steering INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3700 of 3924

AUTOMATIC DRIVE POSITIONERSE-61

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

NG >> GO TO 3.

3.CHECK HARNESS CONTINUITY 1

1. Disconnect automatic drive positioner contro l unit and door mirror (passenger side) connector.

2. Check continuity between automat ic drive positioner control unit

connector M50 terminal 33, 41 and door mirror (passenger side)

connector D32 terminal 1, 9.

3. Check continuity between automat ic drive positioner control unit

connector M50 terminals 33, 41 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between automatic drive positioner control unit and door mirror (pas-

senger side).

4.CHECK HARNESS CONTINUITY 2

1. Check continuity between automat ic drive positioner control unit

connector M49 terminal 5, 21 and door mirror (passenger side)

connector D32 terminal 2, 10.

2. Check continuity between automat ic drive positioner control unit

connector M49 terminal 5, 21 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between automatic drive positioner control unit and door mirror (pas-

senger side).

Check Steering and Door Mirror Sensor Power Supp ly and Ground CircuitINFOID:0000000001328127

1.CHECK STEERING AND DOOR MIRROR SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner control unit

connector M50 terminal 33 and ground.

OK or NG

OK >> GO TO 2.

NG >> Replace automatic drive positioner control unit.

2.CHECK STEERING AND DOOR MIRROR SENSOR GROUND CIRCUIT

33 (G/W) – 1 (BR) : Continuity should exist.

41 (B/Y) – 9 (G) : Continuity should exist.

33 (G/W) – Ground : Continuity should not exist.

41 (B/Y) – Ground : Continuity should not exist.

PIIB8586E

5 (OR) – 2 (LG) : Continuity should exist.

21 (G/Y) – 10 (P) : Cont

inuity should exist.

5 (OR) – Ground : Continuity should not exist.

21 (G/Y) – Ground : Contin uity should not exist.

PIIB8587E

33 (G/W) – Ground : Approx. 5V

PIIA4778E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3701 of 3924

SE-62

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

Check continuity between automatic drive positioner control unit

connector M50 terminal 41 and ground.

OK or NG

OK >> GO TO 3. (Door mirror sensor) GO TO 4. (Steering sensor)

NG >> Replace automatic drive positioner control unit.

3.CHECK HARNESS CONTINUITY (DOOR MIRROR SENSOR)

1. Disconnect automatic drive positioner control unit and door mirror (driver side or passenger side) connec-

tor.

2. Check continuity between automat ic drive positioner control unit

connector M50 terminal 33, 41 and door mirror connector D2

(driver side) or D32 (passenger side) terminal 1, 9.

3. Check continuity between automat ic drive positioner control unit

connector M50 terminal 33, 41 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between automatic dr ive positioner control unit and door mirror (driver

side or passenger side).

4.CHECK HARNESS CONTINUI TY (STEERING SENSOR)

1. Disconnect automatic drive positioner control uni t and tilt sensor and telescopic sensor connector.

2. Check continuity between automat ic drive positioner control unit

connector M50 terminal 33, 41 and tilt sensor and telescopic

sensor connector M28 terminal 1, 4.

3. Check continuity between automat ic drive positioner control unit

connector M50 terminal 33, 41 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between automatic driv e positioner control unit and tilt sensor and tele-

scopic sensor.

Check Front Door Switch (Driver Side) CircuitINFOID:0000000001328128

1.CHECK FUNCTION (WITH CONSULT-III)

With CONSULT-III

Touch “BCM” with “DOOR SW-DR” on the DATA MONITO R, check ON/OFF operation when the driver door is

open and closed. *: Refer to BL-36, "

CONSULT-III Function (BCM)".

41 (B/Y) – Ground : Cont

inuity should exist.

PIIA4779E

33 (G/W) – 1 (OR) : Continuity should exist.

41 (B/Y) – 9 (BR) : Continuity should exist.

33 (G/W) – Ground : Contin uity should not exist.

41 (B/Y) – Ground : Contin uity should not exist.

PIIB8586E

33 (G/W) – 1 (G/W) : Continuity should exist.

41 (B/Y) – 4 (B/Y) : Continuity should exist.

33 (G/W) – Ground : Continuity should not exist.

41 (B/Y) – Ground : Continuity should not exist.

PIIB8588E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3707 of 3924

SE-68

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

OK >> GO TO 3.

NG >> Repair or replace harness between driver seat control unit and power seat switch.

3.CHECK REAR LIFTING SWITCH

Rear lifting switch operate, check continuity betw een power seat switch connector B175 terminal 27, 40 and

61B.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace power seat switch.

Check Power Seat Switch Ground CircuitINFOID:0000000001328133

1.CHECK POWER SEAT SWITCH GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power seat switch connector.

3. Check continuity between power seat switch connector B175 terminal 61B and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between power seat switch and ground.

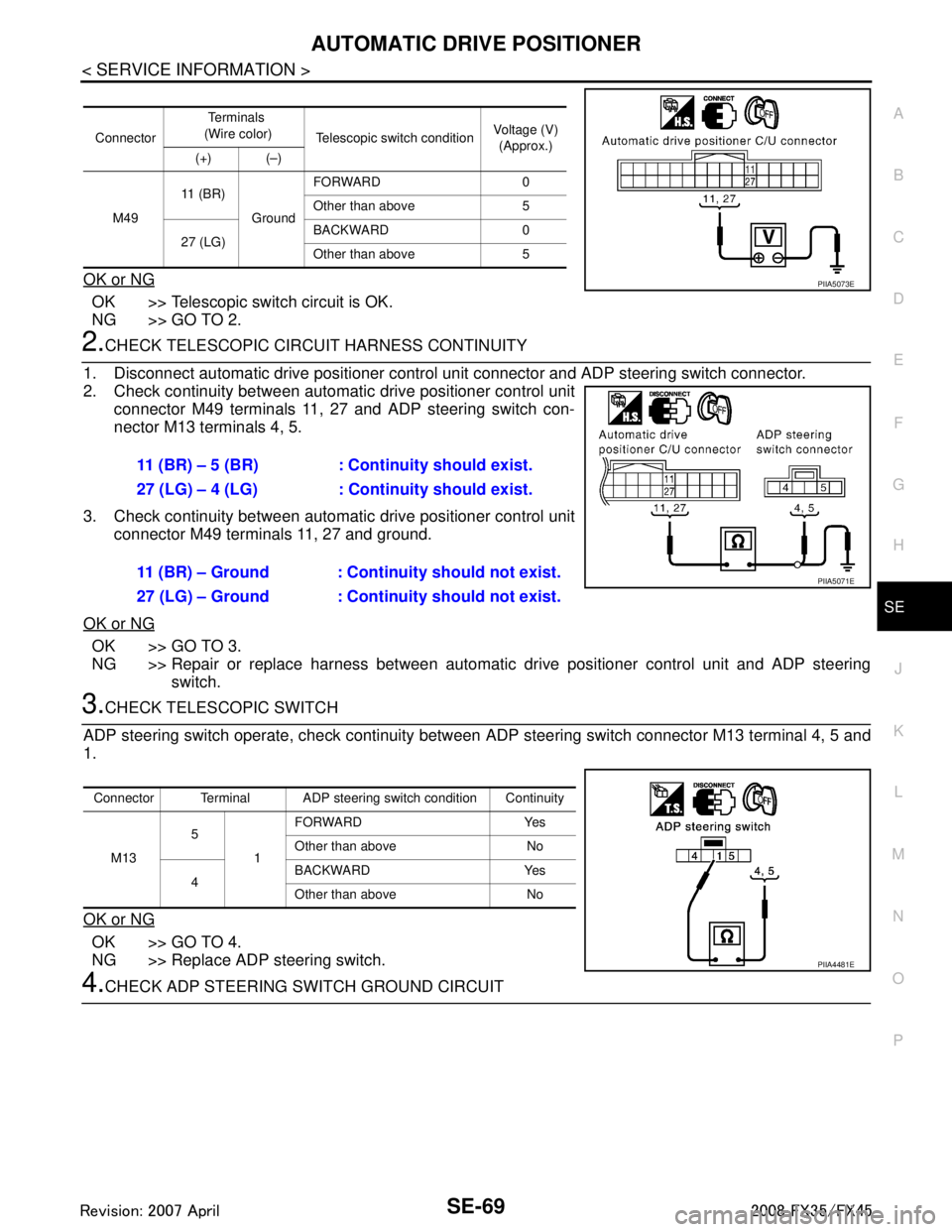

Check Telescopic Switch CircuitINFOID:0000000001328134

1.CHECK FUNCTION

With CONSULT-III

With “TELESCO SW-FR, TELESCO SW-RR” on the DA TA MONITOR, operate the ADP steering switch to

check ON/OFF operation.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Telescopic switch operate, check voltage between aut omatic drive positioner control unit connector and

ground.

Connector Terminal Rear lifting switch condition Continuity

B175 27

61BUP Yes

Other than above No

40 DOWN Yes

Other than above No

PIIB8596E

61B (B/Y) – Ground : Continuity should exist.

PIIB8597E

Monitor item

[OPERATION or UNIT] Contents

TELESCO SW-FR “ON/OFF” (ON/OFF) status judged from the telescoping

switch (FR) signal is displayed.

TELESCO SW-RR “ON/OFF” (ON/OFF) status judged from the telescoping

switch (RR) signal is displayed.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3708 of 3924

AUTOMATIC DRIVE POSITIONERSE-69

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

OK or NG

OK >> Telescopic switch circuit is OK.

NG >> GO TO 2.

2.CHECK TELESCOPIC CIRCUIT HARNESS CONTINUITY

1. Disconnect automatic drive positioner control unit connector and ADP steering switch connector.

2. Check continuity between automat ic drive positioner control unit

connector M49 terminals 11, 27 and ADP steering switch con-

nector M13 terminals 4, 5.

3. Check continuity between automat ic drive positioner control unit

connector M49 terminals 11, 27 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between automatic drive positioner control unit and ADP steering

switch.

3.CHECK TELESCOPIC SWITCH

ADP steering switch operate, check continuity between ADP steering switch connector M13 terminal 4, 5 and

1.

OK or NG

OK >> GO TO 4.

NG >> Replace ADP steering switch.

4.CHECK ADP STEERING SWITCH GROUND CIRCUIT

Connector Te r m i n a l s

(Wire color) Telescopic switch condition Voltage (V)

(Approx.)

(+) (–)

M49 11 ( B R )

GroundFORWARD 0

Other than above 5

27 (LG) BACKWARD 0

Other than above 5

PIIA5073E

11 (BR) – 5 (BR) : Continuity should exist.

27 (LG) – 4 (LG) : Continuity should exist.

11 (BR) – Ground : Continuity should not exist.

27 (LG) – Ground : Continuity should not exist.

PIIA5071E

Connector Terminal ADP steering switch condition Continuity

M13 5

1FORWARD Yes

Other than above No

4 BACKWARD Yes

Other than above No

PIIA4481E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3709 of 3924

SE-70

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

Check continuity between ADP steering switch connector M13 termi-

nal 1 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace or replace harness between ADP steeringswitch and ground.

Check Tilt Switch CircuitINFOID:0000000001328135

1.CHECK FUNCTION

With CONSULT-III

With “TILT SW-UP, TILT SW-DOWN” on the DATA MONI TOR, operate the ADP steering switch to check ON/

OFF operation.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Tilt switch operate, check voltage between automat ic drive positioner control unit connector and ground.

OK or NG

OK >> Tilt switch circuit is OK.

NG >> GO TO 2.

2.CHECK TILT SWITCH CIRCUIT HARNESS CONTINUITY

1. Disconnect automatic drive positioner control unit connector and ADP steering switch connector.

2. Check continuity between automat ic drive positioner control unit

connector M49 terminals 1, 17 and ADP steering switch connec-

tor M13 terminals 2, 3.

3. Check continuity between automat ic drive positioner control unit

connector M49 terminals 1, 17 and ground.

OK or NG

1 (B) – Ground : Continuity should exist.

PIIA3308E

Monitor item

[OPERATION or UNIT] Contents

TILT SW-UP “ON/OFF” (ON/OFF) status judged from the tilt switch

(UP) signal is displayed.

TILT SW-DOWN “ON/OFF” (ON/OFF) status judged from the tilt switch

(DOWN) signal is displayed.

Connector Te r m i n a l s

(Wire color) Tilt switch condition Voltage (V)

(Approx.)

(+) (–)

M49 1 (R)

GroundUP 0

Other than above 5

17 (R/B) DOWN 0

Other than above 5

PIIA5074E

1 (R) – 2 (R) : Continuity should exist.

17 (R/B) – 3 (R/B) : Continuity should exist.

1 (R) – Ground : Continuity should not exist.

17 (R/B) – Ground : Continuity should not exist.

PIIA5072E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3710 of 3924

AUTOMATIC DRIVE POSITIONERSE-71

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

OK >> GO TO 3.

NG >> Repair or replace harness between automatic drive positioner control unit and ADP steering

switch.

3.CHECK ADP TILT STEERING SWITCH

ADP steering switch operate, check c ontinuity between ADP steering switch.

OK or NG

OK >> GO TO 6.

NG >> Replace ADP steering switch.

4.CHECK ADP STEERING SWITCH GROUND CIRCUIT

Check continuity between ADP steer ing switch connector M13 termi-

nal 1 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between ADP steering switch

and ground.

Check Door Mirror Remo te Control Switch (Changeover Switch) CircuitINFOID:0000000001328136

1.CHECK FUNCTION

With CONSULT-III

Check the operation on “MIR CHNG SW-R” or “MIR CHNG SW-L” in the DATA MONITOR.

Without CONSULT-III

1. Turn ignition switch ACC.

2. Changeover switch operate, check voltage between aut omatic drive positioner control unit connector and

ground.

Connector Terminal ADP steering switch condition Continuity

M13 2

1UP Yes

Other than above No

3 DOWN Yes

Other than above No

PIIA4482E

1 (B) – Ground : Continuity should exist.

PIIA3310E

Monitor item

[OPERATION or UNIT] Contents

MIR CHNG SW–R “ON/

OFF” ON/OFF status judged from the door mirror re-

mote control switch (switching to RIGHT) signal is

displayed.

MIR CHNG SW–L “ON/

OFF” ON/OFF status judged from the door mirror re-

mote control switch (switching to LEFT) signal is

displayed.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3744 of 3924

PRECAUTIONSSRS-7

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612877

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for SRS "AIR BAG" and "SEAT BELT PRE-TENSIONER" Service

INFOID:0000000001327741

Do not use electrical test equipment to check SRS ci rcuits unless instructed to in this Service Manual.

Before servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are remov ed, it is still possible for the air bag and seat belt pre-

tensioner to deploy. Therefore, do not work on any SR S connectors or wires until at least 3 minutes have

passed.

Diagnosis sensor unit must always be installed with their arrow marks “ ⇐” pointing towards the front of the

vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

The spiral cable must be aligned with the neutral position since its rotations are limited. Do not turn steering

wheel and column after removal of steering gear.

Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Always replace instrument panel pad following front passenger air bag deployment.

Disposal, recycling, and transportation of air bag m odules and seat belt pre-tensioners should be performed

in compliance with applicable federal, state and local laws and regulations.

Occupant Classification System PrecautionINFOID:0000000001327742

Replace occupant classification system control uni t and passenger front seat cushion as an assembly.

Refer to Refer to Service Manual .

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3771 of 3924

SRS-34

< SERVICE INFORMATION >

DRIVER AIR BAG MODULE

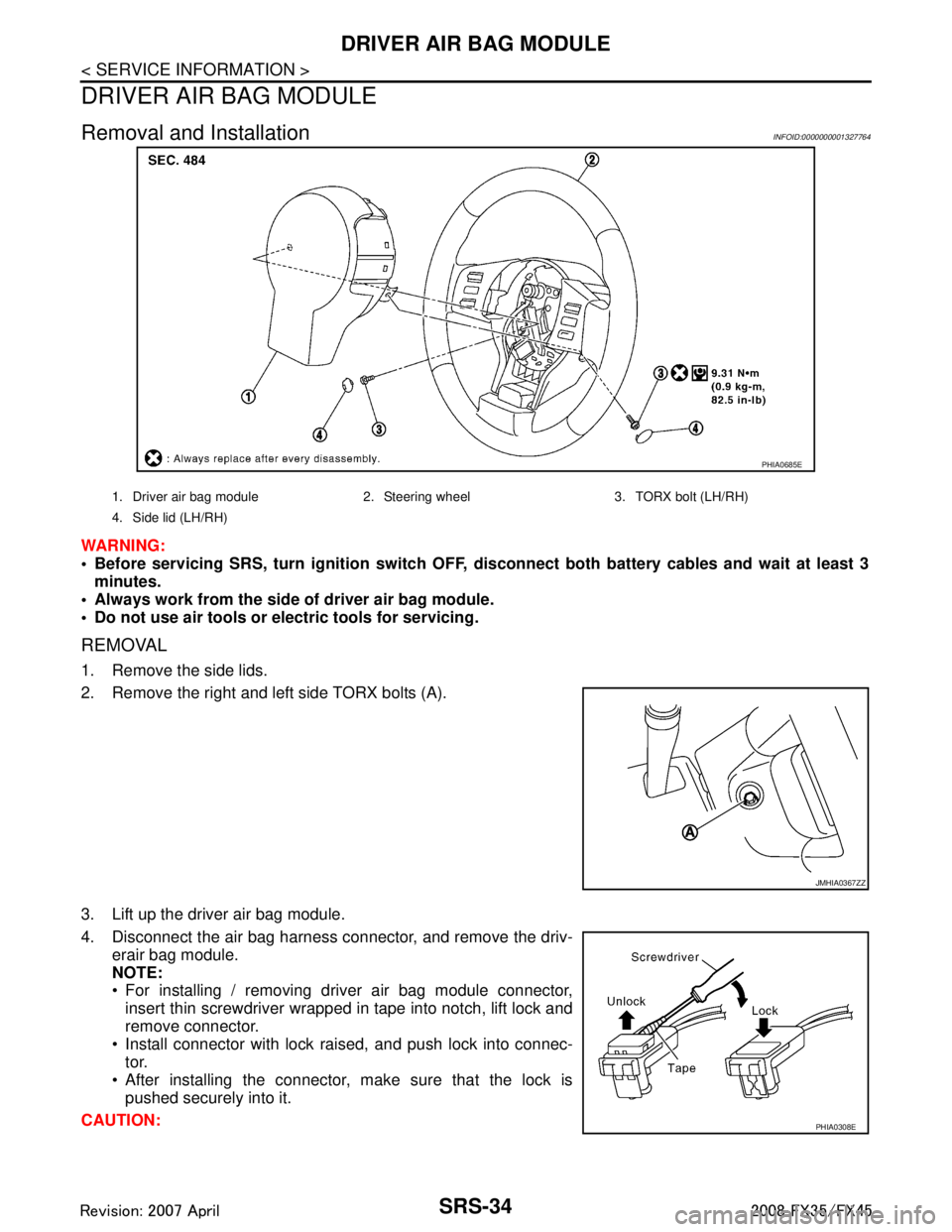

DRIVER AIR BAG MODULE

Removal and InstallationINFOID:0000000001327764

WARNING:

Before servicing SRS, turn ignition switch OFF, disconnect both ba ttery cables and wait at least 3

minutes.

Always work from the side of driver air bag module.

Do not use air tools or el ectric tools for servicing.

REMOVAL

1. Remove the side lids.

2. Remove the right and left side TORX bolts (A).

3. Lift up the driver air bag module.

4. Disconnect the air bag harness connector, and remove the driv-

erair bag module.

NOTE:

For installing / removing driver air bag module connector,insert thin screwdriver wrapped in tape into notch, lift lock and

remove connector.

Install connector with lock raised, and push lock into connec- tor.

After installing the connector, make sure that the lock is pushed securely into it.

CAUTION:

PHIA0685E

1. Driver air bag module 2. Steering wheel 3. TORX bolt (LH/RH)

4. Side lid (LH/RH)

JMHIA0367ZZ

PHIA0308E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3772 of 3924

DRIVER AIR BAG MODULESRS-35

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

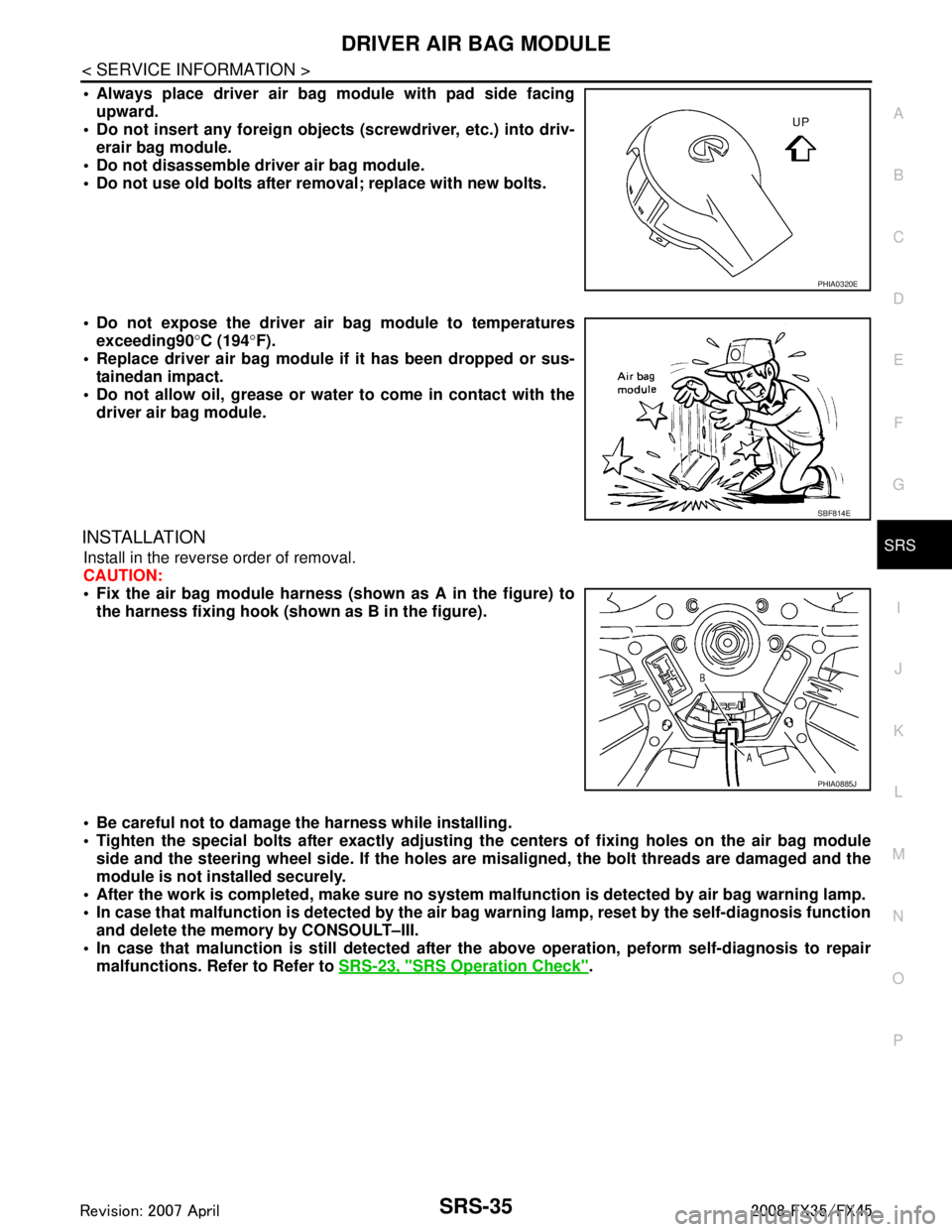

Always place driver air bag module with pad side facing upward.

Do not insert any foreign objects (screwdriver, etc.) into driv-

erair bag module.

Do not disassemble driver air bag module.

Do not use old bolts after removal; replace with new bolts.

Do not expose the driver air bag module to temperatures exceeding90 °C (194 °F).

Replace driver air bag module if it has been dropped or sus-

tainedan impact.

Do not allow oil, grease or water to come in contact with the

driver air bag module.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Fix the air bag module harness (shown as A in the figure) to

the harness fixing hook (s hown as B in the figure).

Be careful not to damage the harness while installing.

Tighten the special bolts after exactly adjusting the centers of fi xing holes on the air bag module

side and the steering wheel side. If the holes are misaligned, the bolt threads are damaged and the

module is not installed securely.

After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

In case that malfunction is detected by the air ba g warning lamp, reset by the self-diagnosis function

and delete the memory by CONSOULT–III.

In case that malunction is still detected after th e above operation, peform self-diagnosis to repair

malfunctions. Refer to Refer to SRS-23, "

SRS Operation Check".

PHIA0320E

SBF814E

PHIA0885J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3773 of 3924

SRS-36

< SERVICE INFORMATION >

SPIRAL CABLE

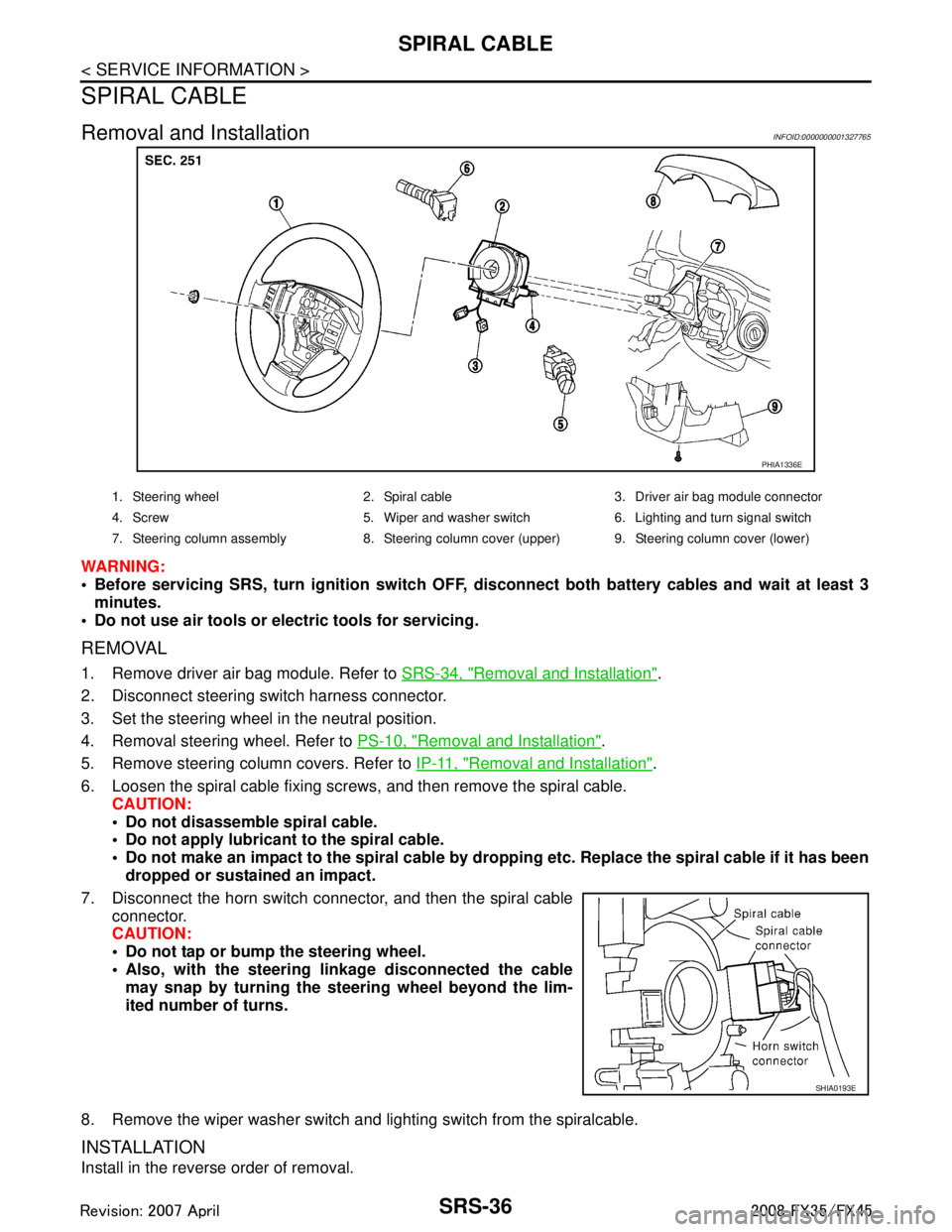

SPIRAL CABLE

Removal and InstallationINFOID:0000000001327765

WARNING:

Before servicing SRS, turn ignition switch OFF, disconnect both ba ttery cables and wait at least 3

minutes.

Do not use air tools or el ectric tools for servicing.

REMOVAL

1. Remove driver air bag module. Refer to SRS-34, "Removal and Installation".

2. Disconnect steering switch harness connector.

3. Set the steering wheel in the neutral position.

4. Removal steering wheel. Refer to PS-10, "

Removal and Installation".

5. Remove steering column covers. Refer to IP-11, "

Removal and Installation".

6. Loosen the spiral cable fixing screws, and then remove the spiral cable. CAUTION:

Do not disassemble spiral cable.

Do not apply lubricant to the spiral cable.

Do not make an impact to the spiral cable by dro pping etc. Replace the spiral cable if it has been

dropped or sustained an impact.

7. Disconnect the horn switch connec tor, and then the spiral cable

connector.

CAUTION:

Do not tap or bump the steering wheel.

Also, with the steering li nkage disconnected the cable

may snap by turning the st eering wheel beyond the lim-

ited number of turns.

8. Remove the wiper washer switch and lighting switch from the spiralcable.

INSTALLATION

Install in the reverse order of removal.

PHIA1336E

1. Steering wheel 2. Spiral cable 3. Driver air bag module connector

4. Screw 5. Wiper and washer switch 6. Lighting and turn signal switch

7. Steering column assembly 8. Steering column cover (upper) 9. Steering column cover (lower)

SHIA0193E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C