headlamp INFINITI FX35 2008 Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2387 of 3924

![INFINITI FX35 2008 Owners Guide

ELECTRICAL LOAD SIGNALEC-1147

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000001327048

The electrical load signal (Headlamp switch si INFINITI FX35 2008 Owners Guide

ELECTRICAL LOAD SIGNALEC-1147

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000001327048

The electrical load signal (Headlamp switch si](/img/42/57017/w960_57017-2386.png)

ELECTRICAL LOAD SIGNALEC-1147

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000001327048

The electrical load signal (Headlamp switch signal, r

ear window defogger switch signal, etc.) is transferred

through the CAN communication line from BCM to ECM via IPDM E/R.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000001327049

Specification data are reference values.

Diagnosis ProcedureINFOID:0000000001327050

1.CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-I

1. Turn ignition switch ON.

2. Connect CONSULT-III and select “DATA MONITOR” mode.

3. Select “LOAD SIGNAL” and check indication under the following conditions.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

Check “LOAD SIGNAL” indication under the following conditions.

OK or NG

OK >> GO TO 3.

NG >> GO TO 5.

3.CHECK HEATER FAN SIGNAL CIRCUIT OVERALL FUNCTION

Select “HEATER FAN SW” and check indication under the following conditions.

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

4.CHECK REAR WINDOW DEFOGGER SYSTEM

MONITOR ITEM CONDITION SPECIFICATION

LOAD SIGNAL Ignition switch: ON Rear window defogger switch: ON

and/or lighting switch: 2nd position

ON

Rear window defogger switch and lighting

switch: OFF OFF

HEATER FAN SW Engine: After warming up, idle the

engine Heater fan switch: ON ON

Heater fan switch: OFF OFF

Condition Indication

Rear window defogger switch: ON ON

Rear window defogger switch: OFF OFF

Condition Indication

Lighting switch: ON at 2nd position ON

Lighting switch: OFF OFF

Condition Indication

Heater fan control switch: ON ON

Heater fan control switch: OFF OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2388 of 3924

![INFINITI FX35 2008 Owners Guide

EC-1148

< SERVICE INFORMATION >[VK45DE]

ELECTRICAL LOAD SIGNAL

Refer to

GW-60.

>> INSPECTION END

5.CHECK HEADLAMP SYSTEM

Refer to LT- 5

.

>> INSPECTION END

6.CHECK HEATER FAN CONTROL SYSTEM

Refer t INFINITI FX35 2008 Owners Guide

EC-1148

< SERVICE INFORMATION >[VK45DE]

ELECTRICAL LOAD SIGNAL

Refer to

GW-60.

>> INSPECTION END

5.CHECK HEADLAMP SYSTEM

Refer to LT- 5

.

>> INSPECTION END

6.CHECK HEATER FAN CONTROL SYSTEM

Refer t](/img/42/57017/w960_57017-2387.png)

EC-1148

< SERVICE INFORMATION >[VK45DE]

ELECTRICAL LOAD SIGNAL

Refer to

GW-60.

>> INSPECTION END

5.CHECK HEADLAMP SYSTEM

Refer to LT- 5

.

>> INSPECTION END

6.CHECK HEATER FAN CONTROL SYSTEM

Refer to AT C - 3 2

.

>> INSPECTION END

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2453 of 3924

EI-16

< SERVICE INFORMATION >

FRONT BUMPER

12. Remove nuts of bumper stay, and remove bumper stay. Removenuts with power tool.

13. Remove nuts of front bumper guard bar, and remove front bumper guard bar. Remove nuts with power tool.

14. Remove fog lamps located in bumper fascia. Refer to LT-76,

"Removal and Installation".

INSTALLATION

Install in the reverse order of removal.

NOTE:

After installation, adjust the clearance.

REMOVAL AND INSTALLATION OF FILLET MOLDING

Removal

1. Remove screws of fillet molding.

2. Remove clips of fillet molding.

3. Remove fillet molding.

Installation

1. Clean adhesive portion of front fender with white gasoline.

2. Strip pattern from the new double adhesive tape and paste on front fender.

3. Fillet molding assembly hold with front fender.

REMOVAL AND INSTALLATION OF BUMPER CENTER MOLDING

Removal

1. Remove front bumper fascia. Refer to EI-15, "Removal and Installation".

2. Remove bumper center molding mounting nuts.

3. Disengage plastic pawls from bumper fascia.

4. Remove bumper center molding.

Installation

Install in the reverse order of removal.

PIIA4339E

Portion Clearance

Front bumper – Front grille A – A 0.5 – 3.5 mm (0.020 – 0.138 in)

Front bumper – Headlamp B – B 1.5 – 4.5 mm (0.059 – 0.177 in)

Front bumper – Front fender C – C 0.0 – 0.5 mm (0.000 – 0.020 in)

PIIA4350E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3029 of 3924

![INFINITI FX35 2008 Owners Guide

TROUBLE DIAGNOSISLAN-9

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Example: Main Line Between Data Link

Connector and ABS Actuator and Electr ic Unit (Control Unit) O INFINITI FX35 2008 Owners Guide

TROUBLE DIAGNOSISLAN-9

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Example: Main Line Between Data Link

Connector and ABS Actuator and Electr ic Unit (Control Unit) O](/img/42/57017/w960_57017-3028.png)

TROUBLE DIAGNOSISLAN-9

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Example: Main Line Between Data Link

Connector and ABS Actuator and Electr ic Unit (Control Unit) Open Circuit

Example: CAN-H, CAN-L Harness Short Circuit

SKIB8740E

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front wip-

er switch being in the intermittent position.

EPS control unit The steering effort increases.

Combination meter The shift position indicator and OD OFF indicator turn OFF.

The speedometer is inoperative.

The odo/trip meter stops.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

SKIB8741E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3030 of 3924

![INFINITI FX35 2008 Owners Guide

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000001451950

CAN Diagnostic Support MonitorINFOID:0000000001451951

CONSULT-III and CAN diagnostic support m INFINITI FX35 2008 Owners Guide

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000001451950

CAN Diagnostic Support MonitorINFOID:0000000001451951

CONSULT-III and CAN diagnostic support m](/img/42/57017/w960_57017-3029.png)

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000001451950

CAN Diagnostic Support MonitorINFOID:0000000001451951

CONSULT-III and CAN diagnostic support monitor (on-boar d diagnosis function) are used for detecting root

cause.

MONITOR ITEM (CONSULT-III)

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

Engine speed drops.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

The room lamp does not turn ON.

The engine does not start (if an error or malfunction occurs while turning the igni- tion switch OFF.)

The steering lock does not release (if an error or malfunction occurs while turning the ignition switch OFF.)

EPS control unit The steeri ng effort increases.

Combination meter The tachometer and the speedometer do not move.

Warning lamps turn ON.

Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

DTC

Self-diagnosis item

(CONSULT-III indication) DTC detection condition Inspection/Action

U1000 CAN COMM CIRCUIT When ECM is not transmitting or receiving CAN

communication signal of OBD (emission-related

diagnosis) for 2 seconds or more.

Refer to LAN-13

.

When a control unit (except for ECM) is not

transmitting or receiving CAN communication

signal for 2 seconds or more.

U1001 CAN COMM CIRCUIT When ECM is not transmitting or receiving CAN

communication signal other than OBD (emis-

sion-related diagnosis) for 2 seconds or more.

U1002 SYSTEM COMM When a control unit is not transmitting or receiv-

ing CAN communication signal for 2 seconds or

less. Start the inspection. Re-

fer to the applicable sec-

tion of the indicated

control unit.

U1010 CONTROL UNIT [CAN] When an error is detected during the initial diag-

nosis for CAN controller of each control unit. Replace the control unit

indicating “U1010”.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3103 of 3924

LT-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION LT

A

B

LT

N

O P

CONTENTS

LIGHTING SYSTEM

SERVICE INFORMATION .. ..........................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

General Precaution for Service Operation ................4

HEADLAMP - XENON TYPE - ............................5

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

5

System Description ...................................................5

CAN Communication System Description .................7

CAN Communication Unit .........................................7

Schematic .................................................................8

Wiring Diagram - H/LAMP - .......................................9

Terminal and Reference Value for BCM .................12

Terminal and Reference Value for IPDM E/R .........14

How to Proceed with Trouble Diagnosis .................14

Preliminary Check ...................................................15

CONSULT-III Functions (BCM) ...............................16

CONSULT-III Functions (IPDM E/R) .......................17

Headlamp Does Not Change To High Beam (Both

Sides) ......................................................................

18

Headlamp Does Not Change To High Beam (One

Side) ........................................................................

20

Headlamp Low Beam Does Not Illuminate (Both

Sides) .................................................................. ....

21

Headlamp Low Beam Does Not Illuminate (One

Side) .................................................................... ....

23

Headlamp RH Low Beam and High Beam Does

Not Illuminate ..........................................................

24

Headlamp LH Low Beam and High Beam Does

Not Illuminate ..........................................................

25

Headlamps Does Not Turn OFF .............................26

General Information for Xenon Headlamp Trouble

Diagnosis ................................................................

26

Caution: ...................................................................26

Xenon Headlamp Trouble Diagnosis ......................27

Aiming Adjustment ..................................................27

Bulb Replacement ...................................................28

Removal and Installation ..................................... ....30

Disassembly and Assembly .....................................30

DAYTIME LIGHT SYSTEM ...............................32

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

32

System Description ..................................................32

CAN Communication System Description ...............33

CAN Communication Unit ........................................33

Schematic ................................................................34

Wiring Diagram - DTRL - .........................................35

Terminal and Reference Value for BCM ..................38

How to Proceed with Trouble Diagnosis ..................41

Preliminary Check ...................................................41

CONSULT-III Functions (BCM) ...............................43

Daytime Light Control Does Not Operate Properly ....44

Aiming Adjustment ...................................................46

Bulb Replacement ...................................................46

Removal and Installation .........................................46

Disassembly and Assembly .....................................46

AUTO LIGHT SYSTEM .....................................47

Component Parts and Harness Connector Loca-

tion ...........................................................................

47

System Description ..................................................47

CAN Communication System Description ...............48

CAN Communication Unit ........................................48

Major Component and Functions ............................48

Schematic ................................................................49

Wiring Diagram - AUTO/L - .....................................50

Terminal and Reference Value for BCM ..................52

Terminal and Reference Value for IPDM E/R ..........54

How to Proceed with Trouble Diagnosis ..................54

Preliminary Check ...................................................55

CONSULT-III Functions (BCM) ...............................56

CONSULT-III Functions (IPDM E/R) .......................57

Symptom Chart ........................................................58

Lighting Switch Inspection .......................................58

Optical sensor System Inspection ...........................59

Removal and Installation of Optical Sensor .............60

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3104 of 3924

LT-2

HEADLAMP AIMING CONTROL ......................61

Schematic ............................................................ ...61

Wiring Diagram - H/AIM - .......................................62

Removal and Installation ........................................64

Switch Circuit Inspection ........................................65

FRONT FOG LAMP ...........................................66

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

66

System Description .................................................66

CAN Communication System Description ..............67

CAN Communication Unit .......................................67

Wiring Diagram - F/FOG - ......................................68

Terminal and Reference Value for BCM .................69

Terminal and Reference Value for IPDM E/R .........70

How to Proceed with Trouble Diagnosis .................71

Preliminary Check ..................................................71

CONSULT-III Functions (BCM) ..............................72

CONSULT-III Functions (IPDM E/R) ......................72

Front Fog Lamps Do Not Illuminate (Both Sides) ...72

Front Fog Lamp Does Not Illuminate (One Side) ...74

Aiming Adjustment ..................................................75

Bulb Replacement ..................................................76

Removal and Installation ........................................76

TURN SIGNAL AND HAZARD WARNING

LAMPS ...............................................................

78

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

78

System Description .................................................78

CAN Communication System Description ..............80

CAN Communication Unit .......................................80

Schematic ...............................................................81

Wiring Diagram - TURN - ........................................82

Terminal and Reference Value for BCM .................84

Terminal and Reference Value for Rear Combina-

tion Lamp Control Unit ............................................

86

How to Proceed with Trouble Diagnosis .................88

Preliminary Check ..................................................88

CONSULT-III Functions (BCM) ..............................89

Turn Signal Lamp Does Not Operate .....................90

Rear Turn Signal Lamp Does Not Operate ............92

Hazard Warning Lamp Does Not Operate But

Turn Signal Lamp Operates ...................................

94

Bulb Replacement (Front Turn Signal Lamp) .........95

Bulb Replacement (Rear Turn Signal Lamp) ..........95

Removal and Installation of Front Turn Signal

Lamp .......................................................................

95

Removal and Installation of Rear Turn Signal

Lamp .......................................................................

95

Removal and Installation of Rear Combination

Lamp Control Unit ...................................................

95

LIGHTING AND TURN SIGNAL SWITCH .........96

Removal and Installation ..................................... ...96

HAZARD SWITCH .............................................97

Removal and Installation ..................................... ...97

COMBINATION SWITCH ..................................98

Wiring Diagram - COMBSW - .............................. ...98

Combination Switch Reading Function ...................98

Terminal and Reference Value for BCM .................99

CONSULT-III Functions (BCM) .............................103

Combination Switch Inspection .............................104

Removal and Installation .......................................107

STOP LAMP .....................................................108

Component Parts and Harness Connector Loca-

tion ....................................................................... .

108

System Description ...............................................108

Schematic .............................................................109

Wiring Diagram - STOP/L - ...................................110

Terminal and Reference Value for Rear Combina-

tion Lamp Control Unit ......................................... .

112

Stop Lamp Does Not Operate ...............................112

High-Mounted Stop Lamp .....................................114

Stop Lamp .............................................................115

Rear Combination Lamp Control Unit ...................115

BACK-UP LAMP ............................................ ..116

Wiring Diagram - BACK/L - .................................. .116

Bulb Replacement .................................................117

Removal and Installation .......................................117

PARKING, LICENSE PLATE AND TAIL

LAMPS ..............................................................

118

Component Parts and Harness Connector Loca-

tion ....................................................................... .

118

System Description ...............................................118

CAN Communication System Description ............120

CAN Communication Unit .....................................120

Schematic .............................................................121

Wiring Diagram - TAIL/L - .....................................122

Terminal and Reference Value for BCM ...............126

Terminal and Reference Value for IPDM E/R .......127

Terminal and Reference Value for Rear Combina-

tion Lamp Control Unit ......................................... .

128

How to Proceed with Trouble Diagnosis ...............128

Preliminary Check .................................................128

CONSULT-III Functions (BCM) .............................129

CONSULT-III Functions (IPDM E/R) .....................129

Parking, License Plate and Side Marker Lamps

Do Not Illuminate ..................................................

129

Tail Lamp Does Not Operate ................................133

Parking, License Plate, Side Maker and Tail

Lamps Do Not Turn OFF (After Approx. 10 Min-

utes) ......................................................................

134

License Plate Lamp ..............................................135

Front Parking Lamp ..............................................135

Tail Lamp ..............................................................135

Front Side Marker Lamp .......................................135

Rear Side Marker Lamp ........................................136

Rear Combination Lamp Control Unit ...................136

REAR COMBINATION LAMP ..........................137

Bulb Replacement ................................................ .137

Removal and Installation .......................................137

INTERIOR ROOM LAMP ..................................138

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3105 of 3924

LT-3

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Component Parts and Harness Connector Loca-

tion ......................................................................

..

138

System Description ...............................................138

Schematic .............................................................143

Wiring Diagram - ROOM/L - ..................................145

Terminal and Reference Value for BCM ...............153

How to Proceed with Trouble Diagnosis ...............154

Preliminary Check .................................................154

CONSULT-III Functions (BCM) .............................155

Interior Room Lamp Control Does Not Operate ....157

Map Lamp Control Does Not Operate ...................158

Personal Lamp Control Does Not Operate ...........160

Ignition Keyhole Illumination Control Does Not

Operate .................................................................

161

All Step Lamps Do Not Operate ............................162

All Interior Room Lamps Do Not Operate .............164

Bulb Replacement ............................................... ..164

Removal and Installation .......................................166

ILLUMINATION ...............................................169

System Description ................................................169

CAN Communication System Description .............170

CAN Communication Unit ......................................170

Schematic ..............................................................171

Wiring Diagram - ILL - ...........................................173

Bulb Replacement .................................................181

Removal and Installation .......................................182

BULB SPECIFICATIONS ................................183

Headlamp ..............................................................183

Exterior Lamp ........................................................183

Interior Lamp/Illumination ......................................183

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3106 of 3924

LT-4

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612924

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

General Precaution for Service OperationINFOID:0000000001328264

Never work with wet hands.

Xenon headlamp includes high voltage generating part. Be sure to disconnect battery negative cable (negative terminal) or power

fuse before removing, installing, or touching the xenon headlamp

(including lamp bulb).

Turn the lighting switch OFF before disconnecting and connecting the connector.

When turning the xenon headlamp on and while it is illuminated, never touch the harness, bulb, and socket of the headlamp.

When checking the headlamp on/off operation, check it on vehicle

and with the power connected to the vehicle-side connector.

Do not touch the headlamp bulb glass surface with bare hands or allow oil or grease to get on it. Do not touch the headl amp bulb just after the headlamp is turned off, because

it is very hot.

Install the xenon headlamp bulb socket co rrectly. If it is installed improperly, high-voltage leak or corona dis-

charge may occur that can melt the bulb, connecto r, and housing. Do not illuminate the xenon headlamp

bulb out of the headlamp housing. Doing so can cause fire and harm your eyes.

When the bulb has burned out, wrap it in a thick vinyl bag and discard. Do not break the bulb.

Leaving the bulb removed from the headlamp housing for a long period of time can deteriorate the perfor- mance of the lens and reflector (dirt, clouding). Al ways prepare a new bulb and have it on hand when replac-

ing the bulb.

When adjusting the headlamp aiming, turn the aiming adjus tment screw only in the tightening direction. (If it

is necessary to loosen the screw, first fully loosen the screw, and then turn it in the tightening direction.)

Do not use organic solvent (paint thinner or gasoline) to clean lamps and to remove old sealant.

PKID0793E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3107 of 3924

HEADLAMP - XENON TYPE -LT-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

HEADLAMP - XENON TYPE -

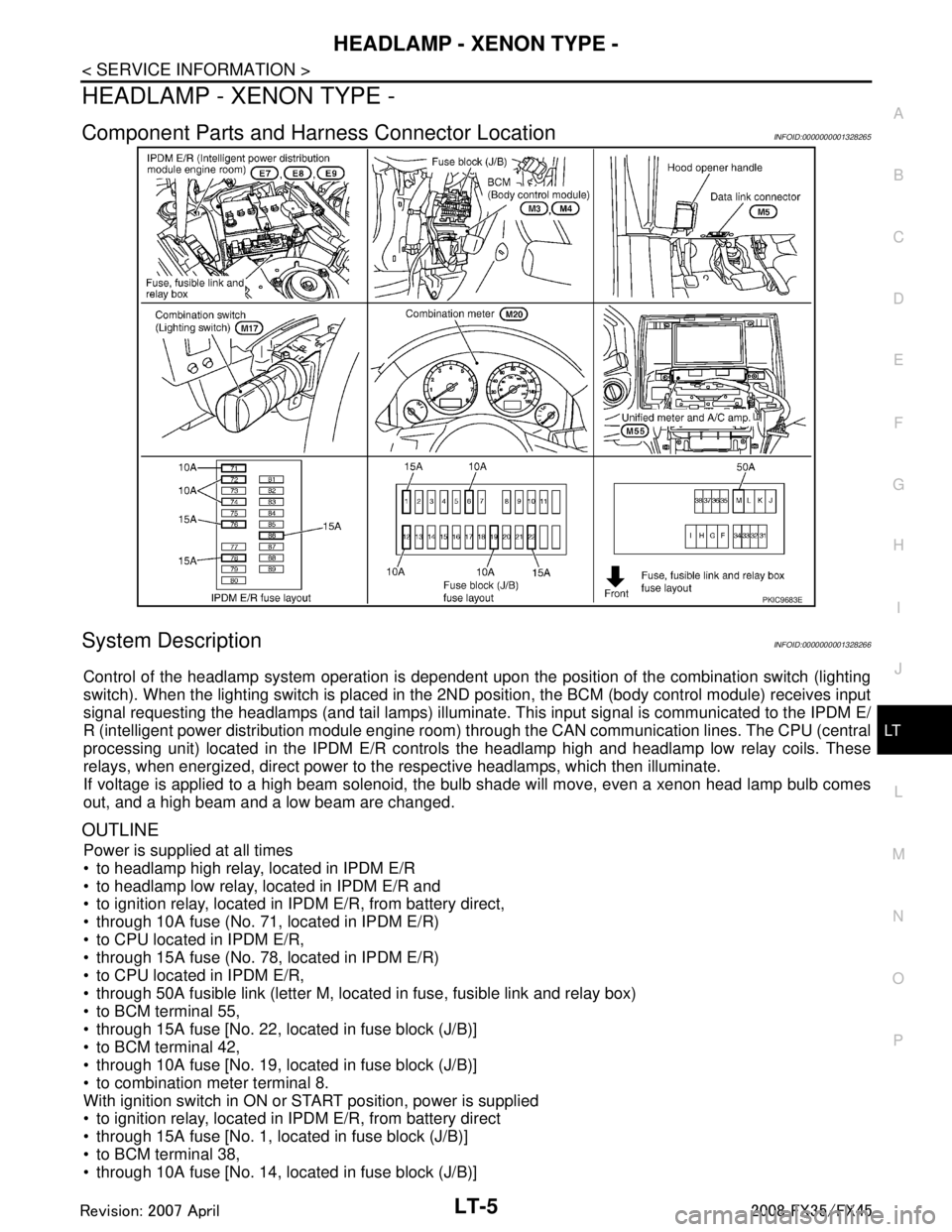

Component Parts and Har ness Connector LocationINFOID:0000000001328265

System DescriptionINFOID:0000000001328266

Control of the headlamp system operation is dependent upon t he position of the combination switch (lighting

switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives input

signal requesting the headlamps (and tail lamps) illuminate. This input signal is communicated to the IPDM E/

R (intelligent power distribution module engine room) through the CAN communication lines. The CPU (central

processing unit) located in the IPDM E/R contro ls the headlamp high and headlamp low relay coils. These

relays, when energized, direct power to the respective headlamps, which then illuminate.

If voltage is applied to a high beam solenoid, the bulb shade will move, even a xenon head lamp bulb comes

out, and a high beam and a low beam are changed.

OUTLINE

Power is supplied at all times

to headlamp high relay, located in IPDM E/R

to headlamp low relay, located in IPDM E/R and

to ignition relay, located in IPDM E/R, from battery direct,

through 10A fuse (No. 71, located in IPDM E/R)

to CPU located in IPDM E/R,

through 15A fuse (No. 78, located in IPDM E/R)

to CPU located in IPDM E/R,

through 50A fusible link (letter M, located in fuse, fusible link and relay box)

to BCM terminal 55,

through 15A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42,

through 10A fuse [No. 19, located in fuse block (J/B)]

to combination meter terminal 8.

With ignition switch in ON or START position, power is supplied

to ignition relay, located in IPDM E/R, from battery direct

through 15A fuse [No. 1, located in fuse block (J/B)]

to BCM terminal 38,

through 10A fuse [No. 14, located in fuse block (J/B)]

PKIC9683E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C