display INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2981 of 3924

GW-68

< SERVICE INFORMATION >

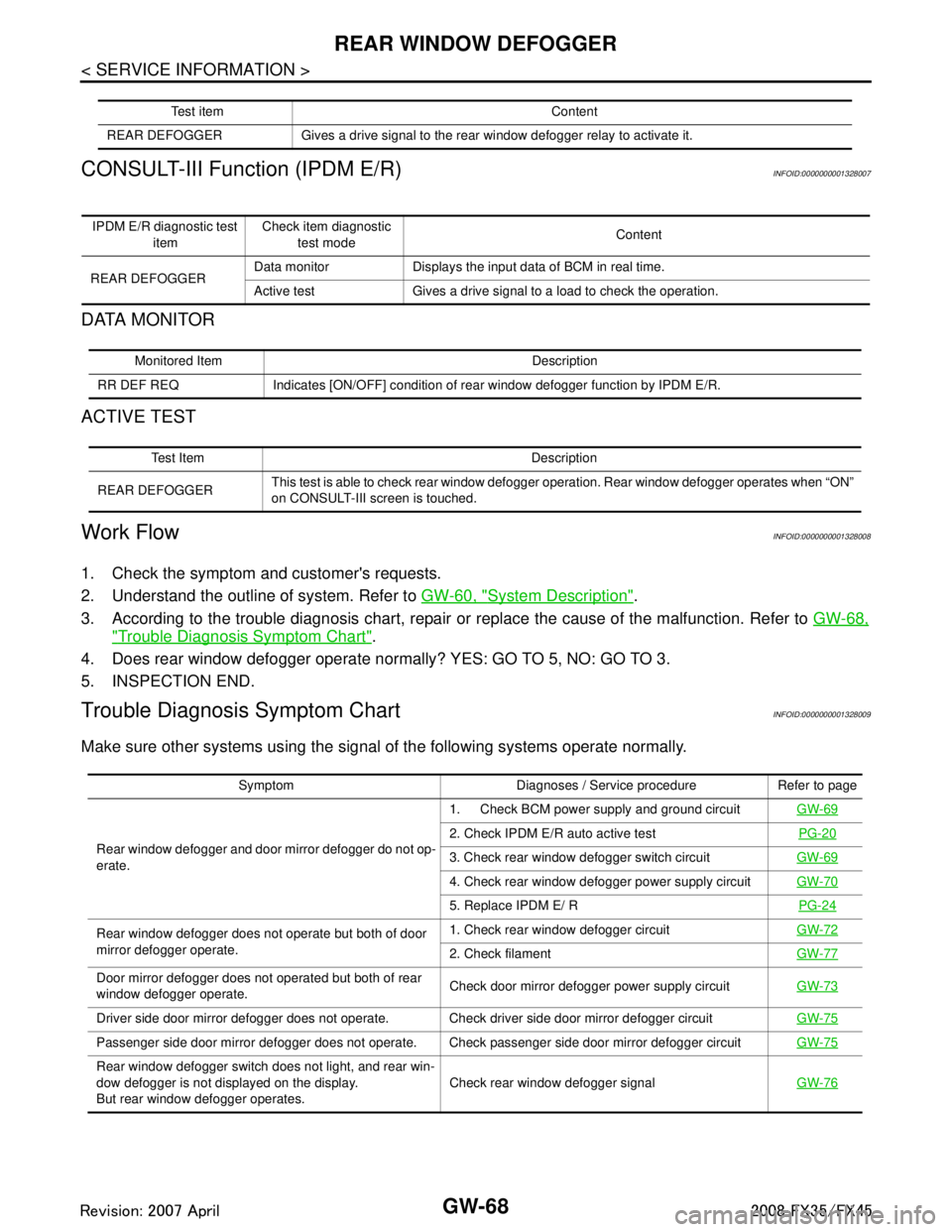

REAR WINDOW DEFOGGER

CONSULT-III Function (IPDM E/R)

INFOID:0000000001328007

DATA MONITOR

ACTIVE TEST

Work FlowINFOID:0000000001328008

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to GW-60, "

System Description".

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to GW-68,

"Trouble Diagnosis Symptom Chart".

4. Does rear window defogger operate no rmally? YES: GO TO 5, NO: GO TO 3.

5. INSPECTION END.

Trouble Diagnosis Symptom ChartINFOID:0000000001328009

Make sure other systems us ing the signal of the following systems operate normally.

Test item Content

REAR DEFOGGER Gives a drive sign al to the rear window defogger rela y to activate it.

IPDM E/R diagnostic test

item Check item diagnostic

test mode Content

REAR DEFOGGER Data monitor Displays the input data of BCM in real time.

Active test Gives a drive signal to a load to check the operation.

Monitored Item Description

RR DEF REQ Indicates [ON/OFF] condition of rear window defogger function by IPDM E/R.

Test Item Description

REAR DEFOGGER This test is able to check rear window defogger operation. Rear window defogger operates when “ON”

on CONSULT-III screen is touched.

Symptom Diagnoses / Service procedure Refer to page

Rear window defogger and door mirror defogger do not op-

erate. 1. Check BCM power supply and ground circuit

GW-69

2. Check IPDM E/R auto active test PG-20

3. Check rear window defogger switch circuit GW-69

4. Check rear window defogger power supply circuit GW-70

5. Replace IPDM E/ R PG-24

Rear window defogger does not operate but both of door

mirror defogger operate. 1. Check rear window defogger circuit

GW-72

2. Check filament GW-77

Door mirror defogger does not operated but both of rear

window defogger operate. Check door mirror defogger power supply circuit

GW-73

Driver side door mirror defogger does not operate. Check driver side door mirror defogger circuit GW-75

Passenger side door mirror defogger does not operate. Check passenger side door mirror defogger circuit GW-75

Rear window defogger switch does not light, and rear win-

dow defogger is not displayed on the display.

But rear window defogger operates. Check rear window defogger signal

GW-76

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2989 of 3924

GW-76

< SERVICE INFORMATION >

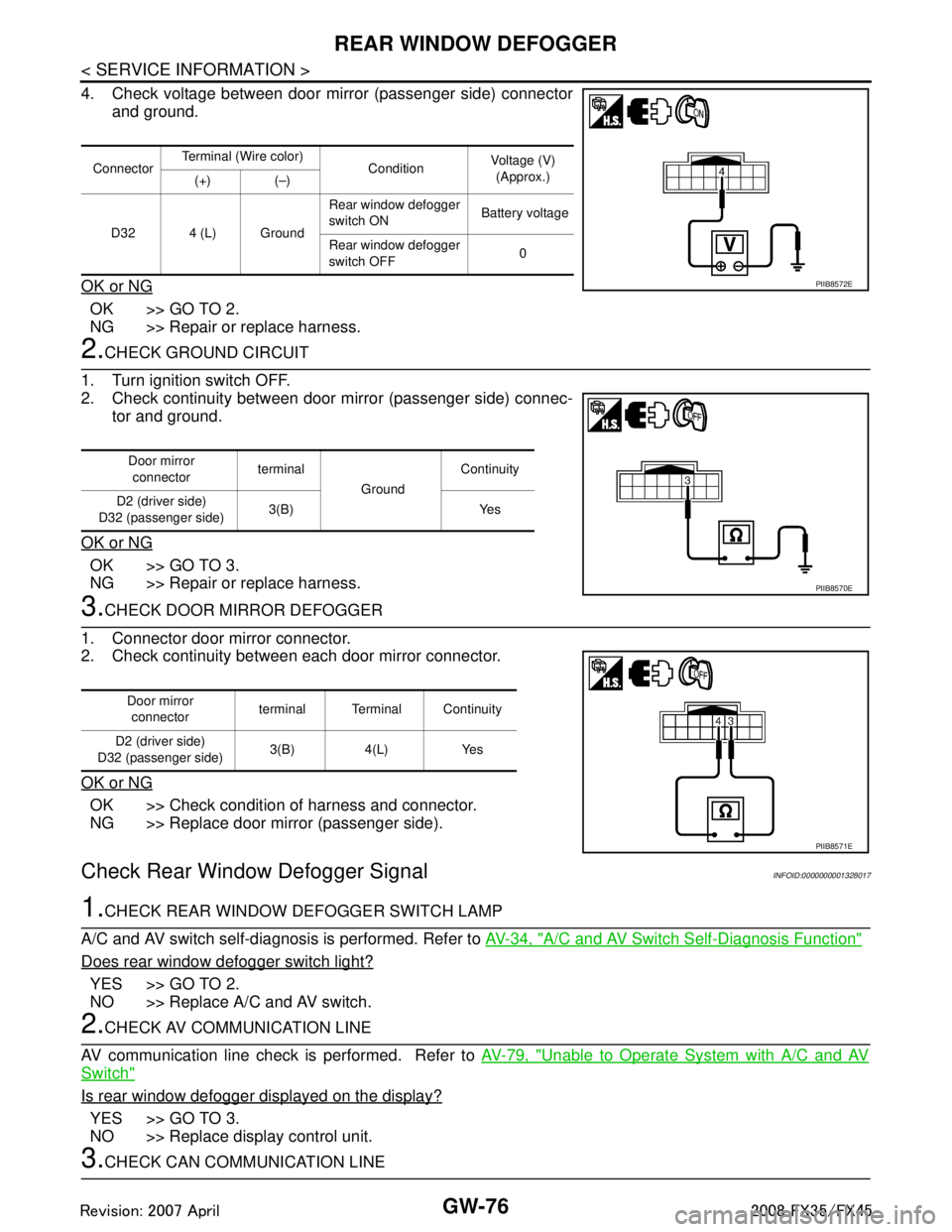

REAR WINDOW DEFOGGER

4. Check voltage between door mirror (passenger side) connectorand ground.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace harness.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between door mirror (passenger side) connec- tor and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK DOOR MIRROR DEFOGGER

1. Connector door mirror connector.

2. Check continuity between each door mirror connector.

OK or NG

OK >> Check condition of harness and connector.

NG >> Replace door mirror (passenger side).

Check Rear Windo w Defogger SignalINFOID:0000000001328017

1.CHECK REAR WINDOW DEFOGGER SWITCH LAMP

A/C and AV switch self-diagnosis is performed. Refer to AV-34, "

A/C and AV Switch Self-Diagnosis Function"

Does rear window defogger switch light?

YES >> GO TO 2.

NO >> Replace A/C and AV switch.

2.CHECK AV COMMUNICATION LINE

AV communication line check is performed. Refer to AV-79, "

Unable to Operate System with A/C and AV

Switch"

Is rear window defogger displayed on the display?

YES >> GO TO 3.

NO >> Replace display control unit.

3.CHECK CAN COMMUNICATION LINE

ConnectorTerminal (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

D32 4 (L) Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

PIIB8572E

Door mirror

connector terminal

GroundContinuity

D2 (driver side)

D32 (passenger side) 3(B) Yes

PIIB8570E

Door mirror

connector terminal Terminal Continuity

D2 (driver side)

D32 (passenger side) 3(B) 4(L) Yes

PIIB8571E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3011 of 3924

IP-10

< SERVICE INFORMATION >

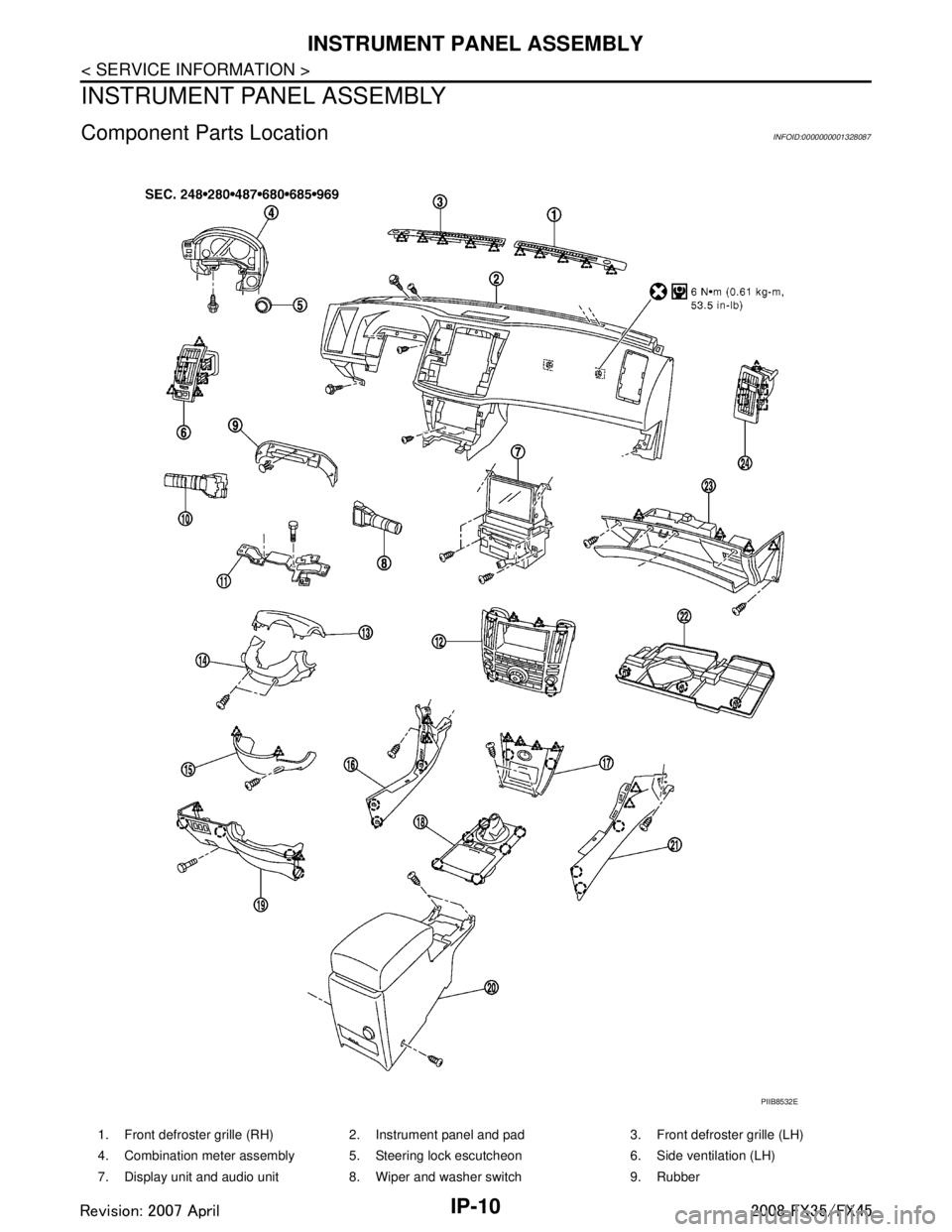

INSTRUMENT PANEL ASSEMBLY

INSTRUMENT PANEL ASSEMBLY

Component Parts LocationINFOID:0000000001328087

1. Front defroster grille (RH) 2. Instrument panel and pad 3. Front defroster grille (LH)

4. Combination meter assembly 5. Steering lock escutcheon 6. Side ventilation (LH)

7. Display unit and audio unit 8. Wiper and washer switch 9. Rubber

PIIB8532E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3012 of 3924

INSTRUMENT PANEL ASSEMBLYIP-11

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

Removal and InstallationINFOID:0000000001328088

WORK STEP

When removing instrument panel and pad, combination me ter, display unit and audio unit, center console take

steps in the order shown by the numbers below.

CAUTION:

Disconnect both battery cables in advance.

Disconnect air bag system line in advance.

Never temper with air bag lid or force air bag lid to open, as this may adversely affect air bag perfor-

mance.

Be careful not to scratch pad and other parts.

10. Lighting and turn signal switch 11. Combination meter bracket 12. Cluster lid C

13. Steering column upper cover 14. Steering column lower cover 15. Steering column front lower cover

16. Instrument side panel (LH) 17. Instrument clock finisher assembly 18. A/T console finisher assembly

19. Instrument driver lower panel 20. Center console 21. Instrument side panel (RH)

22. Instrument lower cover 23. Instrument passenger lower panel 24. Side ventilation (RH)

: Clip

: Pawl

: Metal clip

Parts Reference

page Instrument

panel and pad Combination

meter Display unit

and audio unit Center console

(A) Front kicking plate (RH/LH) EI-38

[1] [1]

(B) Dash side finisher (RH/LH) EI-38

[2] [2]

(C) Front pillar garnish (RH/LH) EI-38

[3]

(D) A/T select lever knob AT- 2 0 5

[4] [1]

(E) Instrument clock finisher assembly (E) Instrument

Clock Finisher [5] [2]

(F) A/T console finisher assembly (F) A/T Console

Finisher [6] [3]

(G) Instrument side panel (RH/LH) (G) Instrument

Side Panel (RH/LH) [7] [4]

(H) Center console (H) Center

Console [8] [5]

(I) Instrument lower cover (I) Instrument

Lower Cover [9]

(J) Instrument passenger lower panel (J) Instrument

Passenger Lower

Panel [10]

(K) Instrument driver lower panel (K) Instrument

Driver Lower Panel [11] [3]

(L) Steering column front lower cover (L) Steering

Column Front Lower Cover [12] [4]

(M) Steering column lower cover (M) Steering

Column Lower

Cover [13] [5]

(N) Steering column upper cover (N) Steering

Column Upper Cover [14] [6]

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3013 of 3924

![INFINITI FX35 2008 Service Manual

IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[]: Number indicates step in removal procedures.

REMOVAL

(A) Front Kicking Plate (RH/LH)

Remove front kicking plate (RH/LH). Refer to EI-38.

(B INFINITI FX35 2008 Service Manual

IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[]: Number indicates step in removal procedures.

REMOVAL

(A) Front Kicking Plate (RH/LH)

Remove front kicking plate (RH/LH). Refer to EI-38.

(B](/img/42/57017/w960_57017-3012.png)

IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[]: Number indicates step in removal procedures.

REMOVAL

(A) Front Kicking Plate (RH/LH)

Remove front kicking plate (RH/LH). Refer to EI-38.

(B) Dash Side Finisher (RH/LH)

1. Remove plastics nut.

2. Remove dash side finisher (RH/LH). Refer to EI-38

.

(C) Front Pillar Garnish (RH/LH)

Pull to inside of vehicle, disengage metal clips and remove front pillar garnish. Refer to EI-38.

(D) A/T Select Lever Knob

1. Pull down knob cover.

2. Remove lock-pin of select lever knob.

3. Lift up select lever knob and remove select lever knob.

Refer to AT-205, "

Control Device Removal and Installation".

(E) Instrument Clock Finisher

1. Remove screw and then pull back to your side of instrument

clock finisher.

2. Disconnect clips and harness connector, and remove instrument clock finisher.

(F) A/T Console Finisher

(O) Wiper and washer switch (O) Wiper and

Washer Switch [15] [7]

(P) Lighting and turn signal switch (P) Lighting and

Turn Signal Switch [16] [8]

(Q) Steering lock escutcheon (Q) Steering Lock

Escutcheon [17] [9]

(R) Combination meter assembly (R) Combination

Meter Assembly [18] [10]

(S) Cluster lid C (S) Cluster Lid C [19] [1] (T) Display unit and audio unit (T) Display Unit

and Audio Unit [20] [2]

(U) Front defroster grille (RH/LH) (U) Front

Defroster Grille (RH/LH) [21]

(V) Combination meter bracket (V) Combination

Meter Bracket [22]

(W) Side ventilation (RH/LH) (W) Side

Ventilation (RH/LH) [23]

(X) Instrument panel and pad (X) Instrument

Panel and Pad [24]

Parts

Reference

page Instrument

panel and pad Combination

meter Display unit

and audio unit Center console

: Clip

: Pawl

PIIB8535E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3016 of 3924

INSTRUMENT PANEL ASSEMBLYIP-15

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

2. Remove bolts with power tool and then disconnect harness con- nector.

CAUTION:

To prevent it from damaged by interference with the combina-

tion meter assembly, protect the combination meter assembly

with cloths.

(S) Cluster Lid C

1. Insert a remover into gap between instrument panel and pad, pull back to your side, and disconnect metal clips below.

2. Disconnect harness connectors, and remove cluster lid C. CAUTION:

Cover surroundings with cloth to avoid scratches or dam-

ages.

(T) Display Unit and Audio Unit

1. Remove screws with power tool.

2. Disconnect harness connector, and remove display unit and

audio unit.

CAUTION:

Unit is heavy, so be careful not to pinch your fingers when

working.

(U) Front Defroster Grille (RH/LH)

Insert a remover into gaps between front defroster grille (RH/LH) and

instrument panel and pad, lift front defroster grille up, and remove

front defroster grille (RH/LH).

(V) Combination Meter Bracket

PIIA5003E

: Clip

: Pawl

PIIB8533E

PIIB1335E

PIIA5009E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3021 of 3924

LAN-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION LAN

A

B

LAN

N

O P

CONTENTS

LAN SYSTEM

CAN FUNDAMENTAL

SERVICE INFORMATION .. ..........................

3

PRECAUTIONS .............................................. .....3

Precaution for Trouble Diagnosis ........................ ......3

Precaution for Harness Repair ..................................3

SYSTEM DESCRIPTION .....................................4

CAN Communication System .............................. ......4

Diag on CAN .............................................................5

TROUBLE DIAGNOSIS ......................................7

Condition of Error Detection ................................ ......7

Symptom When Error Occurs in CAN Communi-

cation System ...................................................... ......

7

Self-Diagnosis .........................................................10

CAN Diagnostic Support Monitor ............................10

TROUBLE DIAGNOSES WORK FLOW ............13

Information Needed for Trouble Diagnosis ......... ....13

How to Use CAN Communication Signal Chart ......13

Trouble Diagnosis Flow Chart .................................14

Trouble Diagnosis Procedure ..................................14

CAN

SERVICE INFORMATION .. .........................

36

INDEX FOR DTC ............................................ ....36

DTC No. Index .................................................... ....36

HOW TO USE THIS SECTION ...........................37

Caution ................................................................ ....37

Abbreviation List ......................................................37

PRECAUTIONS ..................................................38

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

38

Precaution for Trouble Diagnosis ............................38

Precaution for Harness Repair ................................38

TROUBLE DIAGNOSIS ....................................39

CAN Diagnostic Support Monitor ......................... ....39

CAN System Specification Chart .............................43

CAN Communication Signal Chart ..........................44

Schematic ................................................................54

Wiring Diagram - CAN - ...........................................55

Interview Sheet ........................................................58

Data Sheet ...............................................................58

CAN System (Type 1) ..............................................60

CAN System (Type 2) ..............................................61

CAN System (Type 3) ..............................................62

CAN System (Type 4) ..............................................63

CAN System (Type 5) ..............................................64

CAN System (Type 6) ..............................................65

CAN System (Type 7) ..............................................66

CAN system (Type 8) ..............................................67

Component Parts Location ......................................68

Harness Layout .......................................................68

Malfunction Area Chart ............................................68

Main Line Between TCM and Data Link Connector

....

69

Main Line Between Data Link Connector and Uni-

fied Meter and A/C Amp. .........................................

69

Main Line Between Unified Meter and A/C Amp.

and ABS Actuator and Electric Unit (Control Unit) ....

70

Main Line Between ABS Actu ator and Electric Unit

(Control Unit) and Driver Seat Control Unit .............

71

ECM Branch Line Circuit ..................................... ....72

AWD Control Unit Branch Line Circuit .....................72

Display Control Unit Branch Line Circuit .................73

ICC Unit Branch Line Circuit ................................ ....74

TCM Branch Line Circuit .........................................74

BCM Branch Line Circuit .........................................75

Data Link Connector Branch Line Circuit ................75

Intelligent Key Unit Branch Line Circuit ...................76

LDW Camera Unit Branch Line Circuit ....................76

Steering Angle Sensor Branch Line Circuit .............77

Unified Meter and A/C Amp. Branch Line Circuit ....78

ABS Actuator and Electric Unit (Control Unit)

Branch Line Circuit ..................................................

78

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3028 of 3924

![INFINITI FX35 2008 Service Manual

LAN-8

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

When data link connector branch line is open, transmission and reception INFINITI FX35 2008 Service Manual

LAN-8

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

When data link connector branch line is open, transmission and reception](/img/42/57017/w960_57017-3027.png)

LAN-8

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

When data link connector branch line is open, transmission and reception of CAN communication signals

are not affected. Therefore, no symptoms occur. Ho wever, be sure to repair malfunctioning circuit.

When data link connector branch line is open, “ECU list” displayed on the CONSULT-III “CAN DIAG SUP-

PORT MNTR” may be the same as when the CAN communication line has short-circuit. However, symp-

toms differ depending on the case. See below chart for the differences.

EPS control unit No rmal operation.

Combination meter Shift position indicator and OD OFF indicator turn OFF.

Warning lamps turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R Normal operation. Unit name Symptom

SKIB8739E

Unit name Symptom

ECM

Normal operation.

BCM

EPS control unit

Combination meter

ABS actuator and electric unit (control unit)

TCM

IPDM E/R

“ECU list” on the “CAN DIAG SUPPORT MNTR”(CONSULT-III) Difference of symptom

Data link connector branch line open circuit All Diag on CAN units are not

indicated.Normal operation.

CAN-H, CAN-L harness short-circuit Most of the units which are connected to the CAN

communication system enter fail-safe mode or are

deactivated.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3032 of 3924

![INFINITI FX35 2008 Service Manual

LAN-12

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Vehicle Display

ItemResult indi-

cated Error counter Description

CAN_COMM

(Initial diagnosis) OK 0 Normal at present

NG 1 � INFINITI FX35 2008 Service Manual

LAN-12

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Vehicle Display

ItemResult indi-

cated Error counter Description

CAN_COMM

(Initial diagnosis) OK 0 Normal at present

NG 1 �](/img/42/57017/w960_57017-3031.png)

LAN-12

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Vehicle Display

ItemResult indi-

cated Error counter Description

CAN_COMM

(Initial diagnosis) OK 0 Normal at present

NG 1 – 50 Control unit error

(The number indicates how many times diagnosis has been

run.)

CAN_CIRC_1

(Transmission diagnosis) OK 0 Normal at present

UNKWN 1 – 50 Unable to transmit for 2 seconds or more at present.

(The number indicates how many times diagnosis has been

run.)

CAN_CIRC_2 – 9

(Reception diagnosis of each unit) OK 0 Normal at present

UNKWN 1 – 50 Unable to transmit for 2 seconds or more at present.

(The number indicates how many times diagnosis has been

run.)

Diagnosis not performed.

No control unit for receiving signals. (No applicable optional

parts)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3039 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSES WORK FLOWLAN-19

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Some items may not be needed depending on CAN system type of vehicle.

Create On-board Dia INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSES WORK FLOWLAN-19

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Some items may not be needed depending on CAN system type of vehicle.

Create On-board Dia](/img/42/57017/w960_57017-3038.png)

TROUBLE DIAGNOSES WORK FLOWLAN-19

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Some items may not be needed depending on CAN system type of vehicle.

Create On-board Diagnosis Copy Sheet

Display the trouble diagnosis result of CAN communica tion with the on-board diagnosis function on the vehicle

monitor, etc. Copy them on the on-board diagnosis copy sheet.

NOTE:

For some models, CAN communication diagnosis result is received from the vehicle monitor. (CONSULT-III

is not available.)

PKID1212E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C