lock INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3777 of 3924

SRS-40

< SERVICE INFORMATION >

SIDE CURTAIN AIR BAG MODULE

SIDE CURTAIN AIR BAG MODULE

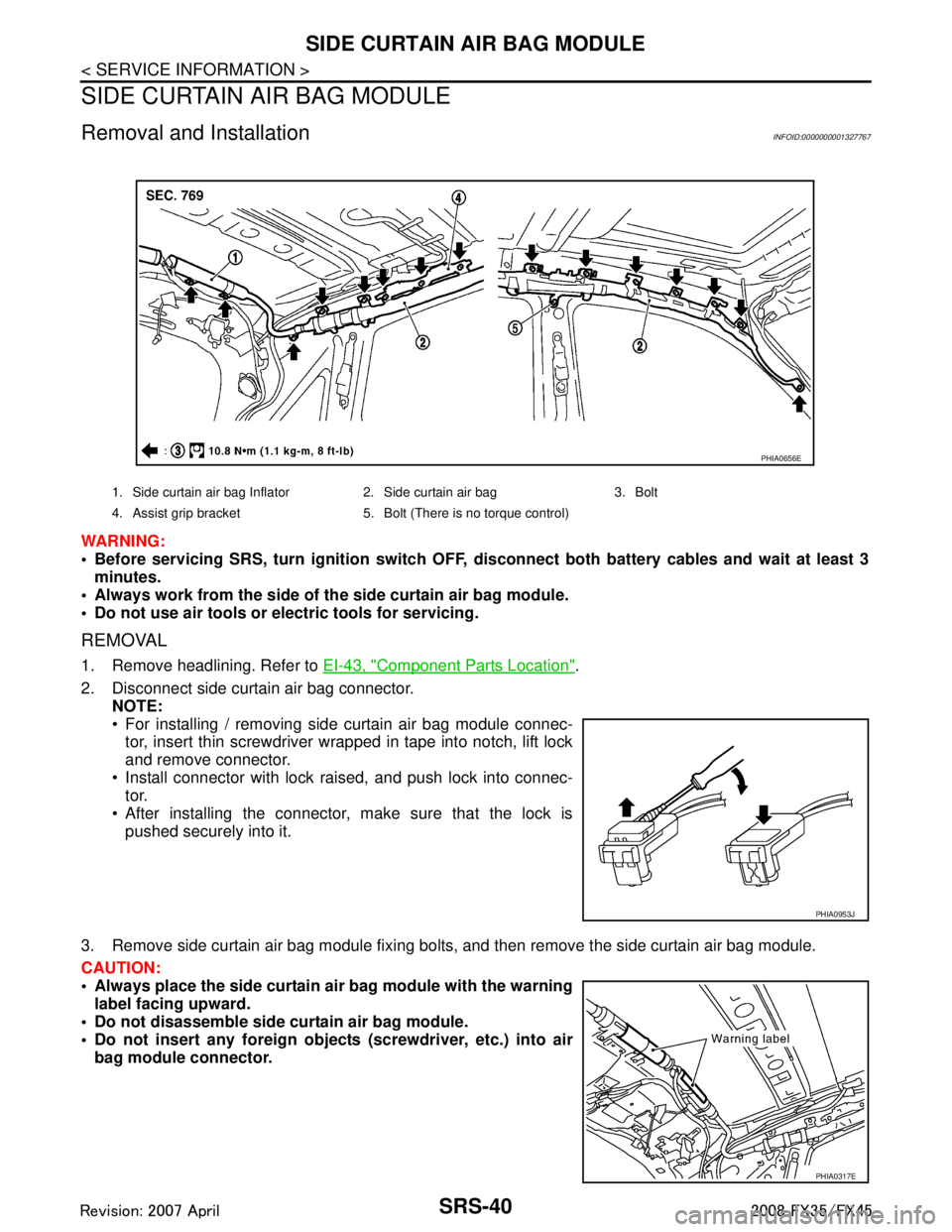

Removal and InstallationINFOID:0000000001327767

WARNING:

Before servicing SRS, turn ignition switch OFF, disconnect both ba ttery cables and wait at least 3

minutes.

Always work from the side of th e side curtain air bag module.

Do not use air tools or el ectric tools for servicing.

REMOVAL

1. Remove headlining. Refer to EI-43, "Component Parts Location".

2. Disconnect side curtain air bag connector. NOTE:

For installing / removing side curtain air bag module connec-

tor, insert thin screwdriver wrapped in tape into notch, lift lock

and remove connector.

Install connector with lock raised, and push lock into connec- tor.

After installing the connector, make sure that the lock is

pushed securely into it.

3. Remove side curtain air bag module fixing bolts, and then remove the side curtain air bag module.

CAUTION:

Always place the side curtain ai r bag module with the warning

label facing upward.

Do not disassemble side cu rtain air bag module.

Do not insert any foreign object s (screwdriver, etc.) into air

bag module connector.

1. Side curtain air bag Inflator 2. Side curtain air bag 3. Bolt

4. Assist grip bracket 5. Bolt (There is no torque control)

PHIA0656E

PHIA0953J

PHIA0317E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3794 of 3924

TF-8

< SERVICE INFORMATION >

PREPARATION

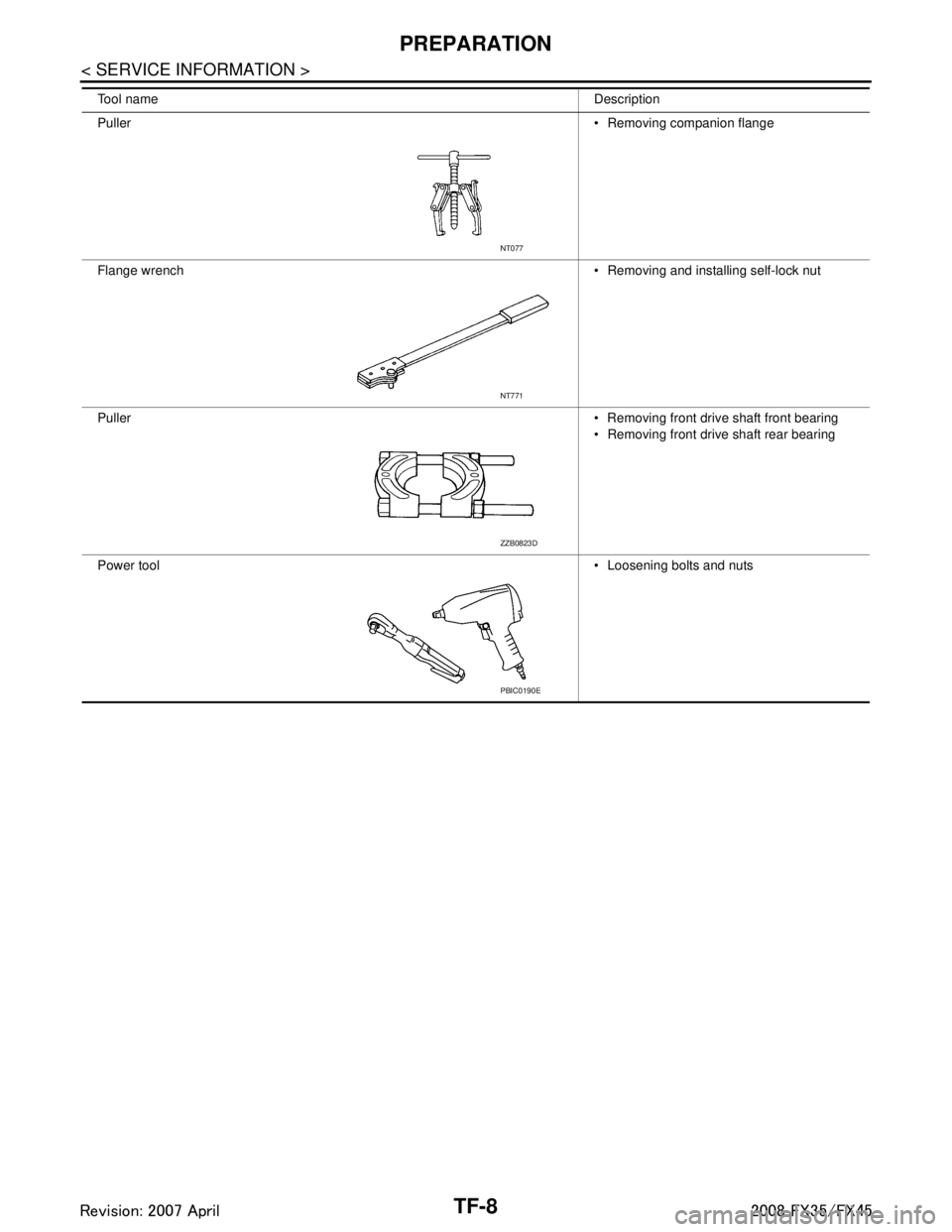

Tool nameDescription

Puller Removing companion flange

Flange wrench Removing and installing self-lock nut

Puller Removing front drive shaft front bearing

Removing front drive shaft rear bearing

Power tool Loosening bolts and nuts

NT077

NT771

ZZB0823D

PBIC0190E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3809 of 3924

TROUBLE DIAGNOSISTF-23

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

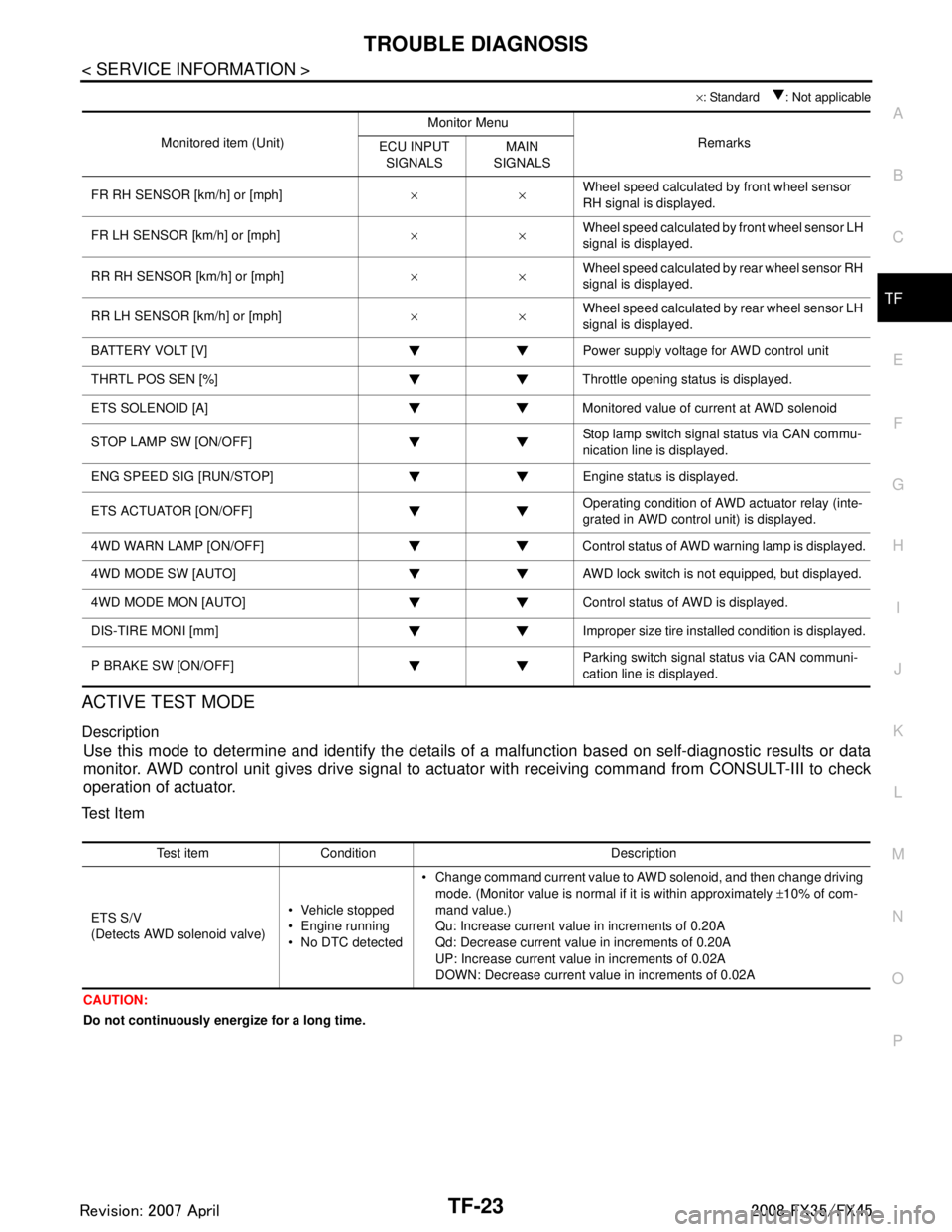

× : Standard : Not applicable

ACTIVE TEST MODE

Description

Use this mode to determine and identify the details of a malfunction based on self-diagnostic results or data

monitor. AWD control unit gives drive signal to actuat or with receiving command from CONSULT-III to check

operation of actuator.

Test Item

CAUTION:

Do not continuously energize for a long time.

Monitored item (Unit) Monitor Menu

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS

FR RH SENSOR [km/h] or [mph] ××Wheel speed calculated by front wheel sensor

RH signal is displayed.

FR LH SENSOR [km/h] or [mph] ××Wheel speed calculated by front wheel sensor LH

signal is displayed.

RR RH SENSOR [km/h] or [mph] ××Wheel speed calculated by rear wheel sensor RH

signal is displayed.

RR LH SENSOR [km/h] or [mph] ××Wheel speed calculated by rear wheel sensor LH

signal is displayed.

BATTERY VOLT [V] Power supply voltage for AWD control unit

THRTL POS SEN [%] Throttle opening status is displayed.

ETS SOLENOID [A] Monitored value of current at AWD solenoid

STOP LAMP SW [ON/OFF] Stop lamp switch signal status via CAN commu-

nication line is displayed.

ENG SPEED SIG [RUN/STOP] Eng ine status is displayed.

ETS ACTUATOR [ON/OFF] Operating condition of AWD actuator relay (inte-

grated in AWD control unit) is displayed.

4WD WARN LAMP [ON/OFF] Control status of AWD warning lamp is displayed.

4WD MODE SW [AUTO] AWD lock switch is not equipped, but displayed.

4WD MODE MON [AUTO] Control status of AWD is displayed.

DIS-TIRE MONI [mm] Improper size tire installed condition is displayed.

P BRAKE SW [ON/OFF] Parking switch signal status via CAN communi-

cation line is displayed.

Test item Condition Description

ETS S/V

(Detects AWD solenoid valve) Vehicle stopped

Engine running

No DTC detected Change command current value to AWD solenoid, and then change driving

mode. (Monitor value is normal if it is within approximately ±10% of com-

mand value.)

Qu: Increase current value in increments of 0.20A

Qd: Decrease current value in increments of 0.20A

UP: Increase current value in increments of 0.02A

DOWN: Decrease current value in increments of 0.02A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3811 of 3924

TROUBLE DIAGNOSIS FOR SYSTEMTF-25

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

DTC C1204 4WD SOLENOIDINFOID:0000000001327446

CONSULT-III REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

*: The values are changed by throttle opening and engine speed.

DIAGNOSTIC PROCEDURE

Check the following if “4WD SOLENOID [C1204]” is di splayed in self-diagnostic results of CONSULT-III.

1.CHECK AWD SOLENOID SIGNAL

With CONSULT-III

1. Start engine.

2. Select “DATA MONITOR” mode for “A LL MODE AWD/4WD” with CONSULT-III.

3. Read out the value of “ETS SOLENOID”.

*: The values are changed by throttle opening and engine speed.

OK or NG

OK >> GO TO 6.

NG >> GO TO 2.

2.CHECK POWER SUPPLY

1. Turn ignition switch “OFF”.

2. Disconnect AWD control unit harness connector.

3. Turn ignition switch “ON”. (Do not start engine.)

4. Check voltage between AWD control unit harness connector ter- minal 9 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

10A fuse [No. 21, located in the fuse block (J/B)]

Harness for short or open between battery and AWD control unit harness connector terminal 9

3.CHECK AWD SOLENOID CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect AWD control unit harness connector.

Monitored item [Unit] Condition Display value

ETS SOLENOID [A] Engine running At idle speed Approx. 0.000A

When depressing accelerator pedal Approx. 0.000 - 2.400A*

Condition Display value

Engine running At idle speed Approx. 0.000A

When depressing accelerator

pedal

Approx. 0.000 - 2.400A*

Connector Terminal Voltage (Approx.)

M92 9 - Ground Battery voltage

SDIA1884E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3815 of 3924

TROUBLE DIAGNOSIS FOR SYSTEMTF-29

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

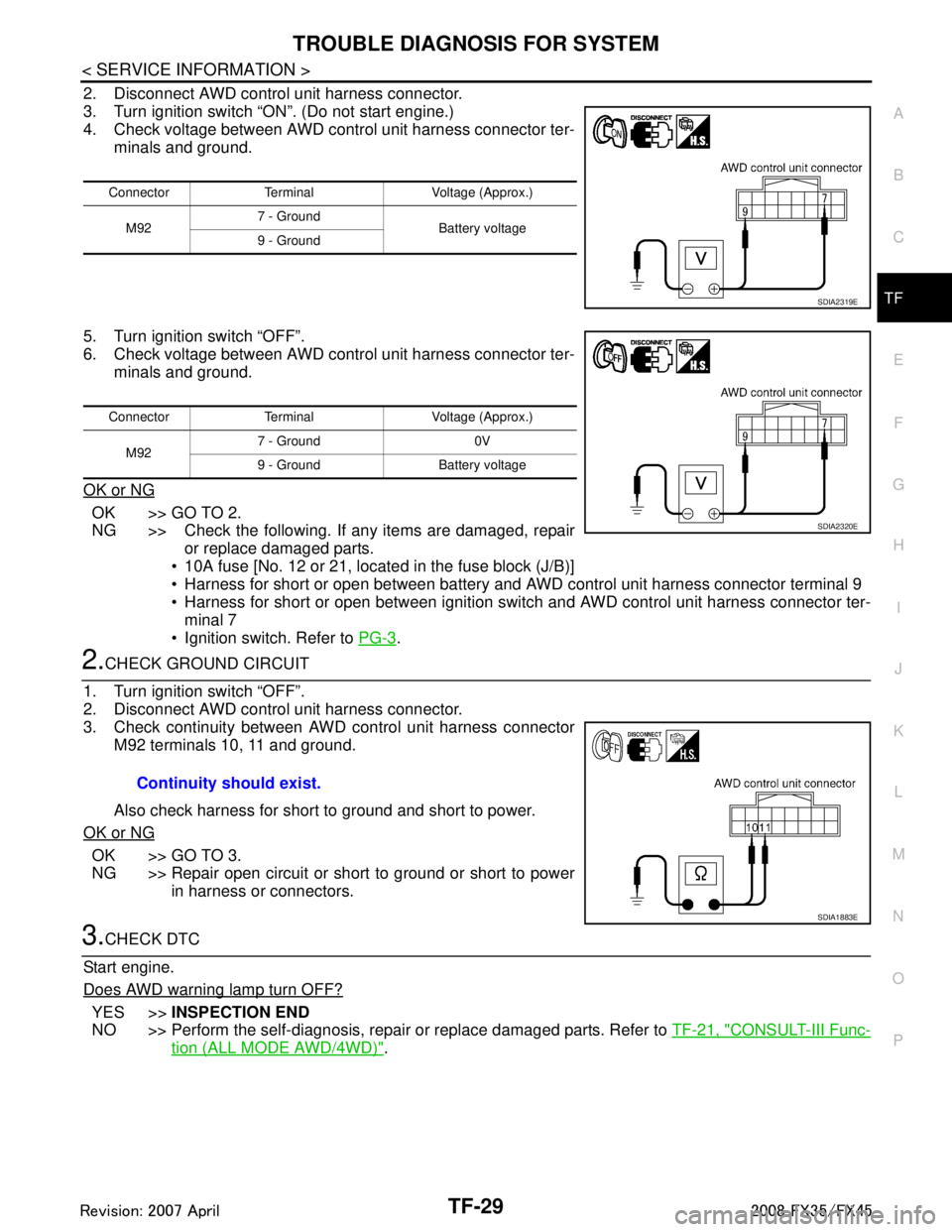

2. Disconnect AWD control unit harness connector.

3. Turn ignition switch “ON”. (Do not start engine.)

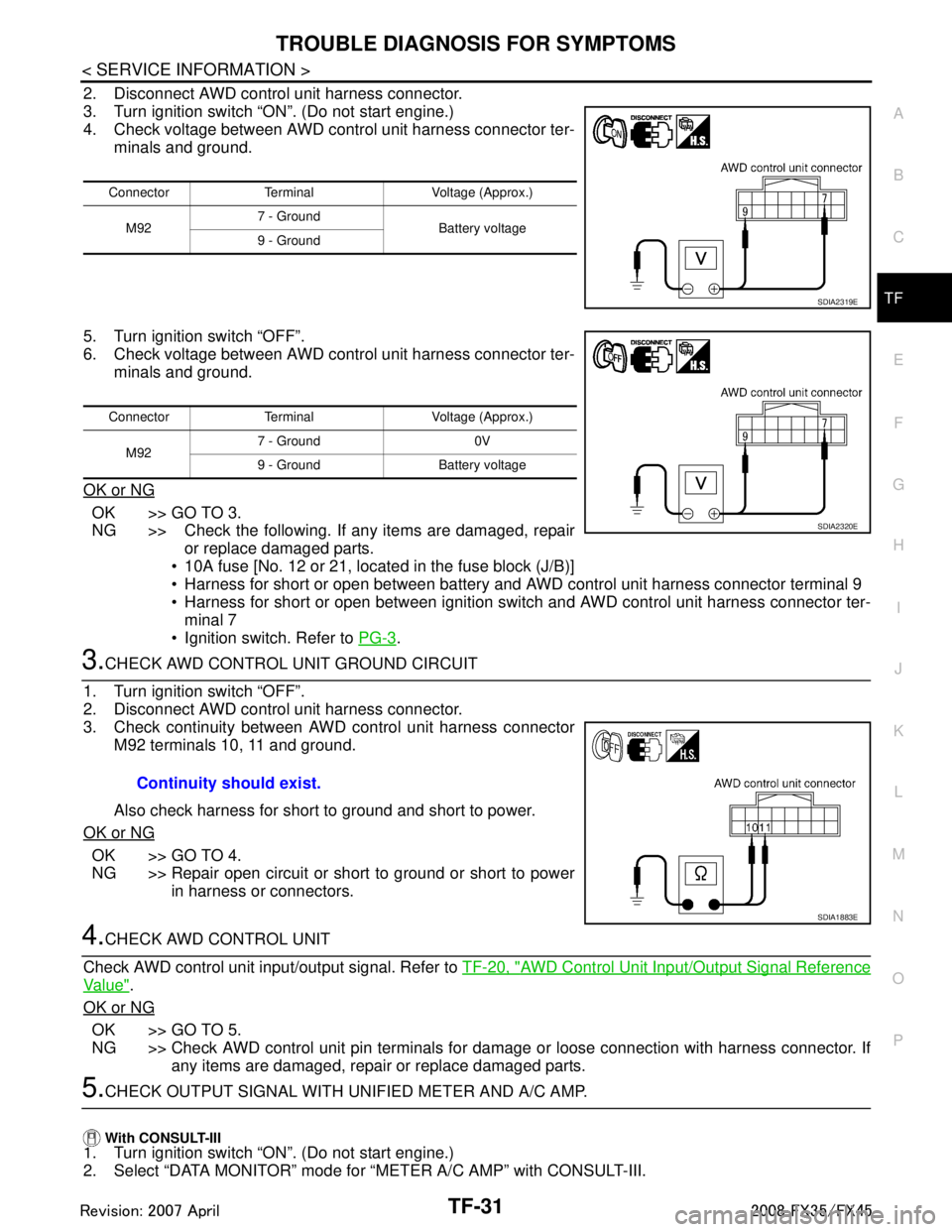

4. Check voltage between AWD control unit harness connector ter- minals and ground.

5. Turn ignition switch “OFF”.

6. Check voltage between AWD control unit harness connector ter- minals and ground.

OK or NG

OK >> GO TO 2.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

10A fuse [No. 12 or 21, located in the fuse block (J/B)]

Harness for short or open between battery and AWD control unit harness connector terminal 9

Harness for short or open between ignition switch and AWD control unit harness connector ter- minal 7

Ignition switch. Refer to PG-3

.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect AWD control unit harness connector.

3. Check continuity between AWD control unit harness connector M92 terminals 10, 11 and ground.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK DTC

Start engine.

Does AWD warning lamp turn OFF?

YES >> INSPECTION END

NO >> Perform the self-diagnosis, repair or replace damaged parts. Refer to TF-21, "

CONSULT-III Func-

tion (ALL MODE AWD/4WD)".

Connector Terminal Voltage (Approx.)

M92 7 - Ground

Battery voltage

9 - Ground

SDIA2319E

Connector Terminal Voltage (Approx.)

M92 7 - Ground 0V

9 - Ground Battery voltage

SDIA2320E

Continuity should exist.

SDIA1883E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3817 of 3924

TROUBLE DIAGNOSIS FOR SYMPTOMSTF-31

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

2. Disconnect AWD control unit harness connector.

3. Turn ignition switch “ON”. (Do not start engine.)

4. Check voltage between AWD control unit harness connector ter- minals and ground.

5. Turn ignition switch “OFF”.

6. Check voltage between AWD control unit harness connector ter- minals and ground.

OK or NG

OK >> GO TO 3.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

10A fuse [No. 12 or 21, located in the fuse block (J/B)]

Harness for short or open between battery and AWD control unit harness connector terminal 9

Harness for short or open between ignition switch and AWD control unit harness connector ter- minal 7

Ignition switch. Refer to PG-3

.

3.CHECK AWD CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect AWD control unit harness connector.

3. Check continuity between AWD control unit harness connector M92 terminals 10, 11 and ground.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e".

OK or NG

OK >> GO TO 5.

NG >> Check AWD control unit pin terminals for damage or loose connection with harness connector. If any items are damaged, repair or replace damaged parts.

5.CHECK OUTPUT SIGNAL WITH UNIFIED METER AND A/C AMP.

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “METER A/C AMP” with CONSULT-III.

Connector Terminal Voltage (Approx.)

M92 7 - Ground

Battery voltage

9 - Ground

SDIA2319E

Connector Terminal Voltage (Approx.)

M92 7 - Ground 0V

9 - Ground Battery voltage

SDIA2320E

Continuity should exist.

SDIA1883E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3823 of 3924

REAR OIL SEALTF-37

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

REAR OIL SEAL

Removal and InstallationINFOID:0000000001327458

REMOVAL

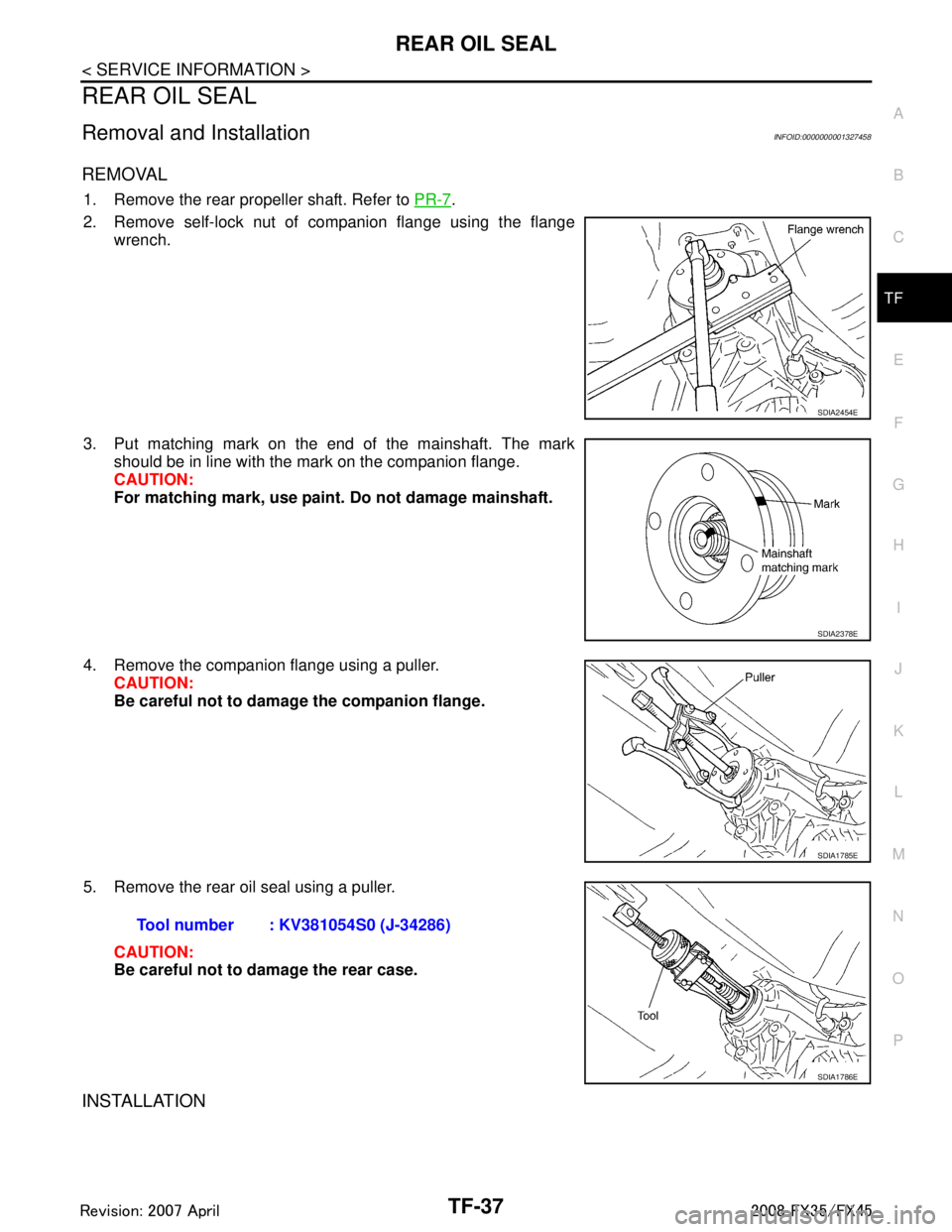

1. Remove the rear propeller shaft. Refer to PR-7.

2. Remove self-lock nut of companion flange using the flange wrench.

3. Put matching mark on the end of the mainshaft. The mark should be in line with the mark on the companion flange.

CAUTION:

For matching mark, use paint. Do not damage mainshaft.

4. Remove the companion flange using a puller. CAUTION:

Be careful not to damage the companion flange.

5. Remove the rear oil seal using a puller. CAUTION:

Be careful not to damage the rear case.

INSTALLATION

SDIA2454E

SDIA2378E

SDIA1785E

Tool number : KV381054S0 (J-34286)

SDIA1786E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3824 of 3924

TF-38

< SERVICE INFORMATION >

REAR OIL SEAL

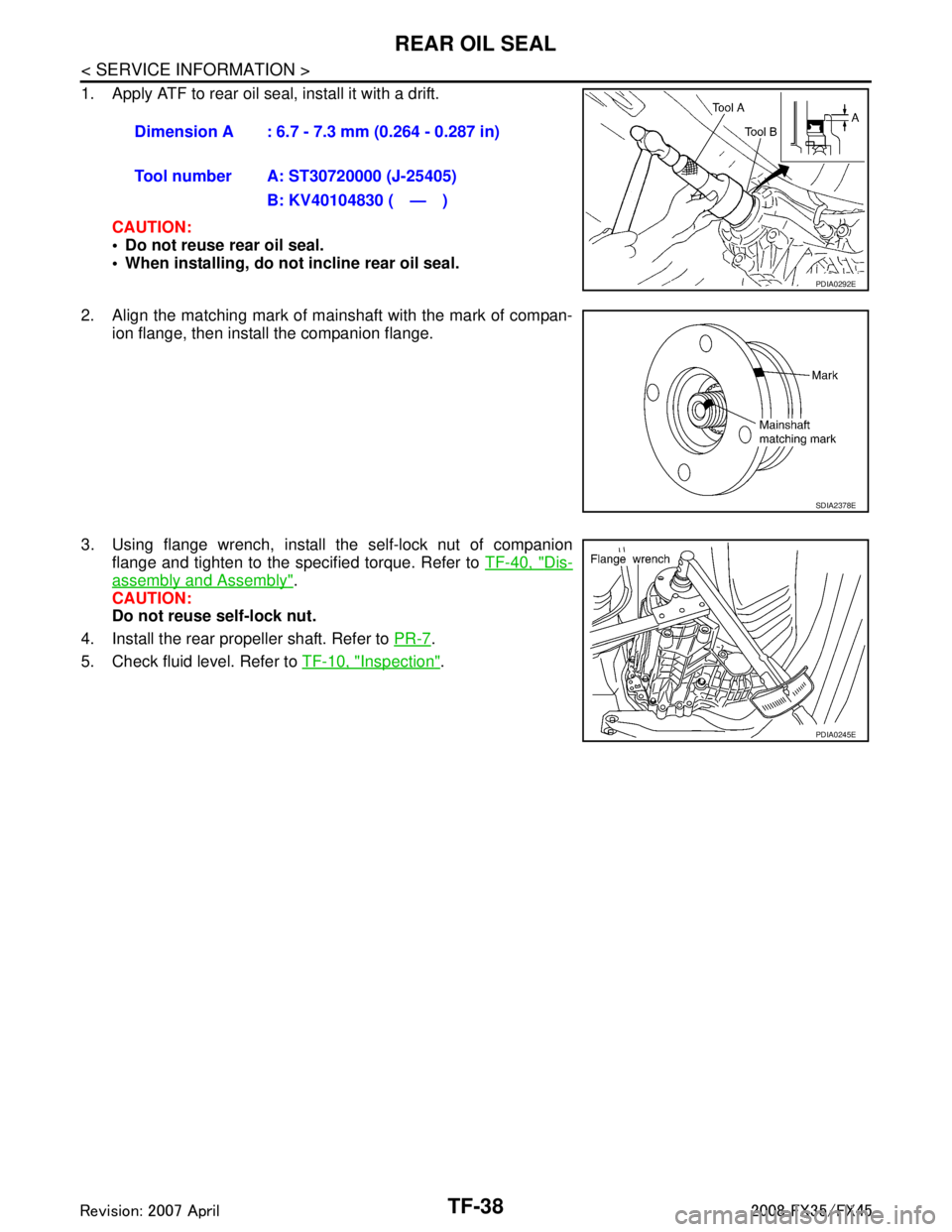

1. Apply ATF to rear oil seal, install it with a drift.CAUTION:

Do not reuse rear oil seal.

When installing, do not incline rear oil seal.

2. Align the matching mark of mainshaft with the mark of compan- ion flange, then install the companion flange.

3. Using flange wrench, install the self-lock nut of companion flange and tighten to the specified torque. Refer to TF-40, "

Dis-

assembly and Assembly".

CAUTION:

Do not reuse self-lock nut.

4. Install the rear propeller shaft. Refer to PR-7

.

5. Check fluid level. Refer to TF-10, "

Inspection".

Dimension A : 6.7 - 7.3 mm (0.264 - 0.287 in)

Tool number A: ST30720000 (J-25405)

B: KV40104830 ( — )

PDIA0292E

SDIA2378E

PDIA0245E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3827 of 3924

TRANSFER ASSEMBLYTF-41

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

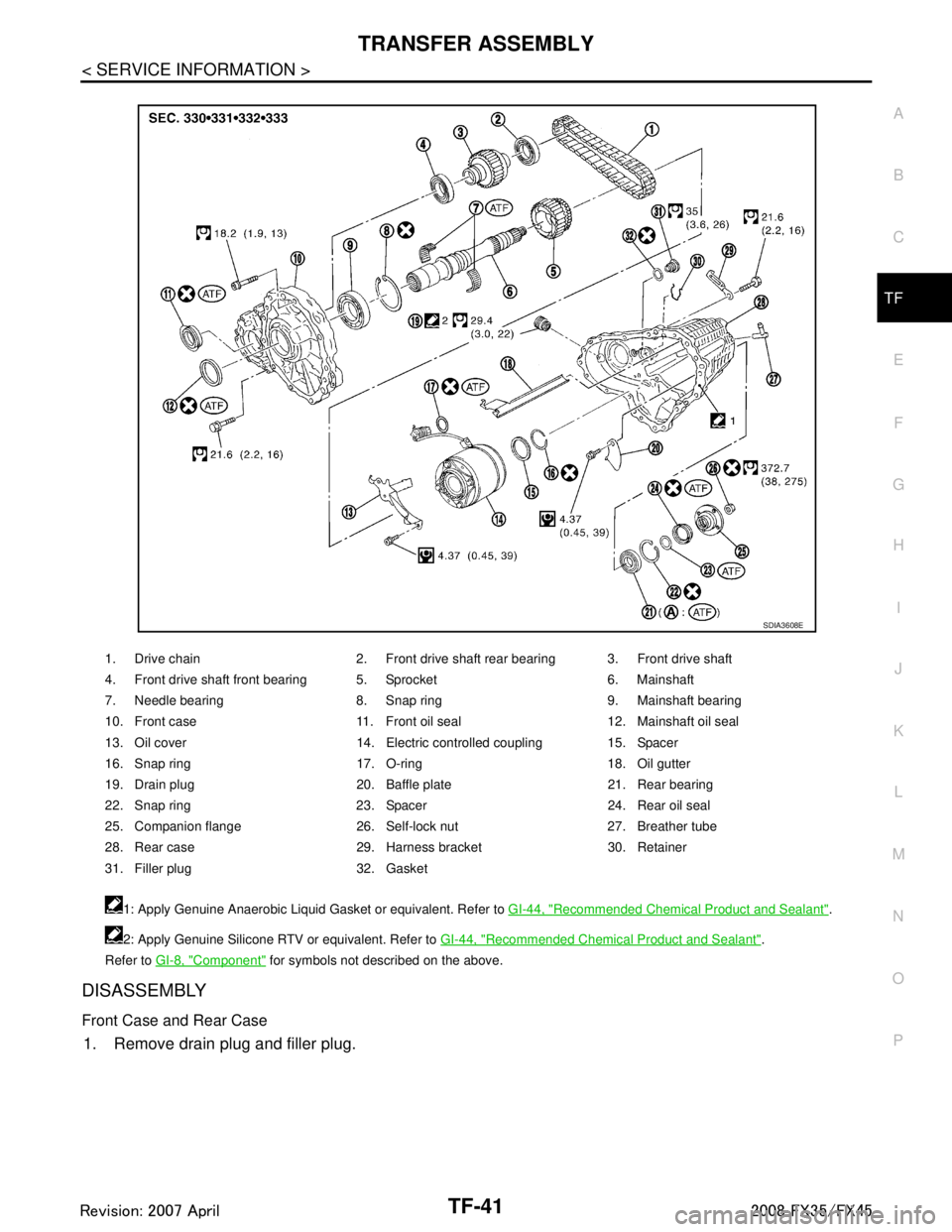

DISASSEMBLY

Front Case and Rear Case

1. Remove drain plug and filler plug.

1. Drive chain 2. Front drive shaft rear bearing 3. Front drive shaft

4. Front drive shaft front bearing 5. Sprocket 6. Mainshaft

7. Needle bearing 8. Snap ring 9. Mainshaft bearing

10. Front case 11. Front oil seal 12. Mainshaft oil seal

13. Oil cover 14. Electric controlled coupling 15. Spacer

16. Snap ring 17. O-ring 18. Oil gutter

19. Drain plug 20. Baffle plate 21. Rear bearing

22. Snap ring 23. Spacer 24. Rear oil seal

25. Companion flange 26. Self-lock nut 27. Breather tube

28. Rear case 29. Harness bracket 30. Retainer

31. Filler plug 32. Gasket 1: Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-44, "

Recommended Chemical Product and Sealant".

2: Apply Genuine Silicone RTV or equivalent. Refer to GI-44, "

Recommended Chemical Product and Sealant".

Refer to GI-8, "

Component" for symbols not described on the above.

SDIA3608E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3828 of 3924

TF-42

< SERVICE INFORMATION >

TRANSFER ASSEMBLY

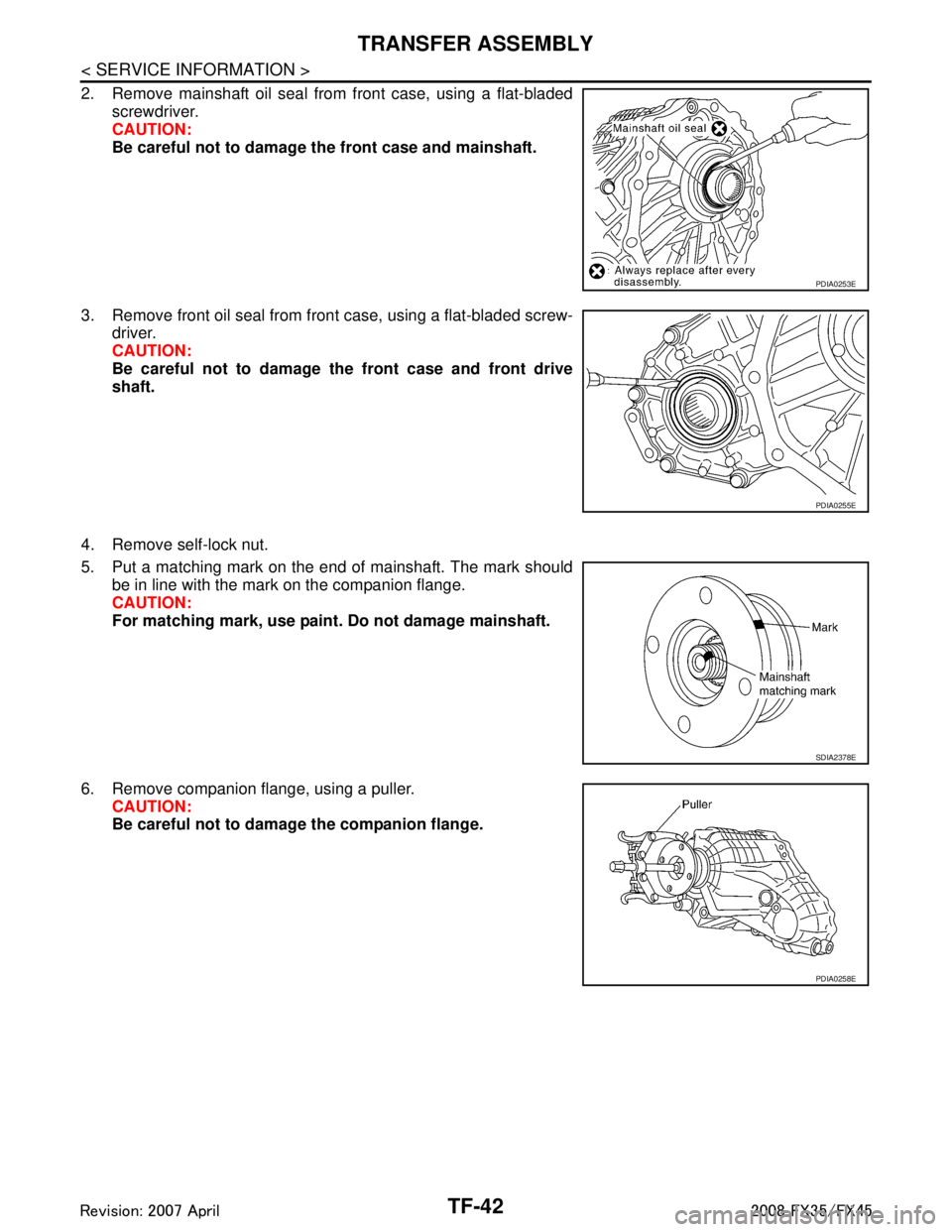

2. Remove mainshaft oil seal from front case, using a flat-bladedscrewdriver.

CAUTION:

Be careful not to damage the front case and mainshaft.

3. Remove front oil seal from front case, using a flat-bladed screw- driver.

CAUTION:

Be careful not to damage the front case and front drive

shaft.

4. Remove self-lock nut.

5. Put a matching mark on the end of mainshaft. The mark should be in line with the mark on the companion flange.

CAUTION:

For matching mark, use paint. Do not damage mainshaft.

6. Remove companion flange, using a puller. CAUTION:

Be careful not to damage the companion flange.

PDIA0253E

PDIA0255E

SDIA2378E

PDIA0258E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C