belt INFINITI FX35 2008 Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1265 of 3924

![INFINITI FX35 2008 Repair Manual

PRECAUTIONSEC-25

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00000 INFINITI FX35 2008 Repair Manual

PRECAUTIONSEC-25

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00000](/img/42/57017/w960_57017-1264.png)

PRECAUTIONSEC-25

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612915

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Procedur e without Cowl Top CoverINFOID:0000000001612935

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

On Board Diagnosis (OBD) System of Engine and A/TINFOID:0000000001325891

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Be sure to turn the ignition switch OFF and di sconnect the negative battery cable before any repair

or inspection work. The op en/short circuit of related switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For descripti on and how to disconnect, refer to PG-68

.

Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit.

Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfuncti on of the EVAP system or fuel injection system,

etc.

Be sure to erase the unnecessary ma lfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PIIB3706J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1376 of 3924

![INFINITI FX35 2008 Repair Manual

EC-136

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnec INFINITI FX35 2008 Repair Manual

EC-136

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnec](/img/42/57017/w960_57017-1375.png)

EC-136

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin terminal and connector for damage, and then reconnect it.

>> GO TO 16.

16.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F AL PHA-B2” in “SPEC” of “DATA MONITOR” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG >> Detect malfunctioning part according to EC-96, "

Symptom Matrix Chart".

17.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

OK or NG

OK >> INSPECTION END

NG (More than the SP value)>>GO TO 18.

NG (Less than the SP value)>>GO TO 25.

18.DETECT MALFUNCTIONING PART

1. Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of power steering, alternat or, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

Crushed air ducts

Malfunctioning seal of air cleaner element

Uneven dirt of air cleaner element

Improper specification of intake air system

OK or NG

OK >> GO TO 21.

NG >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/F UEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG (“B/FUEL SCHDL” is more, “A/F ALPHA-B1”, “A/F ALPHA-B2” are less than the SP value)>>GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1843 of 3924

![INFINITI FX35 2008 Repair Manual

PRECAUTIONSEC-603

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000 INFINITI FX35 2008 Repair Manual

PRECAUTIONSEC-603

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000](/img/42/57017/w960_57017-1842.png)

PRECAUTIONSEC-603

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612919

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Procedur e without Cowl Top CoverINFOID:0000000001612941

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

On Board Diagnosis (OBD) System of Engine and A/TINFOID:0000000001326487

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Be sure to turn the ignition switch OFF and di sconnect the negative battery cable before any repair

or inspection work. The op en/short circuit of related switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For descripti on and how to disconnect, refer to PG-68

.

Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit.

Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfuncti on of the EVAP system or fuel injection system,

etc.

Be sure to erase the unnecessary ma lfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PIIB3706J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1954 of 3924

![INFINITI FX35 2008 Repair Manual

EC-714

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnec INFINITI FX35 2008 Repair Manual

EC-714

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnec](/img/42/57017/w960_57017-1953.png)

EC-714

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin terminal and connector for damage, and then reconnect it.

>> GO TO 16.

16.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F AL PHA-B2” in “SPEC” of “DATA MONITOR” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG >> Detect malfunctioning part according to EC-673, "

Symptom Matrix Chart".

17.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

OK or NG

OK >> INSPECTION END

NG (More than the SP value)>>GO TO 18.

NG (Less than the SP value)>>GO TO 25.

18.DETECT MALFUNCTIONING PART

1. Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of power steering, alternat or, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

Crushed air ducts

Malfunctioning seal of air cleaner element

Uneven dirt of air cleaner element

Improper specification of intake air system

OK or NG

OK >> GO TO 21.

NG >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/F UEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG (“B/FUEL SCHDL” is more, “A/F ALPHA-B1”, “A/F ALPHA-B2” are less than the SP value)>>GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2438 of 3924

EI-1

BODY

C

DE

F

G H

J

K L

M

SECTION EI

A

B

EI

N

O P

CONTENTS

EXTERIOR & INTERIOR

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Procedure without Cowl Top Cover ......3

Precaution for Work ..................................................3

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ................................................................

5

Work Flow ........................................................... ......5

Generic Squeak and Rattle Troubleshooting ............7

Diagnostic Worksheet ...............................................9

CLIP AND FASTENER .......................................11

Clip and Fastener ................................................ ....11

FRONT BUMPER ...............................................14

Component Parts Location .................................. ....14

Removal and Installation .........................................15

REAR BUMPER .................................................17

Component Parts Location .................................. ....17

Removal and Installation .........................................18

FRONT GRILLE .................................................22

Component Parts Location .................................. ....22

Removal and Installation .........................................22

COWL TOP .........................................................23

Component Parts Location .................................. ....23

Removal and Installation .........................................23

FENDER PROTECTOR ......................................24

Component Parts Location .................................. ....24

Removal and Installation .........................................24

DOOR OUTSIDE MOLDING .............................25

Component Parts Location .................................. ....25

Removal and Installation .........................................25

DOOR OUTSIDE LOWER MOLDING ...............26

Component Parts Location ......................................26

Removal and Installation .........................................26

DOOR PARTING SEAL ....................................27

Component Parts Location ......................................27

Removal and Installation .........................................27

CENTER MUD GUARD .....................................29

Component Parts Location ......................................29

Removal and Installation .........................................29

WINDSHIELD MOLDING ..................................30

Component Parts Location ......................................30

Removal and Installation .........................................30

BACK DOOR WINDOW MOLDING ..................31

Component Parts Location .................................. ....31

Removal and Installation .........................................31

ROOF SIDE MOLDING .....................................32

Component Parts Location ......................................32

Removal and Installation .........................................32

ROOF RAIL .......................................................33

Component Parts Location ......................................33

Removal and Installation .........................................33

BACK DOOR FINISHER ...................................35

Component Parts Location ......................................35

Removal and Installation .........................................35

DOOR FINISHER ..............................................36

Component Parts Location ......................................36

Removal and Installation .........................................36

BODY SIDE TRIM .............................................38

Component Parts Location ......................................38

Removal and Installation .........................................38

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2440 of 3924

PRECAUTIONSEI-3

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612896

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Procedur e without Cowl Top CoverINFOID:0000000001612888

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for WorkINFOID:0000000001328053

After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check their

operation.

Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

PIIB3706J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2476 of 3924

BODY SIDE TRIMEI-39

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

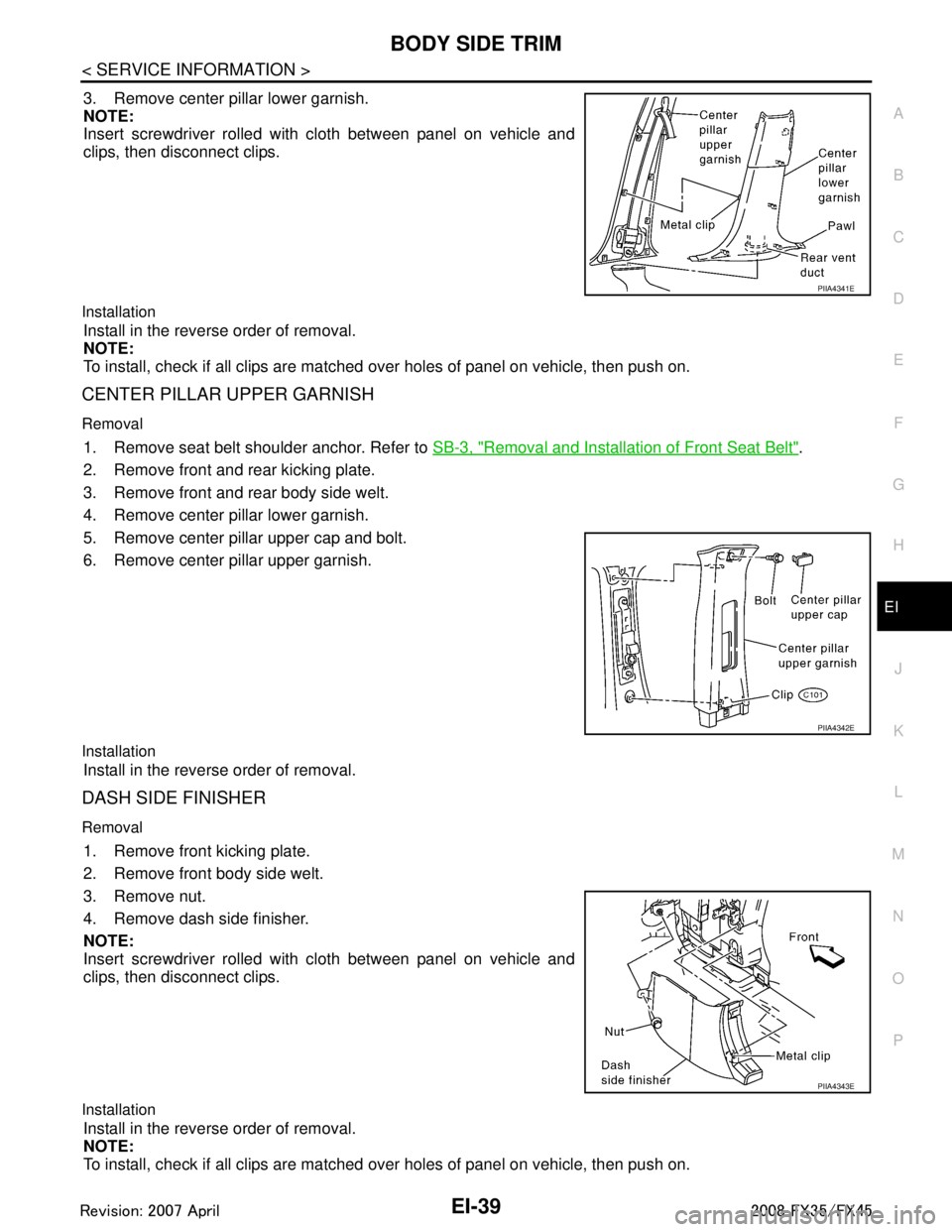

3. Remove center pillar lower garnish.

NOTE:

Insert screwdriver rolled with cloth between panel on vehicle and

clips, then disconnect clips.

Installation

Install in the reverse order of removal.

NOTE:

To install, check if all clips are matched over holes of panel on vehicle, then push on.

CENTER PILLAR UPPER GARNISH

Removal

1. Remove seat belt shoulder anchor. Refer to SB-3, "Removal and Installation of Front Seat Belt".

2. Remove front and rear kicking plate.

3. Remove front and rear body side welt.

4. Remove center pillar lower garnish.

5. Remove center pillar upper cap and bolt.

6. Remove center pillar upper garnish.

Installation

Install in the reverse order of removal.

DASH SIDE FINISHER

Removal

1. Remove front kicking plate.

2. Remove front body side welt.

3. Remove nut.

4. Remove dash side finisher.

NOTE:

Insert screwdriver rolled with cloth between panel on vehicle and

clips, then disconnect clips.

Installation

Install in the reverse order of removal.

NOTE:

To install, check if all clips are matched over holes of panel on vehicle, then push on.

PIIA4341E

PIIA4342E

PIIA4343E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2481 of 3924

EI-44

< SERVICE INFORMATION >

HEADLINING

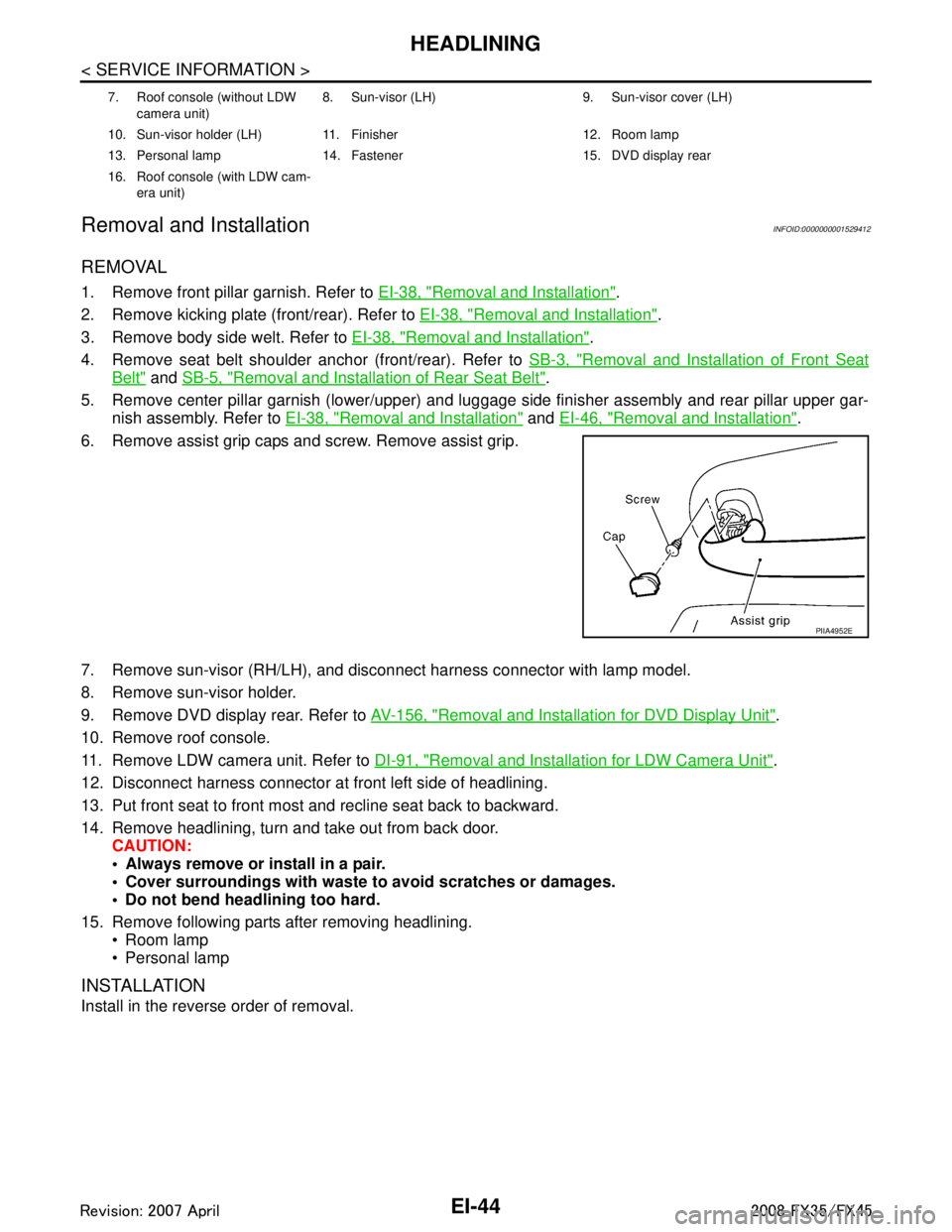

Removal and Installation

INFOID:0000000001529412

REMOVAL

1. Remove front pillar garnish. Refer to EI-38, "Removal and Installation".

2. Remove kicking plate (front/rear). Refer to EI-38, "

Removal and Installation".

3. Remove body side welt. Refer to EI-38, "

Removal and Installation".

4. Remove seat belt shoulder anchor (front/rear). Refer to SB-3, "

Removal and Installation of Front Seat

Belt" and SB-5, "Removal and Installation of Rear Seat Belt".

5. Remove center pillar garnish (lower/upper) and luggage side finisher assembly and rear pillar upper gar- nish assembly. Refer to EI-38, "

Removal and Installation" and EI-46, "Removal and Installation".

6. Remove assist grip caps and screw. Remove assist grip.

7. Remove sun-visor (RH/LH), and disconnect harness connector with lamp model.

8. Remove sun-visor holder.

9. Remove DVD display rear. Refer to AV-156, "

Removal and Installation for DVD Display Unit".

10. Remove roof console.

11. Remove LDW camera unit. Refer to DI-91, "

Removal and Installation for LDW Camera Unit".

12. Disconnect harness connector at front left side of headlining.

13. Put front seat to front most and recline seat back to backward.

14. Remove headlining, turn and take out from back door. CAUTION:

Always remove or install in a pair.

Cover surroundings with waste to avoid scratches or damages.

Do not bend headlining too hard.

15. Remove following parts after removing headlining. Room lamp

Personal lamp

INSTALLATION

Install in the reverse order of removal.

7. Roof console (without LDW

camera unit) 8. Sun-visor (LH) 9. Sun-visor cover (LH)

10. Sun-visor holder (LH) 11. Finisher 12. Room lamp

13. Personal lamp 14. Fastener 15. DVD display rear

16. Roof console (with LDW cam- era unit)

PIIA4952E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2483 of 3924

EI-46

< SERVICE INFORMATION >

LUGGAGE FLOOR TRIM

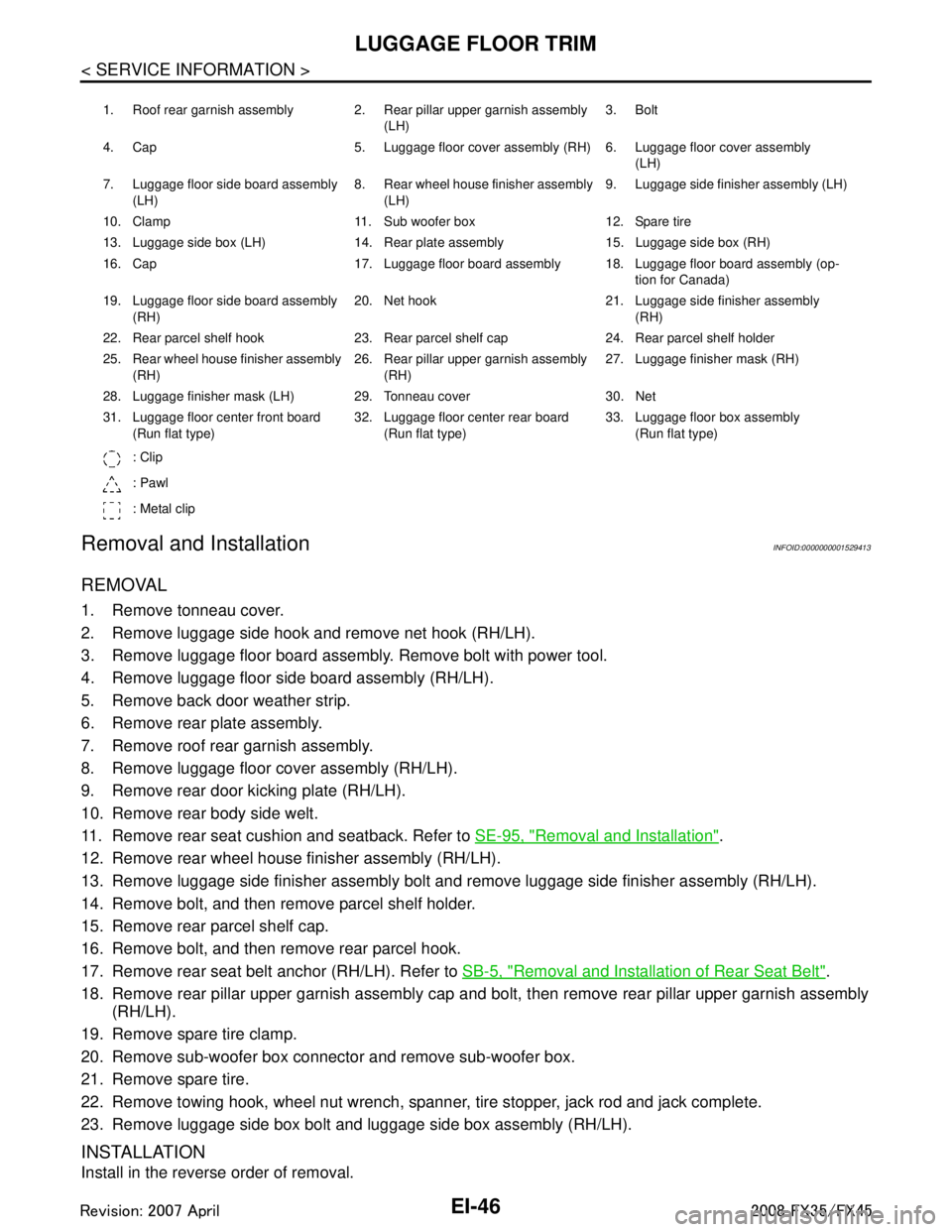

Removal and Installation

INFOID:0000000001529413

REMOVAL

1. Remove tonneau cover.

2. Remove luggage side hook and remove net hook (RH/LH).

3. Remove luggage floor board assembly. Remove bolt with power tool.

4. Remove luggage floor side board assembly (RH/LH).

5. Remove back door weather strip.

6. Remove rear plate assembly.

7. Remove roof rear garnish assembly.

8. Remove luggage floor cover assembly (RH/LH).

9. Remove rear door kicking plate (RH/LH).

10. Remove rear body side welt.

11. Remove rear seat cushion and seatback. Refer to SE-95, "

Removal and Installation".

12. Remove rear wheel house finisher assembly (RH/LH).

13. Remove luggage side finisher assembly bolt and remove luggage side finisher assembly (RH/LH).

14. Remove bolt, and then remove parcel shelf holder.

15. Remove rear parcel shelf cap.

16. Remove bolt, and then remove rear parcel hook.

17. Remove rear seat belt anchor (RH/LH). Refer to SB-5, "

Removal and Installation of Rear Seat Belt".

18. Remove rear pillar upper garnish assembly cap and bolt, then remove rear pillar upper garnish assembly (RH/LH).

19. Remove spare tire clamp.

20. Remove sub-woofer box connector and remove sub-woofer box.

21. Remove spare tire.

22. Remove towing hook, wheel nut wrench, spanner, tire stopper, jack rod and jack complete.

23. Remove luggage side box bolt and luggage side box assembly (RH/LH).

INSTALLATION

Install in the reverse order of removal.

1. Roof rear garnish assembly 2. Rear pillar upper garnish assembly (LH)3. Bolt

4. Cap 5. Luggage floor cover assembly (RH) 6. Luggage floor cover assembly (LH)

7. Luggage floor side board assembly (LH) 8. Rear wheel house finisher assembly

(LH) 9. Luggage side finisher assembly (LH)

10. Clamp 11. Sub woofer box 12. Spare tire

13. Luggage side box (LH) 14. Rear plate assembly 15. Luggage side box (RH)

16. Cap 17. Luggage floor board assembly 18. Luggage floor board assembly (op- tion for Canada)

19. Luggage floor side board assembly (RH) 20. Net hook 21. Luggage side finisher assembly

(RH)

22. Rear parcel shelf hook 23. Rear parcel shelf cap 24. Rear parcel shelf holder

25. Rear wheel house finisher assembly (RH) 26. Rear pillar upper garnish assembly

(RH) 27. Luggage finisher mask (RH)

28. Luggage finisher mask (LH) 29. Tonneau cover 30. Net

31. Luggage floor center front board (Run flat type) 32. Luggage floor center rear board

(Run flat type) 33. Luggage floor box assembly

(Run flat type)

: Clip

: Pawl

: Metal clip

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2485 of 3924

EM-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EM

A

EM

N

O P

CONTENTS

ENGINE MECHANICAL

VQ35DE

SERVICE INFORMATION .. ..........................

4

PRECAUTIONS .............................................. .....4

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Drain Engine Coolant and Engine

Oil ..............................................................................

4

Precaution for Disconnecting Fuel Piping .................4

Precaution for Removal and Disassembly ................4

Precaution for Inspection, Repair and Replace-

ment ..........................................................................

4

Precaution for Assembly and Installation ..................5

Precaution for Angle Tightening ................................5

Precaution for Liquid Gasket .....................................5

PREPARATION ...................................................7

Special Service Tool ........................................... ......7

Commercial Service Tool ..........................................9

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

12

NVH Troubleshooting - Engine Noise ................. ....12

Use the Chart Below to Help You Find the Cause

of the Symptom .......................................................

12

DRIVE BELTS ....................................................14

Checking Drive Belts ........................................... ....14

Tension Adjustment ................................................14

Removal and Installation .........................................15

AIR CLEANER AND AIR DUCT ........................17

Component .......................................................... ....17

Removal and Installation .........................................17

Changing Air Cleaner Filter .....................................18

INTAKE MANIFOLD COLLECTOR ...................19

Component .......................................................... ....19

Removal and Installation .........................................19

INTAKE MANIFOLD ...........................................24

Component .......................................................... ....24

Removal and Installation .........................................24

EXHAUST MANIFOLD AND THREE WAY

CATALYST ........................................................

26

Component ..............................................................26

Removal and Installation .........................................26

OIL PAN AND OIL STRAINER .........................30

Component (2WD Models) ......................................30

Removal and Installation (2WD Models) .................30

Component (AWD Models) ......................................35

Removal and Installation (AWD Models) .................36

IGNITION COIL .................................................42

Component ..............................................................42

Removal and Installation .........................................42

SPARK PLUG (PLATINUM-TIPPED TYPE) .....43

Component ..............................................................43

Removal and Installation .........................................43

FUEL INJECTOR AND FUEL TUBE ................45

Component ..............................................................45

Removal and Installation .........................................45

ROCKER COVER .............................................51

Component ..............................................................51

Removal and Installation .........................................51

FRONT TIMING CHAIN CASE .........................54

Removal and Installation .........................................54

TIMING CHAIN ..................................................64

Component .......................................................... ....64

Removal and Installation .........................................65

CAMSHAFT .......................................................83

Component ..............................................................83

Removal and Installation .........................................84

Valve Clearance ......................................................91

OIL SEAL ..........................................................97

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C