service indicator INFINITI FX35 2008 Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 160 of 3924

TROUBLE DIAGNOSISAT-87

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

*1: Refer to EC-71, "Malfunction Indicator Lamp (MIL)" (for VQ35DE engine) or EC-649, "Malfunction Indicator Lamp (MIL)" (for VK45DE

engine.) A/T TCC S/V

FNCTN

A/T cannot perform lock-up even if electrical circuit is good.

TCM detects as irregular by comparing difference value with slip

rotation. P0744

P0744

(*2)AT- 1 2 6

L/PRESS SOL/

CIRC Normal voltage not applied to solenoid due to cut line, short, or the

like.

TCM detects as irregular by comparing target value with monitor value. P0745 P0745

AT- 1 2 8

TP SEN/CIRC A/TTCM does not receive the proper accelerator pedal position signals

(input by CAN communication) from ECM. P1705 P1705

AT- 1 3 0

ATF TEMP SEN/

CIRC During running, the A/T fluid temperature sensor signal voltage is

excessively high or low.

P1710 P0710

AT- 1 3 2

VEH SPD SE/CIR-

MTR Signal (CAN communication) from vehicle speed sensor MTR not

input due to cut line or the like.

Unexpected signal input during running. P1721 —

AT- 1 3 7

A/T INTERLOCKExcept during shift change, the gear position and ATF pressure

switch states are monitored and comparative judgement made.

P1730 P1730

AT- 1 3 9

A/T 1ST E/BRAK-

INGEach ATF pressure switch and solenoid current is monitored and if

a pattern is detected having engine braking 1st gear other than in the

M1 position, a malfunction is detected.

P1731 —

AT- 1 4 1

I/C SOLENOID/

CIRC Normal voltage not applied to solenoid due to functional malfunc-

tion, cut line, short, or the like.

TCM detects as irregular by comparing target value with monitor value. P1752 P1752

AT- 1 4 3

FR/B SOLENOID/

CIRC Normal voltage not applied to solenoid due to functional malfunc-

tion, cut line, short, or the like.

TCM detects as irregular by comparing target value with monitor value. P1757 P1757

AT- 1 4 5

D/C SOLENOID/

CIRC Normal voltage not applied to solenoid due to cut line, short, or the

like.

TCM detects as irregular by comparing target value with monitor value. P1762 P1762

AT- 1 4 7

HLR/C SOL/CIRC Normal voltage not applied to solenoid due to functional malfunc-

tion, cut line, short, or the like.

TCM detects as irregular by comparing target value with monitor value. P1767 P1767

AT- 1 4 9

LC/B SOLENOID/

CIRCNormal voltage not applied to solenoid due to functional malfunction,

cut line, short, or the like.

P1772 P1772

AT- 1 5 1

LC/B SOLENOID

FNCT TCM detects an improper voltage drop when it tries to operate the

solenoid valve.

Condition of ATF pressure switch 2 is different from monitor value, and relation between gear position and actual gear ratio is irregu-

lar. P1774

P1774(*2)AT- 1 5 3

MANU MODE SW/

CIRC When an impossible pattern of switch signals is detected, a malfunc-

tion is detected.

P1815 —

AT- 1 5 5

NO DTC IS DE-

TECTED FUR-

THER TESTING

MAY BE RE-

QUIREDNo NG item has been detected. X X —

Items (CONSULT-

III screen terms) Malfunction is detected when... TCM self-di-

agnosis OBD-II

(DTC)

Reference page

“TRANS-

MISSION”

with CON- SULT-III MIL indica-

tor lamp

(*1),

“ENGINE”

with CON-

SULT-III or GST

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 164 of 3924

TROUBLE DIAGNOSISAT-91

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

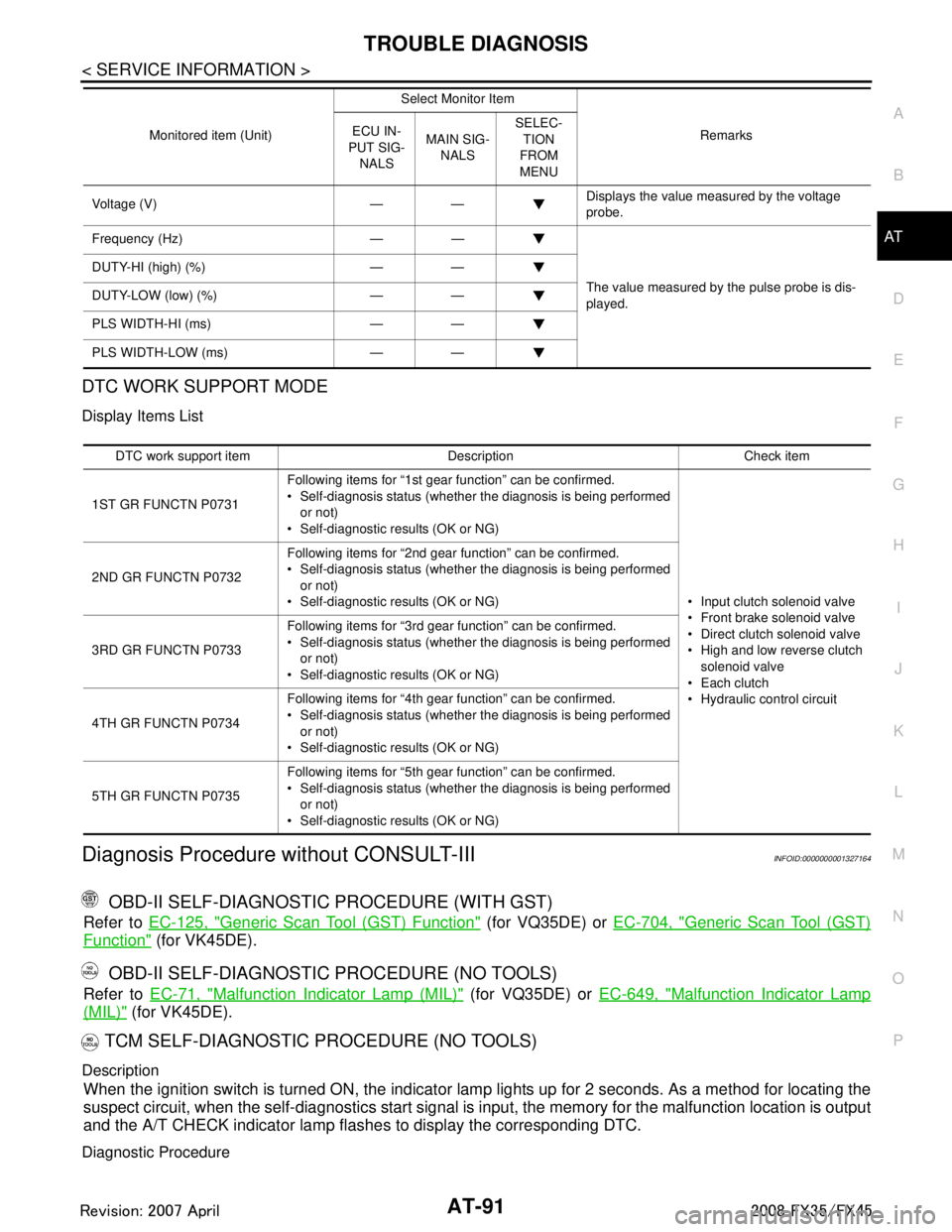

DTC WORK SUPPORT MODE

Display Items List

Diagnosis Procedure without CONSULT-IIIINFOID:0000000001327164

OBD-II SELF-DIAGNOSTIC PROCEDURE (WITH GST)

Refer to EC-125, "Generic Scan Tool (GST) Function" (for VQ35DE) or EC-704, "Generic Scan Tool (GST)

Function" (for VK45DE).

OBD-II SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

Refer to EC-71, "Malfunction Indicator Lamp (MIL)" (for VQ35DE) or EC-649, "Malfunction Indicator Lamp

(MIL)" (for VK45DE).

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

Description

When the ignition switch is turned ON, the indicator la mp lights up for 2 seconds. As a method for locating the

suspect circuit, when the self-diagnostics start signal is input, the memory for the malfunction location is output

and the A/T CHECK indicator lamp flashes to display the corresponding DTC.

Diagnostic Procedure

Voltage (V) — — Displays the value measured by the voltage

probe.

Frequency (Hz) — —

The value measured by the pulse probe is dis-

played.

DUTY-HI (high) (%) — —

DUTY-LOW (low) (%) — —

PLS WIDTH-HI (ms) — —

PLS WIDTH-LOW (ms) — — Monitored item (Unit)

Select Monitor Item

Remarks

ECU IN-

PUT SIG- NALS MAIN SIG-

NALS SELEC-

TION

FROM

MENU

DTC work support item Description Check item

1ST GR FUNCTN P0731 Following items for “1st gear function” can be confirmed.

Self-diagnosis status (whether the diagnosis is being performed

or not)

Self-diagnostic results (OK or NG)

Input clutch solenoid valve

Front brake solenoid valve

Direct clutch solenoid valve

High and low reverse clutch solenoid valve

Each clutch

Hydraulic control circuit

2ND GR FUNCTN P0732

Following items for “2nd gear function” can be confirmed.

Self-diagnosis status (whether the diagnosis is being performed

or not)

Self-diagnostic results (OK or NG)

3RD GR FUNCTN P0733 Following items for “3rd gear function” can be confirmed.

Self-diagnosis status (whether the diagnosis is being performed

or not)

Self-diagnostic results (OK or NG)

4TH GR FUNCTN P0734 Following items for “4th gear function” can be confirmed.

Self-diagnosis status (whether the diagnosis is being performed

or not)

Self-diagnostic results (OK or NG)

5TH GR FUNCTN P0735 Following items for “5th gear function” can be confirmed.

Self-diagnosis status (whether the diagnosis is being performed

or not)

Self-diagnostic results (OK or NG)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 165 of 3924

AT-92

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

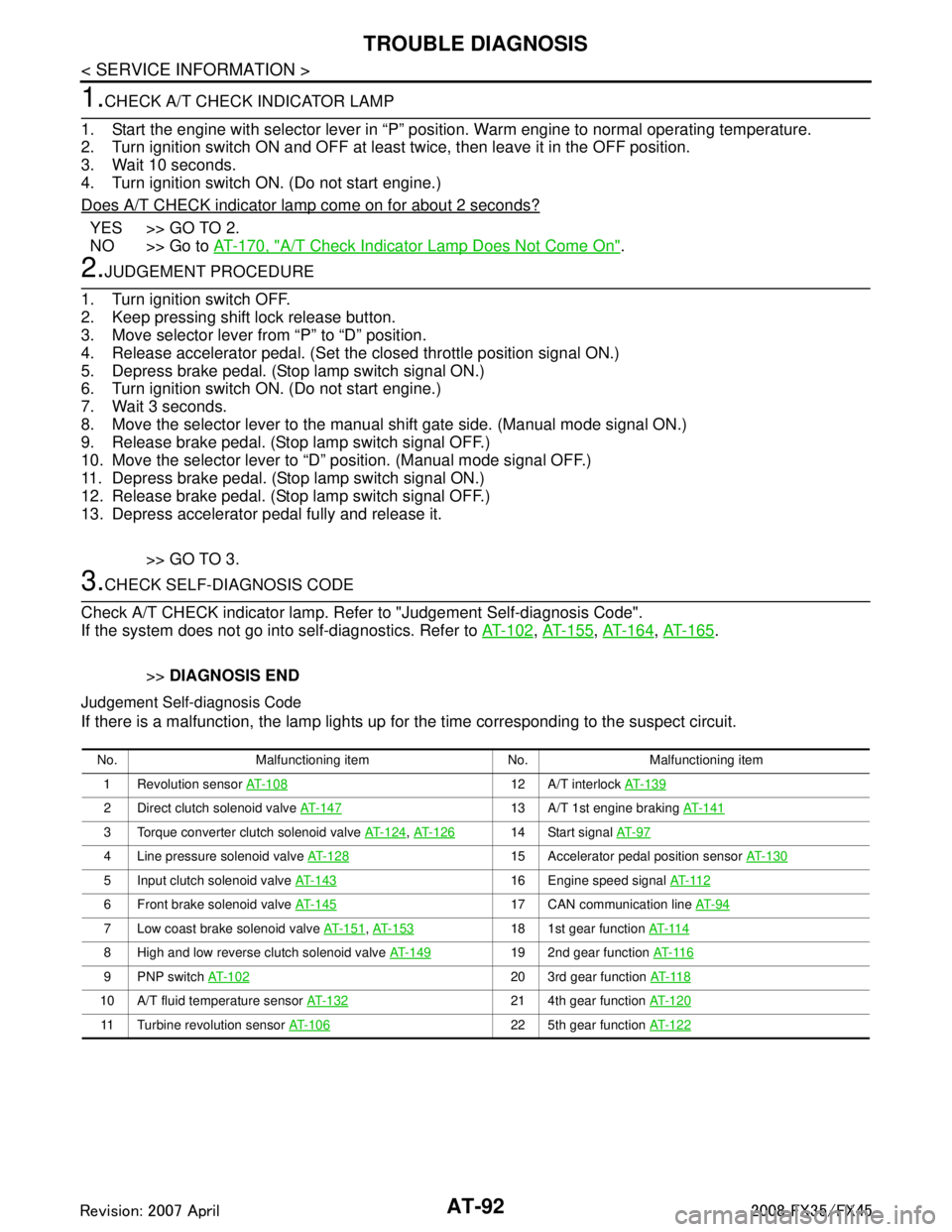

1.CHECK A/T CHECK INDICATOR LAMP

1. Start the engine with selector lever in “P” pos ition. Warm engine to normal operating temperature.

2. Turn ignition switch ON and OFF at least twice, then leave it in the OFF position.

3. Wait 10 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does A/T CHECK indicator lamp come on for about 2 seconds?

YES >> GO TO 2.

NO >> Go to AT-170, "

A/T Check Indicator Lamp Does Not Come On".

2.JUDGEMENT PROCEDURE

1. Turn ignition switch OFF.

2. Keep pressing shift lock release button.

3. Move selector lever from “P” to “D” position.

4. Release accelerator pedal. (Set the closed throttle position signal ON.)

5. Depress brake pedal. (Stop lamp switch signal ON.)

6. Turn ignition switch ON. (Do not start engine.)

7. Wait 3 seconds.

8. Move the selector lever to the manual shift gate side. (Manual mode signal ON.)

9. Release brake pedal. (Stop lamp switch signal OFF.)

10. Move the selector lever to “D” position. (Manual mode signal OFF.)

11. Depress brake pedal. (Stop lamp switch signal ON.)

12. Release brake pedal. (Stop lamp switch signal OFF.)

13. Depress accelerator pedal fully and release it.

>> GO TO 3.

3.CHECK SELF-DIAGNOSIS CODE

Check A/T CHECK indicator lamp. Refer to "Judgement Self-diagnosis Code".

If the system does not go into self-diagnostics. Refer to AT-102

, AT-155, AT-164, AT-165.

>> DIAGNOSIS END

Judgement Self-diagnosis Code

If there is a malfunction, the lamp lights up fo r the time corresponding to the suspect circuit.

No. Malfunctioning item No. Malfunctioning item

1 Revolution sensor AT- 1 0 8

12 A/T interlock AT- 1 3 9

2 Direct clutch solenoid valve AT- 1 4 713 A/T 1st engine braking AT-141

3 Torque converter clutch solenoid valve AT- 1 2 4, AT- 1 2 614 Start signal AT- 9 7

4 Line pressure solenoid valve AT- 1 2 815 Accelerator pedal position sensor AT- 1 3 0

5 Input clutch solenoid valve AT- 1 4 316 Engine speed signal AT- 11 2

6 Front brake solenoid valve AT- 1 4 517 CAN communication line AT- 9 4

7 Low coast brake solenoid valve AT- 1 5 1, AT- 1 5 318 1st gear function AT- 11 4

8 High and low reverse clutch solenoid valve AT- 1 4 919 2nd gear function AT- 11 6

9 PNP switch AT- 1 0 220 3rd gear function AT- 11 8

10 A/T fluid temperature sensor AT-13221 4th gear function AT- 1 2 0

11 Turbine revolution sensor AT- 1 0 622 5th gear function AT- 1 2 2

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 228 of 3924

DTC P1815 MANUAL MODE SWITCHAT-155

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

DTC P1815 MANUAL MODE SWITCH

DescriptionINFOID:0000000001327319

Manual mode switch is installed in A/T device. It sends manual mode switch, shift up and shift down switch

signals to TCM.

TCM sends the switch signals to unified meter and A/ C amp. by CAN communication line. Then manual mode

switch position is indicated on the A/T indicator. For inspection, refer to AT-166

.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001327320

On Board Diagnosis LogicINFOID:0000000001327321

Diagnostic trouble code “P1815 MANU MODE SW/CIR” with CONSULT-IIII is detected when TCM monitors

Manual mode, Non manual mode, Up or Down switch signal, and detects as irregular when impossible input

pattern occurs 1 second or more.

Possible CauseINFOID:0000000001327322

Harness or connectors (These switches circuit is open or shorted.)

Manual mode select switch (Into control device)

Manual mode position select switch (Into control device)

DTC Confirmation ProcedureINFOID:0000000001327323

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “ECU INPUT SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine.

4. Drive vehicle and maintain the following conditions for at least 2 consecutive seconds. MANU MODE SW: ON

5. If DTC is detected, go to AT-158, "

Diagnosis Procedure".

Item name Condition Display Value

MANU MODE SW Manual shift gate position (neutral) ON

Other than the above OFF

NON M-MODE SW Manual shift gate position OFF

Other than the above ON

UP SW LEVER selector lever: + side ON

Other than the above OFF

DOWN SW LEVER selector lever: - side ON

Other than the above OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 239 of 3924

AT-166

< SERVICE INFORMATION >

A/T INDICATOR CIRCUIT

A/T INDICATOR CIRCUIT

DescriptionINFOID:0000000001327357

TCM sends the switch signals to unified meter and A/C amp. by CAN communication line. Then manual mode

switch position is indicated on the A/T indicator.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001327358

Diagnosis ProcedureINFOID:0000000001327359

1.CHECK INPUT SIGNALS

With CONSULT-III

1. Start engine.

2. Select “MAIN SIGNALS” in “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III and read

out the value of “GEAR”.

3. Drive vehicle in the manual mode, and confirm that the actual gear position and the meter's indication of

the position mutually coincide when the selector lever is shifted to the “+ (up)” or “- (down)” side (1st ⇔ 5th

gear).

OK or NG

OK >> INSPECTION END

NG >> Check the following.

A/T INDICATOR SYMPTOM CHART

Item name Condition Display value

GEAR During driving 1, 2, 3, 4, 5

Items Presumed Location of Trouble

The actual gear position does not change, or shifting into the man-

ual mode is not possible (no gear shifting in the manual mode pos-

sible).

The A/T indicator is not indicated. Manual mode switch

Refer to

AT- 1 5 5

.

A/T main system (Fail-safe function actuated)

Refer to AT- 8 4 , "

CONSULT-III Function (TRANSMISSION)".

The actual gear position changes, but the A/T indicator is not indi-

cated. Perform the self-diagnosis function.

Refer to

AT- 8 4 , "

CONSULT-III Function (TRANSMISSION)".

The actual gear position and the indication on the A/T indicator do

not coincide. Perform the self-diagnosis function.

Refer to

AT- 8 4 , "

CONSULT-III Function (TRANSMISSION)".

Only a specific position or positions is/are not indicated on the A/

T indicator. Check the unified meter and A/C amp.

Refer to

DI-5

.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 243 of 3924

AT-170

< SERVICE INFORMATION >

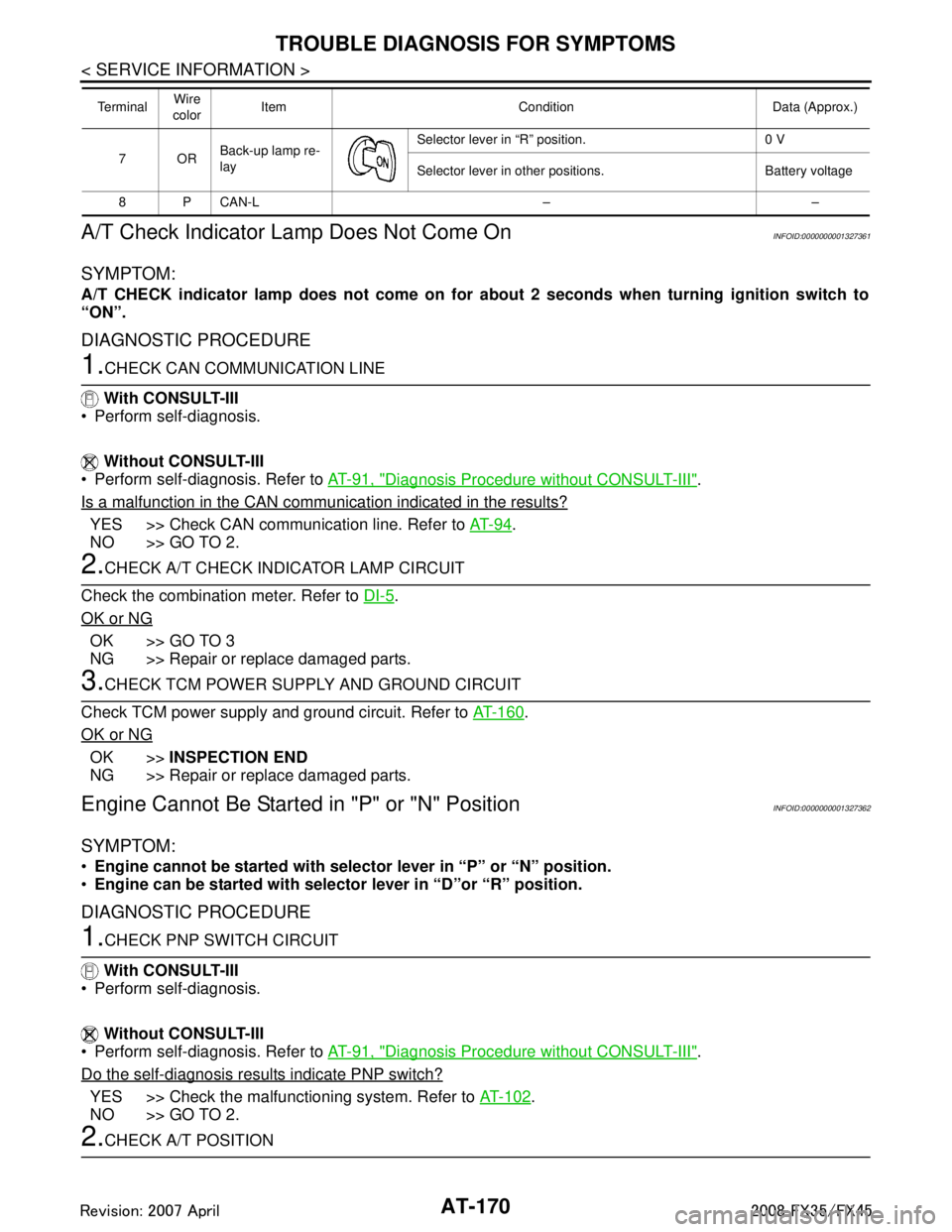

TROUBLE DIAGNOSIS FOR SYMPTOMS

A/T Check Indicator Lamp Does Not Come On

INFOID:0000000001327361

SYMPTOM:

A/T CHECK indicator lamp does not come on for ab out 2 seconds when turning ignition switch to

“ON”.

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION LINE

With CONSULT-III

Perform self-diagnosis.

Without CONSULT-III

Perform self-diagnosis. Refer to AT-91, "

Diagnosis Procedure without CONSULT-III".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 9 4.

NO >> GO TO 2.

2.CHECK A/T CHECK INDICATOR LAMP CIRCUIT

Check the combination meter. Refer to DI-5

.

OK or NG

OK >> GO TO 3

NG >> Repair or replace damaged parts.

3.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to AT-160

.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Engine Cannot Be Started in "P" or "N" PositionINFOID:0000000001327362

SYMPTOM:

Engine cannot be started with select or lever in “P” or “N” position.

Engine can be started with selector lever in “D”or “R” position.

DIAGNOSTIC PROCEDURE

1.CHECK PNP SWITCH CIRCUIT

With CONSULT-III

Perform self-diagnosis.

Without CONSULT-III

Perform self-diagnosis. Refer to AT-91, "

Diagnosis Procedure without CONSULT-III".

Do the self-diagnosis results indicate PNP switch?

YES >> Check the malfunctioning system. Refer to AT-102.

NO >> GO TO 2.

2.CHECK A/T POSITION

7OR Back-up lamp re-

lay Selector lever in “R” position. 0 V

Selector lever in other positions. Battery voltage

8 P CAN-L – –

Te r m i n a l

Wire

color Item Condition Data (Approx.)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 278 of 3924

SHIFT CONTROL SYSTEMAT-205

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

SHIFT CONTROL SYSTEM

Control Device Remo val and InstallationINFOID:0000000001327383

REMOVAL

CAUTION:

Make sure that parking brake is a pplied before removal/installation.

1. Disconnect lower lever of control device and control rod.

1. Selector lever knob 2. Lock pin 3. Position indicator plate

4. A/T device harness connector 5. Snap pin 6. Conical washer

7. Plain washer 8. Busing 9. Collar

10. Control rod 11. Bracket 12. Dust cover

13. Dust cover plate 14. Shift lock solenoid and park position switch assembly15. Control device assembly

16. Position lamp

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SCIA7753E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 280 of 3924

SHIFT CONTROL SYSTEMAT-207

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

1. Disconnect lower lever of control device and control rod.

2. Remove manual lever from A/T assembly.

3. Remove control rod from vehicle.

INSTALLATION

Install in reverse order of removal. Be careful of the following:

After installation is completed, adjust and check A/T position. Refer to AT-207, "

Adjustment of A/T Position"

and AT-207, "Checking of A/T Position".

Adjustment of A/T PositionINFOID:0000000001327385

1. Loosen nut of control rod.

2. Place PNP switch and selector lever in “P” position.

3. While pressing lower lever toward rear of vehicle (in “P” position

direction), tighten nut to the specified torque. Refer to AT-206,

"Control Rod Removal and Installation".

CAUTION:

Do not push the bracket.

Checking of A/T PositionINFOID:0000000001327386

1. Place selector lever in “P” posit ion, and turn ignition switch ON.

2. Check selector lever can be shifted to other than “P” position when brake pedal is depressed. Also check

selector lever can be shifted from “P” position only when brake pedal is depressed.

3. Move the selector lever and check for excessive effort, sticking, noise or rattle.

4. Check the selector lever stops at each position wit h the feel of engagement when it is moved through all

the positions. Check whether or not t he actual position the selector lever is in matches the position shown

by the shift position indicator and the transmission body.

5. The method of operating the lever to individual positions cor- rectly should be as shown in the figure.

6. When selector button is pressed in “P”, “R”, or “N” position with-

out applying forward/backward force to selector lever, check but-

ton operation for sticking.

7. Check the back-up lamps illuminate only when lever is placed in the “R” position. Check the back-up lamps does not illuminate

when selector lever is pushed against “R” position in the “P” or

“N” position.

8. Check the engine can only be started with the selector lever in the “P” and “N” positions. (With selector lever in the “P” position,

engine can be started even when selector lever is moved for-

ward and backward.)

9. Check transmission is locked completely in “P” position.

10. When selector lever is set to manual shift gate, check manual mode is displayed on combination meter. Shift selector lever to “+” and “-” sides, and check set shift position changes. (Only while a vehicle is oper-

ating.)

SCIA5736E

SCIA2119E

SCIA7465E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 410 of 3924

PRECAUTIONSATC-5

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Never release refrigerant into the air. Use appr oved recovery/recycling equipment to capture the

refrigerant every time an air co nditioning system is discharged.

Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

Never store or heat refrigerant containers above 52 °C (126 °F).

Never heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

Never intentionally drop, puncture, or incinerate refrigerant containers.

Keep refrigerant away from open flames: poison ous gas will be produced if refrigerant burns.

Refrigerant will displace oxygen, therefore be certa in to work in well ventilated areas to prevent suf-

focation.

Never pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air conditioning

systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have been

shown to be combustible at elevat ed pressures. These mixtures, if ig nited, may cause injury or prop-

erty damage. Additional health a nd safety information may be obtain ed from refrigerant manufactur-

ers.

Precaution for Refrigerant ConnectionINFOID:0000000001328155

A new type refrigerant connection has been introduced to a ll refrigerant lines except the following location.

Expansion valve to evaporator

Refrigerant pressure sensor to condenser

ABOUT ONE-TOUCH JOINT

Description

One-touch joints are pipe joints which do not require tools during piping connection.

Unlike conventional connection methods using union nuts and flanges, controlling tightening torque at con-

nection point is not necessary.

When removing a pipe joint, use a disconnector.

COMPONENT PARTS

FUNCTIONS OF COMPONENT PARTS

NOTE:

1 Pipe (Male-side) Retains O-rings.

Retains garter spring in cage (A).

2 Garter spring Anchors female-side piping.

3 Indicator ring When connection is made properly, this is ejected from male-side piping. (This part is no longer nec-

essary after connection.)

4 O-ring Seals connection point. (Not reusable)

5 Pipe (Female-side) Seals connection by compressing O-rings.

Anchors piping connection using flare (B) and garter spring.

RJIA4383J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 411 of 3924

ATC-6

< SERVICE INFORMATION >

PRECAUTIONS

Garter spring cannot be removed from cage of male-side piping.

Indicator ring remains near piping connection point, however, this is not a malfunction. (This is to check pip-

ing connection during factory assembly.)

REMOVAL

1. Clean piping connection point, and set a disconnector.

2. Slide disconnector in axial direction of piping, and stretch garter spring with tapered point of disconnector.

3. Slide disconnector farther so that inside diameter of garter spring becomes larger than outside diameter of

female-side piping flare. Then male-side piping can be disconnected.

INSTALLATION

1. Clean piping connection points, and insert male-side piping into female-side piping.

2. Push inserted male-side piping harder so that female-side piping flare stretches garter spring.

3. If inside diameter of garter spring becomes larger t han outside diameter of female-side piping flare, garter

spring seats on flare. Then, it fits in between male-side piping cage and female-side piping flare to anchor

piping connection point.

NOTE:

When garter spring seats on flare, and fits in betw een male-side piping cage and female-side piping flare,

it clicks.

CAUTION:

Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

Insert piping securely until a click is heard.

After piping connection is comple ted, pull male-side piping by hand to make sure that connec-

tion does not come loose.

NOTE: One-touch joint connection is used in points below.

SJIA0106E

SJIA0107E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C