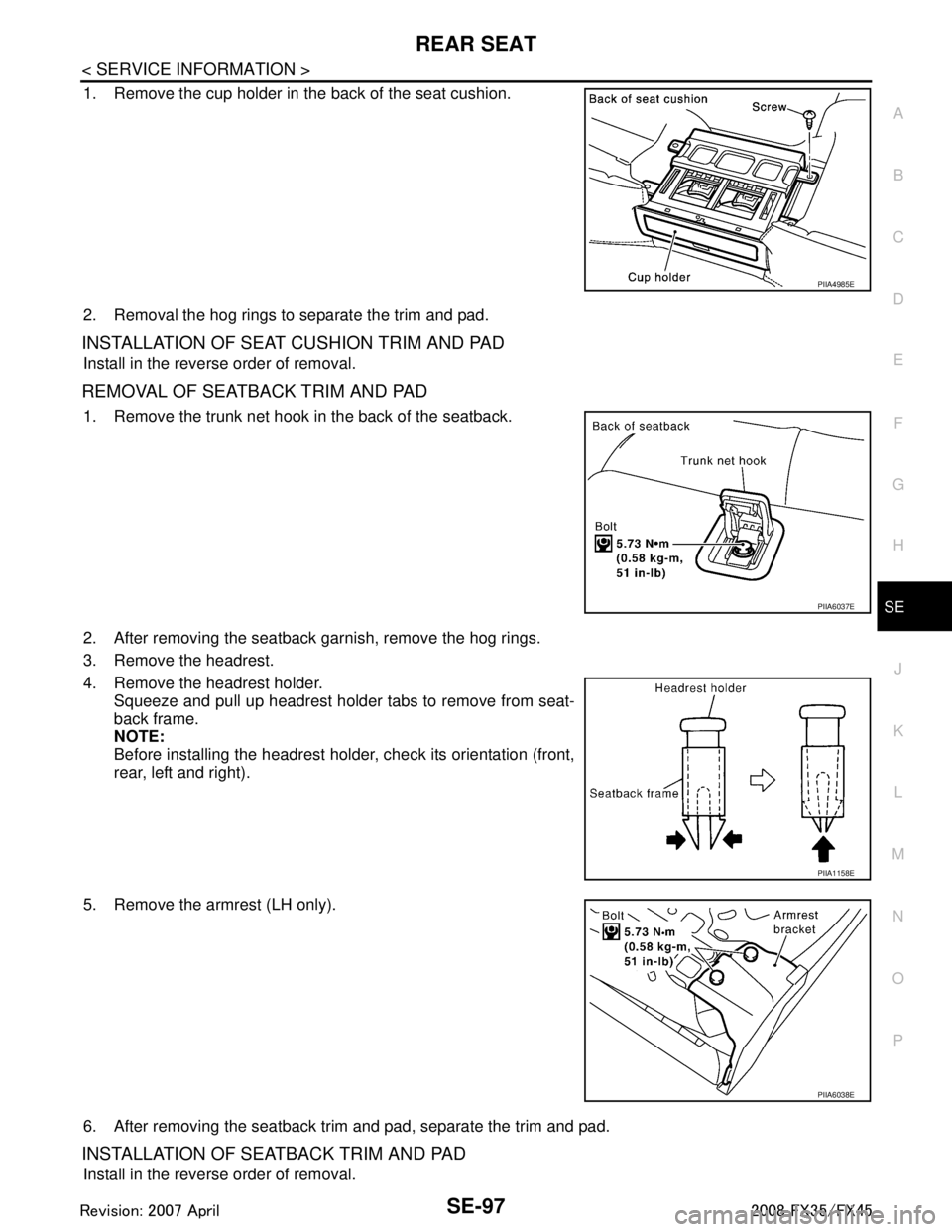

1. Remove the cup holder in the back of the seat cushion.

2. Removal the hog rings to separate the trim and pad.

INSTALLATION OF SEAT CUSHION TRIM AND PAD

Install in the reverse order of removal.

R E M O VA L O F S E AT B A C K T R I M A N D PA D

1. Remove the trunk net hook in the back of the seatback.

2. After removing the seatback garnish, remove the hog rings.

3. Remove the headrest.

4. Remove the headrest holder. Squeeze and pull up headrest holder tabs to remove from seat-

back frame.

NOTE:

Before installing the headrest holder, check its orientation (front,

rear, left and right).

5. Remove the armrest (LH only).

6. After removing the seatback trim and pad, separate the trim and pad.

INSTALLATION OF SEATBACK TRIM AND PAD

Install in the reverse order of removal.

PIIA4985E

PIIA6037E

PIIA1158E

PIIA6038E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C